Environmental Impact & Safety Analysis Report

Uploaded by

thairuvadai.05Environmental Impact & Safety Analysis Report

Uploaded by

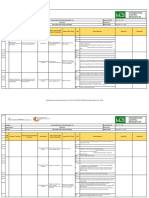

thairuvadai.05ENVIRONMENTAL ASPECTS, IMPACTS, WORKPLACE SAFETY AND HEALTH RISKS ANALYSIS

ELECTRICAL WORK (Cable laying, Termination, Installation &

Title: Doc. No. / Revision: L&W-ITPPK-B2-RA-001 / R-001

commissioning)

Company: L&W Constrcution Pvt. Ltd. [Link]( PM ), Nishanth (Dept Maanger -QA/QC ),Ashok (Sr.

Analysis Conducted by: (Team member names) Engg - P&M ),Vengatesh Bala ([Link] - MEP) ,Abdul Raheem

Process / Location: Tower 1,2 and 3 - Vector Project ([Link] -EHS)

Approved by: Name: Reviewed by: Name:

Date: Sign: Date: 07-05-2024 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health & Environmental Impacts / Health & Initial Risk Ratings Control Measures Law / Compliance Residual Risk Ratings Person-In-Charge

Safety Hazards Safety Risks (PIC)

L S R L S R

1 Resourse H-Health and fitness issues H-Sickness / Disability 3 4 12(M) 1. Fit To Work Certificate Yes 1 3 3(L) Engineer

mobilisation. S-Untrained Worker S-Accidents / Incidents 2. Health Safety Environment Induction Training

S-Unauthorised worker entry S-Security Issues 3. Job specefic In-House training.

to site 4. Tool Box Talk

5. Permit To Work

6. Non-use of mobile phone in restricted areas.

7. Personal Protective Equipment (PPE)

8. ID Cards for workers

4 2 8(M) 1. Arrange Tool Box Talk before starting the activity. Yes 2 2 4(L)

2. Only trained persons to be deployed for work.

3. Ensure recommended PPE to the worker such as safety shoes, helmet, hand

gloves, full body safety harness & goggles etc.

4. Machinery / Vehicles to be checked before use.

5. Area under working to be properly barricaded.

6. Entry of person is strictly restricted in the area swing of boom.

7. Ensure operator having valid driving licenses.

8. Provide caution sign board, and Bank man

E-Noise Polution 9. Emergency path way and Assembly Point shall be clean and clear.

E - Noise Emission

H-Nil 10. Crane, pulley sling D- shackles, U-clamps etc to be certified by competent

2 Material unloading by

H-NIL

s-Employee or public crushed by

Site Engineer

S-Dropping of Load authority and approved safety engineer

Hydra dropping point 11. Capacity of sling D- shackle -2 ton, sling 16 mm dia-2ton, max load to be lifted

will be 1.5ton

12. Proper life line to be used by workers at height.

13. Proper guide rope to be tied to the member during lifting

14. Ensure before starting the work that Worker is in normal state of mind & should

not be drunked.

1. Only Trained Personnel should be deployed for work.

1. Unsafe working platform

2. Tool box talk Shall be conducted before Start the Activity.

2. Conjusted working areas

1. personal injuries 3. Provide recommended PPE’s, safety helmet, safety shoes, reflective jacket,

3. Poor illumination

2. Cut injuries cotton hand gloves, full body safety harness with double lanyard &,safety goggle

Height Work 4. Defective hand tools

3. Hit injuries etc to the workers.

(Cable tray fitting, 5. Defective Power tools

3 Cable Laying, Fixing of 6. Unsafe electrical cable joints

4. Electrical shock 2 4 8 4. Experienced supervisor should be deployed while the erection & dismantling. Yes 1 2 2(L) Site Engineer

5. Injury to human body parts 5. Work permit shall be obtained before

light fixtures)

6. Jerk to human body parts. [Link] of life line rope as anchorage point

7. slip trip hazards

[Link] for safe access

8. Fall from height.

[Link] line rope most tiy-up with cable tray support (anchor fastner bolt capacity is

[Link] laying on cable tray

707 KG )

S- Damage electrical cable 3 3 9 1. Use of Power tools 1 2 2(L)S_

S- Fire hazards 2. Work on lighting fixture

3. Work on electrical cable/wire

4. Work on electrical panel

5. Work on main switch/panel

Working on Live

Electrical hazard 6. Work on electrical bus bar Sie incharge

electrical installation

4 7. Work on distribution boards

[Link] in the cables can lead to electric shock if they come in contact with

conducting material such as metal or liquids or body parts.

10. Contact with live electrical circuit

11. LOTO not provided

Routine Electrical 1. Fault finding on a live electrical panel

equipments 2. Switching ON-OFF of a capacitor panel

mentinence 3. Switching ON-OFF of a main switchYes.

4. Experienced & trained operator shall be put on the job.

5 Electrical hazard 4 2 8 5 Supervisor is monitoring the work all the time Yes 1 2 2(L) Site Engineer

6. Cummins supervisor confirms LOTO system before start of work

S-damage of material 7. If need to work on live panel accompanied Site Engineer

S-short circute

[Link] injury if the hands or fingers or any body part come in contact with the

Excavation equipment

S-damage to propety 4 3 12 [Link] of falling Which may result in Injury Yes 2 1 2(L) Site Engineer

Power tools [Link] every power tool have monthly inspection tag

L W Construction Private Limited

Use of exposed or

rotating machineries.

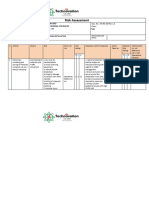

ENVIRONMENTAL ASPECTS, IMPACTS, WORKPLACE SAFETY AND HEALTH RISKS ANALYSIS

ELECTRICAL WORK (Cable laying, Termination, Installation &

Title: Doc. No. / Revision: L&W-ITPPK-B2-RA-001 / R-001

commissioning)

Company: L&W Constrcution Pvt. Ltd. [Link]( PM ), Nishanth (Dept Maanger -QA/QC ),Ashok (Sr.

Analysis Conducted by: (Team member names) Engg - P&M ),Vengatesh Bala ([Link] - MEP) ,Abdul Raheem

Process / Location: Tower 1,2 and 3 - Vector Project ([Link] -EHS)

Approved by: Name: Reviewed by: Name:

Date: Sign: Date: 07-05-2024 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health & Environmental Impacts / Health & Initial Risk Ratings Control Measures Law / Compliance Residual Risk Ratings Person-In-Charge

Safety Hazards Safety Risks (PIC)

Power tools L S R L S R

4. Electric motor and rotating parts must have guard

[Link] should be mandatory for every tools

E - Noise emission E - Noise pollution 1. Carry out maintenance for plant / machineries Yes Respective plant

E- Dust / debris emission E - Air pollution 2. Do not load materials if unfavorable wind presents supervisor

Use of exposed or H - Nil 3. Wear dust mask and ear plug Engineer

rotating machineries.

S - Manual handling S - Injury to worker 1. Wear safety helmet, shoes, and gloves Yes Foreman

6 during rigging unloading materials 2. In-house training given to Operator about safe Safety Personel

S - During stacking the 4 3 12 operation Yes 2 1 2(L) Foreman

materials sliding down 3. Workers must follow safe handling procedure Foreman

S - Blocking access way 4. Materials must be stacked properly without the Yes Foreman

S - Materials damage risk of sliding or collapsing Yes Foreman

S - Material damage, major injuries,

S - Poor Ground Conditions 1. Materials must be stacked at designated area Yes Site Engineer / EHS

fatality and property damage

1. Ground condition must be checked before placement of equipment it should be

compacted and levelled properly.

2. Proper illumination to be provided in working area during night work.

S - Hit by object S - Major injuries, fractures 3 3 9 Yes 2 1 2(L) Site Engineer / EHS

3. Required to be used during work.

4. Close supervision is necessary

7 Loading , Unloading 5. Sling used forsuspended

unloading should

Stay away from load possess a valid third party certificate

Deploy trained and experienced manpower for the task

Barricade the working area to prevent unauthorised entry

While fixing ensure materials away from the lifting workers Site Engineer / EHS /

S - Tripping hazard S - Minor injury 4 2 8 Yes 2 1 2(L)

Ensure proper house keeping in erection area Foreman

All path way, gangway, road free from obstructions

S - Falling of jib together with S - Serious injury / death 3 4 12 1. No overloading Yes 1 2 2(L) Safety Personel

load / lifting gear failure to worker 2. Ensure load limit switch is function Engineer

3. Lifting load according to manufacture's load Foreman

limit chart Crane Operator

4. Avoid jib end loading lifting

5. Avoid dragging of load and sudden slewing

8 6. Regular inspection & maintenance of crane

Putting materials

and lifting tools and tackles, Third Party Inspection.

S - Collapse of crane S - Catastrophic 3 5 15(H) 1. Crane access should be in hard core or steel plate Yes 2 1 2(L) Lifting Supervisor

2. No overloading Engineer

3. Ensure load limit switch if functioning Foreman

4. Lifting load according to manufacture's load Crane Operator

limit chart

1. Experienced & trained operator shall be put on the job.

2. Supervisor is monitoring the work all the time

Workinng at floor &

9 wall opening

S - Uneven Surface S - Minor and Major Injuries 4 2 8 3. Cummins supervisor confirms LOTO system before start of work Yes 3 1 3(L) Site Engineer

4. If need to work on live panel accoumpany Cummins electrical supervisor

5. Barrication around the open duct before start of work

operators/electrician Interferencewith operationalactivity [Link] ensure PTW before Starting the work

Cable laying group Hazard due to operational activity [Link] isolation permit andcon'ned space permit

Material Motion Hazard [Link] competent and authorized personnel to deployed( supervisor to control)

[Link] to give tool box taik prior to start the task and must be documented & This

Communication hazard 4 3 12 shall cover the methodvstatement and risk assessment Yes 3 2 6

health hazards [Link] shall be carried out the personnel supervision of receiving activity

working at height during cable laying [Link] Checklist has to be completed Site incharge

10 Cable laying

[Link] the area which sign board and provide appropriate electricle insulation material

[Link] ventilation to be provided into the confined space if required

[Link] workers involve in working at height must wear their FBH

10. When doing the termination in existing System ensure that power is isolated and no

current in the working place

[Link] that hydraullic crimping tool to be used is calibrated and functional

12. Maintain good house keeping around the area

Material [Link] from height [Link] is inspected for defects or damage prior to use

people [Link] of materials [Link] to use the correct manual handling techniques at all times

[Link] handling 4 3 12 [Link] fall arrest equipment (harness) attached at all times to the scaffold when working Yes 3 2 6

11 Scaffold Site incharge

[Link] or partial collapse/structural failure [Link] handling training for all Staff

[Link] of scaffold 5. using outdrigger when work on more than 3 meter

[Link] erection guidelines displayed on scaffold

12 Working at Night S- Poor illumination [Link] injuries 1. Night work permit before starting the work at night.

E- Noise 2. Hit injuries 2 4 8 2. proper lighting provided.

yes 2 2 4 Site Incharge

L W Construction Private Limited

ENVIRONMENTAL ASPECTS, IMPACTS, WORKPLACE SAFETY AND HEALTH RISKS ANALYSIS

ELECTRICAL WORK (Cable laying, Termination, Installation &

Title: Doc. No. / Revision: L&W-ITPPK-B2-RA-001 / R-001

commissioning)

Company: L&W Constrcution Pvt. Ltd. [Link]( PM ), Nishanth (Dept Maanger -QA/QC ),Ashok (Sr.

Analysis Conducted by: (Team member names) Engg - P&M ),Vengatesh Bala ([Link] - MEP) ,Abdul Raheem

Process / Location: Tower 1,2 and 3 - Vector Project ([Link] -EHS)

Approved by: Name: Reviewed by: Name:

Date: Sign: Date: 07-05-2024 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health & Environmental Impacts / Health & Initial Risk Ratings Control Measures Law / Compliance Residual Risk Ratings Person-In-Charge

Safety Hazards Safety Risks (PIC)

L S R L S R

S- Poor supervision 3. emergency light provided. yes 2 2 4 Site Incharge

[Link] tbt given before start the work.

5. Seamless supervision to be maintened while working at night

L W Construction Private Limited

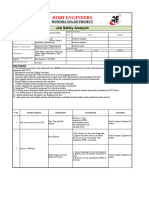

ENVIRONMENTAL ASPECTS, IMPACTS, WORKPLACE SAFETY AND HEALTH RISKS ANALYSIS

ELECTRICAL WORK (Cable laying, Termination, Installation &

Title: Doc. No. / Revision: L&W-ITPPK-B2-RA-001 / R-001

commissioning)

Company: L&W Constrcution Pvt. Ltd. [Link]( PM ), Nishanth (Dept Maanger -QA/QC ),Ashok (Sr.

Analysis Conducted by: (Team member names) Engg - P&M ),Vengatesh Bala ([Link] - MEP) ,Abdul Raheem

Process / Location: Tower 1,2 and 3 - Vector Project ([Link] -EHS)

Approved by: Name: Reviewed by: Name:

Date: Sign: Date: 07-05-2024 Sign:

1. Hazards and Risk Identifications 2. Risk Evaluations and Controls

S/n. Activity Description Environmental Aspects / Health & Environmental Impacts / Health & Initial Risk Ratings Control Measures Law / Compliance Residual Risk Ratings Person-In-Charge

Safety Hazards Safety Risks (PIC)

L S R L S R

13 S- Uses of defective platform 1. Fall of person 1. Before start the work working platform shall be inspected properly.

S- Uses of defective FBH 2. fall of materials 2. Only TPI inspected platform to be used

S- Uses of defective fall arrestor 3. Jerk of human body 3. Only TPI inspected FA should be used

4. Fatal 4 5 20 4. FBH to be inspected before use

Working at height 5. Workplace area should be barricaded Yes 3 3 9 Site Incharge

6. Working at height training to be provided before start the work to workmen

7. Only competent person allow for the working at height

8. Job related PPE to be provided to the workmen

9. Seamless supervision to be ensure at workplace area

S- Uses of defective working

14 platform 1. Fall of person 1. Before start the work working platform shall be inspected properly.

S- uses of defective fall arrestor 2. fall of material 2. Only TPI inspected platform to be used

S- Sharp edge 3. cut injury 3. Only TPI inspected FA should be used

S- Uses of defective FBH 4. Fatal 4 5 20 4. sharp edges shall be protected Yes 3 3 9 Site Incharge

Working in shaft 5. FBH to be inspected before use

6. Workplace area should be barricaded

7. Working at height training to be provided before start the work to workmen

8. Only competent person allow for the working at shaft

9. Job related PPE to be provided to the workmen

10. Seamless supervision to be ensure at workplace area

1. injury from hand tools and power

1. pre-job set up [Link] all tools prior to use

tools

2. slip,trip,fall hazard [Link] the work area

2. drill holes and instal conduit

[Link] eye hazard 3. Remove slip, trip fall hazards from the work area

supports

3. drill holes in junction box 4. Respirable and noise hazards 4. Clear work areas unwanted materials

[Link] conduit on the top roof 5. Thermal contact 5. Evaluate materials to be drilled for potential hazards (e.g., lead based paint,

Conduiting and chemcially treated wood, etc.)

15

Lighting installation 4 4 16 Yes 2 2 4 Site Incharge

5. short circuit 6. falling from height [Link] not wear loose fitting clothing that can get caught in moving parts. Keep hair

and jewelry out of the drill path as well. Keep hands away from rotating drill bit

[Link] not wear loose fitting clothing that can get caught in moving parts. Keep hair and

jewelry out of the drill path as well. Keep hands away from rotating drill bit

[Link] the electricle supply prior to work

3 5 15 1. Emergency Response Plan Yes 2 2 4(L)

16 On-Site Emergency S- Accidents/Incidents/ S-Minor/ Major Injuries 2. On-Site First-Aid facility. Project Manager/

H- Health Issues H-Minor/ Major Sickness 3. Emergency vehicle/Ambulance at site. EHS

H- Snake bites. S/H-Fatality 4. Sudden access to near - by hospital with emergency

treatment and anti-venom treatment facility

Severity (S) Risk Rating (R) Required Action

1 <Minor> - Minor: No lost time / NOT significant, Minor Pollution Index Rating

2 <Appreciable> - Non reportable minor injury; < 3 days MC 1-7 Low No Action Required

Likelihood (L) 3 <Serious> - Reportable serious injury; > 3 days MC 8 - 14 Medium Action Required

1 <Improbable> - Extremely unlikely to occur 4 <Major> - 1 fatality; 3 to 7 days of works delay 15 - 19 High Find Alternative Method

2 <Remote> - Unlikely to occur 5 <Catastrophic> - Multiple fatality; > 7 days of works delay 20 - 25 Very High NOT Acceptable / Stop

Work

3 <Occasional> - Could possibly or known to occur

4 <ProbFollowing situation are consider while during the Aspect / Impact& HIRA for each activity and potential emergency situation.

Environment: Normal, Abnormal (including start up & shutdown as applicable.

L W Construction Private Limited

You might also like

- RIsk Assessment Sp2301 - Earthing System Installation100% (1)RIsk Assessment Sp2301 - Earthing System Installation7 pages

- Jsa MV Cable Pulling, Termination and TestingNo ratings yetJsa MV Cable Pulling, Termination and Testing11 pages

- Job Safety Analysis for Cable Tray InstallationNo ratings yetJob Safety Analysis for Cable Tray Installation3 pages

- Job Safety Analysis for Material HandlingNo ratings yetJob Safety Analysis for Material Handling6 pages

- Safe Work Method Statement for Cable InstallationNo ratings yetSafe Work Method Statement for Cable Installation10 pages

- Scaffolding Erection & Dismantling Safety RisksNo ratings yetScaffolding Erection & Dismantling Safety Risks20 pages

- Risk Assessment For Electrical Testing & CommissioningNo ratings yetRisk Assessment For Electrical Testing & Commissioning6 pages

- Busway Installation Risk Assessment GuideNo ratings yetBusway Installation Risk Assessment Guide21 pages

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionNo ratings yetHIRA & JSA - R1 Conveyor Gallery Dismantling and Erection26 pages

- EHS Safety Guidelines and Best PracticesNo ratings yetEHS Safety Guidelines and Best Practices37 pages

- Furnace Chiller Installation Risk AssessmentNo ratings yetFurnace Chiller Installation Risk Assessment5 pages

- Risk Assesment For Electrical Conducting & Installation WorkNo ratings yetRisk Assesment For Electrical Conducting & Installation Work2 pages

- EHS Risk Assessment for Mactech EngineeringNo ratings yetEHS Risk Assessment for Mactech Engineering3 pages

- Job Safety Analysis for Electrical WorksNo ratings yetJob Safety Analysis for Electrical Works9 pages

- Safe Work Method Statement for Rolling Shutter InstallationNo ratings yetSafe Work Method Statement for Rolling Shutter Installation12 pages

- Cable Installation Risk Assessment GuideNo ratings yetCable Installation Risk Assessment Guide5 pages

- Hazard Identification & Risk Assessment Guide100% (1)Hazard Identification & Risk Assessment Guide79 pages

- Architectural Drawing: Aluminium LouversNo ratings yetArchitectural Drawing: Aluminium Louvers1 page

- Material Safety Data Sheet: 1 IdentificationNo ratings yetMaterial Safety Data Sheet: 1 Identification7 pages

- Haccp Review Meeting - Filled Sample RecordNo ratings yetHaccp Review Meeting - Filled Sample Record3 pages

- Laboratory Safety: CHEM-102 Inorganic Chemistry Lab Lecture-1 by Atika AbidNo ratings yetLaboratory Safety: CHEM-102 Inorganic Chemistry Lab Lecture-1 by Atika Abid33 pages

- Farmers' Guide: Trivor Insecticide SafetyNo ratings yetFarmers' Guide: Trivor Insecticide Safety6 pages

- When Panic Attacks - Module 6 - Dropping Safety Behaviours100% (1)When Panic Attacks - Module 6 - Dropping Safety Behaviours11 pages

- Current Characteristics for Circuit BreakersNo ratings yetCurrent Characteristics for Circuit Breakers1 page

- Safety Culture Ladder Manual - 3.0 FinalNo ratings yetSafety Culture Ladder Manual - 3.0 Final31 pages

- Inspection Engineering Complete Career Path Guide100% (3)Inspection Engineering Complete Career Path Guide25 pages

- f114980000 Potassium Chloride Pellets en SdsNo ratings yetf114980000 Potassium Chloride Pellets en Sds6 pages