Professional Documents

Culture Documents

SERV1 09e BinaryOp

Uploaded by

Neagoe CristianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SERV1 09e BinaryOp

Uploaded by

Neagoe CristianCopyright:

Available Formats

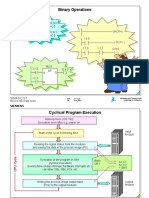

Binary Operations

I 0.0 I 0.1 Q 8.0

Q 8.1 I 1.0 & M8.0

M1.0

I 1.1 P =

I 1.0 &

M1.1 M8.1

I 1.1 N =

M0.0

I 1.2 Q 9.3

SR

S Q

I 1.3

R

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.1

Objectives

Upon completion of this chapter the participant will ...

... understand the difference between ‘real‘ connected NC contacts

and NO contacts and programmed symbols

... be able to explain the terms Result of Logic Operation (RLO),

Status (STAT) and First Check

... be able to program basic binary logic operations

... be able to use and program edge detections for problem solving

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.2

Binary Logic Operations: AND, OR

Circuit Diagram LAD FBD STL

S1 (I 0.0)

I 0.0 I 0.1 Q 8.0 I 0.0 & Q 8.0 A I 0.0

= A I 0.1

AND S2 (I 0.1) I 0.1

= Q 8.0

Q 8.1 Q 8.1 = Q 8.1

=

L1 L2

(Q 8.0) (Q 8.1)

S3

(I 0.2) I 0.2 Q 8.2

Q 8.2 O I 0.2

S4 I 0.2 >=1

OR = O I 0.3

(I 0.3) I 0.3 = Q 8.2

I 0.3

L3 (Q 8.2)

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.3

Binary Logic Operations: Exclusive OR (XOR)

LAD FBD STL

I 0.4 & A I 0.4

I 0.4 I 0.5 Q 8.0 Q 8.0 AN I 0.5

I 0.5 >=1 O

=

AN I 0.4

I 0.4 & A I 0.5

I 0.4 I 0.5 I 0.5 = Q8.0

Q 8.0 X I 0.4

I 0.4 XOR X I 0.5

=

I 0.5 = Q8.0

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.4

Normally Open and Normally Closed Contacts, Sensors and Symbols

Process Interpretation in PLC program

The The sensor Voltage Signal Check for Check for

sensor is ... present state signal state “1” signal state “0”

is a ... at at

input? input Symbol / Result of Symbol / Result of

Instruction check Instruction check

NO activated

contact LAD: LAD:

Yes 1 “Yes“ “No”

1 0

“NO contact” “NC contact”

not No

activated 0 “No” “Yes”

0 1

FBD: FBD:

& &

NC activated No

contact 0 “No” “Yes”

0 1

not STL: STL:

activated Yes 1 “Yes” “No”

A I x.y 1 AN I x.y 0

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.5

Exercise

Goal: In all three examples, the light should be on when S1 is activated and S2 is not activated!

Hardware

S1 S2 S1 S2 S1 S2

II1.0

1.0 II1.1

1.1 II1.0

1.0 II1.1

1.1. II1.0

1.0 II1.1

1.1

Programmable controller Programmable controller Programmable controller

Q 4.0 Q 4.0 Q 4.0

Light Light Light

Software

I 1.0 I 1.1 Q 4.0 I 1.0 I 1.1 Q 4.0 I 1.0 I 1.1 Q 4.0

LAD

I 1.0 & I 1.0 & I 1.0 &

FDB

I 1.1 Q 4.0 I 1.1 Q 4.0 I 1.1 Q 4.0

....... I 1.0 ....... I 1.0 ....... I 1.0

STL ....... I 1.1 ....... I 1.1 ....... I 1.1

....... Q 4.0 ....... Q 4.0 ....... Q 4.0

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.6

Result of Logic Operation, First Check, and Examples

Example 1 Example 2 Example 3

Result of Check

Result of Check

Result of Check

Result of Logic

Result of Logic

Result of Logic

Signal State

Signal State

Signal State

First Check

First Check

First Check

Operation

Operation

Operation

:

:

= M 3.4

A I 1.0 0 1 1

AN I 1.1 0 1 0

A M 4.0 0 1 1

= Q 8.0

= Q 8.1

A I 2.0 0 1 0

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.7

Assignment, Setting, Resetting

LAD FBD STL

I 1.0 I 1.1 Q 8.0 A I 1.0

I 1.0 A I 1.1

& Q 8.0

Assignment ( ) = Q 8.0

I 1.1 =

I 1.2 I 1.3

Q 8.1 I 1.2 A I 1.2

& Q 8.1

Set (S) A I 1.3

I 1.3 S S Q 8.1

I 1.4 Q 8.1

(R) I 1.4 O I 1.4

>=1 Q 8.1 O I 1.5

Reset I 1.5 R R Q 8.1

I 1.5

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.8

Setting / Resetting a Flip Flop

LAD FBD STL

M5.7 M5.7

I 1.2 Q 9.3 A I 1.2

SR SR S M 5.7

Dominant S Q I 1.2 S

Reset A I 1.3

Q9.3 R M 5.7

I 1.3

R Q = A M 5.7

R I 1.3 = Q 9.3

M5.7 M5.7

I 1.3 Q 9.3 A I 1.3

Dominant RS RS R M 5.7

R Q I 1.3 R

Set A I 1.2

Q9.3 S M 5.7

I 1.2

Q = A M 5.7

S I 1.2 S = Q 9.3

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.9

Midline Output Coil

LAD STL

I 1.0 I 1.1 M5.7 I 2.0 I 2.1 M 1.1 Q 4.0

( ) NOT ( ) ( ) A I 1.0

A I 1.1

= M 5.7

A M 5.7

FBD A I 2.0

A I 2.1

NOT

I 1.0 & = M 1.1

M5.7

A M 1.1

I 1.1 &

= Q 4.0

I 2.0 M1.1 Q 4.0

I 2.1 =

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.10

Instructions that Affect the RLO

LAD FBD STL

A I 0.0

I 0.0 I 0.1

Q8.0 I 0.0 & A I 0.1

NOT Q8.0

NOT ( ) I 0.1 = NOT

= Q8.0

Examples:

STAT 0 - Bit memory

CLR

CLR not available not available = M 0.0

STAT 1 - Bit memory

not available not available

SET

SET

= M 0.1

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.11

Exercise: Mode Section of the Distribution Conveyor

DI DO Q 8....

Q 4....

I 0.0 T_System_ON .0

I 0.1 T_System_OFF L_SYSTEM .1

I 0.2 T_Jog_RT L_MAN .2

V

I 0.3 T_Jog_LT L_AUTO .3

I 0.4 S_M/A_Mode_Select .4

I 0.5 T_M/A_Accept .5

-15V...+15V -15V...+15V

AI2 AO1

I 0.6 .6 AI1 AO2

I 0.7 .7

AI1 AI2

Weight V

0 8 1 5 AI1 AI2 AO1 AO2

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.12

Exercise: Mode Section (FC 15), Solution Hints

Network 1: LED for System ON

Q 8.1 (Q 4.1)

SR

ON-condition S

OFF-condition R OUT

Network 2: LED for MANUAL mode

Q 8.2 (Q 4.2)

SR

ON-conditions S

OFF-conditions R OUT

Network 3: LED for AUTO mode

Q 8.3 (Q 4.3)

SR

ON-conditions S

OFF-conditions R OUT

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.13

Exercise: Conveyor Operation in AUTO Mode (1)

Conv. Start Transport Phase Conv. Stop

Prox.Sens.Bay 1

I 16.5 (I 8.5)

M.C.Sw. Bay 1

I 16.1 (I 8.1)

Prox.Sens.Bay 2

I 16.6 (I 8.6)

M.C.Sw. Bay 2

I 16.2 (I 8.2)

Light barrier

(I 16.0 / I 8.0)

Run Conveyor

RIGHT

(Q20.5 / Q8.5)

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.14

Exercise: Conveyor Operation in AUTO Mode (1), Solution Hints

Network x Jog RIGHT in MANUAL mode

Conditions for JOGGING

RIGHT M 16.2 Memory bit for

Jog RIGHT

in MANUAL mode = in MANUAL mode

Network y Run Conveyor RIGHT in AUTO mode

M 16.3

Conditions for

S Memory bit for

Run Conveyor RIGHT Jog RIGHT

in AUTO mode R in AUTO mode

Network z Control Run Conveyor RIGHT

M 16.2 >=1 Q 20.5

(Q 8.5) Run Conveyor RIGHT

M 16.3 =

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.15

RLO - Edge Detection

LAD FBD STL

A I 1.0

I 1.0 I 1.1 M1.0 M8.0 I 1.0 &

M1.0 M8.0 A I 1.1

P FP M1.0

I 1.1 P = = M8.0

I 1.0 I 1.1 M1.1 M8.1 I 1.0 A I 1.0

& M8.1 A I 1.1

M1.1

N FN M1.1

I 1.1 N = = M8.1

OB1-Cycle

I 1.0

I 1.1

RLO

Example

M1.0

M1.1

M8.0

M8.1

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.16

Signal - Edge Detection

LAD FBD STL

I 1.1 I 1.0 & A I 1.0

I 1.0 M8.0 I 1.1 A (

POS POS M8.0 A I 1.1

Q

M1.0 M_BIT = FP

M1.0 M_BIT M1.0

)

I 1.1 I 1.0 =

I 1.0 M8.1 &

I 1.1 M8.0

NEG A I 1.0

Q NEG M8.1

A (

M1.1 M_BIT M1.1 M_BIT = A I 1.1

FN

M1.1

I 1.0 )

=

I 1.1 M8.1

Example M1.0

M1.1

OB1-Cycle

M8.0

M8.1

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.17

Exercise: Conveyor Operation in AUTO Mode (2)

Conv. Start Transport Phase Conv. Stop

Part at

light barrier

Start condition

in AUTO mode

Light barrier

(I 16.0 / I 8.0)

Run Conveyor

RIGHT

(Q20.5 / Q8.5)

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.18

Exercise: Optimizing the Mode Section FC 15

OLD: without edge detection

T_System_ON

(I 0.0)

T_System_OFF

(I 0.1, NC)

L_System

(Q8.1 / Q4.1)

NEW: with edge detection

T_System_ON

(I 0.0)

T_System_OFF

(I 0.1, NC)

L_System

(Q8.1, Q4.1)

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.19

Unconditional Jump (Independent of RLO)

LAD FBD STL

Network 1 Network 1 Network 1

NEW1 NEW1

( JMP ) .... JMP JU NEW1

Network 2 Network 2 Network 2

: : :

: : :

: : :

: : :

Network x Network x Network x

NEW1 NEW1

M5.5 I 4.7 M69.0 NEW1: AN M5.5

M5.5 & M69.0

( ) AN I 4.7

I 4.7 = = M69.0

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.20

Conditional Jump (Dependent on RLO)

LAD FBD STL

I 0.0 I 0.1 NEW1 I 0.0 & A I 0.0

Jump if NEW1 A I 0.1

RLO=1 (JMP) I 0.1 JMP JC NEW1

Jump if I 0.2 I 0.3 I 0.2 & A I 0.2

NEW2 NEW2

RLO=0 A I 0.3

(JMPN) I 0.3 JMPN JCN NEW2

SIMATIC® S7 Date: 03.09.2018 SITRAIN Training for

Automation and Drives

Siemens AG 2003. All rights reserved. File: SERV1_09E.21

You might also like

- Hardware Configuration: Simatic S7Document25 pagesHardware Configuration: Simatic S7Neagoe CristianNo ratings yet

- PRO2 - 11E - Solution SuggestionsDocument61 pagesPRO2 - 11E - Solution SuggestionsmikeNo ratings yet

- PRO1 10E IntroductionMicromasterDocument22 pagesPRO1 10E IntroductionMicromasterSeVictor Rudas CajaNo ratings yet

- PRO2 01eDocument14 pagesPRO2 01eghita_gabrielNo ratings yet

- Serv1 06e HW ComDocument16 pagesServ1 06e HW ComNeagoe CristianNo ratings yet

- SITRAIN Schedule 2011 1st HalfDocument3 pagesSITRAIN Schedule 2011 1st HalfJohn Arllan DiestroNo ratings yet

- Infoplc Net Sitrain04 Hardware ConfigurationDocument32 pagesInfoplc Net Sitrain04 Hardware ConfigurationBijoy RoyNo ratings yet

- Documenting, Saving, Archiving: Simatic S7Document22 pagesDocumenting, Saving, Archiving: Simatic S7Neagoe CristianNo ratings yet

- SERV1 01e SystemFamilyDocument19 pagesSERV1 01e SystemFamilyNeagoe CristianNo ratings yet

- Training Courses For SIMATIC S7-1500 in The TIA PortalDocument2 pagesTraining Courses For SIMATIC S7-1500 in The TIA PortalAssaad100% (1)

- Debug and Start-Up: Simatic S7Document24 pagesDebug and Start-Up: Simatic S7Ahmed KhairyNo ratings yet

- Programming Steps and Transitions: Simatic S7Document21 pagesProgramming Steps and Transitions: Simatic S7Irfan GaniNo ratings yet

- PRO1 13E Organzation BlocksDocument14 pagesPRO1 13E Organzation BlocksLộc QuangNo ratings yet

- Infoplc Net Sitrain 06 SymbolicDocument14 pagesInfoplc Net Sitrain 06 SymbolicBijoy RoyNo ratings yet

- SERV1 13e SolutionsDocument25 pagesSERV1 13e SolutionsNeagoe CristianNo ratings yet

- 04 STARTER Connection To Target Device en - IDESA - BRASKEMDocument41 pages04 STARTER Connection To Target Device en - IDESA - BRASKEMADRIANA ESCOBAR HERNANDEZNo ratings yet

- Digital Operations: CMP IDocument34 pagesDigital Operations: CMP INeagoe CristianNo ratings yet

- d10 cp342 Et200l PDFDocument24 pagesd10 cp342 Et200l PDFMazarel AurelNo ratings yet

- SERV1 05E SymbolicDocument14 pagesSERV1 05E SymbolicAhmed KhairiNo ratings yet

- d05 Cpu315 Et200s PDFDocument34 pagesd05 Cpu315 Et200s PDFMazarel AurelNo ratings yet

- d11 cp342 cp342 PDFDocument38 pagesd11 cp342 cp342 PDFMazarel AurelNo ratings yet

- 1day Plc2013 01 PLC IntroDocument27 pages1day Plc2013 01 PLC IntroasapNo ratings yet

- 03 Control Units and Additional System Components en - IDESA - BRASKEMDocument29 pages03 Control Units and Additional System Components en - IDESA - BRASKEMADRIANA ESCOBAR HERNANDEZNo ratings yet

- SERV1 04e SIMATICManagerDocument18 pagesSERV1 04e SIMATICManagerNeagoe CristianNo ratings yet

- Positioning of The Modular S7 Controllers ........................................................... 1-2Document16 pagesPositioning of The Modular S7 Controllers ........................................................... 1-2MiguelGonzalezNo ratings yet

- IK-TIAPN 06E Topology-EditorDocument30 pagesIK-TIAPN 06E Topology-EditorinvictaecventasNo ratings yet

