Professional Documents

Culture Documents

Ntmp2014 Usm

Uploaded by

Shashank GauravCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ntmp2014 Usm

Uploaded by

Shashank GauravCopyright:

Available Formats

Nontraditional Manufacturing Processes,

MF 30604

Ultrasonic Machining (USM)

Principle of Ultrasonic Machining (USM)

In Ultrasonic Machining process, between the tool and workpiece, the

machining zone is flooded with hard abrasive particles generally in the

form of a water based slurry.

Tool forces the abrasive grits to impact normally and successively on the

work surface at 19-25 kHz, thereby machining the work surface.

Material is removed by micro-chipping or erosion with abrasive particles.

In brittle material: Machining is due to crack initiation, propagation and

brittle fracture.

USM is mainly used for machining brittle materials {which are poor

conductors of electricity and cannot be processed by ECM or EDM }

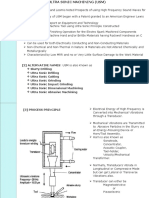

Ultrasonic Machine

Sub-systems:

* Transducer, which

generates the

ultrasonic vibration

* Horn or concentrator,

which mechanically

amplifies the vibration

to required amplitude

of 15 50 m and

holds the tool at its tip.

* Slurry delivery and return system

* Feed mechanism to provide a downward feed to the tool during

machining

Ultrasonic Waves: Frequency ranges from 20 kHz to 1GHz

Generation of Ultrasonic waves: By transducer- a device which

converts energy from one form to another . Two types of transducers

1. Piezoelectric Transducers : Employ the inverse piezoelectric effect

using natural or synthetic single crystals (such as quartz) or ceramics

(such as barium titanate) which have strong piezoelectric behavior.

Electrical voltage oscillation converted to Mechanical Vibration

Advantages of Ceramics over crystals: Easier to shape by casting,

pressing and extruding.

Electromechanical conversion efficiency up to 96%

Usually no need of water cooling

Transducers available with power capabilities up to 900W

2. Magnetostrictive Transducer : Converts magnetic energy into

mechanical vibration .

Generated by applying a strong alternating magnetic field to

certain metals, alloys and ferrites : Laminated stacks of Nickel or

Nickel alloy sheets

Electromechanical conversion efficiency ~ 20-35% Water Cooling

Magnetostrictive Transducers available with power capabilities up to

2400W

Magnitude of Length

change in both types of

transducer limited by

the strength of material

to ~ 25m

Transducer: Magnetostrictive transducers are most popular as they are

robust amongst all and have high power capabilty.

Driven by Electronic generator Creates impulses 19.5 - 20.5 kHz range,

and automatically adjusts the frequency to match the resonant frequency of

the tool, which depends on the horn shape and material

Transducer converts the electrical pulses into vertical stroke.

Vertical stroke is transferred to the horn, which amplifies the stroke amount

in 20-50 m range and is then relayed to the tool .

Vibration amplitude ~ Diameter of the abrasive grit used.

Vibration

propagation &

Amplification

The horn or concentrator can be of different shape like

Tapered or conical

Stepped

Exponential

Machining of tapered or stepped horn much

easier as compared to the exponential one

Mechanical Amplification ~ 5-6

Transducer Vib. Amplitude 3-25m

Tool Vibration Amplitude 5-75m

Materials for horn: Good

acoustic property & Highly

resistance to fatigue cracking

Monel, Titanium, Stainless

steel

Resonance Frequency, f = V

s

/,

Sonic Velocity V

s

= {(E/)((1-)/(1+)(1-2))}

1/2

E= Youngs modulus, = Density, = Poissons ratio

Length of horn l = n/2. or ; depending upon system configuration

Increase in amplitude Function of shape and ratio of end diameters

Abrasive Slurry

1. Aluminum oxide: Best for glass, ceramics & germanium

2. Boron carbide: Expensive but best suited for cutting WC,

tool steel & precious stones

3. Silicon Carbide: Finds maximum applications due to its

hardness and life

4. Diamond dust: machining diamond, Ruby etc.

Abrasive size: 200-2000 grit. (~ 10-100 m)

Surface roughness: 280 grit Ra=0.5micron

800 grit Ra = 0.2 micron

Water based slurry mostly used ( Low viscosity fluid).

Process Parameters and their Effects:

Process parameters which govern the ultrasonic machining process:

Amplitude of vibration (a

o

) : 15 50 m

Frequency of vibration (f) : 19 25 kHz

Feed force (F)

Abrasive size : 15 m 50 m

Abrasive material

Flow strength (plastic deformation) of work material (o

w

)

Flow strength of the tool material (o

t

)

Contact area of the tool A

Volume concentration of abrasive in water slurry C

Tool: Ductile materials e.g. brass, mild steel, stainless steel--

Grits

breakage

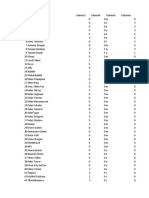

Parametric Dependence of MRR in USM

f-Force

a

0

- Amplitude

d

g

-Grit diameter

f-Frequency

-Ration of

workpiece and

tool strength

c- Grit

concentration in

slurry

d

g

~a

0

Attributes & Applications

Normal hole tolerances ~ 0.007 mm and

surface finish ~ 0.02 to 0.7 m.

* Specific material removal rate on brittle materials~ 0.018

mm

3

/Joule.

* Penetration rates of 5 mm/min

Used for machining hard and brittle metallic alloys,

semiconductors, glass, ceramics, carbides etc.

Used for machining round, square, irregular shaped holes

and surface impressions.

Machining wire drawing, punching or small blanking dies.

Limitations

Low MRR

High tool wear

Low hole depth

http://www.bullentech.com/uploads/images/Old%20Pics/TRIANGULAR%20CAVITY.JPG

Process Modeling:

During one stroke,

When the grit size is close to the

mean position, the tool hits the

grit with its full speed.

Smaller the grit size, the lesser

the momentum it receives from

the tool.

Therefore, there is an effective

speed zone for the tool and,

correspondingly there is an

effective size range for the grits

for effective material removal.

Work

Tool

a

V=0

V=V

max

V=0

a

0

=a/2

Model:

Identical grits of average grit diameter = d

g

Local spherical bulges of diameter

d

b

= .d

2

g

In brittle fracture the volume of material

removed per indentation

I

b

= 2/3t.x

3

= 2/3 t.(d

b

.o

w

)

3/2

as x

2

= d

b

.o

w

MRR = I

b

.n.f = 2/3 t.(d

b

.o

w

)

3/2

.n.f

n= Ave. no. of grits &

f= indentation frequency

Given: Volumetric Concentration of

grits in slurry = C

Area of Tool = A

Space between tool & work when

they are pressing against grits ~ d

g

Volume of Grits = A.d

g

.C

This will be equal to n. t/6d

g

3

n = 6AC/t.d

g

2

Tool & Work pressing each other

against grits will deform inversely

proportional to their flow strength

o

t

/o

W

= o

w

/o

t

=

And, total depth of indentation.

o = o

t

+ o

W

During machining the impulse of

force on the tool & work will be balanced.

= o

t

+o

w

During tool oscillation, it engages & presses grits only during a

time t, a part of one-fourth of the cycle (T/4) when it is moving

from its mid-point towards workpiece

o/a

0

= t / (T/4) t = T(o

t

+o

w

)/4.a

0

Total impulse in a second by the Tool I

t

= n.f.F

max

.t,

where F

max

is the maximum indentation force per abrasive.

Now, the tool is fed with an average force F. Impulse in 1s=F

Thus, F = n.f.F

max

.t = n.f.F

max

T(o

t

+o

w

)/4.a

0

o

t

o

w

The flow strength of work material = o

w

F

max

= t.x

2

. o

w

F = t.x

2

. o

w

.n.f. T(o

t

+o

w

)/4.a

0

Substituting values of x, d

b

, n, & o

t

/o

w

= o

w /

o

t

=

F = (3AC/ 4a

0

). ,o

w

.o

w

2

(1+ ) { f.T = 1, d

b

=d

2

g

}

o

w

= {(4a

0

.F)/ (3A.C. ,o

w

.(1+ ))}

1/2

MRR = I

b

n.f = 2/3 t.(d

b

.o

w

)

3/2

.n.f

= 4A.C.d

g

.

3/2

.f. { (4a

0

F)/(3.A.C.o

w

(1+)}

3/4

MRR d

g.

f (C

1/4

.A

1/4

.F

3/4

.a

0

3/4

.

3/4

)/ {o

w

3/4

(1+)

3/4

}

For tool pressure p, F =A.p

MRR d

g

. f (C

1/4

.A.p

3/4

.a

0

3/4

.

3/4

)/ {o

w

3/4

(1+)

3/4

}

You might also like

- Ultra Sonic Machining (USM) Process OverviewDocument18 pagesUltra Sonic Machining (USM) Process OverviewYogesh PrabhakarNo ratings yet

- Ultrasonic Machining (USM)Document20 pagesUltrasonic Machining (USM)Prateek SharmaNo ratings yet

- USM Working PrincipleDocument3 pagesUSM Working PrincipleAnonymous dL8dsCncNo ratings yet

- Ultrasonic Machining of Titanium: Tool Wear AnalysisDocument48 pagesUltrasonic Machining of Titanium: Tool Wear AnalysisRavichandran GNo ratings yet

- Here are the answers to the quiz questions:1. Germanium 2. Steel3. Increase MRR4. MechanicalDocument13 pagesHere are the answers to the quiz questions:1. Germanium 2. Steel3. Increase MRR4. MechanicalSaswat KhataiNo ratings yet

- # 3 - Ultrasonic MachiningDocument48 pages# 3 - Ultrasonic MachiningRohan RautNo ratings yet

- USM NotesDocument11 pagesUSM Notes18R21A0310 BIYYALA SHESHAGIRINo ratings yet

- Chapter 2Document16 pagesChapter 2KAMALJEET SINGHNo ratings yet

- Ultrasonic MachiningDocument20 pagesUltrasonic MachiningKoushik Rao100% (1)

- Ultra Sound MachiningDocument20 pagesUltra Sound MachiningVishalHarchandaniNo ratings yet

- Ultrasonic Machining (USM) : Dr. Harlal Singh MaliDocument11 pagesUltrasonic Machining (USM) : Dr. Harlal Singh MaliPrashant Singh SankhalaNo ratings yet

- Final Report 2Document16 pagesFinal Report 2Ravi PatelNo ratings yet

- Usm PDFDocument5 pagesUsm PDFPANKWORLDNo ratings yet

- 4D UsmDocument13 pages4D UsmHARSHVARDHAN SINGH RATHORENo ratings yet

- Patented MICROGAP Control Modes and Stack ComponentsDocument3 pagesPatented MICROGAP Control Modes and Stack ComponentsRégis SouzaNo ratings yet

- Bp0385 PDFDocument4 pagesBp0385 PDFjhon vargasNo ratings yet

- Chapter - 4 Advance Manufacturing ProcessesDocument77 pagesChapter - 4 Advance Manufacturing ProcessesKarnal 0388No ratings yet

- Define USM: Ultrasonic Machining Process ExplainedDocument32 pagesDefine USM: Ultrasonic Machining Process ExplainedAshwin DevNo ratings yet

- Assignment#3 Group #2: Manufacturing Process Ultrasonic MachiningDocument16 pagesAssignment#3 Group #2: Manufacturing Process Ultrasonic MachiningThe Noob100% (1)

- Ultrasonic MachiningDocument26 pagesUltrasonic MachiningEmanuel Nuñez ClavecillasNo ratings yet

