Professional Documents

Culture Documents

Shot Peening

Uploaded by

lalamed21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shot Peening

Uploaded by

lalamed21Copyright:

Available Formats

SHOT PEENING

Shot Peening Nedir?

What Is Shot Peening?

hot peening; yzeye souk ekil verme ilemi olarak tanmlanmaktadr. Yksek hzla frlatlan andrclarn btn yzey zerinde bir n gerilme tabakas oluturur. Bu n gerilme mukavemeti yk altnda kullanlan malzemenin yorulma dayanmn nemli lde artrmakla birlikte, stres korozyon atlaklarna kar diren meydana getirir. Shot peening ilemi eitli aamalar kaydedilerek, 19.yy balarnda Amerikal bir mhendis olan B.C.Tilgham tarafndan tarif edilerek patent kayd yaplmtr. Shot Peening is a method of cold working in which compressive stresses are induced in the exposed surface layers of metallic parts by the impingement of a stream of shot, directed at the metal surface at high velocity under controlled conditions. It differs from blast cleaning in primary purpose and in the extent to which it is controlled to yield accurate and reproducible results. Although shot peening cleans the surface being peened, this function is incidental. The major purpose of shot peening is to increase fatigue strength. The process has other useful applications, such as relieving tensile stresses that contribute to stress-corrosion cracking, forming and straightening of metal parts, and testing the adhesion of silver plate on steel.

Yaylar, dililer, torsiyon barlar vb. eitli otomotiv ve hava endstrisinde kullanlan malzemelerin imalatlar esnasnda; talal imalat, kaynak, talama, sl ilem, eme, hadde vb deiik retim srelerinde malzeme i gerilmelere maruz kalr. te shot peening prensip olarak malzemelerde mevcut olan i gerilmelere ve atlaklara kar yzeyde kar diren oluturulmasdr. Bu sayede yk altnda malzemelerin daha uzun mrl olmalar hedeflenmektedir.

Shot peening andrclar olarak kullanlan rnler;

Demir erenler elik Bilya, Yuvarlatlm Tel kesme, Paslanmaz elik Bilya Alminyum, inko, Bakr, Bronz Cam Krecik, Seramik Bilya

Metalik Olanlar Demird Olanlar Metalik Olmayanlar

Media used for peening can be iron, steel, glass shot, cut steel or stainless steel wire. Metallic shot is designated by numbers according to size. Shot numbers, as standardized by MIL-S-13165, range from S70 to S930. The shot number is approximately the same as the nominal diameter of the individual pellets in ten thousandths of an inch. Shot Peening Andrc Standartlar: Standartlar; son kullanclar, andrc reticileri veya uluslar aras kurulular tarafndan yazlmaktadr. En yaygn kullanlan standartlar ise SAE (Society of automotive engineers) tarafndan yaynlanmaktadr. SAE, 'AMS' (Aerospace Material Specification) havaclk endstrisi iin standartlar belirtirken, SAE 'J' genel uygulamalar iin temel standartlar ifade etmektedir.

Yaylar, dililer, torsiyon barlar vb. eitli otomotiv ve hava endstrisinde kullanlan malzemelerin retim aamasnda shot peening kullanlmaktadr. 40

Yzey lem ve Kumlama Dergisi Surface Finishing & Blasting News

SHOT PEENING

Andrc zelliklerine gre standartlar aadaki tabloda verilmitir;

Andrc Tipi/ Abrasives elik Bilya / Cast Steel Shot Tel Kesme / Cut Wire Shot Cam Krecik / Glass Beads Seramik Bilya / Seramic Shot Standart/ Specifications AMS 2431/1 veya/or AMS 2431/2 AMS 2431/3 veya/or AMS 2431/8 AMS 2431/6 AMS 2431/7 Sertlik/ Hardness 45-52 HRC veya/or 55-62 HRC 45-52 HRC veya/or 55-62 HRC 48-52 HRC 58-63 HRC

dier standartlar; zellik / Specification Kimyasal Komposizyon/ Chemical Compositions Sertlik / Hardness Boyut / Size

Younluk (intensity); shot peening yaplm Almen test plakasna ait doyum grafiindeki (saturation curve) arc ykseklii olarak ifade edilir. Doyum noktas ise; doyum grafiinde pskrtme sresinin iki katna ktnda arc yksekliinin en fazla % 10 artt ilk eim noktas olarak tarif edilir. Relation of measuring coverage to peening time. Coverage is considered full at time t, if doubling exposure to time 2t results in change in arc height less than 10%

Peening intensity is governed by the velocity, hardness, size, and weight of the shot pellets, and by the angle at which the stream of shot impinges against the surface of the workpiece. Intensity is expressed as the arc height of an Almen test strip at or at more than saturation coverage. Arc height is the measure of the curvature of a test strip that has been peened on one side only. The lowest peening intensity capable of producing the desired compressive stress is the most efficient and least costly, because the peening process can be achieved with the minimum shot size in the minimum exposure time. Conversely, an intensity may be considered excessive if, as with very thin parts, a condition is produced in which the tensile stresses of the core material outweigh the beneficial compressive stresses induced at the surface.

Standart / Standart ASTM E350 ASTM E384 ASTM E11

Younluk (Peening Intensity): Shot peening ilemi yaplmadan nce bu proses sonras elde edilecek younluun zel yntem ve aletlerle tespit edilmesi ilemidir. General Motors da aratrma mhendisi olan John Almen tarafndan gelitirilen yntemle malzeme zerine transfer edilen kinetik enerjinin lm salanmtr. Almen eritleri ve Almen test cihaz sayesinde bu lm gereklemektedir. Almen test eritleri kalnlklarna gre isimlendirilmiti;

erit Ad/ Standart/ Strip Name Standart C A N

SAE J442

Dzlem/ Sertlik/ Kalnlk/ Flatness Hardness Thickness

+/- 0.025 mm 44-50 HRC 1.29 mm

AMS-S 13165 +/- 0.038 mm 44-50 HRC 0.79 mm

SAE AMS 2432 +/- 0.013 mm 45-58 HRC 2.39 mm

Havaclk endstrisinde shot peening uygulamas nemli yer tutmaktadr.

Shot peening is used on a large scale at the aerospace industry.

Yzey lem ve Kumlama Dergisi Surface Finishing & Blasting News

41

SHOT PEENING

Saturation Curve

Bu grafiin izilmesinde Alcom 5.0 adl otomatik bilgisayar programlar da kullanlmaktadr. Genel olarak en az drt farkl Almen test plakasnn peening ilemi yaplarak arc ykseklikleri llr ve grafie ilenir. Bylece younluk tespit edilerek gerek parann penning ilemine geilir. Normal iletme koullarnda her sekiz (8) saatte bir bu test ileminin yaplmas tavsiye edilmektedir. Younluk (intensity), andrc ak oranna, andrc hzna (basnl sistemlerde basnca), vuru asna ve malzemeye olan uzakla gre deimektedir. Ayrca andrc boyutuna ve sertliine bal olarak ta artmaktadr. Coverage (rtme) Andrc bombardmanna maruz kam yzeyin % olarak ne kadar youn etkilendiinin bir gstergesidir. Andrc pskrtme sresi (Exposure time) ve andrc ak oran (Shot Flow Rate) ile direkt olarak artrlabilmektedir. Genelde grsel olarak shot peening uygulanm yzeyin yeterli bytme yaplarak tespitine dayanmaktadr. Shot peening, yk altnda kullanlan malzemenin yorulma dayanmn nemli lde artrr.

Shot peening pskrtme sresince etkilenen alan Area coverage as a function of exposure time in shot peening Shot peening application rise with increasing automotive industry

Otomotiv sektrndeki gelimelere orantl olarak shot peening uygulama alan artmaktadr.

Surface coverage is a measure of how completely an area has been hit by the myriad of impinging shot particles. Without 100% coverage or saturation, the improvement in fatigue characteristics conventionally produced by shot peening is not obtained. Measurement of Coverage. Direct methods for measuring coverage include visual methods and the Straub method. One of the indirect methods is the Valentine method, which involves layer removal.Visual methods, although not quantitative, are almost universally used. The simplest of these consists of visual inspection, with or without the aid of optical (10x) magnification of the surface of the peened part. This method may be supplemented by a series of reference photographs illustrating various percentages of coverage.

42

Yzey lem ve Kumlama Dergisi Surface Finishing & Blasting News

You might also like

- Malzeme Bilimi Hafta 6 HASARDocument47 pagesMalzeme Bilimi Hafta 6 HASARilyasorhanli.9427No ratings yet

- Mühendi̇sli̇k Malzemeleri̇ni̇n Özelli̇kleri̇ Mekani̇k Özelli̇klerDocument104 pagesMühendi̇sli̇k Malzemeleri̇ni̇n Özelli̇kleri̇ Mekani̇k Özelli̇kler20mustafadumanNo ratings yet

- Yorulma HasarlarıDocument74 pagesYorulma HasarlarıMehmet Akif AyirtNo ratings yet

- Metalik Malzemelerde Yorulma DeneyiDocument9 pagesMetalik Malzemelerde Yorulma DeneyiGökçen Aslan AydemirNo ratings yet

- Deney 01 - J1-1Document21 pagesDeney 01 - J1-1HUSEYIN OGUZHAN SELLINo ratings yet

- Malzeme Bi̇li̇mi̇ - Hafta 6Document42 pagesMalzeme Bi̇li̇mi̇ - Hafta 6Emre AlemdarNo ratings yet

- Acunlar 520Document2 pagesAcunlar 520DİBORNo ratings yet

- Makine Elemanları I - YorulmaDocument19 pagesMakine Elemanları I - YorulmaNoor MukhtarNo ratings yet

- Tabakalı Ve Sandviç Kompozitlerin Darbe Cevabı (3,4) (Serge Abrate-2011)Document14 pagesTabakalı Ve Sandviç Kompozitlerin Darbe Cevabı (3,4) (Serge Abrate-2011)RifatNo ratings yet

- Be Tonda Muay EneDocument68 pagesBe Tonda Muay EneFatih AydınNo ratings yet

- Sicak DövmeDocument10 pagesSicak Dövmemehmetozer1905100% (1)

- TakimomruDocument7 pagesTakimomruBurak ErkanNo ratings yet

- Dea1f810a6512c3 Ek 2Document96 pagesDea1f810a6512c3 Ek 2melihagis58585No ratings yet

- Açık İşletmelerde Maliyete İlişkin Bazı Delme-Patlatma Parametrelerine Genel BakışDocument7 pagesAçık İşletmelerde Maliyete İlişkin Bazı Delme-Patlatma Parametrelerine Genel BakışBarış KoruNo ratings yet

- TribolojiDocument169 pagesTribolojiEray OzsoyNo ratings yet

- Yorulma ÇeşitleriDocument14 pagesYorulma ÇeşitleriEnes BayramNo ratings yet

- Malzemeleri̇n Mekani̇k Özelli̇kleri̇ - 2021Document58 pagesMalzemeleri̇n Mekani̇k Özelli̇kleri̇ - 2021BatuhanNo ratings yet

- Makel 4.konu-Makine Elemanları Kırılma MekaniğiDocument16 pagesMakel 4.konu-Makine Elemanları Kırılma MekaniğiyeteneksizoNo ratings yet

- 87c5c6268e0247a EkDocument35 pages87c5c6268e0247a Ekmuhlisharhar1No ratings yet

- Malzemelerin Mekanik DavranışlarıDocument172 pagesMalzemelerin Mekanik DavranışlarıSalih BalcıNo ratings yet

- Yorulma, AşınmaDocument35 pagesYorulma, Aşınmashaqtr81100% (1)

- 3260 Beton Yüzey Sertliği Yolu Ile Yaklaşık Beton DayanımıDocument6 pages3260 Beton Yüzey Sertliği Yolu Ile Yaklaşık Beton DayanımıKORDEF LABORATUVAR HİZ. LTD. ŞTİ.No ratings yet

- Malzemelerin Mekanik OzellikleriDocument151 pagesMalzemelerin Mekanik OzelliklerihcceylanNo ratings yet

- Alçak Gerilim Anahtarlama Ve Kontrol DüzenleriDocument9 pagesAlçak Gerilim Anahtarlama Ve Kontrol DüzenleriycemalNo ratings yet

- Ts en 12390 2 PDFDocument6 pagesTs en 12390 2 PDFFaruk AtalarNo ratings yet

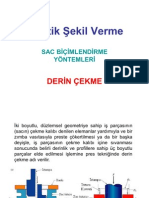

- 93 Deri̇n ÇekmeDocument31 pages93 Deri̇n ÇekmeMümin MutluNo ratings yet

- 2021 TemmuzDocument27 pages2021 TemmuzM DNo ratings yet

- TS 10465Document17 pagesTS 10465Selmin UsluNo ratings yet

- SQPQR-WPQR-RC-01 RC EndüstriDocument5 pagesSQPQR-WPQR-RC-01 RC EndüstriGülşah ArslanNo ratings yet

