Professional Documents

Culture Documents

2850 L3u302 PowerPoint 05

Uploaded by

Keron Bretal0 ratings0% found this document useful (0 votes)

6 views13 pagesThis document provides an overview of engineering materials including ferrous metals like steel and cast iron. It discusses the different types of steel based on their carbon content, including low, medium, and high carbon steels. It also describes alloying elements that can be added to steels to improve properties and introduces high yield steels, stainless steels, and cast irons.

Original Description:

Original Title

2850_l3u302_PowerPoint_05

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of engineering materials including ferrous metals like steel and cast iron. It discusses the different types of steel based on their carbon content, including low, medium, and high carbon steels. It also describes alloying elements that can be added to steels to improve properties and introduces high yield steels, stainless steels, and cast irons.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views13 pages2850 L3u302 PowerPoint 05

Uploaded by

Keron BretalThis document provides an overview of engineering materials including ferrous metals like steel and cast iron. It discusses the different types of steel based on their carbon content, including low, medium, and high carbon steels. It also describes alloying elements that can be added to steels to improve properties and introduces high yield steels, stainless steels, and cast irons.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 13

Unit 302: Engineering principles

Ferrous Engineering Materials

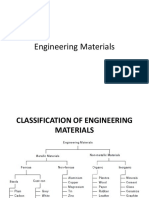

Engineering Materials

• Engineering materials come in a range of types, sizes

and shapes.

• Each material has a particular range of properties

• The selection of the correct material to suit a given

application or environment is essential

• Incorrect selection can lead to expensive re-work or

complete failure of the finished component

Ferrous Metals

• Ferrous metals contain iron (Fe)

• Pure iron is a relatively weak material and not suitable

for modern engineering products.

• The addition of small amounts of carbon (C) produces

steel.

• Steel is the most widely used engineering material.

Steel

• Steel is an alloy (mixture) of iron and carbon.

• The percentage of carbon influences the

properties of the steel.

• Other metals can be added in small amounts to

change steel properties further.

• This group of metals are known as alloy steels.

Steel

• Low carbon steel (LCS)

– contains up to 0.29% carbon

– easily welded by a range of processes

– easily formed into a range of shapes

– sometimes known as mild steel

Steel

• Medium carbon steel (MCS)

– harder and stronger than LCS

– contains from 0.3% to 0.54 carbon

– Can be welded by a range of processes

– Can be formed into a range of shapes

– post production heat treatment may be

required.

Steel

• High carbon steel (HCS)

– hardest of the carbon steels

– hardness levels lead to a brittle material

– contains from 0.55% to 1.2% carbon

– difficult to weld

– can not be formed due to brittleness.

– may need to be annealed prior to machining

– post production hardening and tempering may

be required.

Low Alloy Steels

• All steels are alloys (iron + carbon)

• Some steels have small additions (up to 7%) of other

materials to improve their properties.

Alloying element % Benefit

Chromium 0.5 - 2 Increased hardenability

Vanadium 0.15 Increases strength

Silicon 0.2 – 0.7 Increases strength

Nickel 2-5 Increases toughness

Molybdenum 0.2 - 5 Increases toughness

High Yield Steels

• High yield steels is an alloy steel that has improved

mechanical properties compared to low carbon steels

• Carbon content is between 0.05 - 0.25% to maintain

formability and weldability

• Alloying elements include up to 2% manganese

• Small quantities of copper, nickel or vanadium improve

strength.

• Alloying elements change the microstructure of the

carbon steels to improve the properties.

• High yield steels can be 30% lighter than carbon steels

with comparable strength.

Cast Irons

• Cast iron is a ferrous alloy with typically 2 – 4% carbon

• Additions of silicon improves fluidity when molten

• Usually brittle except for malleable cast iron

• Good compressive strength

• Good machinability and self lubricating due to excess of

carbon (graphite).

Cast Iron Types

Cast iron is available in 4 main types:

•White Cast Iron

•high compressive strength

•Hard with a good resistance to wear

•Grey Cast Iron

•good machinability

•good resistance to wear and galling

•Ductile Cast Iron

•high strength

•high ductility

•Malleable Cast Iron

•White cast iron heat-treated to improve ductility

Stainless Steels

• Stainless steels are commonly used for their corrosion

resistance properties.

• Stainless steels contain a minimum of 10.5% chromium

• Other metals can be added to improve properties

including:

• Nickel

• Molybdenum

• Titanium

• Copper

Austenitic Stainless Steel

• Austenitic stainless steels have good ductility and high

strength compared to carbon steels.

• Welding causes little or no effect on the material

properties.

