MOPO

Uploaded by

Gilchrist DsouzaMOPO

Uploaded by

Gilchrist DsouzaRevision: 4 .

0

Petroleum Development Oman LLC

Effective: February 2020

Appendix 9 Manual of Permitted Operations (MOPO)

The team to develop or review the MOPO should consist of TSE, construction, commissioning, operation and maintenance representative.

The team should be lead by an experienced facilitator and shall:

• Identify Threats and Escalation Factors in the Bow-ties that could compromise safe operating limits.

• Identify other operations and activities that could compromise safe operating limits.

• Develop the MOPO under the appropriate headings of SIMOPs, External Influences and Inactive/Impaired SCE/Critical Man power unavailability.

• Identify the ‘stops’ and ‘proceed with cautions’ using the red/amber traffic light system.

• Provide supporting guidance notes for the ‘proceed with cautions’ that will assist Supervisors etc if/when the situation arises.

• Collectively review the matrices and ensure they reflect current practise and give clear guidance for action to be taken under the specific

circumstances.

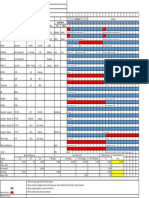

Basis for Adverse weather, Impaired SCE, Simultaneous operations (SIMOPs) MOPO are provided below;

# Basis for Adverse weather, Impaired SCE, Simultaneous operations (SIMOPs) MOPO – Applicable for all facilities

The MOPO is an information and decision making tool to assist supervisors during planning and coordination of operations/construction/commissioning

and decommissioning activities

3 separate MOPOs are

Adverse Weather

Simultaneous Operations (SIMOPS)

Impaired Safety Critical Elements (SCEs) and critical man power unavailability.

A

Cells color coded Green indicate that operations or activities are permitted subject to compliance to normal controls and procedures.

Normal controls and procedures includes but not limited to following; Life

Saving Rules,

PTW system

Process Safety Fundamentals,

Tool box talk,

Facility walkthrough before a job,

Approved Method Statement,

B Approved Lifting Plans (where applicable).

Cells color coded Yellow indicates that operations or activities are permitted subject to additional specified controls being implemented.

controls Normal

and

procedures

are always

C applicable.

Cells color coded Red indicate that operations or activities are not permitted whilst the adverse weather condition/SIMOPs situation exists or the SCE

D is impaired/unavailable or the critical manpower is unavailable.

The SIMOPS MOPO assumes that two or more major activities (e.g. production, drilling, major construction) are simultaneously performed in the same

E location/area. However, the works are undertaken on independent equipment items.

F The Impaired SCE MOPO assumes the operation is in the vicinity of or within the area impacted by the Impaired SCE.

When SCEs are in test mode, alternative controls shall be put in place to ensure their function is provided. Testing of these systems is not generally

G considered “impairment” for purposes of this MOPO.

In case multiple barriers are unavailable/impaired, the combined effects of the simultaneous failure on the activities are to be risk assessed as a separate

H activity outside of this MOPO.

MOPO is specific to scope covered in operation HSE case. In the event of conflict between MOPO and other instruction (e.g. PR-1172), DTL or his

I delegate will have the final decision recorded in writing.

MOPO Colour Coding description are as follows [Applicable for all facilities]

Y Go conditions - Operations or activities are permitted subject to compliance to normal controls and procedures.

() Proceed with caution conditions - Operations or activities are permitted subject to additional specified controls being implemented. Normal controls

and procedures are always applicable and to be complied.

N Stop conditions - Operations or activities are not permitted while adverse condition remains, or SCE is impaired

Additional controls required as indicated in the MOPOs (coloured amber) shall be listed and these are specific to operation HSE case scope. Work shall

only be carried out under the formal control of the Permit to Work (PTW) system, including component elements such as plant isolation certificates, vessel

entry certificates, hot work permits, etc. All applicable procedures and work instructions relating to the work to be undertaken shall be complied with.

