Professional Documents

Culture Documents

36-7500 Part 10

36-7500 Part 10

Uploaded by

SUDIPTA HUIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

36-7500 Part 10

36-7500 Part 10

Uploaded by

SUDIPTA HUICopyright:

Available Formats

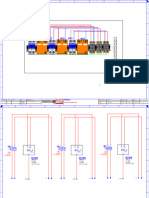

50 690 50

50 690 50 50 690 50 50 690 50

A F G

H

B B B

C C C C

208

208

208

208

D D D D

E E E 50 40 640 40 50

E

820 820 820

820

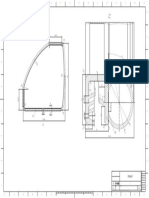

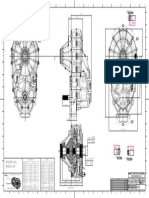

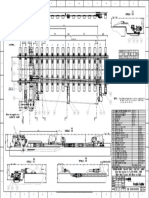

LONG.-GUIDE BEARING ASSEMBLY LGB TRANS.-GUIDE BEARING ASSEMBLY TGB FREE - BEARING ASSEMBLY FB

(SCALE 1:5) (SCALE 1:5) (SCALE 1:5) FREE - BEARING FXB

(SCALE 1:5)

X-SECTIONAL VIEW ACROSS LONGITUDINAL AXIS OF GIRDER (CENTER LINE OF THE GIRDER COINCIDES WITH CENTER LINE OF BEARING SHOWN)

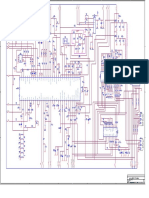

STAINLESS STEEL PLATE 400 3

2+2

90 90

6 MM THICK, WELD 3mm

20 10

790

35

690 358

40

R200

50

5

400

70

ELEVATION

(SCALE 1:7.5)

40

3

10

37 STAINLESS STEEL PLATE 50 62 597 50

STAINLESS STEEL PLATE 25x3x528,

40 40x3x690, WELD 2mm 820

538

528

WELD 2 MM

ELEVATION ELEVATION

(SCALE 1:7.5)

PTFE SHEET 4.5 MM THICK, (SCALE 1:7.5)

DIMPLED OR MODULAR, LEGEND

PASTED IN 2.5 MM DEEP RECESS

SYMBOL

790

50

10 HARDENED SURFACE 300 BHN MINIMUM

5

50 32 40 546 40 32 50

PISTON BASE

DUST SEAL 10x15 ALLROUND

SURFACE HARDENED TO

300 BHN MINIMUM DUST SEAL

538

500 358

VIEW FROM TOP 398

POLY TETERA FLUORO ETHYLENE (PTFE)

(SCALE 1:7.5)

150

49 400 10 HIGH STRENGTH BOLT

VIEW FROM TOP

PISTON WALL

35

10 PART C: BRASS RINGS NUT

R199.50

45

399

FOR RETAINING

ELASTOMER IN POT NOTE:

90

396

4

STAINLESS STEEL PLATE 25x3x528,

(SCALE 1:7.5)

700

500

300

SURFACE HARDENED TO WELD 2 MM 1. All dimensions are in MM.

ELEVATION

KNURLING TOOL OR CHISELLING

300 BHN MINIMUM (NOT TO BE PROVIDED IN FREE BEARING) 32

ROUND WASHER FOR 32 DIA. BOLT

(SCALE 1:7.5) 398 2. The design is in accordance with IRC- 83 (PART-III)-2002.

ISOMETRIC THREAD

DIA.

MIN EMBEDDED LENGTH 330

STAINLESS STEEL PLATE 3. The concrete in bed block shall be of min M40 GRADE.

ELEVATION

SURFACE ROUGHENED BY

6 MM THK, WELD 3 MM (SCALE 1:7.5) 4. Bearings shall be provided before concreting of deck slab is taken up.

ALL ROUND

5

5. Bearings shall be protected during concreting or providing holding down bolts

150

operations. Any mortar or foreign material contaminating the bearing shall be

ELASTOMERIC PAD completely removed.

SURFACE HARDENED TO

300 BHN MINIMUM 6. Manufacture & finishing of bearings shall be as per para 927.2 & 927.3 of IRC 83

Part III

STAINLESS STEEL PLATE 538

3 7. Manufacturing tolerances shall be as per para 927.1 of IRC 83 Part III

33x3x690 WELD 2 mm

5

50

8. Acceptance of bearing shall be as per para 928 of IRC 83 Part III.

VIEW FROM BOTTOM 9. Material to be used for pot, piston and top plate including all guides, lugs etc shall

be of cast steel to IS 1030:1989 grade 340-570W.

PART A: TOP PLATE FOR LONG. GUIDE

(SCALE 1:7.5) ANCHOR BOLT 10. All the flame cut, sawn or planed edges of the plates should be machined. All

358

PISTON

VIEW FROM TOP (SCALE 1:5) sheared corners shall be rounded off with 2 MM radius.

398

398 PART E: POT FOR BEARINGS 11. For welding stainless steel sheet, M1 electrode type with stainless steel core wire as

per IRS: M-28-2012 shall be used.

(SCALE 1:7.5)

3 538 3 12. PTFE sheet shall be pure poly tetra fluoro ethylene, and shall be 4.5 mm thick,

VIEW FROM TOP having either dimples (hot pressed or moulded) or modules as per IRC 83 Part III.

VIEW FROM BOTTOM PART D: ELASTOMER These shall be pasted in recess 2.5 MM deep in the bearing and the peel strength of

glue to be used shall not be less than 4 N/MM.

PART B: PISTON FOR PAD FOR BEARINGS

(SCALE 1:7.5) 13. Material to be used for wiper seal and dust seal shall be of microcellular

FREE/SLIDING BEARINGS polychloroprene rubber or polythene foam & it's adhesion to metal shall be with

polychloroprene rubber based adhesive dunlop S-758, dendrite PC-65 or any other

(SCALE 1:7.5)

790 equivalent brands.

30

690 14. All non-working surfaces shall be given protective coating comprising of 2 coats

of epoxy primer enriched with metallic zinc, one intermediate coat of high build

790 epoxy paint reinforced with mio (micaceous iron oxide) & one coat of high

50 690 50 50 690 50 performance epoxy finish paint as per para 39.2.2 of IRS B1.

50

15. All bearings shall be sent by manufacturer duly set. Marked with center line of

bearing along the girder and across it, along with the shipping mark of the bearing

ELEVATION

78

and fitted with transportation clamps. It is prohibited to open transportation clamps

(SCALE 1:7.5)

520 399 R199.50 before final assembly of the bearing on the girder without the presence of bearing

manufacturer representative.

35

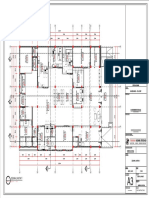

OF BOTTOM LONG. BEAM

SURFACE HARDENED TO

ELEVATION

50

STAINLESS STEEL PLATE 396

40x3x780 WELD 2mm 300 BHN MINIMUM OF SYMMETRY 16. After the girders are properly leveled/ aligned and bearings tied to the girder using

50

(SCALE 1:7.5)

40

ELEVATION

600

LONG. GUIDE BEARING Class 8.8 bolts, transportation clamps shall be opened and all expansion type

FIXED BEARING

(SCALE 1:7.5) BOTTOM LONG. BEAM bearing shall be set properly as per ambient temperature. Thereafter holes in

substructure already provided (shall be drilled at this stage if not already provided),

50

40 32

shall be filled with holding down bolts and quickly grouted.

SURFACE HARDENED

5 TO 300 BHN MINIMUM

173

5 17. Anchor bolts shall be provided in holes (max. dia 40 MM) made in pier top/

150

BOTTOM CROSS BEAM

150

500 pedestals.

18. Anchor bolts and nuts shall be hot dip galvanized 100 micron thick, as per IS:

4759.

12000

DIRECTION OF TRAFFIC

OF BOTTOM LONG. BEAM

300

700

300

700

R. D. S. O.

345

500

546

790

STAINLESS STEEL PLATE

6 MM THICK, WELD 3 MM

38000

ROAD OVER BRIDGE

BOW STRING STEEL GIRDER

150

5 ALL ROUND

150

600

PISTON TRANS. GUIDE BEARING FREE BEARING

173

36m CLEAR SPAN

32 40

ARRANGEMENT OF POT PTFE BEARINGS

50

50

WELD 2 MM ALL ROUND

(SCALE 1:200)

50

50 690 50 50 690 50

3

50 690 50 790 790 DETAILS OF PTFE POT BEARING

790 VIEW FROM BOTTOM VIEW FROM BOTTOM

PART G: TOP PLATE FOR PART H: PISTON FOR FIXED

PROVISIONAL

VIEW FROM BOTTOM

FREE BEARING

PART F: TOP PLATE FOR TRANSVERSE GUIDE

(SCALE 1:7.5)

(SCALE 1:7.5) BEARING

(SCALE 1:7.5) (PAPER SIZE A1) RDSO/B - 10407/9/R

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/8 AutoCAD FILE NO.: B-10407 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V.K.PANDEY (SSE) VIVEK KUMAR (XEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

You might also like

- Kip 3000 Service ManualDocument722 pagesKip 3000 Service Manualjd miller100% (5)

- Design and Control of Concrete Mixtures P 251-360Document110 pagesDesign and Control of Concrete Mixtures P 251-360Narcisa RudnicNo ratings yet

- Stressed Ribbon BridgeDocument2 pagesStressed Ribbon Bridgeanurag30690% (1)

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- M Bow String Girder-10409-9Document1 pageM Bow String Girder-10409-9prejithNo ratings yet

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcNo ratings yet

- Ie02 Instalaciones ElectricasDocument1 pageIe02 Instalaciones Electricasmarcelo.uculmana.rosasNo ratings yet

- ChederRib PDFDocument1 pageChederRib PDFZaharia NicuNo ratings yet

- For Plot - 2016-Ato Gari Simma 2020 April-ModelDocument1 pageFor Plot - 2016-Ato Gari Simma 2020 April-ModelJaspergroup 15No ratings yet

- Cross Country Line F Layout, Elevation & Bom List A0 - : Cerro Pabellon IiiDocument13 pagesCross Country Line F Layout, Elevation & Bom List A0 - : Cerro Pabellon IiicristianNo ratings yet

- Gre - Eec.d.25.es.p.11090.16.259.01 - SS Alqueria - Mapas-01Document1 pageGre - Eec.d.25.es.p.11090.16.259.01 - SS Alqueria - Mapas-01mapermarNo ratings yet

- Attachement - 1 HV PV Combiner BoxDocument2 pagesAttachement - 1 HV PV Combiner Boxabdulkawi alasharyNo ratings yet

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcNo ratings yet

- Me DW 3000Document1 pageMe DW 3000calidadNo ratings yet

- Chassis TA41-40026ADocument2 pagesChassis TA41-40026ARodrymix SoriaNo ratings yet

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcNo ratings yet

- Innna 1Document1 pageInnna 1Thịnh VănNo ratings yet

- StaaloverzichtDocument1 pageStaaloverzichtKoreji WaNo ratings yet

- SPSO-1568-E1 200 AmpDocument1 pageSPSO-1568-E1 200 Ampwg94rvpdb5No ratings yet

- SPSO-1568-E1 600 AmpDocument1 pageSPSO-1568-E1 600 Ampwg94rvpdb5No ratings yet

- KLINIK DOKTER ANAK MAJENANG Rev 4Document26 pagesKLINIK DOKTER ANAK MAJENANG Rev 4Ilyas MNo ratings yet

- Camilla Covid Updated 2 Bueno Dibujo v1Document1 pageCamilla Covid Updated 2 Bueno Dibujo v1Fernando Axel MaljaNo ratings yet

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcNo ratings yet

- 5100045016-Basic Cradle HC160-HC170 - ADocument2 pages5100045016-Basic Cradle HC160-HC170 - ArolandNo ratings yet

- Arquitectura 01Document1 pageArquitectura 01Darwin SánchezNo ratings yet

- 01 GRP Pipe Plan & Profile ViewDocument1 page01 GRP Pipe Plan & Profile ViewUHPB TeamNo ratings yet

- K354-M-120-MH05-515 - 01 - 01 - Pipe Mod Engine - Circ Module ArrDocument1 pageK354-M-120-MH05-515 - 01 - 01 - Pipe Mod Engine - Circ Module ArrWilber MontenegroNo ratings yet

- PML3 Sys PMR02 ZZ DR A 22120 - R0Document1 pagePML3 Sys PMR02 ZZ DR A 22120 - R0mukund maniNo ratings yet

- Esquema Elétrico t600Document2 pagesEsquema Elétrico t600Codeiro SilvaNo ratings yet

- Layout-Matheu ARAUCARIA PDFDocument1 pageLayout-Matheu ARAUCARIA PDFFmwingenieriasa MarojaNo ratings yet

- Midterm Examination: Ce 322 - Building Systems DesignDocument5 pagesMidterm Examination: Ce 322 - Building Systems DesignJEAN KATHLEEN SORIANONo ratings yet

- B B B B: LeyendaDocument1 pageB B B B: Leyendaruddy denisNo ratings yet

- HPD Single Speed TransmissionDocument1 pageHPD Single Speed TransmissionFatih BahşiNo ratings yet

- Issued For Construction: NotesDocument1 pageIssued For Construction: NotesjebripahlaviNo ratings yet

