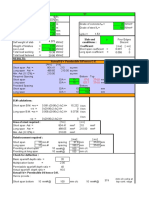

Two way Slab Case # 3

1 Material Stressess

Fc = 750 Psi n = 0.32d1 inch

Fst = 24000 Psi la = 0.89d1 inch

m = 15 k = 107

2 Member data

Long Span effective = 16.75

Short span effective = 14.75

Ratio Ly / Lx Spans = 1.14

3 Bending Moments Co-Efficents

= (-) K S.Span 0.066 = (+) K S.Span 0.049

= (-) K L.Span 0.050 = (+) K L.Span 0.037

4 Slab Thickness

d = Lx/40 = 4.43 inch Thumb Rule Adopted

Over All Depth = 6 inch

d1( lower layer) = 5.25 inch

d2( Upper layer) = 4.75 inch

5 Loadings ( consider 1.0 ft wide Strip)

Self weight of slab = 75 lbs/ft

Floor or ceiling finishes = 30 lbs/ft

Live Load = 80 lbs/ft

Sunk Laod / Partion load = 0 lbs/ft

Total Load = 185 lbs/ft

6 Design of Short Span

(+) ve B.M @ Mid Span = 23666 lbs/inch

Area Of Steel ( Ast) = 0.21 Sq in

Use 1/2 inch dia = 11 C/C

(-) ve B.M @ Mid Span = 31877 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.31 Sq in

Use 1/2 inch dia = 7 C/C

For Effective Depth = 4.98 < d1

7 Design of Long Span

(+) ve B.M @ Mid Span = 23045 lbs/inch

Area Of Steel ( Ast) = 0.23 Sq in

Use 1/2 inch dia = 10 C/C

(-) ve B.M @ Mid Span = 31142 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.31 Sq in

Use 1/2 inch dia = 8 C/C

8 Tortional Steel

Ast= 0.75 * (+ve Ast max) = 0.17 Sq in

Use 3/8 inch dia in Mesh = 8 C/C

9 Equivalent UdL over Supporting Beams

Along Long Span = 1012 lbs/ft

Along Short span = 910 lbs/ft

RESULT

Use 1/2 inch dia Main Steel = 7 inch C/C

�Use 1/2 inch dia Distrubtion Steel = 7 inch C/C

� Two way Slab Case # 3

1 Material Stressess

Fc = 750 Psi n = 0.32d1 inch

Fst = 24000 Psi la = 0.89d1 inch

m = 15 k = 107

2 Member data

Long Span effective Ly = 11.25

Short span effective Lx = 7.5

Ratio Ly / Lx Spans = 1.50

3 Bending Moments Co-Efficents

= (-) K S.Span 0.085 = (+) K S.Span 0.058

= (-) K L.Span 0.058 = (+) K L.Span 0.044

4 Slab Thickness

d = Lx/40 = 2.25 inch Thumb Rule Adopted

Over All Depth = 6 inch

d1( lower layer) = 5.25 inch

d2( Upper layer) = 4.75 inch

5 Loadings ( consider 1.0 ft wide Strip)

Self weight of slab = 75 lbs/ft

Floor or ceiling finishes = 30 lbs/ft

Live Load = 80 lbs/ft

Sunk Laod / Partion load = 0 lbs/ft

Total Load = 185 lbs/ft

6 Design of Short Span

(+) ve B.M @ Mid Span = 7243 lbs/inch

Area Of Steel ( Ast) = 0.06 Sq in

Use 1/2 inch dia = 36 C/C

(-) ve B.M @ Mid Span = 10614 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.10 Sq in

Use 1/2 inch dia = 22 C/C

For Effective Depth = 2.88 < d1

7 Design of Long Span

(+) ve B.M @ Mid Span = 12363 lbs/inch

Area Of Steel ( Ast) = 0.12 Sq in

Use 1/2 inch dia = 19 C/C

(-) ve B.M @ Mid Span = 16296 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.16 Sq in

