Professional Documents

Culture Documents

03 Two Stroke Crosshead Diesel Engine

Uploaded by

anubhavl0 ratings0% found this document useful (0 votes)

107 views9 pagesThe features and specifications of a two strokes Cross head diesel engine.

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe features and specifications of a two strokes Cross head diesel engine.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

107 views9 pages03 Two Stroke Crosshead Diesel Engine

Uploaded by

anubhavlThe features and specifications of a two strokes Cross head diesel engine.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 9

Two Stroke Crosshead

Diesel Engine

The two stroke crosshead type diesel

engine works on the same principle as

two stroke trunk type diesel engine.

The majority of two stroke diesel

engines at sea are of the Crosshead

type. In this type of engine, the

combustion space (formed by the liner,

piston and cylinder head) is separated

from the crankcase by a diaphragm

plate.

The piston rod is bolted to the piston and

passes through a stuffing box mounted in

the diaphragm plate. The stuffing acts as a

seal between the two spaces; stopping oil

from being carried to the scavenge space

and preventing scavenge air from leaking

into the crankcase. The foot of the piston

rod is bolted to the crosshead pin. The top

end of the connecting rod swings about

the crosshead pin as the downward load

from the expanding gas applies a turning

force on to the crankshaft.

To ensure that the crosshead

reciprocates in alignment with the

piston in the liner, guide shoes are

attached on either side of the

crosshead. These shoes are lined

with whitemetal, a bearing material

and a reciprocate against crosshead

guides, which are bolted to the frame

of the engine.

Using the crosshead design, allows the engine

to be built with very long strokes. This enables

engines to burn greater quantity of fuel/stroke

and develop more power and also enables

engines to run at slow speed so that it can be

directly coupled to screw propellers, which drive

ships without the use of reduction gears (higher

the speed of these screw propellers, the lower

their efficiency today the rpm of these engines

about 100 and lower). Non use of reduction

gears results in savings in cost, space and

weight.

Also the fuel used in the engine can be of

an inferior grade having higher sulphur

content than used in a trunk type engine.

Higher alkalinity and viscosity cylinder oil

having different specification from

crankcase oil are used to lubricate the

cylinder liner and piston rings and combat

the affect of acid attacks and high

temperature of the combustion space.

The most powerful diesel

engines are two stroke

crosshead type engines. Some

of these engines have bores

reaching upto one metre and

strokes over 2.5 metres. The

crankshaft may weigh upto 300

tons and engine may weigh over

2000 tons.

You might also like

- 03 Two Stroke Crosshead Diesel EngineDocument9 pages03 Two Stroke Crosshead Diesel EngineVinay Kumar NeelamNo ratings yet

- The 2 Stroke Crosshead EngineDocument9 pagesThe 2 Stroke Crosshead EngineBharatiyulamNo ratings yet

- Running Gear of Diesel Engine ZZDocument26 pagesRunning Gear of Diesel Engine ZZAlaine Jan de Tablan100% (2)

- MCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Document19 pagesMCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Fahim ShahrierNo ratings yet

- Diesel Engine ConstructionDocument42 pagesDiesel Engine Constructionanon_322442463100% (1)

- Me-439 ICE Lec - 6 FrictionDocument27 pagesMe-439 ICE Lec - 6 Frictiontanoli9596No ratings yet

- Diesel Engine ConstructionDocument53 pagesDiesel Engine ConstructionLasse HansenNo ratings yet

- Motor Short AnswersDocument97 pagesMotor Short AnswersRachitNo ratings yet

- Diesel Engine FundamentalsDocument5 pagesDiesel Engine FundamentalsIris JanssenNo ratings yet

- Two StrokeDocument11 pagesTwo StrokeAfzal Shams100% (1)

- Piston - WikipediaDocument30 pagesPiston - WikipediaLAliNo ratings yet

- The Most Powerful Diesel Engine in The WorldDocument8 pagesThe Most Powerful Diesel Engine in The WorldHameedNo ratings yet

- Cross Head BearingsDocument14 pagesCross Head BearingsjohansolNo ratings yet

- The Wartsila-Sulzer RTA96-C Turbocharged Two-Stroke Diesel EngineDocument7 pagesThe Wartsila-Sulzer RTA96-C Turbocharged Two-Stroke Diesel Enginegustavo PabloNo ratings yet

- PPD ReportingDocument46 pagesPPD ReportingFernando CruzNo ratings yet

- Cylinder Lubrication Developments and Lubricants Drain AnalysisDocument14 pagesCylinder Lubrication Developments and Lubricants Drain AnalysisAnto KattikkaranNo ratings yet

- Marine Internal Combustion Diesel Egine I-SbrDocument232 pagesMarine Internal Combustion Diesel Egine I-SbrRENGANATHAN P100% (1)

- What Is The Difference Between A Two Stroke and Four Stroke EngineDocument7 pagesWhat Is The Difference Between A Two Stroke and Four Stroke EngineAllen NopreNo ratings yet

- 2 Stroke Cycle, Marine EngineeringDocument27 pages2 Stroke Cycle, Marine EngineeringRohit PandeyNo ratings yet

- 2 Strok EngineDocument11 pages2 Strok EnginebabublsNo ratings yet

- Crosshead With Connecting Rod PurposeDocument14 pagesCrosshead With Connecting Rod Purposeapi-3701567100% (9)

- 02 Medium Speed Diesel EngineDocument15 pages02 Medium Speed Diesel EngineNaveen Kumar100% (1)