- 2040-000-1050 WipDocument1 page2040-000-1050 WipMina AlbertNo ratings yet

- Hibike Euphonium - March Sky Blue Dream (1) - EuphoniumDocument1 pageHibike Euphonium - March Sky Blue Dream (1) - EuphoniumBruno CarvalhoNo ratings yet

- 20107-Nh-36-Kdcpl-Mjb-Sup-204-Psc Girder-Sup-04Document1 page20107-Nh-36-Kdcpl-Mjb-Sup-204-Psc Girder-Sup-04Er navneet jassiNo ratings yet

- R1c01-Ilf-Cv-Prm-Con-Dga-1012-General Arrangement of Platform LevelDocument1 pageR1c01-Ilf-Cv-Prm-Con-Dga-1012-General Arrangement of Platform LevelrohitNo ratings yet

- Melodic Minor TrebleDocument1 pageMelodic Minor TreblekennethbaptisteNo ratings yet

- Floor PlanDocument1 pageFloor PlanNusaybah Mohamed ShafeeqNo ratings yet

- DetailsDocument1 pageDetailspravin1112No ratings yet

- Planta Primer Nivel Planta Mezzanine Planta Segundo Nivel Planta Tercer NivelDocument1 pagePlanta Primer Nivel Planta Mezzanine Planta Segundo Nivel Planta Tercer NivelAlex Davila LlanosNo ratings yet

- Ddi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)Document1 pageDdi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)rohitNo ratings yet

- Scci - Udh Baguio Topographic Map - 092321Document1 pageScci - Udh Baguio Topographic Map - 092321Staff05 GMTSNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- Mswil Path WD Ar-335 Ground Canteen Layout r0Document1 pageMswil Path WD Ar-335 Ground Canteen Layout r0Bharat BaliyanNo ratings yet

- Map CampuspghDocument1 pageMap CampuspghJairo EspitiaNo ratings yet

- Spare Part List 2201690123Document2 pagesSpare Part List 2201690123Ndikumasabo EtienneNo ratings yet

- Chants de Noël 2021-AccordéonDocument9 pagesChants de Noël 2021-Accordéontilan.dossogneNo ratings yet

- ShamrockDocument1 pageShamrockhamparan arthaNo ratings yet

- Elevation of Tower - 1 (Facing West) Part 2 of 3: LegendsDocument1 pageElevation of Tower - 1 (Facing West) Part 2 of 3: LegendsHozien OnofreNo ratings yet

- AER-P01-1100-0001 Rev01Document1 pageAER-P01-1100-0001 Rev01Andi SandraNo ratings yet

- Denah Lantai 16-20Document1 pageDenah Lantai 16-20WA ODE SITTI AISYAH ANo ratings yet

- Second Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectDocument1 pageSecond Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectJose JohnNo ratings yet

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcNo ratings yet

- Mswil - Path - WD - Ar-340 - Ground Floor Canteen Preparation Area Details - r0Document1 pageMswil - Path - WD - Ar-340 - Ground Floor Canteen Preparation Area Details - r0Bharat BaliyanNo ratings yet

- Chetan Infratech Consultants Pvt. LTDDocument1 pageChetan Infratech Consultants Pvt. LTDvishal18mNo ratings yet

- d0203 FST Erz Ds 71519 Sheet 7 ScheduleDocument1 paged0203 FST Erz Ds 71519 Sheet 7 ScheduleVignesh WaranNo ratings yet

- HS2 Map West Midlands wm15103Document1 pageHS2 Map West Midlands wm15103HighSpeedRailNo ratings yet

- All of Me-Trombone - 3Document1 pageAll of Me-Trombone - 3uriupsNo ratings yet

- Manthan: Himanshu Sharma Manjul MathurDocument5 pagesManthan: Himanshu Sharma Manjul MathurSUDIPTA HUINo ratings yet

- PCE-29261 - HQ (3) /1-D: Ashutosh SoniDocument9 pagesPCE-29261 - HQ (3) /1-D: Ashutosh SoniSUDIPTA HUINo ratings yet

- 21Document1 page21SUDIPTA HUINo ratings yet

- Manthan: Himanshu SharmaDocument5 pagesManthan: Himanshu SharmaSUDIPTA HUINo ratings yet

