Professional Documents

Culture Documents

07 Fuel Oil Systems

Uploaded by

Rajesh Prince0 ratings0% found this document useful (0 votes)

7 views54 pagesOriginal Title

07 Fuel Oil Systems.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views54 pages07 Fuel Oil Systems

Uploaded by

Rajesh PrinceCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 54

• This fuel is not suitable for burning directly in the

diesel engine because it has some solids and

water as impurity, which may cause damage to

the engine parts and also has a very high

viscosity, which makes it difficult for atomization

of fuel in the combustion process. To make this

fuel suitable for burning, it has to go through a

conditioning process consisting of settling,

centrifuging, boosting of pressure, filtering and

heating.

Fuel Oil Systems

Heavy residual fuel consists of

residues left after lighter and costlier

distillates fuels and gases are removed

from petroleum crude oil in an oil

refinery. Marine diesel engines are

designed to burn heavy residual fuel

blended with distillate gasoil to meet

the specification of fuel oil ordered,

especially viscosity and density. This is

popularly known as “heavy fuel oil”.

Fuel oil supply system of a ship.

Specification Data for Fuel Oil

• (a) Density: It is the relationship between mass

and volume at 15C and is measured by

hydrometer. This value changes with

temperature, depending upon the coefficient of

expansion of the substance. For marine fuels the

values are 800-1010 kg/m3.Knowledge of

density is needed for quantity calculations and to

select the optimum size of gravity disc for

purifiers. 991 kg/m3 is the accepted limit for

normal centrifugal purification and 1010 kg/m3 in

ALCAP purifier.

• As already mentioned density is the ratio of the

mass of a substance to its volume, but not its

weight to volume ratio and therefore, density by

definition is in vacuo. The term ‘density in air”,

although often used, is incorrect and should be

referred to as “weight factor”. This is due to the

fact that a substance weighed in air is

supported, to a small extent, by the buoyancy of

the air acting on it. In effect therefore, the weight

of a liquid in air is slightly less than its weight in

vacuo.

• Viscosity : Viscosity can be termed as resistance to

flow. Viscosity is measured in a viscosimeter. The

kinematic viscosity is obtained by dividing dynamic

viscosity by density of the fluid and its unit of

measurement is stoke or centistoke and is quoted with a

reference temperature. For distillate fuels the reference

temperature is 40C and for residual fuels the reference

temperature is usually 50C or 100C. Each fuel has its

own temperature viscosity relationship and although oil

suppliers publish temperature/viscosity charts, it should

be understood that these charts are based on average

data of large number of representative fuels. Precise

relationship would depend upon crude oil source and

refining process. In general, for lower viscosity fuels the

difference is small, but it becomes wider as viscosity of

the fuel increases. A knowledge of viscosity is necessary

for the determination of the heating required for a fuel for

transfer purpose and the temperature range required for

satisfactory injection and combustion at the fuel

atomiser.

• In order to ensure efficient atomization of the charge,

when burning residual fuels it is essential to inject the

fuel at the most suitable viscosity. Despite wide

differences in engine and fuel system designs there is

considerable agreement that the most suitable viscosity

of the fuel leaving the injector nozzle lies between 12.5 -

18.0 cSt. In well designed systems, the viscosity is

controlled automatically within fairly close limits by

means of viscosity controllers.

• Pressure/viscosity characteristics : The viscosity of

hydrocarbon oils increases under pressure. The very

high fuel injection pressures now employed will increase

the fuel viscosity markedly. This should be allowed for

when preheating the fuel.

• Cloud and pour points : The cloud point

of a distillate fuel is the temperature at

which wax starts to crystallise out, and this

is seen when the clear fuel becomes

opaque. For marine fuels this

characteristic is only applicable to some

light grades.

• The pour point of an oil is the lowest

temperature at which the oil remains fluid.

It is determined by cooling the oil in a test

tube having a diameter of approx 30 mm.

The pour point is 3C higher than the

temperature at which the glass can be

held in the horizontal position for 5 second

without any visible signs of movement of

the oil surface.(Solidifying temperature is

3C below pour point). The pour point

result will give guidance regarding the

lowest temperature at which a fuel may be

stored. If fuels are held at temperatures

below pour point, wax will begin to

separate out.

• This wax may cause blocking of filters and can

deposit on heat exchangers. In severe cases the

wax will build up in storage tank bottom and on

heating coils, which can restrict the coils from

heating the fuel. When dealing with heavy

marine fuels, both the pour point and the

viscosity of the fuel need to be considered, if the

fuel is to be maintained at a temperature to

prevent wax formation and allow pumping. For

efficient pumping the viscosity of the fuel should

not be above approximately 600 cSt. If the

suction line from the pump to the tank is very

long the viscosity should be lower.

• Flash Point: The flash point of a fuel is the lowest

temperature at which sufficient vapour is given off to

produce a flash on application of flame under specified

test condition. The flash point may be measured as a

closed or open cup figure and for marine fuels the closed

cup figure is used. The test method uses the Pensky-

Marten apparatus. The minimum flash point for fuel in

the machinery space of a merchant ship is 60C. For

fuels used for emergency purposes, external to the

machinery space, for example the lifeboats, the flash

point must be greater than 43C. The purpose of defining

a minimum flash point is to minimise fire risk during

normal storage and handling. The general rule is that

fuels should not be heated above 10C below the flash

point, unless specific requirements are met. (Solas

Chapter II-2, Regulation 15)

• Fire Point : It is the lowest temperature at which

vapour is generated at a rate sufficient to sustain

combustion for 5 second. The same equipment

which is used for determining flash point is used

for this test also.