- Advanced Machining Processes: Ultrasonic MachiningDocument66 pagesAdvanced Machining Processes: Ultrasonic MachiningKenneth C.LinojNo ratings yet

- Ultrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionDocument26 pagesUltrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionRishiJpNo ratings yet

- Ultrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionDocument26 pagesUltrasonic Machining (Usm) : Brittle Fracture Cavitation Induced Erosion Chemical ErosionRishiJp100% (1)

- Advanced Manufacturing ProcessDocument2 pagesAdvanced Manufacturing ProcessBiswadeep Roy ChoudhuryNo ratings yet

- Modern Manufacturing ProcssesDocument24 pagesModern Manufacturing ProcssesAravind SudheesanNo ratings yet

- Ultrasonic Machining (USM): A Precision Machining Process for Hard and Brittle MaterialsDocument9 pagesUltrasonic Machining (USM): A Precision Machining Process for Hard and Brittle MaterialsAnkit OlaNo ratings yet

- Ultrasonic Machining: An Overview of the Process and Its ElementsDocument45 pagesUltrasonic Machining: An Overview of the Process and Its ElementsBharath KumarNo ratings yet

- Ultrasonic MachiningDocument14 pagesUltrasonic MachiningKeyur SoleNo ratings yet

- El-Hofy Fundamentals of Machining Processes Tema 10Document42 pagesEl-Hofy Fundamentals of Machining Processes Tema 10chompo83No ratings yet

- Ultrasonic TestingDocument85 pagesUltrasonic TestingSathish Raams100% (2)

- Ultrasonic Machining (Usm) : TitleDocument12 pagesUltrasonic Machining (Usm) : TitleKiran KumarNo ratings yet

- Piezoelectric Actuator Ultrasonic: MechanismDocument2 pagesPiezoelectric Actuator Ultrasonic: Mechanism39 Mohit KumarNo ratings yet

- Working PrincipleDocument2 pagesWorking Principle39 Mohit KumarNo ratings yet

- Impact Hammer Product DataDocument4 pagesImpact Hammer Product DatasadettinorhanNo ratings yet

- 215 Sample ChapterDocument23 pages215 Sample ChapterSreekumar RajendrababuNo ratings yet

- Working Principle of Ultrasonic MachiningDocument7 pagesWorking Principle of Ultrasonic MachiningYogesh KandaNo ratings yet

- 5.5 UsmDocument36 pages5.5 UsmAshish MishraNo ratings yet

- Ultrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Document8 pagesUltrasonic Machining Engineering Materials And Manufacuring Technology اشع ديعس نزام ديعس 0147566Saeed AshaNo ratings yet

- Ultrasonic-Machining ProcessDocument16 pagesUltrasonic-Machining ProcessTrung Quoc LeNo ratings yet

- Ultrasonic Machining (USM)Document19 pagesUltrasonic Machining (USM)RakeshSaini100% (2)

- Lecture 2 - 06-03-2024Document19 pagesLecture 2 - 06-03-2024rohithconnect021No ratings yet

- Ultrasonic Machining SeminarDocument11 pagesUltrasonic Machining Seminarhyundai31050% (2)

- Unit-4 Advanced Machining ProcessesDocument61 pagesUnit-4 Advanced Machining ProcessesHarshalPatilNo ratings yet

- UsmDocument21 pagesUsmshaikh javedNo ratings yet

- 6/3/2014 1 Hareesha N G, Dept of Aero Engg, DsceDocument26 pages6/3/2014 1 Hareesha N G, Dept of Aero Engg, DsceInderpal SinghNo ratings yet

- Usm 1Document47 pagesUsm 1Abhishek KumarNo ratings yet

- Mechanical SeminarDocument19 pagesMechanical SeminarLAKKANABOINA LAKSHMANARAONo ratings yet

- Review On Ultrasonic Machining: PergamonDocument17 pagesReview On Ultrasonic Machining: Pergamonanon_85513817No ratings yet