• Austenitic stainless steels contain nickel

• Non magnetic

You might also like

- Steel: Haseeb Ullah Khan Jatoi Department of Chemical Engineering UET LahoreDocument59 pagesSteel: Haseeb Ullah Khan Jatoi Department of Chemical Engineering UET LahoreMuhammad Waqas AkbarNo ratings yet

- Unit 5 W7 DJJ3213 (Metal Alloys)Document35 pagesUnit 5 W7 DJJ3213 (Metal Alloys)Syfull musicNo ratings yet

- Introduction To Material Science and Engineering: Engr. Ana Lorraine M. Dalilis, RcheDocument64 pagesIntroduction To Material Science and Engineering: Engr. Ana Lorraine M. Dalilis, RcheTracy Gale MiddleborgNo ratings yet

- Unit Iii: V 6Cwodc-3VrkDocument237 pagesUnit Iii: V 6Cwodc-3VrkDinesh KumarNo ratings yet

- Unit1-Introduction To Engineering MaterialsDocument80 pagesUnit1-Introduction To Engineering MaterialsYatharth bishtNo ratings yet

- AlloysDocument91 pagesAlloysNiccoloNo ratings yet

- Publication 11 16474 560Document17 pagesPublication 11 16474 560kareem_opoNo ratings yet

- Heat Treatment (Immersion)Document108 pagesHeat Treatment (Immersion)DidSibalNo ratings yet

- Steel With Varied Carbon ContentDocument20 pagesSteel With Varied Carbon ContentTrex JoblinNo ratings yet

- Metal and AlloysDocument45 pagesMetal and AlloysNarender KumarNo ratings yet

- Effect of Alloying ElementsDocument86 pagesEffect of Alloying ElementsNavdeep JainNo ratings yet

- Part 2 - SteelsDocument45 pagesPart 2 - SteelsAlemu MergaNo ratings yet

- Arch111 Lecture 3 SteelDocument76 pagesArch111 Lecture 3 SteelGameli Ayivi-TosuhNo ratings yet

- Basic Metallurgy For Welding and Fabricating ProfessionalsDocument190 pagesBasic Metallurgy For Welding and Fabricating Professionalsmahi1437No ratings yet

- Classification of SteelDocument39 pagesClassification of SteelSudarshan GNo ratings yet

- GKDITRDocument33 pagesGKDITRsenthil muruganNo ratings yet

- Carbon Steel and Mild Steel DifferenceDocument8 pagesCarbon Steel and Mild Steel DifferenceSteinol SolutionsNo ratings yet

- Ador Welding LTD - IBD Division JINDAL SOHAR 1Document113 pagesAdor Welding LTD - IBD Division JINDAL SOHAR 1Maneesh BhartiNo ratings yet

- Use of Metals in Construction: Dr. R. N. BeheraDocument46 pagesUse of Metals in Construction: Dr. R. N. BeheraRishabh SinghNo ratings yet

- 10020dep-Notice 11042020Document32 pages10020dep-Notice 11042020Shivam VermaNo ratings yet

- Note CHP 4 Material Science 281 Uitm Em110Document52 pagesNote CHP 4 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- Classification of Materials: Shivan I. Abdullah Mechanical Engineering Dept. September 2021Document29 pagesClassification of Materials: Shivan I. Abdullah Mechanical Engineering Dept. September 2021Esmail AnasNo ratings yet

- Professor Joe Greene Csu, ChicoDocument41 pagesProfessor Joe Greene Csu, ChicoKamalakanta SahooNo ratings yet

- Properties and Applications of MaterialsDocument65 pagesProperties and Applications of MaterialsSeashell BernzNo ratings yet

- Alloying Elements and Alloys (1) - 17471991 - 2023 - 05 - 31 - 18 - 57Document27 pagesAlloying Elements and Alloys (1) - 17471991 - 2023 - 05 - 31 - 18 - 57Anoop AnuNo ratings yet

- HT 3Document56 pagesHT 3Ivan PratamaNo ratings yet

- Engineering Materials MEE 110: Dr. M. Tauqeer AnwarDocument14 pagesEngineering Materials MEE 110: Dr. M. Tauqeer AnwarAli HassanNo ratings yet

- Classification of SteelsDocument3 pagesClassification of SteelsHaider EjazNo ratings yet

- Engineering MaterialsDocument53 pagesEngineering MaterialsRAGINI PASUPULETINo ratings yet

- Lecture 2 - ECE 2215 PDFDocument24 pagesLecture 2 - ECE 2215 PDFRando ClintonNo ratings yet

- Control of PropertiesDocument65 pagesControl of PropertiesJezzrel Xandy BalmesNo ratings yet

- Physical Metallurgy: Lecture byDocument78 pagesPhysical Metallurgy: Lecture byqaNo ratings yet

- METALSDocument48 pagesMETALSMian Afzaal 72No ratings yet

- Metallurgy Session 2Document52 pagesMetallurgy Session 2vishnuNo ratings yet

- Chapter FiveDocument19 pagesChapter FiveSara 80'No ratings yet

- Steel Grades What Are The Different TypeDocument9 pagesSteel Grades What Are The Different TypeSyed Shoaib RazaNo ratings yet