- 22Document1 page22SUDIPTA HUINo ratings yet

- 25Document1 page25SUDIPTA HUINo ratings yet

- 26Document1 page26SUDIPTA HUINo ratings yet

- 4Document1 page4SUDIPTA HUINo ratings yet

- 8Document1 page8SUDIPTA HUINo ratings yet

- 1Document1 page1SUDIPTA HUINo ratings yet

- 5Document1 page5SUDIPTA HUINo ratings yet

- 8Document1 page8SUDIPTA HUINo ratings yet

- 6Document1 page6SUDIPTA HUINo ratings yet

- 3Document1 page3SUDIPTA HUINo ratings yet

- 9Document1 page9SUDIPTA HUINo ratings yet

- 9Document1 page9SUDIPTA HUINo ratings yet

- 4Document1 page4SUDIPTA HUINo ratings yet

- 3Document1 page3SUDIPTA HUINo ratings yet

- 1Document1 page1SUDIPTA HUINo ratings yet

- 5Document1 page5SUDIPTA HUINo ratings yet

- Letter No.-2772(s) Dt. 03.07.2014Document22 pagesLetter No.-2772(s) Dt. 03.07.2014SUDIPTA HUINo ratings yet

- VigilanceDocument1 pageVigilanceSUDIPTA HUINo ratings yet

- Engg MECHANICS Full Course - 1272768 - 2023 - 07 - 13 - 13 - 4 - 230713 - 135132Document37 pagesEngg MECHANICS Full Course - 1272768 - 2023 - 07 - 13 - 13 - 4 - 230713 - 135132SUDIPTA HUINo ratings yet

- 1Document1 page1SUDIPTA HUINo ratings yet

- Airline /city /airport CodesDocument9 pagesAirline /city /airport CodesJermaine Amargo SadumianoNo ratings yet

- DPP-Chemical Equilibrium - CombinedDocument31 pagesDPP-Chemical Equilibrium - CombinedAtharva WatekarNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument8 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelrajksdNo ratings yet

- Engineering College in HaryanaDocument9 pagesEngineering College in HaryanaUjjawal Mathur100% (1)

- ISO 9000 or TQM: Which Approach To Adopt - A Canadian Case StudyDocument7 pagesISO 9000 or TQM: Which Approach To Adopt - A Canadian Case StudyAdrian SîrbuNo ratings yet

- 3ra Sesion SPT y SPT-T PDFDocument73 pages3ra Sesion SPT y SPT-T PDFSulfure PainchaultNo ratings yet

- Risk Assessment Lifting OperationsDocument5 pagesRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- Using RamdomDocument4 pagesUsing Ramdomvowan44398No ratings yet

- IBR Sec 385 PDFDocument9 pagesIBR Sec 385 PDFgokul_raamNo ratings yet

- Chance Vs HastingsDocument10 pagesChance Vs HastingsNguyễn Thị HườngNo ratings yet

- TCRDocument21 pagesTCRvishal9119No ratings yet

- UPX X.XX OEP FinderDocument2 pagesUPX X.XX OEP FindermankavarNo ratings yet

- 1 1-Simplestress PDFDocument43 pages1 1-Simplestress PDFAsad KhanNo ratings yet

- History MatchDocument78 pagesHistory MatchDucke Cristie Elias Latumeten100% (1)

- Career ObjectiveDocument4 pagesCareer ObjectiveRandy L. TiinNo ratings yet

- 2b. TESDA-OP-CO-01-F14 TOOLSDocument2 pages2b. TESDA-OP-CO-01-F14 TOOLSRommel SelgaNo ratings yet

- Nozzle CatalogDocument202 pagesNozzle CatalogMurat Başak0% (1)

- LANJUTKANDocument79 pagesLANJUTKANPutika ApphaNo ratings yet

- Ultrasonic Sensing - Fundamentals and Its Applications To Nondestructive EvaluationDocument20 pagesUltrasonic Sensing - Fundamentals and Its Applications To Nondestructive Evaluationhacguest8485100% (1)

- Primal ICC 3Document2 pagesPrimal ICC 3hongducxxxNo ratings yet

- General Instruments SpecificationsDocument44 pagesGeneral Instruments Specificationsavinash1109No ratings yet

- Important Linux Commands Working With Shell Lab - 2Document6 pagesImportant Linux Commands Working With Shell Lab - 2Miki YoNo ratings yet

- Advanced Reinforced Concrete Design by Krishna RajuDocument370 pagesAdvanced Reinforced Concrete Design by Krishna RajuZafe Mwoun100% (1)

- LOADMASTER Se7510 Indicator 10052001aDocument32 pagesLOADMASTER Se7510 Indicator 10052001aRoberto Augusto Aristizabal MorenoNo ratings yet

- Specification Inlet Air Heater Volvo EC350DL ExcavatorDocument2 pagesSpecification Inlet Air Heater Volvo EC350DL ExcavatorReymond RoyNo ratings yet

- Eurocode 2 Worked ExamplesDocument52 pagesEurocode 2 Worked ExamplesCatalin Cata100% (4)

- en PDFDocument6 pagesen PDFIonmadalin1000No ratings yet