Professional Documents

Culture Documents

Section 2 Calculations B31.3 New Piping Calculations

Uploaded by

Mohamed ElsayedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 2 Calculations B31.3 New Piping Calculations

Uploaded by

Mohamed ElsayedCopyright:

Available Formats

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2

Calculations

B31.3 New Piping Calculations

Straight Piping Under Internal Pressure B31.3 304.1

Material Stress Allowed and Factor E j B31.3 Tables A-1and A-1B

Required Thickness of Permanent Blanks B31.3 304.5.3

Section 2 Haward Technology Middle East 1

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1B

The formula for calculating the required thickness of

new piping is located in Chapter II paragraph 304.1 of

the B31.3 Code and is as follows:

(a)The required thickness of straight sections of pipe shall

be determined in accordance with Equation. (2):

t m = t +c (2)

The minimum thickness T for the pipe selected,

considering manufacturer's minus tolerance, shall be

not less than t m

Section 2 Haward Technology Middle East 2

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

(b) The following nomenclature is used in the equations for

pressure design of straight pipe.

tm =minimum required thickness, including mechanical, corrosion,

and erosion allowances

t =pressure design thickness, as calculated in accordance with

paragraph. 304.1.2 for internal pressure.

c =the sum of the mechanical allowances (thread or groove

depth) plus corrosion and erosion allowances. For threaded

components, the nominal thread depth (dimension h of ASME

B1.20.1, or equivalent) shall apply. For machined surfaces or

grooves where the tolerance is not specified, the tolerance

shall be assumed to be 0.5 mm (0.02 in.) in addition to the

specified depth of the cut.

Section 2 Haward Technology Middle East 3

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

T =pipe wall thickness (measured or minimum per purchase

specification)

d =inside diameter of pipe. For pressure design calculation, the

inside diameter of the pipe is the maximum value allowable

under the purchase specification.

P =internal design gage pressure

D =outside diameter of pipe as listed in tables of standards or

specifications or as measured.

E =quality factor from Table A-l A or A-l B

S =stress value for material from Table A-l

W =weld strength reduction factor per para. 302.3.5(e)( Note:1.0

seamless pipe)

Y =coefficient from Table 304.1.1, valid for t < D/6 and for

materials shown. The value of Y may be interpolated for

intermediate temperatures.

Section 2 Haward Technology Middle East 4

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

The method for determining T (purchased pipe wall thickness)

follows:

Calculate the design thickness t required for the Internal

Design Pressure P.

Add on to t the corrosion, erosion and mechanical allowances

to find tm

tm = t + c

Add on to t + c the allowance for mill under-run tolerance and

then select the next commercially available schedule of pipe

walls thickness that will satisfy T.

tm = t + c + mill under tolerance

Section 2 Haward Technology Middle East 5

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

The first step requires the use of one of the equations

given in 304.1.2; the equations are as follows:

For t < D/6, the internal pressure design thickness for

straight pipe shall be not less than that calculated in

accordance with Equation 3a.

PD

t=

2(SEW + PY)

Section 2 Haward Technology Middle East 6

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Equation (3b) may be used instead of Equation. (3a):

P(d + 2c)

t=

2[SEW - P(1 - Y)]

For t D/6 or for P/SE > 0.385, This is not on exam

Section 2 Haward Technology Middle East 7

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Both of the equations may be used, as the difference in

required thickness will be insignificant at lower

operating temperatures (less than 900 o F) considering

the required addition of thickness for all of the other

issues such as corrosion, mechanical, and mill under

tolerance.

Section 2 Haward Technology Middle East 8

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

We will use the formula of (3a)

PD

t=

2(SEW + PY)

Section 2 Haward Technology Middle East 9

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Remember that the equations listed in 3(a) and 3(b)

involve the Factor Y, this factor is used to compensate for

the non-linear reduction in allowable stress at design

temperatures above 900 o F (482 o C). Accordingly, if a

piping system is to operate at elevated temperatures one

of those two equations should be used. The value of Y will

come from Table 304.1.1 of B31.3 based on the piping

material, ferritic, austenitic, etc.

Section 2 Haward Technology Middle East 10

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Section 2 Haward Technology Middle East 11

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

The other issue is that of "Mill Under Tolerance", the

value of which is found in the manufacturing specification

of the particular pipe or plate from which pipe is

fabricated.

For standard piping, the under-tolerance means our pipe

could arrive with a thickness as low as 12.5 % below the

stated nominal thickness.

The standard "Mill under Tolerance" for rolled plate from

which piping and permanent blanks can be fabricated is

0.010". So a .500” wall pipe might arrive as low as .490”

Section 2 Haward Technology Middle East 12

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2 Haward Technology Middle East 13

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2 Haward Technology Middle East 14

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Stainless Steel

Piping Schedules

Section 2 Haward Technology Middle East 15

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Example Problem 1:

1. Calculate the required ordered thickness T for a

piping system that will be constructed from A 106

Grade B pipe. The pipes nominal size is to be 12

inches which is manufactured with the actual OD

of 12.75 inches. The fluid service will require a

design temperature of 500 o F at a design pressure

of 350 psi with a corrosion allowance of 1/16 inch.

The piping system will be welded and erosion is

not a design concern.

Section 2 Haward Technology Middle East 16

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

The following information will be required to solve this problem:

P = 350 psi

D = 12.75

S = 18,900 psi at 500 o F from the Stress Table A-1 in B31.3

E = 1.0 for seamless A-106 Grade B from Table A-1B in B31.3

C = 1/16" or 0.0625“ mill under allowance = minus 12.5 % from

or 87.5 % of the nominal thickness.

Y = 0.4

W = weld joint strength reduction factor =1.0 (weld metal = or >

than base metal)

tm=?

Turning to Table A-1 and finding A106 Gr. B

Section 2 Haward Technology Middle East 17

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2 Haward Technology Middle East 18

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2 Haward Technology Middle East 19

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Section 2 Haward Technology Middle East 20

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Calculate the pressure design thickness using the

formula given in B31.3 304.1 3(b);

PD 350x12.75

t=

2(SEW + PY) = 2 x [(18,900 x 1.0x1.0) (350x0.4)] =

4462.5

38080

=.1171 " retire/repair thickness

tm = t + c = required actual minimum measured

thickness with corrosion/erosion

allowance and mechanical strength

consideration.

Section 2 Haward Technology Middle East 21

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure B31.3

304.1

tm = t + c = required actual minimum measured

thickness with corrosion/erosion allowance and

mechanical strength consideration.

tm = 0.1171 +0.0625 = 0.1796"

Section 2 Haward Technology Middle East 22

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

T May not be less than tm therefore it must equal to at

least 0.1796", and as a practical matter would require

the ordering of Schedule 20 piping (see Annex C of

B16.5) which a has nominal thickness of .250 which

after deduction for the minus mill under-run tolerance

of 12.5%, could arrive at a thickness as low as 0.21875"

which is still greater than tm .

T= 0.1796” minimum ordered thickness. Which when

rounded up for thickness is 0.180”. Schedule 20 will be

adequate.

Section 2 Haward Technology Middle East 23

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Example Problem 2:

Demonstration of allowance for mill under-run for

pipe constructed of plate and the use of added

thickness for structural strength.

Section 2 Haward Technology Middle East 24

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

2. Calculate the minium required ordered thickness T by

schedule with allowance for mill under-run tolerance, for

a piping system that will be constructed from a rolled

plate piping material ASTM A 671 Gr. CC70 Class 22. The

pipe's nominal size is to be 16 inches, which is

manufactured with the actual OD of 16 inches. The

service will require a design temperature of 750 o F at a

design pressure of 500 psi. The weight of the fluid will

require added thickness for structural strength of 0.100”.

There must be a corrosion allowance of 1/16 inch.

Section 2 Haward Technology Middle East 25

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

What is the required as measured thickness of this pipe

and what schedule of pipe will meet or exceed this

thickness requirement?

Section 2 Haward Technology Middle East 26

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

The following information will be required to solve this problem:

P = 500 psi @750 o F

D = 16.0”

S = 14,800 psi at 750 o F from the Stress Table A-1 in B31.3

E = 1.0 from Table A-1B B31.3

W = 1.0

C = 0.0625" + 0.100”

Y = 0.4 From table 304.1.1

Mill under allowance = minus 0.010" for rolled plate.

T = ? (pressure design thickness)

T = ? pipe wall thickness (measured or minimum per purchase

specification)

Section 2 Haward Technology Middle East 27

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Calculate the pressure design thickness using the

formula given in B31.3 304.1 3(b);

PD

=

500x16

=

8000

t=

2(SEW + PY) 2x[(14800x1.0x1.0) (500x0.4)] 30000

t = 0.2666“ tm = t + c = 0.2666" + 0.0625" + 0.100 =

0.4291"

T = Rounded up to 0.430" measured or minimum per

purchase specification.

Section 2 Haward Technology Middle East 28

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Straight Piping Under Internal Pressure

B31.3 304.1

Note: The normal rules of rounding values do not apply in

ASME /API Code calculations. Always round up no matter

what. Rounding this solution to 0.429 would not be the

proper procedure for a Code calculation on any API exam.

From RP 574 page 6, 16” Schedule 40 has a nominal

thickness of 0.500. Since this specification of pipe is

made from plate the under-tolerance is 0.010”.

Subtracting the mill under-run tolerance from the

nominal we have, 0.500” - 0.010” = 0.490”

0.490 > 0.430” Use Schedule 40

Section 2 Haward Technology Middle East 29

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent Blanks

B31.3 304.5

304.5.3 Blanks

Please notice that the calculation for t at the design

pressure, plus corrosion, erosion , and mechanical

wear are all combined in the following permanent

blank formula, by placing the + c on the basic design

thickness equation. The manufacturer's minus

tolerance must also be considered.

Section 2 Haward Technology Middle East 30

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent

Blanks B31.3 304.5

The minimum required thickness of permanent blanks

shall be calculated in accordance with this equation.

3P

t =d

m g +c

16SEW

Section 2 Haward Technology Middle East 31

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent

Blanks B31.3 304.5

where:

dg = inside diameter of gasket for raised or flat face

flanges, or the gasket pitch diameter for ring joint

and fully retained gasketed flanges

E = same as defined in paragraph. 304.1.1

P = design gage pressure

S = same as defined in paragraph. 304.1.1

c = sum of allowances defined in paragraph. 304.1.1

Section 2 Haward Technology Middle East 32

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent Blanks

B31.3 304.5

Example problem 1:

Calculate the required thickness for a permanent

blank to be installed in a piping system that

constructed of ASTM A 285 Gr. B seamless rolled plate

material. The piping is standard schedule 12.75 OD

the ID of the piping is 12.0 inches. For the dg value

uses the ID of the piping plus .500 so dg will equal

12.50 inches. The system will operate at a

temperature of 400 o F and under a design pressure of

500 psi. A corrosion allowance of 0.0625" applies to

both sides of the permanent blank

Section 2 Haward Technology Middle East 33

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent Blanks

B31.3 304.5

The following information will be required to solve this problem:

P = 500 psi design gage pressure

dg = 12.50

S = 15,400 psi at 400 o F from the Stress Table A-1 in B31.3

E = 1.0 for Seamless materials from Table A-1B B31.3

C = 1/16" or 0.0625“

Mill under-run allowance = minus 0.010" for rolled plate.

T = ? (Pressure design thickness)

Tm =?

T =?

Section 2 Haward Technology Middle East 34

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent Blanks

B31.3 304.5

Calculate the pressure design thickness using the formula

given in B31.3 304.5.3 ;

3 x 500

=

3P

t =d

m g +c 12.50 +c

16SEW 16x15,400x1.0x1.0

1500

12.50

246,400

+c = 12.50 x 0.0060876 + c

Section 2 Haward Technology Middle East 35

API 570: PIPING INSPECTION CODE: Inspection,

Repair, Alteration & Rerating of Inservice Piping

Systems (API Exam Preparation Training)

Required Thickness of Permanent Blanks

B31.3 304.5

= (12.50 x 0.078023) +c = 0.9752875 + c

Allowing for corrosion both sides of the blank of the plate

material we have the following required T. Remember to

allow for the under-run of 0.010 typical for plate

when ordering.

T = 0.9752875" + (2 x 0.0625") = 1.1002875“

The obvious variations of this type of problem are the

cases where there is no corrosion, or corrosion on only

one side.

Section 2 Haward Technology Middle East 36

You might also like

- Section 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Document37 pagesSection 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Mohamed ElsayedNo ratings yet

- Codes and Standards: ASME B31 Piping CodesDocument44 pagesCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNo ratings yet

- Piping Design Training - Piping Codes and Standards - OilandgasclubDocument4 pagesPiping Design Training - Piping Codes and Standards - Oilandgasclubchandramohan murugan100% (2)

- Type 6B flange dimensions for various pressure ratingsDocument63 pagesType 6B flange dimensions for various pressure ratingsNaeem NematiNo ratings yet

- 1Document156 pages1Abhijeet DarvekarNo ratings yet

- Piping BasicsDocument10 pagesPiping Basicstulasirao.nammiNo ratings yet

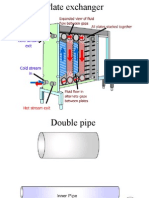

- Heat ExchangerDocument36 pagesHeat ExchangerUsman MansuriNo ratings yet

- Heat Exchanger Concepts (Att. VIII)Document28 pagesHeat Exchanger Concepts (Att. VIII)Syed M. Imran Ali100% (1)

- Piping Engineering Interview Questions: Datasheet PDF Search Site. - Download Datasheets For FreeDocument18 pagesPiping Engineering Interview Questions: Datasheet PDF Search Site. - Download Datasheets For FreeG mohan PrasaadNo ratings yet

- Piping Standards and Codes: American Society of Mechanical EngineersDocument3 pagesPiping Standards and Codes: American Society of Mechanical EngineersPSKUMAR2012No ratings yet

- Task KPI Prerequisite Post Task: Code ApplicationDocument6 pagesTask KPI Prerequisite Post Task: Code ApplicationvikasNo ratings yet

- Nafems India Webinar Fem For Engineering Analysis PDFDocument27 pagesNafems India Webinar Fem For Engineering Analysis PDFjohn_max03No ratings yet

- Certified Welding Inspector QA QC in USA Resume Matthew MerketDocument3 pagesCertified Welding Inspector QA QC in USA Resume Matthew MerketMatthewMerketNo ratings yet

- Important Notes On Cwi 3.2Document24 pagesImportant Notes On Cwi 3.2يوسف عادل حسانينNo ratings yet

- Piping Foreman Job Interview Questions and AnswersDocument13 pagesPiping Foreman Job Interview Questions and AnswersZishan KhanNo ratings yet

- Piping QC Guide (For Saudi Aramco Project)Document11 pagesPiping QC Guide (For Saudi Aramco Project)HengNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- ΔL, SIF, Hoop Stress, API StandardsDocument3 pagesΔL, SIF, Hoop Stress, API StandardsVijay KumarNo ratings yet

- Piping Study Guide ASME Codes Standards MaterialsDocument15 pagesPiping Study Guide ASME Codes Standards MaterialsnandajntuNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Piping MaterialDocument125 pagesPiping MaterialSargunam SankaravadivelNo ratings yet

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- Sockolet Gap Control Threaded Joints - PR - 0XXDocument14 pagesSockolet Gap Control Threaded Joints - PR - 0XXRAMAKRISHNANo ratings yet

- Api510 FormulasDocument2 pagesApi510 FormulasSakthi PkNo ratings yet

- Piping 2Document7 pagesPiping 2Jeffrey SsalonNo ratings yet

- Drawings: Md. Habib Naukhez Gulf Asia Saudi ArabDocument13 pagesDrawings: Md. Habib Naukhez Gulf Asia Saudi ArabRaheel JibranNo ratings yet

- Sylabus For Piping TrainingDocument5 pagesSylabus For Piping TrainingDilip YadavNo ratings yet

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocument2 pagesCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajNo ratings yet

- SBU-Quality Valve InspectionDocument85 pagesSBU-Quality Valve InspectionChetan kharkarNo ratings yet

- Tips For Piping Designer Interviews. - Piping Designer Jobs - IndeedDocument5 pagesTips For Piping Designer Interviews. - Piping Designer Jobs - Indeedprakhar agarwalNo ratings yet

- Static Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDocument397 pagesStatic Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDivyesh PatelNo ratings yet

- Static Equipment EngineerDocument5 pagesStatic Equipment EngineerSakthikumar ChandrasekaranNo ratings yet

- PWHT Specification References: 1 AWS D1.1/D1.1M:2010, 5.8.1, 2Document1 pagePWHT Specification References: 1 AWS D1.1/D1.1M:2010, 5.8.1, 2rustamriyadiNo ratings yet

- ASMEDocument27 pagesASMERoy DreinaNo ratings yet

- B31.3 Process Piping Course - 13 Inspection, Examination and TestingDocument19 pagesB31.3 Process Piping Course - 13 Inspection, Examination and TestingLuong AnhNo ratings yet

- Implementing Expansion Loops to Absorb Thermal StressDocument13 pagesImplementing Expansion Loops to Absorb Thermal StressAan DamaiNo ratings yet

- QR2 - Mechanical Maintenance Question RecordDocument2 pagesQR2 - Mechanical Maintenance Question RecordMicky PlumbNo ratings yet

- Reflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightDocument3 pagesReflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightAnonymous DMdGdsOENo ratings yet

- Technical Notes - B31.3Document36 pagesTechnical Notes - B31.3Amit Pandey100% (1)

- Presentation On Piping Stress AnalysisDocument17 pagesPresentation On Piping Stress AnalysisTasawwur TahirNo ratings yet

- What Is Piping MTO or Material Take-OffDocument4 pagesWhat Is Piping MTO or Material Take-Offvenkatraju.Y100% (1)

- Piping Questionnaire - Piping Study-NDocument14 pagesPiping Questionnaire - Piping Study-NBhanu Prakash100% (1)

- Certified QA QC Inspector PipingDocument5 pagesCertified QA QC Inspector Pipingamit84indNo ratings yet

- Curriculum Vitae: Sridhar VijayanDocument5 pagesCurriculum Vitae: Sridhar VijayanSridhar VijayanNo ratings yet

- Heat Exchanger AnimationDocument12 pagesHeat Exchanger AnimationShan AliNo ratings yet

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- 01 Basic of Piping MaterialDocument39 pages01 Basic of Piping Materialravi00098No ratings yet

- PMP CH 5-2Document76 pagesPMP CH 5-2عصمت ضيف اللهNo ratings yet

- Pipe Stress Amp SupportDocument24 pagesPipe Stress Amp SupportShilpa GanganNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- SPPID QnsDocument3 pagesSPPID QnsShunmugaNo ratings yet

- Piping QuizDocument20 pagesPiping QuizAlex CarreraNo ratings yet

- Pipe Fittings and Piping AuxiliariesDocument38 pagesPipe Fittings and Piping Auxiliariesmsaad2No ratings yet

- Valve QuestionnaireDocument5 pagesValve Questionnaireprnsh_k100% (2)

- ASME Training and Development-Spring-Catalog PDFDocument100 pagesASME Training and Development-Spring-Catalog PDFJiménez Chávez JaimeNo ratings yet

- 01 SAIP 02 - Retirement Thickness PDFDocument6 pages01 SAIP 02 - Retirement Thickness PDFAbdelrahman HosnyNo ratings yet

- Review API570 Calculations - FirstDocument38 pagesReview API570 Calculations - FirstnasrNo ratings yet

- 01 Saip 02Document6 pages01 Saip 02Arjun RawatNo ratings yet

- Contour Wa 1461503 PL LTR 01 Rev0Document12 pagesContour Wa 1461503 PL LTR 01 Rev0jairht29No ratings yet

- Questions CswipDocument63 pagesQuestions CswipMohamed ElsayedNo ratings yet

- Questions CswipDocument63 pagesQuestions CswipMohamed ElsayedNo ratings yet

- 17914Document11 pages17914Anonymous qhVGVpNo ratings yet

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 pagesHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNo ratings yet

- Impact & Pressure TestsDocument21 pagesImpact & Pressure TestsMohamed ElsayedNo ratings yet

- Flash Report L&T 8&9.12.2019Document2 pagesFlash Report L&T 8&9.12.2019Mohamed ElsayedNo ratings yet

- Joint FactorDocument8 pagesJoint FactorMohamed ElsayedNo ratings yet

- Pressure Test EquationDocument1 pagePressure Test EquationMohamed ElsayedNo ratings yet

- E Factor For CastingDocument1 pageE Factor For CastingMohamed ElsayedNo ratings yet

- 312 Flanged Joints: ASME B31.3-2012Document2 pages312 Flanged Joints: ASME B31.3-2012Mohamed ElsayedNo ratings yet

- E Joint Factor 2 PDFDocument1 pageE Joint Factor 2 PDFMohamed ElsayedNo ratings yet

- Impact Test DocumentDocument12 pagesImpact Test DocumentMohamed ElsayedNo ratings yet

- Api ReviewDocument59 pagesApi ReviewMohamed Elsayed100% (1)

- Table 302.3.4 Longitudinal Weld Joint Quality Factor, EDocument1 pageTable 302.3.4 Longitudinal Weld Joint Quality Factor, EMohamed ElsayedNo ratings yet

- Table A-1 Basic Allowable Stresses in Tension For MetalsDocument28 pagesTable A-1 Basic Allowable Stresses in Tension For MetalsMohamed ElsayedNo ratings yet

- API Standard 653 - Tank Inspection PDFDocument18 pagesAPI Standard 653 - Tank Inspection PDFcristinelbNo ratings yet

- TWW Tool Guide PDFDocument8 pagesTWW Tool Guide PDFVictor GrigorasNo ratings yet

- Asme 16.5 OgsDocument13 pagesAsme 16.5 OgsMohamed ElsayedNo ratings yet

- Neway-Dodsal 02 Valve Reports & RFIDocument4 pagesNeway-Dodsal 02 Valve Reports & RFIMohamed ElsayedNo ratings yet

- QC Questions InterviewsDocument23 pagesQC Questions InterviewsMohamed ElsayedNo ratings yet

- TWW Tool Guide PDFDocument8 pagesTWW Tool Guide PDFVictor GrigorasNo ratings yet

- Travelling Itinerary: MS 2614 Economy 03 Jul 18 CAI - Cairo Intl Arpt KWI - Kuwait 2030 2359 Confirmed Nb8SsuDocument1 pageTravelling Itinerary: MS 2614 Economy 03 Jul 18 CAI - Cairo Intl Arpt KWI - Kuwait 2030 2359 Confirmed Nb8SsuMohamed ElsayedNo ratings yet

- Fan Allambala FrenchPDF PDFDocument272 pagesFan Allambala FrenchPDF PDFMohamed ElsayedNo ratings yet

- CLASS 251031-KS: DEP 31.38.01.12-Gen Class 251031-KS, Rev. H Page 1 of 12Document12 pagesCLASS 251031-KS: DEP 31.38.01.12-Gen Class 251031-KS, Rev. H Page 1 of 12SaguesoNo ratings yet

- Tapa Gorro 234Document2 pagesTapa Gorro 234Marcel Alexander PatiñoNo ratings yet

- Compact Performance 437Document20 pagesCompact Performance 437Syarip HidayatNo ratings yet

- SPIRAX MANUAL - Steam Pipes and Pipe Sizing GCM - 75Document22 pagesSPIRAX MANUAL - Steam Pipes and Pipe Sizing GCM - 75stankoub100% (1)

- Aalco Stainless Steel Tube Product GuideDocument92 pagesAalco Stainless Steel Tube Product GuideAnonymous 5S5j8wONo ratings yet

- Fittings: Figure 250 - Cast Concentric Reducer, 350 - Fabricated Concentric ReducerDocument2 pagesFittings: Figure 250 - Cast Concentric Reducer, 350 - Fabricated Concentric ReducerLuis PárragaNo ratings yet

- Manuals 92b Pressure Reducing Valve Instruction Manual Fisher en en 5991282Document24 pagesManuals 92b Pressure Reducing Valve Instruction Manual Fisher en en 5991282Cristian Contreras PerezNo ratings yet

- Division 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentDocument14 pagesDivision 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentAhmed EbrahimNo ratings yet

- PN15CS1S01Document4 pagesPN15CS1S01joadNo ratings yet

- BGPP Uzle D 200 000 0 PR Phi 00007 e A1Document43 pagesBGPP Uzle D 200 000 0 PR Phi 00007 e A1vivekvijayan16No ratings yet

- PGHU-EH-LSPDS-001209 R1 General Requirement For ValvesDocument13 pagesPGHU-EH-LSPDS-001209 R1 General Requirement For ValvesRiyan EsapermanaNo ratings yet

- 0000 Pi SPC 002Document24 pages0000 Pi SPC 002zsmithNo ratings yet

- Wake FrequencyDocument7 pagesWake FrequencyRakesh B BalehosurNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- MSS SP-75 - 2019Document42 pagesMSS SP-75 - 2019Simone Torretta100% (2)

- Spiraxsarco Pipe SizingDocument52 pagesSpiraxsarco Pipe SizingJan Van PeteghemNo ratings yet

- Astral Pipes AquarisDocument12 pagesAstral Pipes AquarisPirpasha UjedeNo ratings yet

- Specification For Carbon Steel Pipes & FittingsDocument27 pagesSpecification For Carbon Steel Pipes & FittingsNoor Anter100% (1)

- 03SA0S04Document5 pages03SA0S04Jhonny RinconesNo ratings yet

- Plastic Piping HandbookDocument359 pagesPlastic Piping Handbookgnilagg100% (4)

- Asme Section Ii A Sa-409 Sa-409m PDFDocument10 pagesAsme Section Ii A Sa-409 Sa-409m PDFdavid perezNo ratings yet

- ASTM Pipe Schedule DimensionsDocument5 pagesASTM Pipe Schedule DimensionshemnNo ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- ASTM A53 pipe steel specification and material comparison tablesDocument2 pagesASTM A53 pipe steel specification and material comparison tablesRifky NetriadyNo ratings yet

- Manage Your Steam With Greater Safety, Reliability and EfficiencyDocument28 pagesManage Your Steam With Greater Safety, Reliability and EfficiencyMohammad FouladiNo ratings yet

- Flow and Pressure of Water Through Steel PipesDocument2 pagesFlow and Pressure of Water Through Steel PipesLUDERNo ratings yet

- Astm A333Document7 pagesAstm A333Kishor JadhavNo ratings yet

- Ball Valve - An Overview - ScienceDirect TopicsDocument23 pagesBall Valve - An Overview - ScienceDirect TopicsMalik DaniyalNo ratings yet

- ALUMINIUM PIPE BUS SPECIFICATIONDocument6 pagesALUMINIUM PIPE BUS SPECIFICATIONvairam_eee01No ratings yet