Where necessary, the requirement for undertaking risk assessment shall be noted. Measures shall be taken to maintain risks at ALARP and the

effectiveness of the measures shall be verified. All actions involving bypassing the safeguarding systems shall be authorised as per PDO standards and in

consultation with relevant discipline technical authority.

Examples of the three MOPOs (Adverse Weather, SIMOPs, and SCE Impairment) follow. During MOPO assessment related to SCE /critical manpower

impairment, project should consider impairment of applicable fire protection related SCE’s in line with SP-1992.These shall be used as guidance for

construction of a new MOPO or for review of an existing MOPO. The notes within the MOPO are intended to support rather than supersede the specific risk

assessments required. For a MOPO to be effective it must provide clear concise information to the Operator of immediate action to be taken under the

specified conditions, e.g. if working at height is ongoing and wind speed increases, he needs to be able to quickly see when to stop the activity in question.

Page 1 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Revision: 4 .0

Petroleum Development Oman LLC

Effective: February 2020

MOPO additional specified controls to be fulfilled [EXAMPLE]

No. MOPO additional controls or requirement to be fulfilled

1 Custodianship transfer from Amal operations to Drilling team. Subject to compliance to well engineering and well services (work over, hoisting, etc)

procedures. Wells are handed over to Well Services team for work over, hoist.

2 At wind speed >40Knot, operation not permitted for OTSG,HRSG and Flare

3a Permitted for start-up subject to approval from OSOT1. Routine maintenance is not permitted. Night time working and night time manpower are to

be minimized.

3b Permitted for shutdown subject to approval from OSOT1. Routine maintenance is not permitted. Night time working and night time manpower are to

be minimized.

4a Permitted only for critical well activity and subject to approval from OSOT1/OSOT4

4b Permitted only for ALSE activity subject to approval from OSOT1/OSOT4 and Adhering to SOP- Tanker loading/unloading

5a Continued work subject to heat stress evaluation. Schedule work during cooler part of day. Provide shaded areas and

cold water (not iced). Summer working hours and extended lunch breaks apply.

5b Permitted only for critical activity with protective clothing

6 Simultaneous drilling and production operations permitted subject to compliance with minimum separation distances between live wells and flow

lines. Simultaneous drilling and production operations not permitted inside separation distances.

Risk assessment with specified controls or mitigation (when necessary or when there is an uncertainty) is essential.

Compliance to Normal controls and procedures are always applicable.

7 Permitted subject to approval from OSOT1 and only manual excavation is permitted at night with appropriate lighting and buddy system

8 Permitted subject to approval from OSOT1 and compliance with PR-1148 (Entry in to the confined space)

9 Subject to approval from OSOT1 with full time manning (Minimum of 2 people). Continuous presence at well test location is mandatory.

10 Permitted subject to risk assessment with specified controls or mitigation in place

11 Permitted subject to availability of redundant equipment/system, F&G detectors, additional competent manpower

Page 2 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Revision: 4 .0

Petroleum Development Oman LLC

Effective: February 2020

Heavy Temperature Lowest

Heavy wind Dust Night Time Heavy Rain or

Mist or Lighting >50 Temperature

>20 knots Storms Working Wadi Flooding

Fog Centigrade in Winter

Operation/activity

Drilling 1 1 1 1 1 1 1 1

Well Services 1 1 1 1 1 1 1 1

Operate AE wells/ flowlines/ headers injection Y Y Y Y Y Y Y Y

Operate AE wells/ flowlines/ headers production Y Y Y Y Y Y Y Y

Operate AE wells/ flowlines/ headers cold production Y Y Y Y Y Y Y Y

Operate AW wells/ flowlines/ headers injection Y Y Y Y Y Y Y Y

Operate AW wells/ flowlines/ headers production Y Y Y Y Y Y Y Y

Operate APO wells/ flowlines/ headers production Y Y Y Y Y Y Y Y

Operate DWD (Relocation) Y Y Y Y Y Y Y Y

Operate ALSE wells/storage tank Y Y Y Y Y Y Y Y

Well startup (AE/AW Production wells) N N 4a 4a N N 5a 5b

Well startup (AE/AW steam injection wells) N N 4a 4a N N 5a 4 a, 5b

Start up ALSE wells/storage tank N N 4b 4b N N 5a 4 b,5b

Remote Start up of APO wells

Field/manual Start up of APO wells N N 4a 4a N N 5a 5b

AE/AW/APO/Disposal(relocation) production well N N 4a 4a N N 5a 5b

shutdown - (Field/manual)

ALSE Production Well shutdown - (Field/manual) N N 4b 4b N N 5a 5b

AE/AW steam injection Well shutdown - N N 4a 4a N N 5a 5b

(Field/manual)

Operate Automatic Well Testing (AWT) Y Y Y Y Y Y Y Y

Portable/Mobile well test unit (hook-up ) N N N N N N 5a 5b

Portable/Mobile well test unit ( testing) N N 9,10 9,10 N N 5a 5b

Operate Amal Steam Plant (ASP) Y Y Y Y Y Y Y Y

Start Up ASP N N 3a,10 3a,10 N N 5a 5b

Shutdown ASP - planned N N 3b, 10 3b, 10 N N 5a 5b

Operate OTSG (single) 2 Y Y Y Y Y Y Y

Start up OTSG (single) N N 3a,10 3a,10 N N 5a 5b

Shutdown OTSG - planned (single) N N 3b, 10 3b, 10 N N 5a 5b

Shutdown OTSG - planned (all) N N 3b, 10 3b, 10 N N 5a 5b

Operate steam distribution system Y Y Y Y Y Y Y Y

5b

Start-up steam distribution system N N 3a,10 3a,10 N N 5a

Shutdown steam distribution system - planned N N 3b, 10 3b, 10 N N 5a 5b

Operate WTP Y Y Y Y Y Y Y Y

Start-up WTP N N 3a,10 3a,10 N N 5a 5b

Shutdown WTP - planned N N 3b, 10 3b, 10 N N 5a 5b

Operate HC system and gross export pipeline Y Y Y Y Y Y Y Y

Start up HC system and gross export pipeline N N 3a,10 3a,10 N N 5a 5b

Shutdown HC system and gross export pipeline - N N 3b, 10 3b, 10 N N 5a 5b

planned

HRSG operate (1B/1C) 2 Y Y Y Y Y Y Y

HRSG start-up (1B/1C) N N 3a,10 3a,10 N N 5a 5b

HRSG shut down (1B/1C) N N 3b, 10 3b, 10 N N 5a 5b

Pigging - HRSG/OTSG tubing N N 10 10 N N 5a 5b

Operate Solar phase 1 and 2 N N N N N N Y Y

Start-up /shutdown Solar phase 1 and 2 N N N N N N Y Y

Pigging - 1.1 km 18" header from ASP to Alburj N N N N N N 5a 5b

station

Routine Activities

N2 purging and N2/He Leak Testing N N N N N N 5a 5b

Listen look feel (LLF) walk around N N N N N N 5a 5b

Page 3 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Revision: 4 .0

Petroleum Development Oman LLC

Effective: February 2020

Sampling N N N N N N 5a 5b

Radiography N N 10 N N N N 5b

Vehicle Movement on-plot N N 10 N N N 5a 5b

Vehicle Movement off-plot N N 10 N N N 5a 5b

Road Maintenance/ Grading N N N N N N 5a 5b

Grit Blasting / HP Water Jet N N N N N N 5a 5b

Lifting/Crane Operations N N N N N N 5a, 10 5b

Fork Lift Truck Operations N N N N N N 5a, 10 5b

Excavation /trenching Activities N N 10, 7 N N N 5a 5b

Work at Height (scofolding,temporary platforms) N N 10 N N N 5a 5b

Working on Tall Structures N N 10 N N N 5a 5b

Zone 0 Area work N N N N N N 5a 5b

Zone 1 Area Work N N 10 N N N 5a 5b

Zone 2 Area Work N N 10 N N N 5a 5b

Intrusive Maintenance (Requires

shutdown/isolation/vessel entry and potential

exposure to hazardous materials) N N 10 N N N 5a 5b

Class A Permit Work N N 10 N N N 5a 5b