- USM Machining Guide: Principles, Parameters, Applications & Case StudiesDocument29 pagesUSM Machining Guide: Principles, Parameters, Applications & Case StudiesAnonymous ML4hh4MOyBNo ratings yet

- Determine AC Mains Frequency Using SonometerDocument4 pagesDetermine AC Mains Frequency Using SonometerDr. Deepak GuptaNo ratings yet

- Ultrasonic TestingDocument81 pagesUltrasonic Testingmanafl salhlNo ratings yet

- Module-3: Advanced Material Removal Processes: Lecture No-8 Ultrasonic Machine and Its Process ParametersDocument4 pagesModule-3: Advanced Material Removal Processes: Lecture No-8 Ultrasonic Machine and Its Process ParametersrakeshchandrooNo ratings yet

- Electronic Instruments and Measurements: Unit-5 TransducerDocument42 pagesElectronic Instruments and Measurements: Unit-5 TransducerTenda TiyNo ratings yet

- TX-MPI Mine Locator ManualDocument14 pagesTX-MPI Mine Locator ManualDragan CiricNo ratings yet

- Ultrasonic WeldingDocument20 pagesUltrasonic Weldingnayeem100% (3)

- Electronic Instruments and Measurements: Transducers and SensorsDocument42 pagesElectronic Instruments and Measurements: Transducers and SensorsTenda TiyNo ratings yet

- UsmDocument38 pagesUsmJPSAONANo ratings yet

- Ilovepdf MergedDocument74 pagesIlovepdf MergedAbdulrahman goudaNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Investment Fundamentals Guide PDFDocument36 pagesInvestment Fundamentals Guide PDFShashank Gaurav100% (1)

- ReadmeDocument9 pagesReadmedongdt2k325390No ratings yet

- 2013 Philosophy First Merit ListDocument1 page2013 Philosophy First Merit ListShashank GauravNo ratings yet

- Certificate of Students'S Practical TrainingDocument1 pageCertificate of Students'S Practical TrainingShashank GauravNo ratings yet

- Online PaymentDocument5 pagesOnline PaymentShashank GauravNo ratings yet

- Nontraditional Manufacturing Processes - SupplementaryDocument2 pagesNontraditional Manufacturing Processes - SupplementaryShashank GauravNo ratings yet

- Dell Strategy AnalysisDocument13 pagesDell Strategy AnalysisShashank GauravNo ratings yet

- Windows 8 - Notice PDFDocument1 pageWindows 8 - Notice PDFSanthosh KumarNo ratings yet

- 2013 Hindi First Merit ListDocument1 page2013 Hindi First Merit ListShashank GauravNo ratings yet

- IRCTC LTD, Booked Ticket PrintingDocument2 pagesIRCTC LTD, Booked Ticket PrintingShashank GauravNo ratings yet

- Systems and ControlDocument2 pagesSystems and ControlShashank GauravNo ratings yet

- Robots and Computer Controlled MechanicsDocument2 pagesRobots and Computer Controlled MechanicsShashank GauravNo ratings yet

- Hindi PaperDocument1 pageHindi PaperShashank GauravNo ratings yet

- Director IITB Approval For SRF 2014Document1 pageDirector IITB Approval For SRF 2014Shashank GauravNo ratings yet

- Application - ArchiDocument3 pagesApplication - ArchiShashank GauravNo ratings yet

- ApplicationDocument1 pageApplicationShashank GauravNo ratings yet

- Course Structure For Machine Tools & MachiningDocument4 pagesCourse Structure For Machine Tools & MachiningShashank GauravNo ratings yet

- Bryonia PDFDocument2 pagesBryonia PDFShashank GauravNo ratings yet

- Dell Strategy AnalysisDocument13 pagesDell Strategy AnalysisShashank GauravNo ratings yet

- Electrical TechnologyDocument2 pagesElectrical TechnologyShashank GauravNo ratings yet

