0% found this document useful (0 votes)

47 views4 pagesSteel Plate Girder Design Analysis

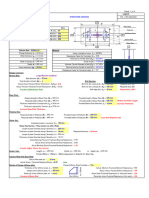

This document provides the design calculations for redesigning a plate girder with a thin web plate. It includes calculating the bending moment capacity, checking shear resistance of the web, and designing load carrying stiffeners at support locations.

Uploaded by

bhavya pooniaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

47 views4 pagesSteel Plate Girder Design Analysis

This document provides the design calculations for redesigning a plate girder with a thin web plate. It includes calculating the bending moment capacity, checking shear resistance of the web, and designing load carrying stiffeners at support locations.

Uploaded by

bhavya pooniaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd