100% found this document useful (2 votes)

2K views41 pagesConcrete Microstructure and Properties

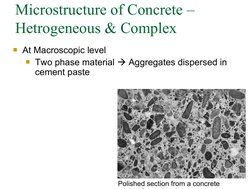

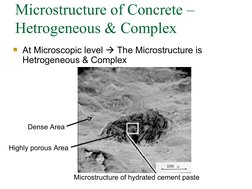

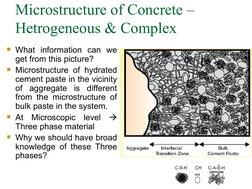

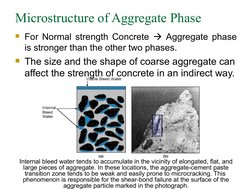

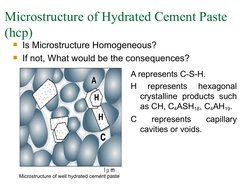

The document discusses the microstructure of concrete at the macro, micro, and nanoscale levels. At the macro level, concrete is a two-phase material of aggregates dispersed in cement paste. At the micro level, it is a three-phase material with the addition of the interfacial transition zone (ITZ) between the aggregate and cement paste. The cement paste microstructure is heterogeneous and complex, containing hydrated cement products like calcium silicate hydrate (C-S-H) and calcium hydroxide, as well as capillary pores. The ITZ has a higher porosity than the bulk cement paste, making it weaker. The complex microstructure of concrete, particularly the ITZ, helps explain its in

Uploaded by

AwaisZahidOrakzaiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

2K views41 pagesConcrete Microstructure and Properties

The document discusses the microstructure of concrete at the macro, micro, and nanoscale levels. At the macro level, concrete is a two-phase material of aggregates dispersed in cement paste. At the micro level, it is a three-phase material with the addition of the interfacial transition zone (ITZ) between the aggregate and cement paste. The cement paste microstructure is heterogeneous and complex, containing hydrated cement products like calcium silicate hydrate (C-S-H) and calcium hydroxide, as well as capillary pores. The ITZ has a higher porosity than the bulk cement paste, making it weaker. The complex microstructure of concrete, particularly the ITZ, helps explain its in

Uploaded by

AwaisZahidOrakzaiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Significance of Microstructure: Explains the importance of understanding the microstructure for developing properties and relationships in concrete materials.

- Microstructure of Concrete: Discusses the heterogeneous and complex nature of concrete's microstructure at various scales and its implications.

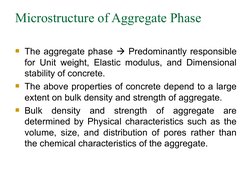

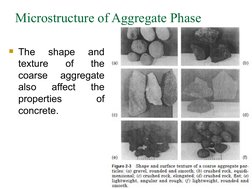

- Microstructure of Aggregate Phase: Explores the role and properties of the aggregate phase in contributing to the overall properties of concrete.

- Microstructure of Hydrated Cement Paste: Analyzes the composition and different phases within hydrated cement paste, highlighting its structural and material characteristics.

- Water inside the Pores: Describes the classification and role of different types of water held within the pores of concrete materials.

- Microstructure-Property Relationship in hcp: Examines how the microstructural features of hardened cement paste influence its strength, stability, and durability.

- Interfacial Transition Zone (ITZ): Focuses on the characteristics and significance of ITZ in determining concrete's mechanical behavior.

- Microstructural Improvement: Discusses methods for enhancing the microstructural properties of concrete through material and chemical modification.