- Recent Studies On The Use of Lasers in AgricultureDocument16 pagesRecent Studies On The Use of Lasers in AgricultureCeren KılıçNo ratings yet

- Introduction To Dilute Magnetic Semiconductors: PACS NumbersDocument7 pagesIntroduction To Dilute Magnetic Semiconductors: PACS NumbersSubhash ChandraNo ratings yet

- Omni 352 Scanner PDFDocument2 pagesOmni 352 Scanner PDFErxhan Ahmeti0% (1)

- Labino Apollo 1.0 UV WL MeterDocument1 pageLabino Apollo 1.0 UV WL MeterPP043No ratings yet

- 26 - Jaxa-Rozen Cold Work Stainless Steell PDFDocument13 pages26 - Jaxa-Rozen Cold Work Stainless Steell PDFSergio MuñozNo ratings yet

- Ze Fgl32a22 EngDocument20 pagesZe Fgl32a22 EngManuel Antonio CostaNo ratings yet

- Gis 30-851Document24 pagesGis 30-851Felix JaimesNo ratings yet

- Raman Amplification For FiberDocument15 pagesRaman Amplification For Fiberhas samNo ratings yet

- Forever ClassicDocument2 pagesForever ClassicioanNo ratings yet

- Panasonic SA-AK350-47471 PDFDocument107 pagesPanasonic SA-AK350-47471 PDFjose antonio paezNo ratings yet

- Reference Guide To Fiber Optic Testing: Second EditionDocument43 pagesReference Guide To Fiber Optic Testing: Second EditionCarlos Alvaro Ch100% (1)

- Metamaterials Part1Document31 pagesMetamaterials Part1LIAKMANNo ratings yet

- On The Basic Concept of Nano-TechnologyDocument6 pagesOn The Basic Concept of Nano-TechnologyfungedoreNo ratings yet

- Application Note Vapor Recovery Units PDFDocument4 pagesApplication Note Vapor Recovery Units PDFNicolae VisanNo ratings yet

- Service & Parts Manual 2060 NewDocument94 pagesService & Parts Manual 2060 NewJose Lopez RuizNo ratings yet

- VeinFinder_VE800 Brochure V1.0Document2 pagesVeinFinder_VE800 Brochure V1.0hanrong912No ratings yet

- Denver and Hong Kong baggage system failuresDocument18 pagesDenver and Hong Kong baggage system failuresKunal ChopraNo ratings yet

- Physics Project On Optical Fiber and Its ApplicationsDocument15 pagesPhysics Project On Optical Fiber and Its ApplicationsFerry Sofat100% (1)

- A Seminar On Carbon NanaotubesDocument24 pagesA Seminar On Carbon NanaotubesRupam TiaryNo ratings yet

- Astm 34Document4 pagesAstm 34MNMNo ratings yet

- Unit 3 PDFDocument126 pagesUnit 3 PDFFlorence MercyNo ratings yet

- CD overviewDocument11 pagesCD overviewSidra SiddiquiNo ratings yet

- Chapter 2 Plane Surfaces and PrismsDocument22 pagesChapter 2 Plane Surfaces and PrismsEric Doctore KrageNo ratings yet

- Semiconductor Device Formula SheetDocument2 pagesSemiconductor Device Formula SheetSRIKAR SAI SYAMA P100% (3)

- Laser Marking PresentationDocument20 pagesLaser Marking Presentationไทยคม ผิวปานแก้วNo ratings yet

- Optical Fibre Communication SystemsDocument3 pagesOptical Fibre Communication Systemsकृष्णा कुमार कश्यपNo ratings yet

- Sales Sheet Solar GloDocument1 pageSales Sheet Solar GloJonathan YañezNo ratings yet

- Claxton LSCMIntroDocument37 pagesClaxton LSCMIntroBilge Can YıldızNo ratings yet

- Column Card Data TableDocument300 pagesColumn Card Data TableKtoffel BrotNo ratings yet

- Science 10Document5 pagesScience 10ARCHEL SUPOTNo ratings yet