Use 1/2 inch dia = 15 C/C

8 Tortional Steel

Ast= 0.75 * (+ve Ast max) = 0.09 Sq in

Use 3/8 inch dia in Mesh = 14 C/C

9 Equivalent UdL over Supporting Beams

Along Long Span = 591 lbs/ft

Along Short span = 463 lbs/ft

RESULT

Use 1/2 inch dia Main Steel = 8 inch C/C

�Use 1/2 inch dia Distrubtion Steel = 8 inch C/C

� Two way Slab Case # 4

1 Material Stressess

Fc = 750 Psi n = 0.32d1 inch

Fst = 24000 Psi la = 0.89d1 inch

m = 15 k = 107

2 Member data

Long Span effective Ly = 20

Short span effective Lx = 14

Ratio Ly / Lx Spans = 1.43 < 2

3 Bending Moments Co-Efficents

= (-) K S.Span 0.071 = (+) K S.Span 0

= (-) K L.Span 0.053 = (+) K L.Span 0.044

4 Slab Thickness

d = Lx/40 = 4.20 inch Thumb Rule Adopted

Over All Depth = 6 inch

d1( lower layer) = 5.25 inch

d2( Upper layer) = 4.75 inch

5 Loadings ( consider 1.0 ft wide Strip)

Self weight of slab = 75 lbs/ft

Floor or ceiling finishes = 30 lbs/ft

Live Load = 80 lbs/ft

Sunk Laod / Partion load = 0 lbs/ft

Total Load = 185 lbs/ft

6 Design of Short Span

(+) ve B.M @ Mid Span = 0 lbs/inch

Area Of Steel ( Ast) = 0.00 Sq in

Use 1/2 inch dia = #DIV/0! C/C

(-) ve B.M @ Mid Span = 30894 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.30 Sq in

Use 1/2 inch dia = 8 C/C

For Effective Depth = 4.91 < d1

7 Design of Long Span

(+) ve B.M @ Mid Span = 39072 lbs/inch

Area Of Steel ( Ast) = 0.39 Sq in

Use 1/2 inch dia = 6 C/C

(-) ve B.M @ Mid Span = 47064 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.46 Sq in

Use 1/2 inch dia = 5 C/C

8 Tortional Steel

Ast= 0.75 * (+ve Ast max) = 0.29 Sq in

Use 3/8 inch dia in Mesh = 5 C/C

9 Equivalent UdL over Supporting Beams

Along Long Span = 1083 lbs/ft

Along Short span = 863 lbs/ft

RESULT

Use 1/2 inch dia Main Steel = 8 inch C/C

�Use 1/2 inch dia Distrubtion Steel = 8 inch C/C

� Two way Slab Case # 4

1 Material Stressess

Fc = 750 Psi n = 0.32d1 inch

Fst = 24000 Psi la = 0.89d1 inch

m = 15 k = 107

2 Member data

Effective Span Le = 11.5 ft

C.C Spacing Between Two Ribs = 14.0 Ft

Depth Of Slab ( ds) = 6.0 in

Breadth Of Rib (br) = 9.0 in

Depth of Rib( dr) = 24.0 in

Effective Depth of Beam ( d1) = 28.5 in

Lever arm( La)= ( d1-ds)/2 = 11.3 in

3 Width of flange

B=12 x (Le/3) = 11.5 ft

C.C Spacing Between Two Ribs = 14.0 Ft

Depth Of Slab ( ds) = 6.0 in

Breadth Of Rib (br) = 9.0 in

Depth of Rib( dr) = 24.0 in

Effective Depth of Beam ( d1) = 28.5 in

Lever arm( La)= ( d1-ds)/2 = 11.3 in

4 Slab Thickness

d = Lx/40 = 4.20 inch Thumb Rule Adopted

Over All Depth = 6 inch

d1( lower layer) = 5.25 inch

d2( Upper layer) = 4.75 inch

5 Loadings ( consider 1.0 ft wide Strip)

Self weight of slab = 75 lbs/ft

Floor or ceiling finishes = 30 lbs/ft

Live Load = 80 lbs/ft

Sunk Laod / Partion load = 0 lbs/ft

Total Load = 185 lbs/ft

6 Design of Short Span

(+) ve B.M @ Mid Span = 0 lbs/inch

Area Of Steel ( Ast) = 0.00 Sq in

Use 1/2 inch dia = #DIV/0! C/C

(-) ve B.M @ Mid Span = 0 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.00 Sq in

Use 1/2 inch dia = #DIV/0! C/C

For Effective Depth = 0.00 < d1

7 Design of Long Span

(+) ve B.M @ Mid Span = 0 lbs/inch

Area Of Steel ( Ast) = 0.00 Sq in

Use 1/2 inch dia = #DIV/0! C/C

(-) ve B.M @ Mid Span = 0 lbs/inch Maximum B.M

Area Of Steel ( Ast) = 0.00 Sq in

Use 1/2 inch dia = #DIV/0! C/C

8 Tortional Steel

Ast= 0.75 * (+ve Ast max) = 0.00 Sq in

Use 3/8 inch dia in Mesh = #DIV/0! C/C

�9 Equivalent UdL over Supporting Beams

Along Long Span = 655 lbs/ft

Along Short span = 863 lbs/ft

RESULT

Use 1/2 inch dia Main Steel = 8 inch C/C

Use 1/2 inch dia Distrubtion Steel = 8 inch C/C