- SISTRAIN PRO3 02E FBs Multi Instances - 2 PDFDocument32 pagesSISTRAIN PRO3 02E FBs Multi Instances - 2 PDFSam eagle goodNo ratings yet

- PRO1 02E Training UnitsDocument11 pagesPRO1 02E Training UnitsLộc QuangNo ratings yet

- WCC en-USDocument7,346 pagesWCC en-USCésar TapiaNo ratings yet

- Sce 142 100 Industrial Ethernet Xc208 r1906 enDocument68 pagesSce 142 100 Industrial Ethernet Xc208 r1906 endanko1du2458No ratings yet

- PRO1 02E Training UnitsDocument10 pagesPRO1 02E Training UnitsMarinel MoraruNo ratings yet

- 1SIMATIC TIA Flyer en Verlinkt FinalDocument20 pages1SIMATIC TIA Flyer en Verlinkt FinaldaywalkeryNo ratings yet

- Brochure Course TIA Portal Wincc (TIA-WCCM)Document2 pagesBrochure Course TIA Portal Wincc (TIA-WCCM)Olga FireAgentNo ratings yet

- 01 1 SIN Komp - Po-Mod - EDocument21 pages01 1 SIN Komp - Po-Mod - EFelipe Polix BarbosaNo ratings yet

- Sce 142 200 Industrial Security s615 r1906 enDocument59 pagesSce 142 200 Industrial Security s615 r1906 enQuang LêNo ratings yet

- HW Config: Simatic Pcs 7Document25 pagesHW Config: Simatic Pcs 7Ali PadaryamNo ratings yet

- Sinamics Drivesim Basic Doc v105 enDocument136 pagesSinamics Drivesim Basic Doc v105 enJordan Pintado100% (1)

- System Overview: Simatic HmiDocument21 pagesSystem Overview: Simatic HmiEngenheiro AmoedoNo ratings yet

- Siemens Indirect Addressing & MessagesDocument2 pagesSiemens Indirect Addressing & MessagesM Saad KhulsaiNo ratings yet

- G120 Fieldbus FCT Man 0418 en-US PDFDocument244 pagesG120 Fieldbus FCT Man 0418 en-US PDFWilson Barco MNo ratings yet

- Digital Operations: Simatic S7Document35 pagesDigital Operations: Simatic S7SeVictor Rudas Caja100% (1)

- SitrainDocument20 pagesSitrainAhmed KhairyNo ratings yet

- 5-Tia Micro1 05e PLC TagsDocument24 pages5-Tia Micro1 05e PLC TagsFernando LeonNo ratings yet

- SERV1 17E TrainingAndSupportDocument10 pagesSERV1 17E TrainingAndSupportHayashi JimenezNo ratings yet

- CoverDocument1 pageCoversokol_poleceNo ratings yet

- S120 Startdrive Commiss Man 0620 en-USDocument366 pagesS120 Startdrive Commiss Man 0620 en-USMarian ChobodaNo ratings yet

- Simatic Manager SoftwareDocument18 pagesSimatic Manager SoftwareEssamNo ratings yet

- 01 IK IESYS e Communications OverviewDocument12 pages01 IK IESYS e Communications OverviewHernando AlborNo ratings yet

- Infoplc Net Sitrain 15 Documenting Saving ArchivingDocument26 pagesInfoplc Net Sitrain 15 Documenting Saving ArchivingBijoy RoyNo ratings yet

- BR IE Switches enDocument26 pagesBR IE Switches enHugo Patricio Roco CastroNo ratings yet

- SERV1 14e What's NextDocument22 pagesSERV1 14e What's NextNeagoe CristianNo ratings yet

- 10 Working With SCL PDFDocument16 pages10 Working With SCL PDFAZMNo ratings yet

- 7 Binary OperationsDocument23 pages7 Binary Operationshaftu gideyNo ratings yet

- Binary & Logic OperationDocument16 pagesBinary & Logic OperationEssamNo ratings yet

- 05 Binary Operations - R01Document14 pages05 Binary Operations - R01thaibkproNo ratings yet

- Binary Operations: Simatic S7Document22 pagesBinary Operations: Simatic S7mhaioocNo ratings yet

- PRO1 08E Digital OperationsDocument29 pagesPRO1 08E Digital OperationsLộc QuangNo ratings yet

- Bai Tap 1-12Document16 pagesBai Tap 1-12hoiphiho2No ratings yet

- Binary & Logic Operation: SiemensDocument16 pagesBinary & Logic Operation: SiemensjhuskanovicNo ratings yet

- SERV1 14e What's NextDocument22 pagesSERV1 14e What's NextNeagoe CristianNo ratings yet

- SERV1 09e BinaryOpDocument21 pagesSERV1 09e BinaryOpNeagoe CristianNo ratings yet

- SERV1 13e SolutionsDocument25 pagesSERV1 13e SolutionsNeagoe CristianNo ratings yet

- Rewiring A User Program: Simatic S7Document16 pagesRewiring A User Program: Simatic S7Neagoe CristianNo ratings yet

- Documenting, Saving, Archiving: Simatic S7Document22 pagesDocumenting, Saving, Archiving: Simatic S7Neagoe CristianNo ratings yet

- Block Architecture and Block Editor: OB1 FB FC FBDocument25 pagesBlock Architecture and Block Editor: OB1 FB FC FBNeagoe CristianNo ratings yet

- SERV1 09e BinaryOpDocument21 pagesSERV1 09e BinaryOpNeagoe CristianNo ratings yet

- Digital Operations: CMP IDocument34 pagesDigital Operations: CMP INeagoe CristianNo ratings yet

- Digital Operations: CMP IDocument34 pagesDigital Operations: CMP INeagoe CristianNo ratings yet

- PRSERV - 05E - SW Commissioning and TroubleshootingDocument12 pagesPRSERV - 05E - SW Commissioning and TroubleshootingNeagoe CristianNo ratings yet

- Instructor S Guide ST-7PRSERV, A5.2: Project Structure - SolutionsDocument2 pagesInstructor S Guide ST-7PRSERV, A5.2: Project Structure - SolutionsNeagoe CristianNo ratings yet

- Profibus Diagnostic PDFDocument10 pagesProfibus Diagnostic PDFNeagoe CristianNo ratings yet

- SERV1 01e SystemFamilyDocument19 pagesSERV1 01e SystemFamilyNeagoe CristianNo ratings yet

- SERV1 04e SIMATICManagerDocument18 pagesSERV1 04e SIMATICManagerNeagoe CristianNo ratings yet

- Introduction To PROFIBUS and Profinet: Andy Verwer Technical Officer For PROFIBUS UK Verwer Training & Consultancy LTDDocument31 pagesIntroduction To PROFIBUS and Profinet: Andy Verwer Technical Officer For PROFIBUS UK Verwer Training & Consultancy LTDNeagoe CristianNo ratings yet

- Solutions For Exercises Simatic S7Document44 pagesSolutions For Exercises Simatic S7Neagoe CristianNo ratings yet

- Creating A Program For An Assembly Line: Simatic S7Document24 pagesCreating A Program For An Assembly Line: Simatic S7Neagoe CristianNo ratings yet

- Information and Training Automation and Drives PDFDocument345 pagesInformation and Training Automation and Drives PDFNeagoe Cristian100% (1)

- 08 Symbols Simatic S7Document15 pages08 Symbols Simatic S7Neagoe CristianNo ratings yet

- SAP Testing Roles and ResponsibilitiesDocument3 pagesSAP Testing Roles and ResponsibilitiesAnonymous 0wXXmp1No ratings yet

- Deposit EP BVADocument3 pagesDeposit EP BVAThirunavukarasuMunusamyNo ratings yet