• (f) Auto-ignition temperature or Self ignition

temperature : It is the lowest temperature at

which the generated vapour will ignite

spontaneously without any source of ignition.

• Calorific Value or Heat of Combustion or

Specific Energy : Heat of combustion of a fuel

is the amount of heat released during

combustion of a unit mass under following

circumstances:

• (a) The temperature of fuel before combustion

and that of the combustion products after

combustion is 20C.

• (b) The combustion products from carbon and

sulphur are solely gaseous carbon dioxide and

sulphur dioxide and no oxidation of nitrogen has

occurred.

• In gross heat of combustion, the water existing before

combustion as well as the water generated by the

combustion process is to be found in the combustion

products in liquid state. In net heat of combustion the

above mentioned water is to be found in the form of

vapour at 20C. The gross heat of combustion can be

determined by Berthlot-Mahler calorimeter. The net heat

of combustion(hi) is calculated if the gross heat of

combustion(hs) is known. hi = hs - 25 (f+w) kJ/kg

where water content of fuel is f% by mass, and that w%

by mass of water is generated by combustion of

hydrogen in fuel.

• Heat of combustion can be calculated with a degree of

accuracy sufficient for normal purposes from the density

of the fuel and the application of corrections for any

sulphur, water and ash that are present. On a world-wide

basis the heat of combustion does vary slightly,

depending mainly on density and sulphur content of the

fuel.

• Water - Normally the water content in the

fuel oil is very low and 0.1-0.2% by volume

is typical. Ingress of water can come from

tank condensation, tank leakage and

heating coil leakage. Water is normally

removed by gravitational separation in fuel

oil tanks and centrifugal purification

system.

• Ash : Nickel, Aluminium, Silicon, Sodium and

Vanadium

• The ash content is defined as the residue left after all the

combustible components of the oil has been burnt. In

distillate fuel this quantity is negligible. The ash

constituents are concentrated in residual fuels. The ash

consists generally of oxides and/or sulphates of nickel,

aluminium, silicon, sodium and vanadium. The sources

of these are (a) inorganic material naturally present in

the crude oil, (b) Catalytic fines picked during refining

process ( Catalytic fines are particles arising from the

catalytic cracking process in the refinery and are in the

form of complex alumino-silicates) (c) Contamination by

sand, dirt, rust scale and sea water subsequent to

refining process.

• Sodium and Vanadium - Fuels leaving refinery have

sodium level below 50 mg/kg. If contaminated with

sea water subsequently, sodium level will increase. A

1% sea water contamination represents a potential

100 mg/kg increase. Normally sea water can be

removed by gravitation separation in settling tank

and centrifugal separation. Vanadium is present in

all crude oils in an oil soluble form and the levels

found in residual fuels depends mainly on the crude

oil source, with those from Venezuela and Mexico

having the highest levels. The actual level is also

related to the concentrating effect of the refining

processes used in the production of the residual

fuel. There is no economic process for removing

vanadium from either the crude oil or residue.

• During combustion of the fuel, vanadium and

sodium constituents form a mixture of sodium

sulphate and vanadium pentoxide. This mixture has

a low melting point (approx 500-600C)

corresponding to the temperature of the exhaust

valve seating. The semi-fluid particles of ash adhere

firmly to the surfaces they touch, gradually forming a

very hard, thin layer of slag which, after having

reached a certain thickness, allows the hot

combustion gases to leak out, the result being that

the slag melts forming a narrow channel. If the layer

of slag is of sufficient thickness, the channel grows

and the combustion gases heat up the seating

material, causing what is known as high-temperature

oxidation, which in turn results in the seating

material melting in the vicinity of the channel. The

most critical sodium to vanadium ratio is about 1 to

3.

• Silicon and aluminium :Silicon may be present in the fuel

in form of sand and aluminium may also be present in

very small quantities, having been picked up by the

crude oil in sub-surface rocks. However presence of

aluminium and silicon is mainly due to catalytic fines

discussed earlier. Catalyst is an expensive material for

the oil refiner and stringent methods are taken for its

retention but some still find their way in residual fuel.

Excessive catalytic fines can lead to high wear of piston

rings and liners, fuel pump barrels and plungers, and fuel

injector nozzle needle and guide. The level of catalytic

fines in delivered fuels can be significantly reduced by

efficient centrifugal purification prior to combustion in the

engine.

• Carbon Residue: The carbon residue of a fuel

is the tendency to form carbon deposits under

high temperature conditions in an inert

atmosphere, and may be expressed as either

Ramsbottom carbon residue, Conradson carbon

residue (CCR) or micro carbon residue (MCR).

This parameter is considered by some to give an

approximate indication of the

combustibility/deposit forming tendency of the

fuel.

• Sulphur: Sulphur is naturally occurring element

in crude oil which is concentrated in the residual

component. The amount of sulphur in fuel oil

depends mainly on the source of crude oil and to

a lesser extent on the refining process. Sulphur

content is typically 1.5-4% wt in residual fuel

world wide. In the combustion process in a

diesel engine the presence of sulphur in the fuel

can give rise to corrosive wear. This can be

minimised by suitable operating conditions, and

suitable lubrication of the cylinder liner with

alkaline lubricant. MARPOL Annex VI limits the

sulphur content of marine oil to reduce

atmospheric pollution, in the form of sulphur

dioxide, from international shipping.

Amendment to Marpol Annex VI

• Regulation 14 of MARPOL Annex VI has

been significantly revised. For the Global

Cap, the sulphur content limits are as

follows:

• 4.5% prior to 1 January 2012

• 3.50% on and after 1 January 2012

• 0.50% on and after 1 January 2020

Special Emission Control Areas

• For the Special Emission Control Areas,

the sulphur content will be as follows:

• 1.50% prior to 1 March 2010

• 1.00% on and after 1 March 2010

• 0.10% on and after 1 January 2015

• The existing Emission Control Areas

(ECAs) are the North Sea and the Baltic

Sea.

Review provision

• The amended Regulation 14 has a “review

provision” which requires the IMO to

complete by 2018 a review of the

availability of the 0.50% sulphur content

fuel. Based on the results of such a

review, the Parties to MARPOL Annex VI

will decide whether the global cap of

0.50% can be enforced from 1 January

2020. If not, the 0.50% sulphur global cap

will be enforced on 1 January 2025 without

any additional review.

• Ignition Quality : Cetane number - The cetane

number for any fuel is a measure of the oil’s

readiness to ignite, under conditions prevailing

in the diesel engine. This number is determined

by comparing the oil with a mixture of cetane

and heptamethylnanone. Cetane, which has a

very high spontaneous combustion ability is

rated at 100 and the corresponding cetane

number for heptamethylnonane is 15. The oil for

which cetane number is to be determined is

used as fuel in a so-called CFR (Co-operation

Fuel Research) engine, which is a single

cylinder diesel engine with a variable and

controllable compression ratio.

• Fuel injection and combustion timing are controlled by

electronic equipment. When these have been

determined then engine is run with different mixtures of

of cetane and heptamethylnanone until a mixture gives

same results. Cetane number = a -0.15 x b, where a is

the volume % of cetane and b the volume % of

heptamethylnanone. For high speed diesel engines, a

cetane number of over 50 is desirable. Medium speed

diesel engines require a fuel with a cetane number of

around 40-50. Large, slow speed diesel engines operate

satisfactorily with fuels having a cetane number of

approx 30. However slow speed engines are said to be

not so sensitive to with regard to the cetane number and

it is not normally specified for these engine types.

• (b) Calculated Ignition Index (CII) and Calculated Carbon

Aromatic Index(CCAI) :These are calculated by

empirical equations ,where use is made of the density

and viscosity of the residual fuel.

Standards of Fuels - Need for

quality control in bunker fuel

• The cost of bunker fuel is one of the most

significant components of a ships operating cost.

Ship owners in their effort to limit this cost have

preferentially turned to the use of heavier and

thus less expensive bunker fuels. Technology

developments in petroleum refining, such as in

vacuum distillation, catalytic cracking etc, often

result in a deterioration of the characteristics of

heavy fuels as lesser volumes of residues are

left after petroleum refining.

• These residuals may contain elevated levels of

undesirable constituents such as Aluminium and

Silicon, compounds that could result to

significant engine wear and damage. In addition

to the above the supply of marine bunker fuels is

nowadays often the result of a complex

sequence of buying, selling and mixing of fuels

of different origins. The use of poor quality fuel is

known to result to the serious damage of boilers,

fuel pumps springs, pistons and cylinders.

ISO 8217

• During 2005 and 2006 the set of regulations included in

MARPOL Annex VI that relate to the use of the marine

bunker fuels came into effect. The sampling of the

bunkered fuels became mandatory, following a detailed

list of requirements listed in the above document and in

the MEPC.96(47) IMO document.

• To obviate dispute between ship owners and bunker

suppliers and also to meet MARPOL Annex VI

requirements, International Organisation for Standards

published the first edition of International fuel

specification ISO 8217 known as “Petroleum products -

Fuels (class F) - Specifications of marine fuels” in 1987.

It was revised in 1996 and again in 2005. ISO 8217-2005

defines four distillate grades (DMX, DMA, DMB, DMC)

and ten residual grades.

• Distillate grades remain same and the main changes are

in marine residual fuels:

• Reduction of residual fuel grades from 15 to 10 - With

the viscosity classification of residual fuel grades being

measured at 50 °C (instead of 100°C as under ISO

8217-1996), the names of the 10 residual fuel grades

have been changed as follows – RMA30, RMB30,

RMD80, RME180, RMF180, RMG380RMH380,

RMK380, RMH700 AND RMK700.

• Maximum sulphur limit reduced to 4.5% - for all the

residual fuel grades with viscosity higher than that of

RMD 80. For RMA, RMB and RMD grades the previous

lower sulphur limits have been retained.

• Fuel to be free of ULO (used lubricating oil)

• Reduced water content - from 1.0%v to 0.5%v.

• Reduced ash content

CATEGORY ISO - F

LIMI

CHARACTERISTIC DM DM DMB DMC(a)

T

X A

Density at 15°C (Kg/m3) max. --- 890,0 900,0 920,0

(mm2/s min. 1,40 1,50 --- ---

Viscosity at 40°C

b) max. 5,50 6,00 11,0 14,0

Flash Point (°C) min. 43 60 60 60

Sulfur (% m/m) max. 1,00 1,50 2,00 2,00 (e)

(e)

Cetane index min. 45 40 35 ---

Carbon residue (%m/m) max. --- --- 0,30 2,50

Carbon res. on 10% (V/V) distillation (% m/m) max. 0,30 0,30 --- ---

bottoms

Ash (% m/m) max. 0,01 0,01 0,01 0,05

Appearance (f) Clear and (f) ---

bright

Total Sediment Existent (% m/m) max. --- --- 0,10 0,10

(f)

Water (% V/V) max. --- --- 0,3 (f) 0,3

Vanadium (mg/kg) max. --- --- --- 100

Aluminum plus silicon (mg/kg) max. --- --- --- 25

Aluminum plus silicon (mg/kg) max. --- --- --- 25

Used lubricating oil (ULO) The fuel shall be free of ULO

1.Zinc ____ ____ (g) 15

mg/kg max. _____

2.Phosphorus _ _ 15

3.Calcium 30

• Fuel Testing: Analysis of particular

characteristics of the fuel delivered may be

carried out by some independent shore based

laboratory or by tests carried out on board.

Testing of fuel on board may range from one or

two tests to fully automated online monitors

where direct read out of viscosity, density and

elemental analysis (e.g. sulphur, silicon,

vanadium) as well as derived parameters such

as ‘ignition index’ expressed as CII or CCAI are

available.

• Storage and Transfer : The pump for fuel transfer is of

the positive displacement type and are usually of screw

or gear design. The temperature of fuel in the storage

should be maintained 5C above its pour point otherwise

there is a possibility of wax formation and in case of high

wax content, if left to cool, it may be difficult to reheat the

fuel to a temperature above the pour point. Also the

temperature has to be raised for higher viscosity fuel to

45C to bring it below 500 cSt for pumping it. Fuel oil is

heated in storage tanks by low pressure steam, but in

some ships thermal fluid heating is used.

STORAGE

• Bunkering: Marine heavy fuel oils are blends of

viscous residues from various refinery operations,

cut back with distillate cutter stock. The growing

trend is towards cracked residues of a highly

aromatic/asphaltic nature to be cut back to an

acceptable viscosity with cracked aromatic

distillates. Both components have a high

carbon/hydrogen ratio, cracked distillates having

good solvency properties for large-asphaltene

hydrocarbons. In a stable fuel the asphaltenes are

carried in a colloidal dispersion in the lighter phase.

If the equilibrium between the two phases is

disturbed the asphaltene will agglomerate to a size

which can no longer be maintained in suspension,

and they will tend to separate out as ‘sludge’. If

sludge deposition does occur this is made worse,

not better, by the addition of more distillate,

• This is particularly true if a high-quality straight-run

paraffinic distillate is added to a cracked, high

asphaltenic content, residual fuel. It is possible that

two residual fuels, each stable by themselves, when

mixed together can prove to be incompatible and

throw down objectionable sludge or sediment. If

compatibility tests have not been carried out

beforehand, when bunkering, every effort should be

made to segregate bunkers from different source in

different tanks to avoid potential problems of

incompatibility. In such a case an unstable blend

may occur in the ship’s tanks, which could result in

precipitation of asphaltenic deposits as sludge in the

tanks, pipes, filters and centrifuges.

TREATMENT OF FUEL OIL

• Before the fuel is burnt in diesel engine or a

boiler, a shipboard treatment takes place.

Distillate fuels are generally filtered through a

coalescer type filter to remove water and solid

impurities. For boilers burning residual fuels, in

addition to settling tanks, cold and hot filters are

installed in the system prior to boiler. In case of

diesel engines burning residual fuel, in addition

to settling tanks and filters, centrifuges are

installed to clean the fuel to take account of the

fine clearances which exist in fuel system of

diesel engine.

• Treatment of High Density Fuel: As the density

of fuel oil increases and exceeds 991kg/m3, the

density difference between the fuel oil and fresh

water is so small that any change in oil

temperature, viscosity or flow rate will cause the

oil/water interface to fluctuate leading to a

potential failure of water seal. For residual fuel

having density above 991 kg/m3, alternative

arrangements to traditional purifier are used.

One such arrangement called ALCAP system is

used, where fuels of density upto 1010 kg/m3

can be treated. The centrifuge operates as a

clarifier and clean oil is continuously discharged

from clean oil outlet, and any free water and

separated sludge accumulate at the periphery of

the bowl.

• When the sludge space is filled up, the

separated water approaches the disc and traces

water start to escape with clean oil. Increased

water content in clean oil is sensed by the water

transducer in the clean oil outlet side. The

electrical signal from water transducer are

continuously transmitted to and interpreted by

the control unit. When the water content in clean

oil reaches a specific ‘trigger’ point, the control

unit determines, based on the time elapsed

since the last sludge sequence, which of the two

methods it will use to empty the bowl. This can

either be through a water drain valve or with the

sludge through the sludge ports at the periphery

of the bowl.