Class B Permit Work N N 10 N N N 5a 5b

Confined Space Entry N N 10,8 N N N 5a 5b

Flaring 2 Y Y Y Y Y Y Y

Local Venting (HC & H2S) N N N N N N N N

Local Venting (Steam) N N 5b N N N 5a 5b

Draining to open pits (Water) N N 5b N N N 5a 5b

Draining to open pits (HC) N N N N N N N N

Chemical unloading N N N N N N N 5b

Vacuum Truck Activity (Gross fluid transport, Sludge N N 10 N N N 5a 5b

and AWT relief vessel)

Construction/Decommissioning Activities N N 10 N N N 5a 5b

MOPO – ADVERSE WEATHER CONDITIONS [EXAMPLE]

Page 4 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Revision: 4 .0

Petroleum Development Oman LLC

Effective: February 2020

MOPO – SIMOPs [EXAMPLE]

AE Pig

Op /A gin

era Op AE W Sh g-

Op Op AL

te era /A ste utd 1.1

Op Op era SE Sh Op Sta

era AE te W/ am ow km

era era te Pro utd era rt

te we AP We AP inj n 18"

te te A du ow te up

AE lls/ O ll O/ ect Por HC Sta he

AE A W We cti Op n HC HC

we flo we sta ion Por ad

W Dis on era tab ste sys rt-

we lls/ we ll rtu tab sys sys

wli lls/ Fiel pos We le/ Sh te up er

lls/ we lls/ sta We te Op Op Sta am

flo nes flo Op p Sta d/ ll le/ te te fro

lls/ al(r ll Au Mo utd era rt- dis m /sh

flo wli / flo era rtu (AE rt Mo era Sh m m

wli Re ma elo sh bil ow te up an Pig utd m

wli flo wli p sh to te utd tri an an Op

nes he nes te /A up mo nu cat utd bil AS

wli utd ma e n ste ste but d gin ow

nes / nes Op AL (AE W AL e Am ow d d era

ad

nes / te al ionshu ow

ow

tic we Sh OT am am ion

Sh gro HR g- n P

/ he / era SE /A ste SE we al n gro gro te

ers he Sta Sta ) tdo n- ll utd Op Sta SG dis dis utd ss HR HR SG HR Sol to

he / he te we W n- We Ste OT sys ss ss Sol

ad am we ll

col

he ad rt rt prown (Fi

(Fi

ll tes ow era rt - tri tri te

ow ex SG SG sh SG ar Alb

ad ers ad D lls/ Pro inj lls/ tes am SG ex ex ar

d ers up up du - eld t n te up pla but but n por op sta ut /O ph urj

ers ad ers W sto du eld Tes Pla - m- por por ph

pro ect sto t

pro

ers pro of of cti (Fi /m

/m

tin uni AS OT OT nn ion ion pla

WT t era rt- do TS ase sta

We inj du pro D rag cti ion rag uni nt Sta pla t t ase

du du AP AP on eld an t P- SG SG ed sys sys

Op Sta P - pip te up wn G 1 tio

ect inj du (Re e on an g (AS rt nn nn pip pip 1

ll cti we e t(

cti

ect cti O O wel/m ual

ual

(A (ho pla (si (si (si te te ed

era rt- pla eli (1B (1B (1B tub an n

Ser ion on cti loc tan we lls) tan tes P) ed eli eli an

on on we we l an ) ok- Up nn ngl ngl ngl m m

te up nn ne pla /1C /1C /1C ing d2

Dril vic ion on ati k lls) ) WT (all ne ne d2

k lls lls ual tin AS ed e) e) WT WT ed ) ) )

