Professional Documents

Culture Documents

Washability Characteristics of Coal

Washability Characteristics of Coal

Uploaded by

Danial Afzal0 ratings0% found this document useful (0 votes)

47 views7 pagesThis document discusses methods for analyzing the washability characteristics of coal through float-sink analysis. Coal particles are separated by immersion in liquids of increasing density, and the results are plotted on washability curves. These curves allow calculation of the yield, quality, and density required to produce coal at a specified ash content. They also provide information on the quality of discard and distribution of ash between coal and mineral fractions.

Original Description:

Original Title

washability characteristics of coal

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses methods for analyzing the washability characteristics of coal through float-sink analysis. Coal particles are separated by immersion in liquids of increasing density, and the results are plotted on washability curves. These curves allow calculation of the yield, quality, and density required to produce coal at a specified ash content. They also provide information on the quality of discard and distribution of ash between coal and mineral fractions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views7 pagesWashability Characteristics of Coal

Washability Characteristics of Coal

Uploaded by

Danial AfzalThis document discusses methods for analyzing the washability characteristics of coal through float-sink analysis. Coal particles are separated by immersion in liquids of increasing density, and the results are plotted on washability curves. These curves allow calculation of the yield, quality, and density required to produce coal at a specified ash content. They also provide information on the quality of discard and distribution of ash between coal and mineral fractions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 7

Washability Characteristics of coal

Float Sink analysis of coal

• Coal particles are separated into density fractions by

immersion in a series of liquids of known relative

density,

• usually ranging from 1.30 to 2.00. Commencing with

the lowest relative density, the sinking fraction is

transferred to the next liquid in the series and so on.

• Using the results given in Table 4.20, these may be

plotted graphically as a series of ‘washability curves’.

Significance

These are used to calculate

• The amount of coal that can be obtained at a

particular quality,

• The density required to effect such a

separation and

• The quality of the discard left behind.

Significance

• The amounts of coal and mineral matter or

discard can be determined for a specific

relative density, so enabling a product of

specified ash content to be produced using

liquids of known relative density.

• The latter figure is useful to the coal

preparation engineer for coal blending

calculations.

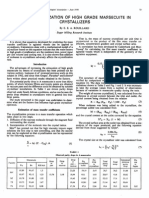

Cumulative floats curve which plots column I vs G,

the densimetric curve which plots column G vs C,

the cumulative sinks curve which plots column L vs J, and

the elementary ash curve which plots column G vs E (see Table 4.21).

Significance

• Quantitatively, an examination of the cumulative floats

curve will give yield values for a given quality,

• and the densimetric curve will indicate the density at

which to wash (i.e. washing density) in order to obtain

that yield and quality.

• This can also be calculated in reverse.

• The curves can also be used on a more qualitative

basis, for example if the density value that is required

is on the steep part of the densimetric curve then it

will be more difficult to maintain a consistent quality.

A coal with an ash

content of 5% will

give a yield of 68.6%,

and a density of 1.47

will be needed to

achieve this.

The ash of the sinks

(reject) will be 76%

and the percentage

of those ash particles

in the floats will be

16.6%.

You might also like

- Modulus of Subgrade ReactionDocument41 pagesModulus of Subgrade Reactionsuryakanta padhi100% (1)

- Pit Limits CH 6Document10 pagesPit Limits CH 6Waqar AnwarNo ratings yet

- EOR WaterfloodingDocument176 pagesEOR WaterfloodingChris ChijiokeNo ratings yet

- Turbulent Flow and Friction Factor in Porous MediaDocument39 pagesTurbulent Flow and Friction Factor in Porous MediaAminNo ratings yet

- 1978 - Rouillard - The Crystallization of HighDocument7 pages1978 - Rouillard - The Crystallization of Higheal3019No ratings yet

- Coal, Oil Sampling and Their AnalysisDocument68 pagesCoal, Oil Sampling and Their AnalysisAshwani DograNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Calculation of Raw Mix CompositionDocument45 pagesCalculation of Raw Mix CompositionGirma Tesema100% (1)

- Analysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionDocument23 pagesAnalysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionHemant PatilNo ratings yet

- Metallurgical Accounting, Control and SimulationDocument39 pagesMetallurgical Accounting, Control and SimulationTakudzwa Alfred Tickey100% (1)

- Road Note MethodDocument10 pagesRoad Note Methodramya_an2411100% (1)

- A SUMMARY OF EXPERIENCES RELATED TO Combustion Optimization PDFDocument60 pagesA SUMMARY OF EXPERIENCES RELATED TO Combustion Optimization PDFAna Paula SiqueiraNo ratings yet

- Ball Mill PulveriserDocument67 pagesBall Mill PulveriserMURALIGOCAM_29070605100% (1)

- Drilling Fluids ExercisesDocument17 pagesDrilling Fluids ExercisesJohn Kevin De CastroNo ratings yet

- HGIDocument4 pagesHGIMutiara Dwi SeptianiNo ratings yet

- Performanece Ananlysis of CoalDocument67 pagesPerformanece Ananlysis of Coalsen_subhasis_58No ratings yet

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- Manuscript-Raveen (Latest)Document6 pagesManuscript-Raveen (Latest)Raveen LingamNo ratings yet

- Pulveriser-Power PlantDocument67 pagesPulveriser-Power PlantARUNGREESMANo ratings yet

- Absorber Design: Sizing A Packed TowerDocument24 pagesAbsorber Design: Sizing A Packed TowerMbarouk Shaame MbaroukNo ratings yet

- HGIDocument8 pagesHGIMutiara Dwi SeptianiNo ratings yet

- Che 321 Centrifugation 2Document33 pagesChe 321 Centrifugation 2Glory UsoroNo ratings yet

- Mix Proportioning of CementDocument28 pagesMix Proportioning of CementAkshay WaimNo ratings yet

- Soil Correlations: Caltrans Geotechnical ManualDocument5 pagesSoil Correlations: Caltrans Geotechnical ManualHandi ThomasNo ratings yet

- Reservoir Modelling Simulation: Computer Modelling Group (CMG)Document20 pagesReservoir Modelling Simulation: Computer Modelling Group (CMG)Anonymous CsU0x3AWjNo ratings yet

- Rheology of Shear Thinning Polymer Solutions: L. JohnDocument4 pagesRheology of Shear Thinning Polymer Solutions: L. Johnvandna kushwahaNo ratings yet

- Properties of Fine Aggregate:: Gradation and TextureDocument12 pagesProperties of Fine Aggregate:: Gradation and Texturesalil dubeyNo ratings yet

- Manufacturing Processes (ME361) Lecture 11: Instructor: Shantanu BhattacharyaDocument30 pagesManufacturing Processes (ME361) Lecture 11: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Reference Manual Surface and AppearanceDocument36 pagesReference Manual Surface and AppearancePavan SamudralaNo ratings yet

- Concrete MaterialDocument38 pagesConcrete MaterialRwitika TarafderNo ratings yet

- Coal MicronizationDocument8 pagesCoal MicronizationKevin David Guao BolanoNo ratings yet

- Analysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionDocument23 pagesAnalysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionKamal RajuNo ratings yet

- Mel725 40Document23 pagesMel725 40thangammalNo ratings yet

- Mel725 40Document23 pagesMel725 40thangammalNo ratings yet

- Mel725 40Document23 pagesMel725 40thangammalNo ratings yet

- Field Separation of Oil From GasDocument54 pagesField Separation of Oil From GasRajat SharmaNo ratings yet

- Week 2 - Coal Seam AnalysesDocument9 pagesWeek 2 - Coal Seam AnalysesMuhammad ShahrukhNo ratings yet

- Soil Texture Triangle WorksheetDocument2 pagesSoil Texture Triangle WorksheetYcarta Sleumas0% (1)

- What Is Gradient Retention Factor, K ?Document4 pagesWhat Is Gradient Retention Factor, K ?Yeoh XWNo ratings yet

- Percent of Diluent Evaporated From Cutback Asphalt Over Time.Document4 pagesPercent of Diluent Evaporated From Cutback Asphalt Over Time.arbiNo ratings yet

- Learning Unit 2 - AbsorptionDocument68 pagesLearning Unit 2 - AbsorptionTshwarelo MahlakoaneNo ratings yet

- Journal GilbertDocument5 pagesJournal GilbertGilbert SunaryoNo ratings yet

- Absorption: Instructor: Zafar ShakoorDocument18 pagesAbsorption: Instructor: Zafar ShakoorFASIH AFZAL KHANNo ratings yet

- 003 - Feeding System For Steel Casting by MR J N Baad PDFDocument18 pages003 - Feeding System For Steel Casting by MR J N Baad PDFDarshan AlloyNo ratings yet

- How Do We Estimate Materials For Different Ratio Concrete?Document7 pagesHow Do We Estimate Materials For Different Ratio Concrete?TanvirNo ratings yet

- CE2812 - Sieve Analysis and Hydrometer AnalysisDocument12 pagesCE2812 - Sieve Analysis and Hydrometer AnalysisRashmiNo ratings yet

- Chemical Gauging Method (Dilution MethodDocument38 pagesChemical Gauging Method (Dilution MethodAsjad UllahNo ratings yet

- ICEMINE 2020 Coal Quality Geostatistics 1607321487Document13 pagesICEMINE 2020 Coal Quality Geostatistics 1607321487Hamdan MaulanaNo ratings yet

- Effects of Slurry Rheology and Coating On Abrasive Wear and The Grinding Rate of QuartziteDocument6 pagesEffects of Slurry Rheology and Coating On Abrasive Wear and The Grinding Rate of QuartziteBenito Quispe A.No ratings yet

- Second Review - Batch 03-1Document16 pagesSecond Review - Batch 03-119114 GovindNo ratings yet

- Appendix 5 IRC SP 114Document5 pagesAppendix 5 IRC SP 114Sharath RMNo ratings yet

- Internship Presentation Madhucon Projects LimitedDocument43 pagesInternship Presentation Madhucon Projects Limiteddineshkumar1009No ratings yet

- Risers Design Unit-IDocument24 pagesRisers Design Unit-IQUAZI ADYAN AHMAD 160419736049No ratings yet

- Estimating Compressive Strength With SilverSchmidtDocument2 pagesEstimating Compressive Strength With SilverSchmidtlokeshlokNo ratings yet

- Chapter Two DRDocument30 pagesChapter Two DRيا ابا صالح المهديNo ratings yet

- Resrvoir Part-2Document31 pagesResrvoir Part-2Oringa Williams ApolloNo ratings yet

- RS - Lecture 3Document37 pagesRS - Lecture 3Omer IkhlasNo ratings yet

- Unit2 Chapter4 Bituminous Paving MixesDocument16 pagesUnit2 Chapter4 Bituminous Paving MixesSajja Satish Assistant Professor, CE, VRSECNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document5 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document5 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document6 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document5 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816: Lab Report 3 Date:22/12/2020Document4 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816: Lab Report 3 Date:22/12/2020Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document3 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet

- Name: Danial Afzal Malik Reg No: 17PWMIN0816Document3 pagesName: Danial Afzal Malik Reg No: 17PWMIN0816Danial AfzalNo ratings yet