0% found this document useful (0 votes)

316 views46 pagesRail and Runway Engineering Guide

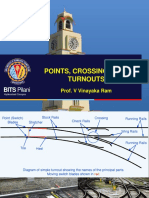

The document discusses different types of wear that can occur on railway rails, including wear on the top/head, sides, and ends of rails. It describes remedies for each type of wear such as using special alloy steel, lubricating rail surfaces, and minimizing joints. Other rail issues covered include rail corrugations, hogging, buckling, and failures. Components of turnouts like points, crossings, and their parts are also defined.

Uploaded by

Nawaz AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

316 views46 pagesRail and Runway Engineering Guide

The document discusses different types of wear that can occur on railway rails, including wear on the top/head, sides, and ends of rails. It describes remedies for each type of wear such as using special alloy steel, lubricating rail surfaces, and minimizing joints. Other rail issues covered include rail corrugations, hogging, buckling, and failures. Components of turnouts like points, crossings, and their parts are also defined.

Uploaded by

Nawaz AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd