Professional Documents

Culture Documents

FM-2 Lecture 15 Lots of Formulas

Uploaded by

Salman0 ratings0% found this document useful (0 votes)

18 views23 pagesOriginal Title

FM-2 Lecture 15 Lots of formulas

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views23 pagesFM-2 Lecture 15 Lots of Formulas

Uploaded by

SalmanCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 23

CE-UG-2018

Spring FEB-JUN 2020

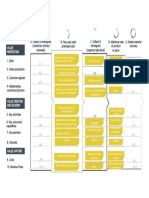

Ratio of efficiencies of two

similar machines is unity

Type Number

The performance of the machines belonging from different

families may be compared by plotting their dimensionless

characteristics on the same graph, but it lacks brevity

required in the machine classification.

This is obtained by the use of Type Number also known as

specific speed.

The type number is obtained from dimensionless coefficients.

With the aid of type number various types of pumps and

turbines may be classified and compared.

The type number refers to design point, it is used as the most

important design parameter.

Every machine is designed to meet a specific

duty, usually referred to as the design point.

For a pump, for example, this would be

stated in terms of the flow rate and the head

developed and, thus, represents a particular

point on its basic performance characteristic.

The design point is normally associated with

the maximum efficiency of the machine.

It is thus , informative to compare machines

by quoting the values of KQ , KH and Kp

corresponding to their design points.

Type number for Pumps

Since for pumps KQ and KH are the two most

important parameters, their ratio would

indicate the suitability of a particular pump for

large or small volumes relative to the head

developed. If the ratio is obtained in such a way

that the impeller diameter is eliminated from it,

then the comparison becomes independent of

machine size.

This is achieved by raising KQ to the power ½

and KH to the power ¾.

Type number for Pumps

Type number for turbines

The comparison of turbines is also achieved by the

use of their type numbers.

However since for turbine power developed is the

most important variable, an alternative expression for

type number in terms of power developed is obtained

by eliminating D from the ratio of power and head

coefficients.

This is achieved by raising the power coefficient to

the power of ½ and head coefficient to the power of

5/4 and taking their ratio.

Type number for turbines

It must be realized that a value of type number can be

calculated for any point on the characteristic curve.

Such values are, however, of no practical interest and

only the type number at the design point, usually

referred to as the type number, is used for

classification, comparison and design purposes.

Since the type number refers to the design point, it is

used as the most important design parameter.

Water Turbines

Turbines are subdivided into impulse and reaction

machines.

Impulse Turbine Reaction Turbine

In impulse turbine the total head is In reaction turbines fluid first passes

first converted into the kinetic energy. through a ring of stationary guide vanes in

This is usually accomplished in one which only part of total head is being

or more nozzles. converted in kinetic energy.

The jet issuing from the nozzle The guide vane discharge directly into the

strike vanes attached to the runner along the whole of its periphery, so

periphery of the rotating wheel. that fluid entering the runner has pressure

Since the fluid energy which is energy as well as kinetic energy.

reduced on passing through the The pressure energy is converted into

runner is entirely kinetic energy. It kinetic energy in the runner (the passage

follows that absolute velocity at the running full)

outlet is less than that of inlet.

Impulse Turbine:

The total head available is first converted into K.E.

Accomplished in one or more nozzles.

The jets issuing form nozzles strike vanes attached to the periphery of the

rotating wheel.

Energy transferred , due to rate of change of angular momentum

Fluid energy is entirely K.E.

v1>v2

Fluid pressure is atmospheric

Relative velocity is constant.

Reaction turbine:

the fluid passes first through a ring of

stationary guide vanes.

In guide vanes, part of available total head

is converted into K.E.

The guide vanes discharges directly into

the runner along the whole of its

periphery.

The fluid entering the runner has pressure

energy as well as K.E.

Pressure Energy is converted into K.E, in

the runner.

Relative velocity is not constant , increases

through the runner.

There is pressure difference across the

runner.

Degree of Reaction

The parameter which describes reaction turbine is

degree of reaction “it is the ratio of static pressure drop

and total Energy transferred per unit weight of fluid.

Water turbines are mainly used in power stations to drive electric generators.

There are three well-known types which are used:

the Pelton wheel, which is an impulse turbine,

the Francis type and the axial flow (Kaplan) turbines, both being of the reaction type.

Pelton Wheel

where k represents the reduction of the relative

velocity due to friction.

This equation shows that there is no energy transfer when the vane velocity is

either zero or equal to the jet velocity. It is reasonable to expect, therefore, that the

maximum energy transfer will occur at some intermediate value of the vane velocity.

This may be obtained by differentiation as follows:

Francis Turbine

The total head available to the machine is H and the water velocity on entering

the guide vanes is v0. The velocity leaving the guide vanes is v1 and is related to v0 by

the continuity equation

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- How To Measure Superheat and SubcoolingDocument10 pagesHow To Measure Superheat and SubcoolingRay Ravel83% (6)

- Axial and Radial Flow TurbinesDocument138 pagesAxial and Radial Flow TurbinesPRAVEEN100% (1)

- Efficiency and Input Power of The PumpDocument14 pagesEfficiency and Input Power of The PumpMohammed BrashdiNo ratings yet

- Energy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurDocument37 pagesEnergy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurmvpngpNo ratings yet

- Basic Equation of Energy in Fluid MachinesDocument28 pagesBasic Equation of Energy in Fluid Machinesabhigoyal1989No ratings yet

- Impulse and Reaction Blading of Gas TurbinesDocument4 pagesImpulse and Reaction Blading of Gas Turbinesapi-271354682100% (3)

- Griffith Drilling JarDocument1 pageGriffith Drilling JarFakhrurrozi ArbianNo ratings yet

- Dry Out & Curing of Refractory LiningDocument2 pagesDry Out & Curing of Refractory Liningmasoud_968370957100% (1)

- An Introduction To Foreign Policy Definition, Nature DeterminantsDocument9 pagesAn Introduction To Foreign Policy Definition, Nature DeterminantsHaseeb KhanNo ratings yet

- Axial Flow TurbinesDocument145 pagesAxial Flow TurbinesRaj Narayan100% (1)

- 05 Steam TurbineDocument11 pages05 Steam TurbineJohn Paulo ArchinueNo ratings yet

- Pneumatic MotorDocument4 pagesPneumatic MotorabyzenNo ratings yet

- 4 Applied HydraulicsDocument30 pages4 Applied Hydraulicsمهندس ابينNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Flowcheck Guide To Pumps PDFDocument3 pagesFlowcheck Guide To Pumps PDFashrefrasliNo ratings yet

- A Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceDocument6 pagesA Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceAudrey Patrick KallaNo ratings yet

- Design of Water Tanks-CE 05014 p3 6Document65 pagesDesign of Water Tanks-CE 05014 p3 6engineerkranthi4055100% (1)

- Part 4: Lateral Earth Pressure and Earth-Retaining StructuresDocument25 pagesPart 4: Lateral Earth Pressure and Earth-Retaining StructuresiosamNo ratings yet

- PC 1 FlowAssurance PDFDocument21 pagesPC 1 FlowAssurance PDFAlvaro VelardeNo ratings yet

- How To Read Basic Pump CurvesDocument5 pagesHow To Read Basic Pump CurvesGauravNo ratings yet

- Steam TurbineDocument77 pagesSteam TurbineAmit KhadkaNo ratings yet

- RFQ On Consultancy Pipeline Project-1Document6 pagesRFQ On Consultancy Pipeline Project-1Atty AttyNo ratings yet

- Fluid MachinesDocument161 pagesFluid MachinesHaroon GhaniNo ratings yet

- Iso - 28300 2009Document3 pagesIso - 28300 2009Joost van den Heuvel100% (2)

- CE-UG-2018 Spring FEB-JUN 2020Document43 pagesCE-UG-2018 Spring FEB-JUN 2020SalmanNo ratings yet

- Working of Steam Turbine Learn EngineeringDocument4 pagesWorking of Steam Turbine Learn EngineeringWahid HusainNo ratings yet

- Rotodynamic Machines: Engine or Motor Is UsedDocument25 pagesRotodynamic Machines: Engine or Motor Is UsedWika ElmasryNo ratings yet

- Hydraulic TurbinesDocument43 pagesHydraulic TurbinesKarim SayedNo ratings yet

- Objective of PumpsDocument6 pagesObjective of PumpsTomide OlasupoNo ratings yet

- MCE 403-Francis Türbini Deney FöyüDocument6 pagesMCE 403-Francis Türbini Deney FöyüAnonymous tE5Xw9rA5No ratings yet

- TM 3pdfDocument14 pagesTM 3pdfMohith Gowda KgNo ratings yet

- CIVE240001 Fluid Mechanics Section 2: Pumps: 1. Some General Notes About Fluid MachineryDocument11 pagesCIVE240001 Fluid Mechanics Section 2: Pumps: 1. Some General Notes About Fluid Machinerybikesh032No ratings yet

- Ecuación General de La Energía - RemovedDocument10 pagesEcuación General de La Energía - RemovedJuan Sebastian Ortiz DelgadoNo ratings yet

- Me Ee-411 Term Paper TH Engg (Copy)Document7 pagesMe Ee-411 Term Paper TH Engg (Copy)PRANAB KUMAR PALNo ratings yet

- 1.0 Abstracts: Fluid Pressure Pumps TurbinesDocument11 pages1.0 Abstracts: Fluid Pressure Pumps TurbinesZahid ZakariaNo ratings yet

- Turbo Machines 15ME53Document83 pagesTurbo Machines 15ME53mulualemNo ratings yet

- 2 Performance of Rotodynamic MachinesDocument28 pages2 Performance of Rotodynamic MachinesOmar AhmedNo ratings yet

- Hemanth Karmali & Deepak Pai - FomentoDocument46 pagesHemanth Karmali & Deepak Pai - FomentoNileshNo ratings yet

- Cseelements of Mechanical Engg. L2Document13 pagesCseelements of Mechanical Engg. L2bhatchinmay7No ratings yet

- Theory On The Kaplan Turbne Operation 1Document18 pagesTheory On The Kaplan Turbne Operation 1Anonymous 1VhXp1No ratings yet

- Steam EffDocument4 pagesSteam EffViola ZakariaNo ratings yet

- Turbo Machinery (ME 5001) - Unit 1 - WWW - Rgpvnotes.in PDFDocument11 pagesTurbo Machinery (ME 5001) - Unit 1 - WWW - Rgpvnotes.in PDFMohammed AhmedNo ratings yet

- Francis Turbine ManualDocument6 pagesFrancis Turbine ManualshubhamNo ratings yet

- HM Assingment 02Document7 pagesHM Assingment 02PradneshNo ratings yet

- Title: Figure 1: Categories of Centrifugal PumpDocument7 pagesTitle: Figure 1: Categories of Centrifugal PumpHaziq Pazli100% (1)

- Fluid Machines: Chapter 3: Water TurbineDocument22 pagesFluid Machines: Chapter 3: Water TurbineSneha SahNo ratings yet

- Transportation of Fluids: Prepared By: Engr. Joseph R. OrteneroDocument48 pagesTransportation of Fluids: Prepared By: Engr. Joseph R. OrteneroChristianNo ratings yet

- Experimental Analysis On Kaplan Turbine To Determine The Performance Charactertsttcs Curve at Part Load ConditionsDocument7 pagesExperimental Analysis On Kaplan Turbine To Determine The Performance Charactertsttcs Curve at Part Load ConditionsAnonymous 8Mc8boONNo ratings yet

- Basic Pump Parameters and The Affinity LawsDocument7 pagesBasic Pump Parameters and The Affinity LawsAhmedSameerNo ratings yet

- Classificaitons of Fluid MachinesDocument4 pagesClassificaitons of Fluid MachinesaadhanNo ratings yet

- Pumps and Turbines - Cheruiyot PDFDocument40 pagesPumps and Turbines - Cheruiyot PDFMwiti TizianoNo ratings yet

- Ecuación General de La EnergíaDocument25 pagesEcuación General de La EnergíaSergio Andres Velasco DiazNo ratings yet

- T M D F: Urning Oment Iagrams AND LywheelDocument21 pagesT M D F: Urning Oment Iagrams AND LywheelAmandeep Singh Bansal100% (1)

- Axial Flow CompressorDocument50 pagesAxial Flow CompressorSunil Panwar100% (1)

- On FlywheelDocument34 pagesOn FlywheelHarikumar ANo ratings yet

- FM Module I - Turbines - Note - PPTDocument52 pagesFM Module I - Turbines - Note - PPT916 Maneesh nn ME BNo ratings yet

- لقطة شاشة ٢٠٢٤-٠٢-١١ في ٨.٣٨.٤٩ صDocument28 pagesلقطة شاشة ٢٠٢٤-٠٢-١١ في ٨.٣٨.٤٩ صabdollahali2004No ratings yet

- CIVE240001 Fluid Mechanics Section 2: Pumps: 1. Some General Notes About Fluid MachineryDocument22 pagesCIVE240001 Fluid Mechanics Section 2: Pumps: 1. Some General Notes About Fluid MachinerySameer TamboliNo ratings yet

- Optimisation of Pumps in Thermal Power StationsDocument69 pagesOptimisation of Pumps in Thermal Power StationsShaik Nizam UddinNo ratings yet

- Unit CommDocument56 pagesUnit CommkgurumoorthiNo ratings yet

- PMFM Viva QuestionsDocument17 pagesPMFM Viva QuestionsVineet KumarNo ratings yet

- Chapter - 3 - Hydraulic TurbinesDocument78 pagesChapter - 3 - Hydraulic TurbinesLauria LavdaNo ratings yet

- Laboratory ManualDocument52 pagesLaboratory ManualOsan ThorpeNo ratings yet

- Turbine: Navigation Search Turbine (Disambiguation)Document7 pagesTurbine: Navigation Search Turbine (Disambiguation)ranjithkumar_252No ratings yet

- 2 - 4energy Exchange in TurbomachinesDocument28 pages2 - 4energy Exchange in TurbomachinesYash RathodNo ratings yet

- 1.1 Introduction To TurbomachineDocument38 pages1.1 Introduction To TurbomachinemohamedovicNo ratings yet

- Geography 2Document19 pagesGeography 2SalmanNo ratings yet

- Lab Report 9Document10 pagesLab Report 9SalmanNo ratings yet

- Ocean DepositDocument5 pagesOcean DepositSalmanNo ratings yet

- Digital Distraction: Shedding Light On The 21st-Century College ClassroomDocument16 pagesDigital Distraction: Shedding Light On The 21st-Century College ClassroomSalmanNo ratings yet

- Hawaiian Calderas!: Hawaii Institute of Geophysics Contribution No. 92Document15 pagesHawaiian Calderas!: Hawaii Institute of Geophysics Contribution No. 92SalmanNo ratings yet

- School of Mechanical and Manufacturing Engineering Nust Applied Physics Lab Report # 2 PascarDocument15 pagesSchool of Mechanical and Manufacturing Engineering Nust Applied Physics Lab Report # 2 PascarSalmanNo ratings yet

- School of Mechanical and Manufacturing Engineering Nust Applied Physics Lab Report # 5 Ac DC ElectronicsDocument6 pagesSchool of Mechanical and Manufacturing Engineering Nust Applied Physics Lab Report # 5 Ac DC ElectronicsSalmanNo ratings yet

- Lecture - 7 - FRW CH 7 8 Problems (Work, KE, PE Conservation of Energy)Document6 pagesLecture - 7 - FRW CH 7 8 Problems (Work, KE, PE Conservation of Energy)SalmanNo ratings yet

- Lab Report No: Physics Ac-Dc ElectronicsDocument17 pagesLab Report No: Physics Ac-Dc ElectronicsSalmanNo ratings yet

- PASCO AC DC Electronics KitDocument126 pagesPASCO AC DC Electronics KitMaria Abdullah AbbasiNo ratings yet

- Chapter 22: Electric Field ProblemsDocument18 pagesChapter 22: Electric Field ProblemsSalmanNo ratings yet

- Lecture - 10 (Coulombs Law)Document8 pagesLecture - 10 (Coulombs Law)SalmanNo ratings yet

- Lab Report Smme, Nust: Applied Physics (PHY-102) Lab #4Document12 pagesLab Report Smme, Nust: Applied Physics (PHY-102) Lab #4SalmanNo ratings yet

- ANALYSIS OF PAK-INDIA COMPOSITE DIALOGUE - Islamabad Policy Research InstituteDocument4 pagesANALYSIS OF PAK-INDIA COMPOSITE DIALOGUE - Islamabad Policy Research InstituteSalmanNo ratings yet

- Brochure-ParkEnclaveExt S PDFDocument21 pagesBrochure-ParkEnclaveExt S PDFBill 007No ratings yet

- WIS DOT Bridge Manual Retaining Wall PDFDocument260 pagesWIS DOT Bridge Manual Retaining Wall PDFPrashant JhaNo ratings yet

- Hydraulics Solution Sheet 11 - Pumps and TurbinesDocument3 pagesHydraulics Solution Sheet 11 - Pumps and TurbinesSalmanNo ratings yet

- BookDocument217 pagesBookjuan diegoNo ratings yet

- Building RapportDocument4 pagesBuilding RapportSalmanNo ratings yet

- Durability Performance of Lightweight Aggregate Concrete For Housing ConstructionDocument11 pagesDurability Performance of Lightweight Aggregate Concrete For Housing ConstructionSalmanNo ratings yet

- HydrologyDocument4 pagesHydrologyRafia AbidNo ratings yet

- Chapter No. 01 and 02 Introduction To Hydrology. PrecipitationDocument96 pagesChapter No. 01 and 02 Introduction To Hydrology. PrecipitationRahat ullah0% (1)

- W4 - Exercise Caterpillar Business Model PDFDocument1 pageW4 - Exercise Caterpillar Business Model PDFJuan David Cruz NegreteNo ratings yet

- Test Method: Subject: ApprovedDocument4 pagesTest Method: Subject: ApprovedLucky KhanNo ratings yet

- Watertank GS PDFDocument24 pagesWatertank GS PDFManoj RautNo ratings yet

- Sec 11 172Document11 pagesSec 11 172Anonymous fInhe7No ratings yet

- Fourth Semester B.Tech Degree Examination July 2021 (2019 Scheme)Document3 pagesFourth Semester B.Tech Degree Examination July 2021 (2019 Scheme)MidhunNo ratings yet

- CLD 20202 Exp 1-Control ValveDocument15 pagesCLD 20202 Exp 1-Control ValveAbu RectifyNo ratings yet

- CE123 FinalsDocument1 pageCE123 FinalsZENRIRNo ratings yet

- Control of Particulate Matter Emissions: APTI Course 413 Third EditionDocument358 pagesControl of Particulate Matter Emissions: APTI Course 413 Third EditionAlex RomeroNo ratings yet

- DistillationDocument109 pagesDistillationAmna AnjumNo ratings yet

- Chapter 4 Design of Intercepting SewersDocument24 pagesChapter 4 Design of Intercepting SewersAce ThunderNo ratings yet

- Positive Displacement PumpsDocument20 pagesPositive Displacement PumpspavijayaNo ratings yet

- EE2 Module 1 TeacherDocument44 pagesEE2 Module 1 Teacherlakshmi dileepNo ratings yet

- Seminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018Document54 pagesSeminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018INSTECH Consulting100% (1)

- ELGi AIRLUBE 500 HRS & ELGi AIRLUBE PLUS 750 HRSDocument1 pageELGi AIRLUBE 500 HRS & ELGi AIRLUBE PLUS 750 HRSANILNo ratings yet

- 3.1 Overview of Flat Plate Collectors: PrintDocument3 pages3.1 Overview of Flat Plate Collectors: Printsuseendran sNo ratings yet

- RelativeResourceManager PDFDocument113 pagesRelativeResourceManager PDFMuhammad Irfan SalahuddinNo ratings yet

- Xacto Electrical ThickwallDocument3 pagesXacto Electrical ThickwallzippyzevenNo ratings yet

- Thermal Energy Storage System Using Phase Change Materials - Constant Heat SourceDocument8 pagesThermal Energy Storage System Using Phase Change Materials - Constant Heat SourceLue niNo ratings yet

- DATA SHEET VCM Condenser No 2Document1 pageDATA SHEET VCM Condenser No 2nabila OktavianiNo ratings yet

- Armas 800 SeriesDocument44 pagesArmas 800 SeriesAlexisVillaNo ratings yet

- A Novel Method For Determining Residence Time Distribution in Intricately Structured MicroreactorsDocument8 pagesA Novel Method For Determining Residence Time Distribution in Intricately Structured MicroreactorsMohit JagtapNo ratings yet

- Stopple Fittings: ASME B31.3 - Sizes 4-Through 12 - & 16-InchDocument6 pagesStopple Fittings: ASME B31.3 - Sizes 4-Through 12 - & 16-Inchadventure11111No ratings yet

- Cengel Fluid Mechanics 6 Edition PDFDocument7 pagesCengel Fluid Mechanics 6 Edition PDFVenkat MacharlaNo ratings yet

- Effective Synthesis of N-Butyl Salicylate Over Wash Coated Cordierite Honeycomb by Zirconia and Its Mixed Oxides: A Kinetic StudyDocument2 pagesEffective Synthesis of N-Butyl Salicylate Over Wash Coated Cordierite Honeycomb by Zirconia and Its Mixed Oxides: A Kinetic StudySudimanNo ratings yet

- Pin Fin Seminar ReportDocument23 pagesPin Fin Seminar ReportMuhammedShafeeqNo ratings yet

- Form U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsDocument4 pagesForm U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsAmit SharmaNo ratings yet

- Advanced Valve Solutions CDocument81 pagesAdvanced Valve Solutions Cpartha6789No ratings yet

- Symbols Used in Vacuum Technology Vacuum SymbolsDocument5 pagesSymbols Used in Vacuum Technology Vacuum SymbolsbabaNo ratings yet