Professional Documents

Culture Documents

PE-02 Piping Codes and Standards

Uploaded by

deepak0 ratings0% found this document useful (0 votes)

8 views23 pagesCopyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views23 pagesPE-02 Piping Codes and Standards

Uploaded by

deepakCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 23

INTRODUCTION

Codes usually set forth requirements for design,

materials, fabrication, erection, test, and inspection of

piping systems.

standards contain design and construction rules and

requirements for individual piping components such as

elbows, tees, returns, flanges, valves, and other in-line

items.

The codes and standards which relate to piping systems

and piping components are published by various

organizations.

INTRODUCTION

While designing a piping system in accordance with a

code or a standard, the designer must comply with the

most restrictive requirements which apply to any of the

piping elements.

In regard to applicability of a particular edition, issue,

addendum, or revision of a code or standard, one must

be aware of the national, state, provincial, and local laws

and regulations governing its applicability in addition to

the commitments made by the owner and the limitations

delineated in the code or standard.

AMERICAN SOCIETY OF MECHANICAL

ENGINEERS (ASME)

The American Society of Mechanical Engineers (ASME) is

one of the leading organizations in the world which

develops and publishes codes and standards.

The ASME established a committee in 1911 to formulate

rules for the construction of steam boilers and other

pressure vessels.

This committee is now known as the ASME Boiler and

Pressure Vessel Committee, and it is responsible for the

ASME Boiler and Pressure Vessel Code.

The ASME has established other committees which

develop many other codes and standards

ASME BOILER AND PRESSURE VESSEL CODE

Section I Power Boilers

Section V Nondestructive Examination

Section VIII Pressure Vessels

Section IX Welding and Brazing Qualifications

ASME SECTION I: POWER BOILERS

ASME Section I has total administrative jurisdiction and

technical responsibility for boiler.

The piping defined as boiler external piping (BEP) is

required to comply with the mandatory certification by

code symbol stamping, ASME data forms, and authorized

inspection requirements, called Administrative

Jurisdiction, of ASME Section I.

it must satisfy the technical requirements (design,

materials, fabrication, installation, nondestructive

examination, etc.) of ASME B31.1, Power Piping Code.

ASME SECTION V:

NONDESTRUCTIVE EXAMINATION

ASME Section V comprises Subsection A, Subsection B,

and mandatory and no mandatory appendixes.

Subsection A delineates the methods of nondestructive

examination, and Subsection B contains various ASTM

standards covering nondestructive examination methods

that have been adopted as standards.

The nondestructive examination requirements and

methods included in ASME SectionV are mandatory to

the extent they are invoked by other codes and standards

or by the purchaser’s specifications.

ASME SECTION VIII: PRESSURE VESSELS

The rules of ASME Section VIII constitute construction

requirements for pressure vessels.

The rules of ASME Section VIII apply to flanges, bolts,

closures, and pressure relieving devices of a piping system

when and where required by the code governing the

construction of the piping.

For example, ASME B31.1 requires that the safety and

relief valves on nonboiler external piping, except for

reheat safety valves, shall be in accordance with the

requirements of ASME Section VIII, Division 1, UG- 126

through UG-133.

ASME SECTION IX: WELDING AND

BRAZING QUALIFICATIONS

ASME Section IX consists of two parts—Part QW and Part

QB—which deal with welding and brazing, respectively.

ASME Section IX requirements relate to the qualification

of welders, welding operators, brazers, and brazing

operators and the procedures used in welding and

brazing.

They establish the basic criteria for welding and brazing

observed in the preparation of welding and brazing

requirements that affect procedure and performance.

ASME B31: CODE FOR PRESSURE PIPING

Presently, the following sections of ASME B31, Code for

Pressure Piping are

ASME B31.1 Power Piping

ASME B31.3 Process Piping

ASME B31.4 Liquid Transportation Systems for

Hydrocarbons, Liquid Petroleum Gas, Anhydrous Ammonia,

and Alcohol

ASME B31.5 Refrigeration Piping

ASME B31.8 Gas Transmission and Distribution Piping

Systems

ASME B31.1: POWER PIPING CODE

ASME B31.1, Power Piping Code, prescribes requirements

for the design, material, fabrication, erection, test, and

inspection of power and auxiliary service piping systems

for electric generation stations, industrial and

institutional plants, central and district heating plants,

and district heating systems.

The requirements of this code apply to central and district

heating systems for distribution of steam and hot water

away from the plants whether underground or elsewhere,

and geothermal steam and hot water piping both to and

from wellheads.

ASME B31.3: PROCESS PIPING

This code prescribes requirements for the materials,

design, fabrication, assembly, erection, examination,

inspection, and testing of piping within the property

limits of facilities engaged in the processing or handling of

chemical petroleum or related products.

The requirements of ASME B31.3 apply to piping for all

fluids, including raw, intermediate, and finished

chemicals; petroleum products, gas, steam, air, and

water; fluidized solids; and refrigerants.