- 3-Tahribatlı Muayene-SertlikDocument233 pages3-Tahribatlı Muayene-SertlikEmre DemirkolNo ratings yet

- 1.2379 So - Uk - Tak - M - Eli - I Delme Z - Mbalar - Nda AlTiN, TiSiN Ve TiN, PVD Kaplamalar - N Tak - M - MR - Ne Etkisi (#781621) - 1244416Document6 pages1.2379 So - Uk - Tak - M - Eli - I Delme Z - Mbalar - Nda AlTiN, TiSiN Ve TiN, PVD Kaplamalar - N Tak - M - MR - Ne Etkisi (#781621) - 1244416ergün cebeciNo ratings yet

- TS en 12504-1Document7 pagesTS en 12504-1plenusssNo ratings yet

- 4-BELEDİYE EK HİZMET BİNASI İNCE İNŞAAT İŞLERİ Teknik Şartname Dış CepheDocument4 pages4-BELEDİYE EK HİZMET BİNASI İNCE İNŞAAT İŞLERİ Teknik Şartname Dış CepheHSNNo ratings yet

- Malzeme Hasar Tespit YönetimiDocument167 pagesMalzeme Hasar Tespit YönetimiYusuf Ensar Topçu100% (1)

- Mekanik Testler (ÇEKME TESTİ)Document12 pagesMekanik Testler (ÇEKME TESTİ)Damla KaymakçıNo ratings yet

- Seramik Kesici Takımların İşlenebilirliğe EtkisiDocument35 pagesSeramik Kesici Takımların İşlenebilirliğe Etkisigoksu1No ratings yet

- Borşen BrochureDocument24 pagesBorşen BrochurealihaydartekinNo ratings yet

- Lecture 1Document19 pagesLecture 1vortex123No ratings yet

- Imalat Islemleri II PDFDocument82 pagesImalat Islemleri II PDFakingultekNo ratings yet

- Mem 354 - Bolum 3Document31 pagesMem 354 - Bolum 3Yaren FilizNo ratings yet

- TS en 679 Gaz Beton - Kuruma Büzülmesi̇ Tayi̇ni̇Document6 pagesTS en 679 Gaz Beton - Kuruma Büzülmesi̇ Tayi̇ni̇kordef zeminNo ratings yet

- Dövme El Ki̇tabi1Document18 pagesDövme El Ki̇tabi1Ahmet ÖZTAŞÇINo ratings yet

- 05 Teorik Kohesif MukavemetDocument10 pages05 Teorik Kohesif MukavemetEmre YılmazNo ratings yet

- Ders Notu 4 YorulmaDocument24 pagesDers Notu 4 YorulmaErsen ArslanNo ratings yet

- Zemi̇n Ankraj Hesabi Ve Şartnamesi̇Document16 pagesZemi̇n Ankraj Hesabi Ve Şartnamesi̇cengizNo ratings yet

- Maki̇ne Elemanlari Ders SlaytlariDocument35 pagesMaki̇ne Elemanlari Ders SlaytlariÜstün Onur BaktırNo ratings yet

- Triboloji SunumDocument20 pagesTriboloji SunumzeynepNo ratings yet

- SertlikDocument7 pagesSertlikMesut PatozNo ratings yet

- Ders Notu Malzeme BilimiDocument18 pagesDers Notu Malzeme Bilimiasd dsaNo ratings yet

- Imal PŞV Bölüm 2.3 Ekstrüzyo Ve ÇekmeDocument33 pagesImal PŞV Bölüm 2.3 Ekstrüzyo Ve ÇekmeHasan OruçNo ratings yet

- Beton Basınç Dayanımının BelirlenmesiDocument57 pagesBeton Basınç Dayanımının BelirlenmesiOğuz CanbolatNo ratings yet

- Leme Parametreler Nden Kesme Hizinin Inconel 718 S Per Ala Imin Leneb L RL Ne Etk S (#88846) - 76059Document6 pagesLeme Parametreler Nden Kesme Hizinin Inconel 718 S Per Ala Imin Leneb L RL Ne Etk S (#88846) - 76059kemalNo ratings yet

- Hardox 400 Celiğinin Sert Dolgu KaynağıDocument8 pagesHardox 400 Celiğinin Sert Dolgu KaynağıMustafa Ersin EkremNo ratings yet