Professional Documents

Culture Documents

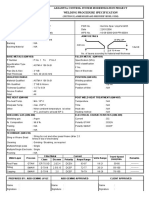

Reliance Engineering Associates (P) Limited Welding Procedure Specification

Uploaded by

deepakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reliance Engineering Associates (P) Limited Welding Procedure Specification

Uploaded by

deepakCopyright:

Available Formats

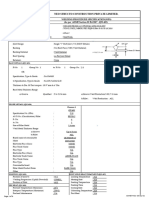

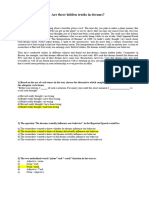

WELDING PROCEDURE

RELIANCE SPECIFICATION

ENGINEERING ASSOCIATES (P) LIMITED

WPS No.- 1153 Rev. No.- 01 Date :- 01/02/2005

Code : ASME Sec IX Supporting PQR(s) No. : 54 , 55

Welding Process : SMAW Type : MANUAL

JOINTS (QW 402) BASE MATERIAL (QW 403) POSITION (QW 405)

Groove Design : ALL P No.: 1 Gr : 1,2 P No.: 1 Gr : 1,2 Groove: ALL

Root Spacing: 2.5 -3mm ? Spec of Unassigned : NA Fillet : NA ?

Backing : N.A. for root pass (groove), Base Material Thickness: 2.75 – 19 mm ? Weld Progression: UPHILL

Weld metal for subsequent passes (groove) ?

Backing Material Type : Weld metal ?

Retainer & Consumable Insert : NA Weld Pass Thickness <12.7mm

GAS (QW 408) PREHEAT (QW 406 ) PWHT (QW 407)

Purpose Gas % Flow Preheat Temperature Interpass Temperature Type of PWHT : NA

RateL (min): 10?C (max): 250?C ?

PM

ShieldingGas NA NA NA Method of Preheating : Preheat Maintenance : Soaking Temp: Soaking Time :

Coil/Burner, as applicable ? During welding ? NA NA

Backing Gas NA NA NA Postheating Temp: NA Heating Rate : NA

Trailinig Gas NA NA NA Postheating Time: NA Cooling Rate : NA

FILLER METALS ELECTRICAL CHARACTERISTICS & TECHNIQUE STANDARD JOINT DESIGN DRGS

(QW 404 , 409 & 410)

Process(es) ? SMAW SMAW

E6010 E7018-1 37 ½ + 2 ½ ° (Typ)

AWS Class

F/A No. 3 /1 4 /1

9

SFA No. 5.1 5.1 7 8

Brand Name ? Only REAL approved brands shall be used. 5 6

Dia (mm) ? 2.5 3.15 2.5 3.15 4.0

3

4

Polarity ? DCEP DCEP DCEP DCEP DCEP 2 Root Face 1-2 mm

1 (Typ)

Current Range(A) ? 60-80 70-100 80-100 110-135 160-190

Root Gap 2.5-3 mm

Voltage Range(V) ? 22-26 22-28 22-28 22-28 22-28 (Typ)

Deposited Weld Metal Thk (mm) ? 2.5mm(max) 16.5mm (max)

Travel Speed(mm/min) ? 55(min) 55(min) 75(min) 100(min)

Heat Input(KJ/min) ? 3.10 (max)

Flux Type NA NA GENERAL NOTES: ?

Gas Cup Size(mm) NA NA 1)Application of this WPS shall be limited

Tungsten Type NA NA to construction of process/power piping

Tungsten Size(mm) 2.4 NA under ASME B31.3/31.1

Mode of Metal Transfer NA NA

2)# # Weave width shall not exceed 3

String & Weave String/Weave, as applicable times diameter of the electrode.

Oscillation NA 3)PQR are impact tested at minus 48

Contact Tube Distance(mm) NA degree C

Method of back gougng NA 4)$$Welding shall be carried out with

Initual & Interpass cleaning ? Grinding & Brushing, as applicable minimum two passes using the

Multi/Single Pass $$? Single Single/ Multiple combination of electrodes.