• Fuel Heating : Residual fuels have to be heated

to reduce the viscosity to that required for

atomisation. In case of boilers this is in the range

of 15-65 cSt, whilst for diesel engines the

injection viscosity is usually 12.5 -18 cSt. Fuel

heaters may be operated by low pressure

saturated steam, a thermal fluid or electrical

elements. It is important to maintain correct

viscosity range under all conditions. Local

overheating may cause cracking of fuel, which

may lay down deposits on the heating surface,

impairing efficient operation of the heater.

• Viscosity Controller : A viscosity controller

is often installed downstream of a fuel oil

heater so that a constant injection

viscosity can be maintained. There are

various types of these. One of these

measures the differential pressure

resulting from laminar flow through a

capillary tube and compares this value to a

set point, generating a signal to control the

temperature of fuel oil heater.

• Additives :There are two types of additives: (a) Which

reduce problem in pre-combustion phase

• (b)Which react during post combustion phase

• (a)With normal fuel handling procedures, with respect to

correct heating, and avoidance of mixing of fuels from

different bunkering, no problem should occur. In the

event of problems, an effective additive should

contribute as follows :

• (1) Dispersion of possible sludge in fuel oil tanks.

• (2)Promotion of separation of any dispersed water.

• (3) Prevention of sludge formation.

• (b)An additive which has the effect of an ash modifier

(ability to raise the melting temperature of ash) may be

beneficial. Slagging and high temperature corrosion

occurs when molten ash adheres to the metal surface.

By increasing the melting temperature the ash is not in

molten form and less likely to stick to metal surfaces.

Combustion In Diesel Engine

• For combustion of fuel in a diesel engine, the air charge

is highly compressed to a temperature well above the

spontaneous ignition temperature (SIT) of the fuel. As

the piston approaches TDC fuel is injected at high

pressure and suitable viscosity. This continues for 14-28

degrees of crankshaft rotation, depending upon engine

speed and design. The fuel passes through the following

phases :

1. A delay period between the commencement of injection

of the very finely divided fuel droplets and the

commencement of ignition.

2. Rapid combustion of the fuel accumulated in the cylinder

during the initial delay period, accompanied by a rise in

pressure.

3. Steady combustion of the remainder of the fuel charge

as it is mixed.

4. An after burning period during which remaining unburnt

fuel finds oxygen and combustion is completed.

Factors Influencing ignition

1. Exactly when ignition commences is dependent upon

several factors, the most important being:

2. The size of the droplets injected into the cylinder;

3. The pressure of the fuel at the injector tip;

4. The velocity of the droplets entering the dense air mass;

5. The air pressure and temperature in the cylinder;

6. The air turbulence in the cylinder;

7. The ignition delay properties of the fuel;

8. The surface tension of the fuel;

9. The chemical composition of the fuel;

10. The engine design.

Droplet formation and size

• The size of the droplets in the injected fuel spray is

controlled primarily by the size, shape and number of

holes in the injector tip, their position and the fuel

injection pressure and the viscosity of the fuel leaving

the injector. The higher the viscosity, the larger will be

the droplet size. As the fuel leaves the small injector

orifices at pressures in modern pressure-charged

engines of upto 1500 bar the pressure falls sharply as it

enters the cylinder, in which the charge-air pressure is

much lower. The pressure energy is converted into

kinetic energy, so that there is a sharp rise in velocity.

Both the fall in pressure and the shearing action as the

fuel passes through the dense air charge at high velocity

break up the liquid stream, while its viscosity and surface

tension form the mechanically disrupted liquid into small

droplets.

• The droplets sprayed into the cylinder are of varying

sizes; the higher the injection pressure, the higher the

percentage of small droplets. With current trend towards

much higher injection pressures fuel droplet sizes will be

reduced correspondingly. The droplet size decreases as

the compression pressure increases. The increased

density of the air charge helps to break up the spray into

smaller droplets. This is beneficial, as the smaller the

droplets, the quicker they will vaporize as there is a

greater overall area of the oil charge exposed to the hot

compressed air. This reduces the ignition delay period,

measured either in milliseconds or degrees of crank

angle.

Importance of high fuel pressure

• If the droplets leaving the injector have a diameter of

about 20-40m, there is minimum delay in combustion.

Conversely, if the droplet diameter exceeds some 100-

120m, the combustion period is so long that even a

slow-speed, two-stroke engine runs the risk of some

particles remaining unburnt when the exhaust ports or

valves open. Below 20m droplet size there is

insufficient kinetic energy in the tiny droplet to penetrate

the dense air mass in the cylinder, resulting in poor

fuel/air admixture. In order to ensure the required fine

droplet size, an injection pressure exceeding 1200 bar is

being used by some engine manufacturers.

The effect of air temperature

• The temperature of the air compressed in the cylinder

has a major effect upon ignition delay. The higher the

temperature, the shorter the delay period, everything

else being equal. Several factors determine the air

compression temperature, the main ones being the

engine compression pressure, which, in turn, is

determined by the charge air pressure, the compression

ratio and the volumetric clearance, the temperature of

the induction air entering the cylinder, and the

temperature of the cylinder head, liner and piston crown.

In turn, the combustion chamber and piston

temperatures are controlled by the temperature of the

cooling water, or oil, and by the design of the combustion

chamber and piston components. Compression

temperatures in normally aspirated engines are in the

order of 500-600C, but in modern highly pressure-

charged medium and large output engines, they may be

as high as 700C.