) up e) - nn

lin es on) ) g) P ) P P

) ed

Operation/activity g

Drilling 1 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 Y 6 6 Y Y Y Y Y Y Y Y 6 6 Y Y Y Y Y Y Y 6 6 Y Y Y Y

Well Services (FBU,Hoisting,fishing,wireline) 1 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 Y 6 6 Y Y Y Y Y Y Y Y 6 6 Y Y Y Y Y Y Y 6 6 Y Y Y Y

Operate AE wells/ flowlines/ headers injection 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate AE wells/ flowlines/ headers production 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate AE wells/ flowlines/ headers cold production 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate AW wells/ flowlines/ headers injection 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate AW wells/ flowlines/ headers production 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate APO wells/ flowlines/ headers production 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y

Operate DWD (Relocation) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y

Operate ALSE wells/storage tank 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Well startup (AE/AW Production wells) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N

Well startup (AE/AW steam injection wells) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Start up ALSE wells/storage tank 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Remote Start up of APO wells 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y

Field/manual Start up of APO wells 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y

AE/AW/APO/Disposal(relocation) production well shutdown - 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

(Field/manual)

ALSE Production Well shutdown - (Field/manual) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

AE/AW steam injection Well shutdown - (Field/manual) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate Automatic Well Testing (AWT) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y

Portable/Mobile well test unit (hook-up ) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Portable/Mobile well test unit ( testing) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y

Operate Amal Steam Plant (ASP) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Start Up ASP Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N

Shutdown ASP - planned Y Y N N N N N N N Y N N Y N N Y Y Y N Y N N N N N Y Y N N Y N N Y N N Y N N Y N N N N

Operate OTSG (single) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y N Y Y N Y Y N Y Y Y Y Y Y Y Y Y Y

Start up OTSG (single) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y N N Y Y N Y Y N Y Y Y Y Y Y Y Y Y Y

Shutdown OTSG - planned (single) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Shutdown OTSG - planned (all) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N N Y N N Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate steam distribution system Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y N Y N Y Y N Y Y Y Y Y Y Y Y Y Y

Start-up steam distribution system 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y N Y N Y Y N Y Y Y Y Y Y Y Y Y Y

Shutdown steam distribution system - planned 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N N Y Y N N Y Y Y Y Y Y N N Y Y N N Y

Operate WTP Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y

Start-up WTP Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y N Y Y Y N N Y Y N N Y

Shutdown WTP - planned Y Y Y Y Y Y Y N N Y Y Y Y N N Y Y Y Y Y Y Y Y Y N N Y Y N N Y N N Y Y Y N N Y Y N N Y

Operate HC system and gross export pipeline Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y

Start up HC system and gross export pipeline Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N

Shutdown HC system and gross export pipeline - planned Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y N Y N Y Y Y Y Y Y Y Y Y Y Y Y Y N N Y Y Y Y Y Y N

HRSG operate (1B/1C) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N Y N N Y Y Y Y N Y Y Y Y

HRSG start-up (1B/1C) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N Y N N Y Y Y Y N Y N N Y

HRSG shut down (1B/1C) 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N N Y N N Y

Pigging - HRSG/OTSG tubing Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Operate Solar phase 1 and 2 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N Y N N Y Y Y Y N N Y Y Y

Start-up /shutdown Solar phase 1 and 2 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y N Y N N Y Y Y Y N N Y Y Y

Pigging - 1.1 km 18" header from ASP to Alburj station Y Y Y Y Y Y Y Y Y Y N Y Y Y Y Y Y Y Y Y Y Y N N Y Y Y Y Y Y Y Y Y Y Y N N Y Y Y Y Y Y

Routine Activities

N2 purging and N2/He Leak Testing Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Listen look feel (LLF) walk around Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Page 5 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Revision: 4 .0

Petroleum Development Oman LLC

Effective: February 2020

Sampling Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Radiography N N Y Y Y Y Y Y Y Y Y Y Y Y Y N N N Y Y Y Y N Y Y N Y Y Y N Y Y N Y Y N Y Y N Y Y Y 6 Y