- Pimsat Colleges Engineering Materials 1Document8 pagesPimsat Colleges Engineering Materials 1Sev Anne T. GonzalesNo ratings yet

- Two-Stroke Engine - WikipediaDocument59 pagesTwo-Stroke Engine - WikipediaDIPU KUMARNo ratings yet

- ASSIGNMENT 2 by b3Document16 pagesASSIGNMENT 2 by b3devmarineacademyNo ratings yet

- EM II, 2 Engleza, PDFDocument36 pagesEM II, 2 Engleza, PDFAndrei Minca100% (2)

- Notes On Motor 03 Oct 09Document51 pagesNotes On Motor 03 Oct 09NarineNo ratings yet

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- Engine Lubrication SystemsDocument8 pagesEngine Lubrication SystemsMentsnot GetuNo ratings yet

- Theory of Engine OperationDocument19 pagesTheory of Engine OperationGabriel Dela Cruz LagmanNo ratings yet

- How A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineDocument8 pagesHow A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineKarim Sowley DelgadoNo ratings yet

- Component Parts of Internal Combustion EnginesDocument26 pagesComponent Parts of Internal Combustion EnginesPeter AshrafNo ratings yet

- Car Engine Bearing FunctionsDocument1 pageCar Engine Bearing Functionsphutd09No ratings yet

- PPD ReviewerDocument4 pagesPPD ReviewerMark Alvin CuyaNo ratings yet

- What Is Piston How Does A Piston WorkDocument15 pagesWhat Is Piston How Does A Piston WorkRony henneryNo ratings yet

- Two Stroke EngineDocument13 pagesTwo Stroke EngineAaron PriceNo ratings yet

- Advantages and Disadvantages of Different Types of EngineDocument11 pagesAdvantages and Disadvantages of Different Types of EngineJerome BalatbatNo ratings yet

- Connecting Rods Types and MaterialsDocument2 pagesConnecting Rods Types and MaterialsTibebu MerideNo ratings yet

- AMTE126 - 10B Wet and Dry Sump Advantages and DisadvantagesDocument3 pagesAMTE126 - 10B Wet and Dry Sump Advantages and DisadvantagesRebecca Lepon Legaspi50% (2)

- Advantages of 4 Stroke EngineDocument6 pagesAdvantages of 4 Stroke EngineJILLIEN KAITH ARELLANONo ratings yet

- Himsen Cat h1728Document12 pagesHimsen Cat h1728Mohsen100% (1)

- How Two Stroke Engine WorksDocument7 pagesHow Two Stroke Engine Works01parthNo ratings yet

- Final-Advance Breaking System For Hill Drive VehiclesDocument59 pagesFinal-Advance Breaking System For Hill Drive VehiclesMurali VannappanNo ratings yet

- Propulsion LabDocument39 pagesPropulsion LabKalpit KauraseNo ratings yet

- Motor Oil Four-Stroke Two-Stroke Piston Internal Combustion Engines Oil Pumps Wet-Sump SumpDocument2 pagesMotor Oil Four-Stroke Two-Stroke Piston Internal Combustion Engines Oil Pumps Wet-Sump SumpPrinceNo ratings yet

- Classification of Automobiles: Automotive TechnologyDocument50 pagesClassification of Automobiles: Automotive TechnologyAjay KumarNo ratings yet

- Four-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanDocument27 pagesFour-Stroke, Four Cylinder Diesel Engine: BY Shubham Kulshrestha Atul Yadav Irfan KhanShubham Kulshrestha100% (1)

- 2stroke TuningDocument5 pages2stroke TuningRaka Dozer MahardhikaNo ratings yet

- Engine Design & Basic TheoryDocument16 pagesEngine Design & Basic Theoryİsmet Sezer100% (2)

- Four-Stroke Diesel EngineDocument18 pagesFour-Stroke Diesel Enginebs esliye me aap ka fan ho gya100% (2)

- IceDocument83 pagesIceAJ BantayNo ratings yet

- Basic Two Stroke Tuning by Eric Gorr (I Think)Document7 pagesBasic Two Stroke Tuning by Eric Gorr (I Think)Dr DNo ratings yet

- Scavenging in 2 Stroke Engine FinalDocument35 pagesScavenging in 2 Stroke Engine Finalnitin_parwaniNo ratings yet

- Comparisons of Cross Head and Trunk Piston EnginesDocument1 pageComparisons of Cross Head and Trunk Piston EnginesJitendra KumarNo ratings yet

- Unit 2-2Document10 pagesUnit 2-2Regele ArthurNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

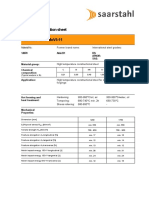

- 21CrMoV5 11Document1 page21CrMoV5 11anubhavlNo ratings yet

- MESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423Document7 pagesMESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423sathi11189100% (1)

- Indigital Userguide CHANNELSDocument20 pagesIndigital Userguide CHANNELSanubhavlNo ratings yet

- Tools India IntroductionDocument1 pageTools India IntroductionanubhavlNo ratings yet

- Mechanical Standard For Metallic MaterialDocument2 pagesMechanical Standard For Metallic MaterialanubhavlNo ratings yet

- CH 14 CarbonandAlloySteelsDocument42 pagesCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- CAT UltraCleanCatalogDocument10 pagesCAT UltraCleanCataloganubhavlNo ratings yet

- TCR Material Testing Price List IndiaDocument4 pagesTCR Material Testing Price List IndiaanubhavlNo ratings yet