The requirements of ASME B31.3 do not apply to piping

systems designed for internal gauge pressures at or above

0 but less than 15 (100 kPa gauge) psig.

ASME B31.4: LIQUID TRANSPORTATION SYSTEMS FOR

HYDROCARBONS, LIQUID PETROLEUM GAS,

ANHYDROUS AMMONIA, AND ALCOHOLS

Section B31.4 of the ASME Pressure Piping Code

prescribes requirements for the design, materials,

construction, assembly, inspection, and testing of piping

transporting liquids such as crude oil, condensate, natural

gasoline, natural gas liquids, liquefied petroleum gas,

liquid alcohol, liquid anhydrous ammonia, and liquid

petroleum products between producers’ lease facilities,

tank farms, natural-gas processing plants, refineries,

stations, ammonia plants, terminals, and other delivery

and receiving points.

ASME B31.5: REFRIGERATION PIPING

This section of ASME B31, Pressure Piping Code, contains

requirements for the materials, design, fabrication,

assembly, erection, testing, and inspection of refrigerant

and secondary coolant piping for temperatures as low as

320F (195.5C), except when other sections of the code

cover requirements for refrigeration piping.

ASME B31.8: GAS TRANSMISSION AND

DISTRIBUTION PIPING SYSTEMS

ASME B31.8 prescribes requirements for the design,

fabrication, installation, testing, and safety aspects of

operation and maintenance of gas transmission and

distribution piping systems, including gas pipelines, gas

compressor stations, gas metering and regulation

stations, gas mains, and service lines up to the outlet of

the customer’s meter set assembly.

Also included within the scope of ASME B31.8 are gas

storage equipment of the closed-pipe type, fabricated or

forged from pipe or fabricated from pipe and fittings, and

gas storage lines.

AMERICAN PETROLEUM INSTITUTE

The American Petroleum Institute (API) publishes

specifications (Spec.), bulletins (Bull.), recommended

practices (RP), standards (Std.), and other publications

(Publ.) as an aid to procurement of standardized

equipment and materials.

AMERICAN WELDING SOCIETY

The American Welding Society (AWS) publishes

handbooks, manuals, guides, recommended practices,

specifications, and codes.

MANUFACTURERS STANDARDIZATION SOCIETY

OF THE VALVE AND FITTINGS INDUSTRY -MSS

The Manufacturers Standardization Society (MSS)

publishes Standard Practices (SP) which provide a basis

for common practice by the manufacturers, the user, and

the general public.

Compliance to the Standard Practices of MSS is required

by reference in a code, specification, sales contract, law,

or regulation.

The MSS is also represented on the committees of other

standardization groups, such as ANSI and ASME.

FOREIGN CODES AND STANDARDS

BRITISH STANDARDS AND SPECIFICATIONS

DIN STANDARDS AND SPECIFICATIONS

JAPANESE STANDARDS AND SPECIFICATIONS

ISO STANDARDS AND SPECIFICATIONS

BRITISH STANDARDS AND SPECIFICATIONS

Pipe, Tube, and Fittings:

Appendix E10, Table E10.B1 lists British standards and

specifications for pipe, tube, and fittings.

Flanges, Bolts, Nuts, and Gaskets

Appendix E10, Table E10.B2 lists British standards and

specifications for flanges, bolts, nuts, and gaskets.

Valves

Appendix E10, Table E10.B3 lists British standards and

specifications for valves.

DIN STANDARDS AND SPECIFICATIONS

Pipe, Tube, and Fittings:

Appendix E10, Table E10.D1 lists DIN standards and

specifications for pipe, tube, and fittings.

Flanges, Bolts, Nuts, and Gaskets

Appendix E10, Table E10.D2 lists DIN standards and

specifications for flanges, bolts, nuts, and gaskets

Valves

Appendix E10, Table E10.D3 lists DIN standards and

specifications for valves.

JAPANESE STANDARDS AND SPECIFICATIONS

Pipe, Tube, and Fittings:

Appendix E10, Table E10.J1 lists Japanese standards and

specifications for pipe, tube, and fittings.

Flanges, Bolts, Nuts, and Gaskets

Appendix E10, Table E10.J2 lists Japanese standards and

specifications for flanges, bolts, nuts, and gaskets.

Valves

Appendix E10, Table E10.J3 lists Japanese standards and

specifications for valves.

ISO STANDARDS AND SPECIFICATIONS

Pipe, Tube, and Fittings:

Appendix E10, Table E10.I1 lists ISO standards and

specifications for pipe, tube and fittings.

Flanges, Bolts, Nuts, and Gaskets

Appendix E10, Table E10.I2 lists ISO standards and

specifications for flanges, bolts, nuts, and gaskets.

Valves

Appendix E10, Table E10.I3 lists ISO standards and

specifications for valves.

You might also like

- Stress & DistortionDocument49 pagesStress & DistortiondeepakNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- 01-WIS5 Terms 2006Document30 pages01-WIS5 Terms 2006deepakNo ratings yet

- World Centre For Materials Joining TechnologyDocument4 pagesWorld Centre For Materials Joining TechnologydeepakNo ratings yet

- Albi AntonyDocument2 pagesAlbi AntonydeepakNo ratings yet

- Piping IsometricDocument19 pagesPiping IsometricdeepakNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Halliburton: VR Safety JointDocument2 pagesHalliburton: VR Safety Jointsaeed65No ratings yet

- Equipment Lab4 BBL - BoilerType2Document917 pagesEquipment Lab4 BBL - BoilerType2umairsaleem606No ratings yet

- Polypropylene: Section GuideDocument55 pagesPolypropylene: Section GuideKarthik RajNo ratings yet

- 1.CO2 CylinderDocument7 pages1.CO2 Cylinderabdelrahman shaalanNo ratings yet

- Ko-111-01 Repair Welding+manual eDocument156 pagesKo-111-01 Repair Welding+manual eJayantha parakrama ThennakoonNo ratings yet

- ArmaFlex Application UkDocument36 pagesArmaFlex Application UkDave StaelensNo ratings yet

- GEBERIT Final PriceNET - 2021Document5 pagesGEBERIT Final PriceNET - 2021zaNo ratings yet

- Definition and Details of FlangesDocument39 pagesDefinition and Details of FlangesMohd AmaniNo ratings yet

- ASTM A123 Standard Specification For Zinc (Hot-Dip Galvanized) Coatings On Iron and Steel ProductsDocument8 pagesASTM A123 Standard Specification For Zinc (Hot-Dip Galvanized) Coatings On Iron and Steel ProductsDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- 117T6809 Module Specification & Test InstructionDocument30 pages117T6809 Module Specification & Test InstructionRaziel Mini AtksNo ratings yet

- Seko TEKNA DPG Pump Instruction ManualDocument23 pagesSeko TEKNA DPG Pump Instruction ManualManuel Marín MartínezNo ratings yet

- Magnehelic Gauge CalibrationDocument7 pagesMagnehelic Gauge CalibrationgrajukankayyaNo ratings yet

- Piedmont StyleDDocument1 pagePiedmont StyleDBenjamin MillerNo ratings yet

- CIAT Coadis - Line - 600 KASETADocument19 pagesCIAT Coadis - Line - 600 KASETAIgor SpasovicNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- 2022 Water Specifications FinalDocument168 pages2022 Water Specifications FinalScott FreemanNo ratings yet

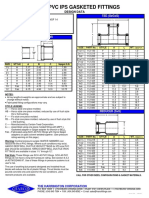

- Harco PVC Ips Gasketed Fittings: Tee (GXGXG)Document6 pagesHarco PVC Ips Gasketed Fittings: Tee (GXGXG)DALGYNo ratings yet

- Takeuchi Excavator TB153FR CJ2E000 WM 06860Document686 pagesTakeuchi Excavator TB153FR CJ2E000 WM 06860rok.feleNo ratings yet

- Concrete Pipe and Box CulvertsDocument157 pagesConcrete Pipe and Box CulvertsUMC100% (1)

- General Purpose Hydraulic Valves: Float Level Control ValveDocument2 pagesGeneral Purpose Hydraulic Valves: Float Level Control Valvevelikimag87No ratings yet

- Online TRG CourseDocument12 pagesOnline TRG Coursegreyphen greyNo ratings yet

- Asco Today v7375r5Document34 pagesAsco Today v7375r5Jesus N RodriguezNo ratings yet

- Seal Installation and Operation GuideDocument16 pagesSeal Installation and Operation GuideErick AmadeuNo ratings yet

- SAWS-EnG-0631 Fine Materials For Pipe EmbedmentDocument27 pagesSAWS-EnG-0631 Fine Materials For Pipe Embedmentpirke2412No ratings yet

- Ravi CellDocument45 pagesRavi Cellapi-3725726100% (1)

- External Reservoir For Seal Barrier: Safematic Safesiphon 10Document4 pagesExternal Reservoir For Seal Barrier: Safematic Safesiphon 10laringeNo ratings yet

- British Standards Institution - Bsi: BSI - Engineering Components and Equipment CollectionDocument163 pagesBritish Standards Institution - Bsi: BSI - Engineering Components and Equipment CollectionCode ValmirNo ratings yet

- Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeDocument0 pagesDin 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeAdrian MarinNo ratings yet

- Optimization of The Tank Rotating Machine in Estanc AsDocument81 pagesOptimization of The Tank Rotating Machine in Estanc AssauravNo ratings yet

- Modeling of Shell and Tube Heat Exchanger in Caesar II For Stress AnalysisDocument6 pagesModeling of Shell and Tube Heat Exchanger in Caesar II For Stress AnalysisJayasharathi IyapillaiNo ratings yet