Multi/Single Electrode Single Single

Peening NA NA

01 01/02/05 YES Marked as ? T.DATTA S.N.SAMADDAR A.J.VYAS

REV NO DATE PARAMETER DESCRIPTION OF PREPARED BY: REVIEWED BY : APROVED BY:

REVISED REVISION

Format No:2QM00FMTME091, Rev. 00, Date :-20/03/2002, Page 1 of 1

You might also like

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- GMAW welding parameters for SS400 pipeDocument2 pagesGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- PWPS 102 - CopyDocument2 pagesPWPS 102 - CopyCyril J PadiyathNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- AECOM ASME PQR for SA-516 Pipe WeldsDocument3 pagesAECOM ASME PQR for SA-516 Pipe Weldscorey jacobsNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Request welding procedure approvalDocument18 pagesRequest welding procedure approvalecsuperal100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- DEE-920-12 - Rev 0Document3 pagesDEE-920-12 - Rev 0Karim ZahranNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- CSWIP 3.1 Welding InspectionDocument12 pagesCSWIP 3.1 Welding InspectiondeepakNo ratings yet

- World Centre For Materials Joining TechnologyDocument4 pagesWorld Centre For Materials Joining TechnologydeepakNo ratings yet

- Stress & DistortionDocument49 pagesStress & DistortiondeepakNo ratings yet

- WPS 2006Document33 pagesWPS 2006dombipinNo ratings yet

- 01-WIS5 Terms 2006Document30 pages01-WIS5 Terms 2006deepakNo ratings yet

- Visual TestingDocument37 pagesVisual TestingdeepakNo ratings yet

- Probe Selection Engl Rev 1.0 2013-09-12Document50 pagesProbe Selection Engl Rev 1.0 2013-09-12Monojit GhoshNo ratings yet

- Oil and gas exploration methodsDocument8 pagesOil and gas exploration methodsdeepakNo ratings yet

- Albi Antony Resume for QA/QC EngineerDocument2 pagesAlbi Antony Resume for QA/QC EngineerdeepakNo ratings yet

- WFP 2-01-Att-1-R1Document3 pagesWFP 2-01-Att-1-R1Hakim 'n BilalNo ratings yet

- PIPEDocument64 pagesPIPEdeepakNo ratings yet

- Piping IsometricDocument19 pagesPiping IsometricdeepakNo ratings yet

- PE-02 Piping Codes and StandardsDocument23 pagesPE-02 Piping Codes and StandardsdeepakNo ratings yet

- PIPEDocument64 pagesPIPEdeepakNo ratings yet

- Piping Isometric TutorialDocument45 pagesPiping Isometric Tutorialcepong89100% (1)

- SymbolsDocument4 pagesSymbolsdeepakNo ratings yet

- Ball Full Bore PDFDocument11 pagesBall Full Bore PDFdeepakNo ratings yet

- PE-02 Piping Codes and StandardsDocument23 pagesPE-02 Piping Codes and StandardsdeepakNo ratings yet

- Piping Isometric TutorialDocument45 pagesPiping Isometric Tutorialcepong89100% (1)

- WFP 2-01-Att-1-R1Document3 pagesWFP 2-01-Att-1-R1Hakim 'n BilalNo ratings yet

- RT Asmeb31.3 Withoutsecure PDFDocument4 pagesRT Asmeb31.3 Withoutsecure PDFkishorekumar.animuNo ratings yet

- Lisa ChangDocument8 pagesLisa ChangOmerMurtazaNo ratings yet

- Circulating Current Test:: DIE 4B 115/13.8kV SSDocument1 pageCirculating Current Test:: DIE 4B 115/13.8kV SSVinod KumarNo ratings yet

- Quastion in Ingles GOLDocument12 pagesQuastion in Ingles GOLAlda Ghisi FrigiNo ratings yet

- Ac Generator 2Document22 pagesAc Generator 2Gilian Joy Mari PerezNo ratings yet

- ITP-CI-026a-02 (Building Finishing Works)Document4 pagesITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyNo ratings yet

- Mod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot PlantDocument4 pagesMod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot Plantessam essNo ratings yet

- Balluff BHS0032 DatasheetDocument2 pagesBalluff BHS0032 Datasheetcamilo torresNo ratings yet

- 550030170-Single Speed Powershift Aluminum Chain Drive-UsDocument86 pages550030170-Single Speed Powershift Aluminum Chain Drive-UsFrancisco DiazNo ratings yet

- Personal Maintenance LogbookDocument30 pagesPersonal Maintenance LogbookPatrickNo ratings yet

- Workshop One Notes-1Document40 pagesWorkshop One Notes-1jeff madibaNo ratings yet

- Assignment - 107 Report 1Document16 pagesAssignment - 107 Report 1Warla Rahman Maha 2131503630No ratings yet

- 2021-10-25 CEB Greenfield Renewable Energy Scheme FrameworkDocument4 pages2021-10-25 CEB Greenfield Renewable Energy Scheme FrameworkKeessun FokeerahNo ratings yet

- 2409 Steel and The Skyscraper City A Study On The Influence of Steel On The Design of Tall BuildingsDocument11 pages2409 Steel and The Skyscraper City A Study On The Influence of Steel On The Design of Tall BuildingsAndrea Perez PellegrinoNo ratings yet

- Bimtech Case Analysis Competition 2021-22, NdimDocument7 pagesBimtech Case Analysis Competition 2021-22, Ndimshreyansh chaudharyNo ratings yet

- Global Impact of Russia-Ukraine Conflict PDFDocument7 pagesGlobal Impact of Russia-Ukraine Conflict PDFBipul RahulNo ratings yet

- DIY Solar Bottle LampDocument81 pagesDIY Solar Bottle LampJaymar DavilaNo ratings yet

- The Governments Action Plan For Green ShippingDocument72 pagesThe Governments Action Plan For Green ShippingYosun KarasuNo ratings yet

- Power Plant Engineering Lecture Notes on Flow Through NozzlesDocument13 pagesPower Plant Engineering Lecture Notes on Flow Through NozzlesBharat SharmaNo ratings yet

- Materials 1 QPDocument10 pagesMaterials 1 QPnotgettingitNo ratings yet

- Measurement of Insulation Resistance (IR) - Part 2 - EEP PDFDocument16 pagesMeasurement of Insulation Resistance (IR) - Part 2 - EEP PDFHeri SulaimanNo ratings yet

- Dreame Cordless Vacuum Cleaner User ManualDocument248 pagesDreame Cordless Vacuum Cleaner User ManualXuan TranNo ratings yet

- Ultra C6 fabric provides advanced flame resistanceDocument1 pageUltra C6 fabric provides advanced flame resistancedaniel garcia cortesNo ratings yet

- 3.2.4 - Enviro Politics - Student VersionDocument14 pages3.2.4 - Enviro Politics - Student VersionMatthew PringleNo ratings yet

- Ficha Tecnica D12000Document1 pageFicha Tecnica D12000Nguyễn Hữu ĐồngNo ratings yet

- PhysicsDocument54 pagesPhysicsLee KcNo ratings yet

- SI10 Simulation Indicator Production ManualDocument5 pagesSI10 Simulation Indicator Production ManualDANIEL BURILLO HOMBRIA0% (1)

- Ntomani Sugar Company - Fund Raising Report - FinalDocument36 pagesNtomani Sugar Company - Fund Raising Report - FinalKamlesh SamaliyaNo ratings yet

- RI-EZLUBE Trouble Shooting (Revised 2-7-19)Document2 pagesRI-EZLUBE Trouble Shooting (Revised 2-7-19)jesusNo ratings yet

- Wind Lab and TMDDocument28 pagesWind Lab and TMDsergiostolovasNo ratings yet

- MethanolDocument17 pagesMethanolWahyu PermanaNo ratings yet

- DC Regulated Power SupplyDocument16 pagesDC Regulated Power SupplyDev KumarNo ratings yet