Compression Pressure

• Increased compression pressure (or

densities), which are now as high as 90-

110 bar in modern crosshead and trunk

piston engines, not only promote the

formation of more, smaller fuel droplets

but, equally important, reduce the

spontaneous ignition temperature of the

fuel appreciably.

Air Turbulence

• Turbulence or swirl, in the compressed air

charge promotes efficient distribution of

the fuel spray droplets throughout the

combustion chamber, ensuring thorough

mixing of the fuel and clean air (increasing

the rate of heating and vaporization) thus

tending to reduce ignition delay and

assisting in efficient burning of the fuel

charge.

Droplet combustion process

• If an individual fuel droplet is considered it will be found

to be very small, the size depending upon factors

discussed previously but, as compared with the physical

size of individual hydrocarbon molecules which form the

droplet, they are relatively large. Even the smallest

droplets in the fuel spray contain thousands of

hydrocarbon molecules having widely different chemical

structures. This is particularly true of heavy residual fuels

with high carbon-numbers. The molecules vary

appreciably in their volatility, ignition temperature, rate of

burning, the completeness of burning and their tendency

to release carbon and associated organometallic

compounds. The heating of the spherical droplet occurs

from the outer surface inwards to the centre, so that

evaporation and subsequent ignition commences at the

surface. The more volatile constituents with the lowest

ignition temperatures burn first, leaving the less

combustible hydrocarbon constituents to find clean air

and burn slowly.

Advanced injection timing

• During a long ignition delay, injection of fuel into the

cylinder continues, so that the longer the delay, the

greater is the amount injected before ignition

commences. When ignition finally occurs, the

accumulated fuel ignites violently with a very rapid, high-

pressure rise. The resultant high pressure causes shock

loading on the piston and running-gear bearings. With a

poor equivalent Cetane Number residual fuel, within

fairly narrow limits one way of reducing this harmful

effect is to advance the ignition timing. In case of low-

speed crosshead engines, upto 2 degrees crank angle

may be adequate, with a somewhat greater advance for

medium-speed engines - possibly 3 to 6 degrees,

depending upon engine design and, in particular, engine

speed. Advancing the injection timing enables ignition to

occur at maximum compression pressure and

temperature and smooth combustion to be completed

earlier in the stroke. The manufacturer's maximum firing

pressure, related to load conditions, should be

maintained.

Injector recirculation

From DO Supply

Tank Pumps

You might also like

- Marine FuelDocument17 pagesMarine FuelviviwulanNo ratings yet

- AALBORG ThermalFluidSystemDocument10 pagesAALBORG ThermalFluidSystemrafiradityaNo ratings yet

- LBFD Boat 20 (Bilge Pumping Systems)Document33 pagesLBFD Boat 20 (Bilge Pumping Systems)Mayura RanatungaNo ratings yet

- Fuel Oil Temperature Control System in Marine BoilerDocument10 pagesFuel Oil Temperature Control System in Marine BoilerArun K DasNo ratings yet

- 02 Bilge Pumping Systems: Manual Diaphragm PumpsDocument24 pages02 Bilge Pumping Systems: Manual Diaphragm PumpsAli QomariahNo ratings yet

- Sewage System Onboard ShipsDocument11 pagesSewage System Onboard ShipsRohit KakadeNo ratings yet

- Important Lube Oil PropertiesDocument3 pagesImportant Lube Oil PropertiesmavericksailorNo ratings yet

- Fresh Water Generator or Evaporator Used On Ships BRAVO 2Document5 pagesFresh Water Generator or Evaporator Used On Ships BRAVO 2Dan EzraNo ratings yet

- 6 Activities of ClassNK-LNG Fuelled ShipDocument32 pages6 Activities of ClassNK-LNG Fuelled ShipKaran Doshi100% (1)

- Chevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPDocument32 pagesChevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPNamal FernandoNo ratings yet

- Bilge Pump - SOLAS Regulations For Merchant ShipsDocument2 pagesBilge Pump - SOLAS Regulations For Merchant ShipssimNo ratings yet

- Bunkering: Fuel & Diesel Oil TanksDocument6 pagesBunkering: Fuel & Diesel Oil TanksPanagiotis MouzenidisNo ratings yet

- Mechanical Foam Type ExtinguisherDocument2 pagesMechanical Foam Type ExtinguisherAayush AgrawalNo ratings yet

- Marine Piping SystemDocument75 pagesMarine Piping SystemNguyễn Hoàng Thành100% (1)

- Troubleshooting Boiler OperationDocument5 pagesTroubleshooting Boiler OperationRahul ChandrawarNo ratings yet

- Composite BoilerDocument390 pagesComposite BoilerBogdan Florin TudorofNo ratings yet

- Chemicalcleaning For BoilerDocument16 pagesChemicalcleaning For Boilerak_thimiriNo ratings yet

- Octo Q and Ans CE PADAMDocument90 pagesOcto Q and Ans CE PADAMPadam Nabh100% (1)

- MARINE OIL SEPARATOR PPT 1st ReviewDocument12 pagesMARINE OIL SEPARATOR PPT 1st ReviewretechNo ratings yet

- Cooling Water System 1Document18 pagesCooling Water System 1anupam01013787No ratings yet

- IG Venting Termal Expansion and High RVP CargosDocument4 pagesIG Venting Termal Expansion and High RVP CargosRahulChoudharyNo ratings yet

- 3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationDocument14 pages3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationZhafira OspNo ratings yet

- Boiler Tube Failure PDFDocument8 pagesBoiler Tube Failure PDFmhd_bashiriNo ratings yet

- Steam PDFDocument467 pagesSteam PDFRavi Bhaskar100% (1)

- Boil Off GasDocument6 pagesBoil Off GasJitendra singh palNo ratings yet

- Cargo Plant GuidelinesDocument93 pagesCargo Plant GuidelinesPhani PrahladNo ratings yet

- Phase II Boiler QuestionsDocument12 pagesPhase II Boiler QuestionsNithin VargheseNo ratings yet

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- SulphurDocument0 pagesSulphurMahdi BordbarNo ratings yet

- Fuel Oil SystemDocument1 pageFuel Oil SystemMuhammadMahfudNo ratings yet

- Ship Oily Bilge Water SystemDocument8 pagesShip Oily Bilge Water SystemEyüphan UlusoyNo ratings yet

- Coc Oral Boiler Safety Valve13 PDFDocument6 pagesCoc Oral Boiler Safety Valve13 PDFshamratNo ratings yet

- MgpsDocument2 pagesMgpsSumeet SawantNo ratings yet

- INCINERATOR PresentationDocument31 pagesINCINERATOR PresentationSangharsh Rathore100% (1)

- An Oily Water SeparatorDocument3 pagesAn Oily Water SeparatorMin SoeNo ratings yet

- Marine Engineering Review (Engine)Document662 pagesMarine Engineering Review (Engine)Raymond FranciscoNo ratings yet

- Allborg BoilersDocument2 pagesAllborg BoilersHIPAP100% (1)

- Tank Cleaning Guide BP 2004Document1 pageTank Cleaning Guide BP 2004mabrouk2013No ratings yet

- Boiler Feed Water TreatmentDocument18 pagesBoiler Feed Water TreatmentBIDYUT CHAKRABORTYNo ratings yet

- Fire Control Plan IMO SymbolDocument13 pagesFire Control Plan IMO SymbolAkshay A KumarNo ratings yet

- Mep - Sox ScrubberDocument12 pagesMep - Sox Scrubbernacer zidiNo ratings yet

- Bilge Pumping SystemsDocument2 pagesBilge Pumping SystemsKhaing26No ratings yet

- 7.1 - Cooling Water SystemDocument8 pages7.1 - Cooling Water SystemSayem kaifNo ratings yet

- CO2 Flooding System or Central Bank CO2 System Is One of The Common Fixed Fire Fighting System Installed On Most of The ShipsDocument15 pagesCO2 Flooding System or Central Bank CO2 System Is One of The Common Fixed Fire Fighting System Installed On Most of The ShipsSuresh JangidNo ratings yet

- How To Prevent Crankcase Explosion On A ShipDocument40 pagesHow To Prevent Crankcase Explosion On A ShiprajishrrrNo ratings yet

- Ships PipingDocument25 pagesShips Pipinggopaltry100% (1)

- Fire Aboard ShipDocument16 pagesFire Aboard ShipAiman FikriNo ratings yet

- Marine Vapour ControlDocument3 pagesMarine Vapour Controlgatzbu81100% (1)

- Tailshaft SurveyDocument6 pagesTailshaft SurveyArun S100% (1)

- Fixed Co2 Fire Fighting SystemDocument20 pagesFixed Co2 Fire Fighting SystemMagesh ShanmughamNo ratings yet

- Raising Steam From A Cold ConditionDocument3 pagesRaising Steam From A Cold ConditionbadpplNo ratings yet

- ODMEDocument5 pagesODMEAkhil MathewNo ratings yet

- Pa ManuelDocument82 pagesPa ManuelThanh Nghị BùiNo ratings yet

- LNG - Storage - Tank - Rollover PDFDocument7 pagesLNG - Storage - Tank - Rollover PDFchemsac20% (1)

- Fireman OutfitDocument13 pagesFireman OutfitD'Landoh Palace100% (1)

- How To Operate An Oily Water SeparatorDocument2 pagesHow To Operate An Oily Water SeparatorKHOI TIMNo ratings yet

- Feen Marine Catalogue 2019Document16 pagesFeen Marine Catalogue 2019putra adeNo ratings yet

- Condenser Water Box LiningTech SheetDocument1 pageCondenser Water Box LiningTech Sheetatee_hua66100% (1)

- Case Study - Fuel OilDocument34 pagesCase Study - Fuel OilironiteNo ratings yet

- Fuel Oil PresentationDocument43 pagesFuel Oil PresentationBhupender Ramchandani100% (1)

- Safety and Security of Women, How?Document3 pagesSafety and Security of Women, How?Babu AravindNo ratings yet

- Insunews: Insurance Institute of IndiaDocument6 pagesInsunews: Insurance Institute of IndiaBabu AravindNo ratings yet

- Pure Math 30 - Combinatorics Lesson 4Document9 pagesPure Math 30 - Combinatorics Lesson 4Babu AravindNo ratings yet

- Turbine Supervisory GuideDocument2 pagesTurbine Supervisory GuideBabu AravindNo ratings yet

- A Comparative Analysis On Qos Multicast Routing Protocols in ManetsDocument5 pagesA Comparative Analysis On Qos Multicast Routing Protocols in ManetsBabu AravindNo ratings yet

- Labview DSC Module Labview DSC Module: JJ - Arumugam C & I LabDocument5 pagesLabview DSC Module Labview DSC Module: JJ - Arumugam C & I LabBabu AravindNo ratings yet

- Complete Winners List of 61st National Film AwardsDocument2 pagesComplete Winners List of 61st National Film AwardsBabu AravindNo ratings yet

- Sample Process Application: 2. Adjusting The Sludge's PH To Neutralize Any Acid or AlkaliDocument2 pagesSample Process Application: 2. Adjusting The Sludge's PH To Neutralize Any Acid or AlkaliBabu AravindNo ratings yet

- 220v DC SystemDocument16 pages220v DC SystemsanjeevchhabraNo ratings yet

- 4008TAG1-2A - 844-924kWm Emission Compliant Epak PN1833 - 3Document2 pages4008TAG1-2A - 844-924kWm Emission Compliant Epak PN1833 - 3Ali Reza PishevarNo ratings yet

- Electric Power GenerationDocument496 pagesElectric Power Generationbill100% (1)

- Focus SE 2013 2.0LDocument419 pagesFocus SE 2013 2.0LRoberto Carlos Cardenas QuirozNo ratings yet

- LC 40Document1 pageLC 40MauricioNo ratings yet

- Truck PDFDocument218 pagesTruck PDFCharles Claycomb100% (1)

- DT250:360:400 Ignition GuideDocument3 pagesDT250:360:400 Ignition Guidemarcusrex0% (1)

- 2ZZ-GE Valve Lifter Selection ChartDocument2 pages2ZZ-GE Valve Lifter Selection ChartnovyNo ratings yet

- Troubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 ChannelDocument1 pageTroubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 ChannelSurena RafiNo ratings yet

- 89p303 Touareg Electronic Diesel Control EDC 16 Design and FunctionDocument55 pages89p303 Touareg Electronic Diesel Control EDC 16 Design and Functioneduardorojas007100% (1)

- Engine Performance Data at 1800 RPM: Curve Number: Basic Engine ModelDocument3 pagesEngine Performance Data at 1800 RPM: Curve Number: Basic Engine ModelMohamed ElsayedNo ratings yet

- Chapter - 4 Characteristics of The EnginesDocument6 pagesChapter - 4 Characteristics of The EnginesKenmoe T DonasNo ratings yet

- Doosan Forklift Service Manual G424fe Lpdual Fuel Engine g424f LP EngineDocument20 pagesDoosan Forklift Service Manual G424fe Lpdual Fuel Engine g424f LP Enginemary100% (54)

- Common Rail High Pressure Fuel Injection 9-2010Document33 pagesCommon Rail High Pressure Fuel Injection 9-2010gmmarinov100% (5)

- THEORY: Reciprocating Engine Vibration: Lloyd JohnsonDocument3 pagesTHEORY: Reciprocating Engine Vibration: Lloyd JohnsonJameel KhanNo ratings yet

- Compressor Instrumentation PDFDocument37 pagesCompressor Instrumentation PDFsgh1355100% (1)

- Mechanical EngineeringDocument19 pagesMechanical EngineeringhenoksolNo ratings yet

- Spec 5320 469Document99 pagesSpec 5320 469IvánGarcíaNo ratings yet

- Gasoline Direct Injection: Method of OperationDocument4 pagesGasoline Direct Injection: Method of OperationNandepu Sravan KumarNo ratings yet

- Perkins 4.107 4.108 4.99 Workshop ManualDocument114 pagesPerkins 4.107 4.108 4.99 Workshop Manualjay100% (3)

- Kohler Model7ERDocument4 pagesKohler Model7ERWilliamBrown6No ratings yet

- 6081HF001 - B John DeereDocument2 pages6081HF001 - B John DeereJosé MontillaNo ratings yet

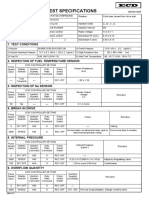

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- FsefsfDocument3 pagesFsefsfAnatol MorariNo ratings yet

- Purchase Order: To: Pt. Talenta Gelora Serafim Date: January 8, 2013 Att: S. Manurung, Mr. Ref: 10-AE-01-2013Document2 pagesPurchase Order: To: Pt. Talenta Gelora Serafim Date: January 8, 2013 Att: S. Manurung, Mr. Ref: 10-AE-01-2013kampretolNo ratings yet

- Air-Standard Cycles and Their AnalysisDocument40 pagesAir-Standard Cycles and Their AnalysisSrimanthula Srikanth100% (1)

- Engine Manual 3W 157xi B2 / TS / CSDocument19 pagesEngine Manual 3W 157xi B2 / TS / CSStanley Ochieng' OumaNo ratings yet

- C18 Industrial Engine WRH00001 - Sensor Eg GroupDocument2 pagesC18 Industrial Engine WRH00001 - Sensor Eg GroupBlog Teknisi100% (1)

- International VT365 PDF Service ManualDocument102 pagesInternational VT365 PDF Service ManualZeck100% (10)

- Mikasa MTDocument25 pagesMikasa MTBAHRNo ratings yet

- 2 Stroke TuningDocument6 pages2 Stroke TuningRahul NakheNo ratings yet