- Solution Manual Classical MechanicsDocument14 pagesSolution Manual Classical MechanicsAgyeman Emmanuel10% (71)

- Artificial NetworkDocument9 pagesArtificial NetworkMaliha IslamNo ratings yet

- MPS & MRPDocument41 pagesMPS & MRPdeliciousfood96No ratings yet

- Evaluation of Management ThoughtDocument15 pagesEvaluation of Management ThoughtRayon100% (1)

- Control TheoryDocument11 pagesControl TheorySyedAhsanKamalNo ratings yet

- Share '6. The General Systems Model of The Firm - PPT'Document17 pagesShare '6. The General Systems Model of The Firm - PPT'khannakasNo ratings yet

- AutomationDocument18 pagesAutomationGanesh ChodisettiNo ratings yet

- The NAFEMS World CongressDocument3 pagesThe NAFEMS World Congressalagarg137691No ratings yet

- Thermodynamics: The Second Law of ThermodynamicsDocument41 pagesThermodynamics: The Second Law of ThermodynamicsEgis KrismaNo ratings yet

- Ch1 - Introduction To SCADA SystemsDocument15 pagesCh1 - Introduction To SCADA Systemsgrand_ammarNo ratings yet

- The Computational MindDocument11 pagesThe Computational Mindapi-291710774No ratings yet

- Single Layer Perceptron Learning Algorithm and Flowchart of The Program and The Code of The Program in CDocument8 pagesSingle Layer Perceptron Learning Algorithm and Flowchart of The Program and The Code of The Program in CSuchita GuptaNo ratings yet

- ADP04Document29 pagesADP04Nam NamNo ratings yet

- Dynamic Soil-Structure Interaction Analysis of Buildings by Neural NetworksDocument13 pagesDynamic Soil-Structure Interaction Analysis of Buildings by Neural NetworksmanjubondNo ratings yet

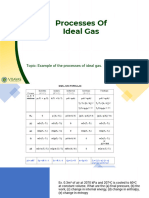

- Ideal Gas Processes ExampleDocument14 pagesIdeal Gas Processes ExampleMary Joy AlmerenoNo ratings yet

- TOCBooksDocument15 pagesTOCBooksinfaredmailmanNo ratings yet

- Combating TCP Port Scan Attacks Using Sequential Neural NetworksDocument16 pagesCombating TCP Port Scan Attacks Using Sequential Neural Networksvenkata karthikNo ratings yet

- AGVDocument32 pagesAGVitzgayaNo ratings yet

- INTRO To MaintenanceDocument76 pagesINTRO To MaintenancehwhhadiNo ratings yet

- 5.6 Notes On Material Requirements PlanningDocument2 pages5.6 Notes On Material Requirements PlanningsaisenthNo ratings yet

- Rex On Se Approach Implementation in AlstomDocument13 pagesRex On Se Approach Implementation in Alstomrakesh.parmarNo ratings yet

- Exercises 05 Block Diagram ReductionDocument3 pagesExercises 05 Block Diagram ReductionKabo MphanyaneNo ratings yet

- DSP - VlsiDocument1 pageDSP - VlsiGayathri SrinivasaNo ratings yet

- Effect of The Internet-Of-Things On Fire Control and Weapon SystemsDocument20 pagesEffect of The Internet-Of-Things On Fire Control and Weapon SystemsMimidbe BibiNo ratings yet

- Kinetic Theory of Gases and ThermodynamicsDocument19 pagesKinetic Theory of Gases and ThermodynamicsTimothy SaxenaNo ratings yet

- FeedbackDocument54 pagesFeedbackRan XanNo ratings yet

- ISTQB Sample Paper # 1Document52 pagesISTQB Sample Paper # 1SanchitNo ratings yet

- SBSP - Rnav Gnss Z Rwy 17r - Iac - 20171207Document1 pageSBSP - Rnav Gnss Z Rwy 17r - Iac - 20171207Guilherme Kazuo OgawaNo ratings yet