0% found this document useful (0 votes)

358 views10 pagesMethod Statement Crane Track Installation

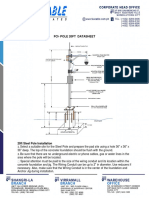

The document provides guidelines for installing crane rail tracks, including preparing the concrete foundation, installing soleplates, selecting the proper clips and holding down bolts based on load ratings, and ensuring safety during the process.

Uploaded by

munawarsyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

358 views10 pagesMethod Statement Crane Track Installation

The document provides guidelines for installing crane rail tracks, including preparing the concrete foundation, installing soleplates, selecting the proper clips and holding down bolts based on load ratings, and ensuring safety during the process.

Uploaded by

munawarsyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd