100% found this document useful (1 vote)

1K views47 pagesBuilding Material - Timber & Wood

Timber is wood that has been processed for use in construction or manufacturing. It comes from trees and is stronger and more durable than raw wood. Some key points:

- Timber refers to wood that has been cut, sawn, and prepared for use while wood is raw material in its natural state.

- Timber is used widely in construction for beams, floors, furniture and other structural applications due to its strength and availability.

- There are defects that can occur in timber like shakes, knots, and cracks which impact the quality and strength. Proper selection and processing helps ensure good quality timber.

Uploaded by

Saurav ShresthaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

1K views47 pagesBuilding Material - Timber & Wood

Timber is wood that has been processed for use in construction or manufacturing. It comes from trees and is stronger and more durable than raw wood. Some key points:

- Timber refers to wood that has been cut, sawn, and prepared for use while wood is raw material in its natural state.

- Timber is used widely in construction for beams, floors, furniture and other structural applications due to its strength and availability.

- There are defects that can occur in timber like shakes, knots, and cracks which impact the quality and strength. Proper selection and processing helps ensure good quality timber.

Uploaded by

Saurav ShresthaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

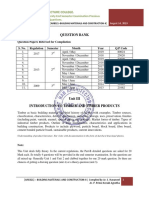

- Introduction

- Timber and Its Types

- Uses of Timber

- Classification of Trees and Wood

- Tree Growth and Timber Quality

- Defects in Timber

- Timber Seasoning

- Timber Decay and Preservation

- Common Wood Products