Vehicle Movement on-plot Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Vehicle Movement off-plot 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 Y Y Y Y Y Y Y Y Y 6 Y Y Y Y 6 6 Y 6 6 Y Y Y Y

Road Maintenance/ Grading 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 Y Y 6 Y

Grit Blasting / HP Water Jet Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Lifting/Crane Operations 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Fork Lift Truck Operations 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Excavation /trenching Activities 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Work at Height (scofolding,temporary platforms) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Working on Tall Structures Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Zone 0 Area work 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Zone 1 Area Work 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Zone 2 Area Work 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Intrusive Maintenance (Requires shutdown/isolation/vessel entry and

potential exposure to hazardous materials) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y N Y Y Y N Y Y N Y Y N Y Y N Y Y Y N Y

Class A Permit Work 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Class B Permit Work 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Confined Space Entry 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

Flaring Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Local Venting (HC & H2S) N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N

Local Venting (Steam) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Draining to open pits (Water) Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Draining to open pits (HC) N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N N

Chemical unloading Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Vacuum Truck Activity (Gross fluid transport, Sludge and AWT relief 6 6 Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

vessel)

Construction Activities/Decommissioning/demolition activities 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Page 6 SP-2062 Specification for HSE Cases Printed 27/07/2020

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

MOPO – SCE & CRITICAL MANPOWER IMPAIRMENT/UNAVAILABILITY [EXAMPLE]

Ge

ner

Lift al

Sta ing Act

rt- an ivit

up d ies

Op (m

Eq hoi

Op era ain

uip sti

era te ten

me ng

te AE an

nt ov

Op Eq /A Pre

/ er ce,

era Syseq uip W

HC ins pai ssu

tio te uip me /A

eq pe nti re/

nal m me nt LSE

uip cti ng, Le

Sta (of col ak

Act (relnt, / Op me on,

rt- f- d Tes

ivit atesys Sys era nt

up plo wo tin

ies d te te te

m) m AS AS t) rk) g

P P

Impaired/Unavailable SCE and critical manpower unavailability

SCE Group SCE Failure Mode

SI001, SI002 Foundation and Top side structures Observed or detected foundation and structural defect/damage N N 10 10 10 10 10 10

SI003 Heavy lift cranes and mechanical handling Dropped load/Impact to live HC/process fluid containing equipment N N N N N N N N

equipment

PC001 - PC006 Process Containment Uncontrolled release of process fluids N N N 10,11 10,11 N 10 N

PC007 Relief System Unavailability or inadequate relief design N N N 10,11 10,11 10,11 10,11 10

PC008 Operational Well Containment Uncontrolled release of well fluid resulting in increased risk of MAH N N Y Y 10 10 10 10

PC009 Fired heaters (OTSG) Fired heaters are unavailable/impaired N N Y Y Y Y Y Y

IC003 Certified Electrical Equipment Certified electrical equipment fails to meet PS requirement resulting in 10,

increased risk of ignition N N 11 10,11 10 10 Y 10

IC005 Earth Bonding Earth bonding fails to meet PS requirement resulting in increased risk N 10 N 10 Y 10

of ignition

IC006 Fuel gas purge system Fuel gas purge system is unavailable N N N N N 10 10 10

IC009 Flare Tip Ignition System Loss of primary & secondary flare ignition systems resulting in flare N N N N N 10 10 N

out

DS001 Fire and Gas - Total loss Total loss of F&G detection system N N N N N 10 10 10

DS001 Fire and Gas - Local or partial loss Loss of F&G detection end element resulting in impaired local N 10,11 10,11 10,11 Y 10,11 10,11 10

functionality e.g. 2ooN in voted system & 1ooN in non-voted systems

DS002 Security Systems (CCTV) Loss of access control to facilities

10 10 Y Y Y Y Y Y

PS010 Electrical protection systems Transformers/switchgears/circuit breaker/PMRs are unavailable

(Transformers/switchgears/circuit breaker/PMRs) N N N N N 10 10 10

PS013 Chemical Injection System Inability to provide required chemical injection flow 10 10 10 10 10 10 10 10

SD001 ESD System - Total loss Total loss of ESD system N N N N N 10 10 10

SD001 ESD System - Local or partial loss Local or partial loss of ESD system

N 10,11 10,11 10,11 10,11 10,11 10,11 10

SD002 Depressurisation System - Total loss Total loss of EDP system N N N N N 10 10 10

SD002 Depressurisation System - Local or partial loss Local or partial loss of EDP system N N 10,11 10,11 10,11 10,11 10,11 10

SD004 Operational Well Isolation Inability to isolate steam injection well or annulus resulting in potential

back flow of HC N N Y Y 10 10 10 10

SD006 Process ESDV Inability of ESD end element valve to adequately isolate process N N 10 10 10 10 10 10

resulting potential escalation of MAH

ER001 Primary Muster Area (Assembly point) Primary Muster Area (Assembly point) unavailable or impaired 10 10 10 10 10 10 10 10

ER002 Escape/ Evacuation Routes Escape/ evacuation routes impaired 10 10 10 10 10 10 10 10

ER003 Emergency/ Escape Lighting (Control Emergency/ escape Lighting impaired

rooms/FCUs)

10 10 10 10 10 10 10 10

ER004 Communication Systems - Tetra Loss of communication system

Page 7 SP-2062 Specification for HSE Cases

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

Petroleum Development Oman LLC

10 10 10 10 10 10 10 10

PS002 Fire explosion protection Unavailability or lack of fire extinguishers 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

ER004 Communication Systems - Loss of ER Loss ER communication system including radios and landlines

N 10 N 10 10 10 10 10

communications

ER005 Uninterrupted Power Supply (UPS) Inability to provide emergency power supply to essential systems 10 10 10 10 10 Y Y Y

LS001 Personal Survival Equipment - Personal H2S Personal H2S Monitors below minimum level or faulty or unavailable

monitors N 10 N 10 10 N N N

LS001 Personal Survival Equipment - Escape sets Portable BA Sets below minimum level or faulty (Escape Sets)or N 10 N 10 10 N N N

unavailable

LS001 Personal Survival Equipment - Safety Safety showers/Eye wash stations not available or inoperable

showers/Eye wash stations 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

Critical Manpower Unavailability

ER - Team Members ER team members are not available or not competent 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

ER - Nimr Fire Brigade Nimr fire brigade not available for extended period 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

ER - First Aider Insufficient number of first aiders available on-site 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

LEBC LEBC is not available or not trained 10,11 10,11 10,11 10,11 10,11 10,11 10,11 10

Page 8 SP-2062 Specification for HSE Cases

The controlled version of this CMS Document resides online in Livelink®. Printed copies are UNCONTROLLED.

You might also like

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionNo ratings yetPR-1709 - Lifting and Hoisting Procedure Lift Planning Execution43 pages

- HSE-E&D.GE.009 Guidelines For SIMOPS On Rigs - FinalNo ratings yetHSE-E&D.GE.009 Guidelines For SIMOPS On Rigs - Final16 pages

- Draft: Emirates Authority For Standardization & Metrology (ESMA)No ratings yetDraft: Emirates Authority For Standardization & Metrology (ESMA)16 pages

- Mobile Offshore Drill. Unit Safety Certificate (General) - 2020-02-26No ratings yetMobile Offshore Drill. Unit Safety Certificate (General) - 2020-02-265 pages

- SP-1010 - Specification For Environmental Noise and VibrationNo ratings yetSP-1010 - Specification For Environmental Noise and Vibration11 pages

- Tag Line Safety Alert: Near Miss IncidentNo ratings yetTag Line Safety Alert: Near Miss Incident1 page

- PSB-221 Worker Hit by A Reversing VehicleNo ratings yetPSB-221 Worker Hit by A Reversing Vehicle1 page

- Approved Risk Assessment For Hydrostatic Test For GRE Piping - Rev.0No ratings yetApproved Risk Assessment For Hydrostatic Test For GRE Piping - Rev.020 pages

- TTK Hydrocarbon Leak Detection Sensor Cleaning Procedure100% (1)TTK Hydrocarbon Leak Detection Sensor Cleaning Procedure3 pages

- Safe Loading and Unloading Guideline 23.06.2024 Rev 06 HSE TeamNo ratings yetSafe Loading and Unloading Guideline 23.06.2024 Rev 06 HSE Team11 pages

- Best Practices of Lifting Operations and Equipment 22.06.11100% (1)Best Practices of Lifting Operations and Equipment 22.06.1133 pages

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsNo ratings yetSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation Lessons4 pages

- PDO WW Specification SP-2515 v.1 July15, 2025No ratings yetPDO WW Specification SP-2515 v.1 July15, 202537 pages

- Electrical Installation Method StatementNo ratings yetElectrical Installation Method Statement10 pages

- Cam Pressure Training-Level 2-1701061600ZNo ratings yetCam Pressure Training-Level 2-1701061600Z68 pages

- A Guide To The ANSI Z358.1-2009 StandardNo ratings yetA Guide To The ANSI Z358.1-2009 Standard3 pages

- PDO 03 - PR - 1172 - Permit - To - Work - Procedure100% (1)PDO 03 - PR - 1172 - Permit - To - Work - Procedure120 pages

- Ballast Water Management System Commissioning Testing: Guidance Notes OnNo ratings yetBallast Water Management System Commissioning Testing: Guidance Notes On9 pages

- Risk Assessment For The Irrigation Pump StationNo ratings yetRisk Assessment For The Irrigation Pump Station14 pages

- DP Operations Risk Management Tools (CAMO-ASOG) Rev ENo ratings yetDP Operations Risk Management Tools (CAMO-ASOG) Rev E10 pages

- Permit To Work Energy Isolation: The Golden Rules0% (1)Permit To Work Energy Isolation: The Golden Rules1 page

- What Happened?: Construction, Engineering, Drilling, Operations & LogisticsNo ratings yetWhat Happened?: Construction, Engineering, Drilling, Operations & Logistics1 page

- Fatigue Management Guidelines: To: Contract Holders and HSE Team Leaders From: Corporate Road Safety (MSE/7)No ratings yetFatigue Management Guidelines: To: Contract Holders and HSE Team Leaders From: Corporate Road Safety (MSE/7)1 page

- PDO COW Training Presentation - Level 1B Permit SignatoriesNo ratings yetPDO COW Training Presentation - Level 1B Permit Signatories151 pages

- Spare Parts: Airfield Lighting RELIANCE 12" Inset Light (RC-RZ-RX)No ratings yetSpare Parts: Airfield Lighting RELIANCE 12" Inset Light (RC-RZ-RX)14 pages

- AMSA - BULLETIN Thinking - Mooring SafetyNo ratings yetAMSA - BULLETIN Thinking - Mooring Safety4 pages

- Bomag Roller Bw71e-2 Operational ManualNo ratings yetBomag Roller Bw71e-2 Operational Manual98 pages

- Construction Safety Compliance CommitmentNo ratings yetConstruction Safety Compliance Commitment12 pages

- Exposure Measurement: Air Sampling: Control Approach 4No ratings yetExposure Measurement: Air Sampling: Control Approach 44 pages

- HSE Requirements For Contractor Mobilization To SiteNo ratings yetHSE Requirements For Contractor Mobilization To Site2 pages

- Reintjes MANUAL 63986 - 87 - WVS730K21 - enNo ratings yetReintjes MANUAL 63986 - 87 - WVS730K21 - en81 pages

- Work at Height Safety Inspection ChecklistNo ratings yetWork at Height Safety Inspection Checklist1 page

- Course Outline: OCCUPATIONAL SAFETY AND HEALTH Course Is Designed To Impart100% (2)Course Outline: OCCUPATIONAL SAFETY AND HEALTH Course Is Designed To Impart5 pages