- Steel ManufacturingDocument29 pagesSteel ManufacturingNDTInstructor100% (3)

- 211 2aDocument33 pages211 2aMada ChohNo ratings yet

- Lecture 4 Ferrous MetalDocument26 pagesLecture 4 Ferrous MetalKashif UsmanNo ratings yet

- Classification of Carbon and Low-Alloy Steels: AbstractDocument23 pagesClassification of Carbon and Low-Alloy Steels: AbstractharieduidNo ratings yet

- Carbon SteelDocument9 pagesCarbon SteelArfanAliNo ratings yet

- Funamental of MetallurgyDocument235 pagesFunamental of Metallurgysoumyo broto dasNo ratings yet

- Type MaterialDocument31 pagesType MaterialChristopherGunawanNo ratings yet

- Steel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenDocument14 pagesSteel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenSanjay SaxenaNo ratings yet

- APM Steel and Cast IronsDocument48 pagesAPM Steel and Cast Ironsvarniraj patelmetNo ratings yet

- ME007 - Mechanical Properties and Metals-1Document44 pagesME007 - Mechanical Properties and Metals-1albert narioNo ratings yet

- Alloy SteelDocument6 pagesAlloy SteelSiva BhaskarNo ratings yet

- Classification of Engineering Materials: by - Gaurav SinghDocument20 pagesClassification of Engineering Materials: by - Gaurav SinghRishith RajNo ratings yet

- Mechanics of Materials: Balaji Y SDocument32 pagesMechanics of Materials: Balaji Y SSubhashree PanigrahyNo ratings yet

- 2-BMCG2312 Manufaturing MaterialsDocument80 pages2-BMCG2312 Manufaturing MaterialsMuhd IzzNo ratings yet

- Iron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiDocument41 pagesIron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiAmrit MallickNo ratings yet

- Metals and Alloys & Heat Treatment of Steels 2,4Document82 pagesMetals and Alloys & Heat Treatment of Steels 2,4Vimukthi KumaraNo ratings yet

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- What Is SteelDocument4 pagesWhat Is SteelViswatej ChoudaryNo ratings yet

- Steel ClassificationDocument3 pagesSteel Classificationasfarjee100% (1)

- Engineering Materials PresentationDocument26 pagesEngineering Materials Presentationguravdr100% (1)

- AlloysDocument33 pagesAlloyshenryNo ratings yet

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Electrical IaDocument33 pagesElectrical IaKeron BretalNo ratings yet

- Marks English SbaDocument14 pagesMarks English SbaKeron BretalNo ratings yet

- Lab 89Document3 pagesLab 89Keron BretalNo ratings yet

- Lead - Acid CellsDocument4 pagesLead - Acid CellsKeron BretalNo ratings yet

- Geo QuestionnaireDocument2 pagesGeo QuestionnaireKeron BretalNo ratings yet

- Integrated Mathematics Internal AssessmentDocument19 pagesIntegrated Mathematics Internal AssessmentKeron BretalNo ratings yet

- Unit 302: Engineering PrinciplesDocument22 pagesUnit 302: Engineering PrinciplesKeron Bretal100% (1)

- Unit 302: Engineering PrinciplesDocument24 pagesUnit 302: Engineering PrinciplesKeron BretalNo ratings yet

- Unit 302: Engineering Principles: Characteristics of Engineering MaterialsDocument22 pagesUnit 302: Engineering Principles: Characteristics of Engineering MaterialsKeron BretalNo ratings yet

- Unit 302: Engineering PrinciplesDocument10 pagesUnit 302: Engineering PrinciplesKeron BretalNo ratings yet

- Health & Safety Regulations: Control of Substances Hazardous To Health (Coshh)Document12 pagesHealth & Safety Regulations: Control of Substances Hazardous To Health (Coshh)Keron BretalNo ratings yet

- Power System Engineering Second Edition by Nagrath KothariDocument839 pagesPower System Engineering Second Edition by Nagrath KothariKeron Bretal67% (3)

- Power System Engineering Second Edition by Nagrath KothariDocument839 pagesPower System Engineering Second Edition by Nagrath KothariKeron BretalNo ratings yet

- Cambridge Checkpoint Lower Secondary Science Workbook 7 (2021) AnswersDocument28 pagesCambridge Checkpoint Lower Secondary Science Workbook 7 (2021) AnswersNaruto Uzumaki67% (3)

- 0620 s15 QP 13Document16 pages0620 s15 QP 13karan79No ratings yet

- Incompatibilidades Entre QuimicosDocument3 pagesIncompatibilidades Entre QuimicosPedro GonçalvesNo ratings yet

- SEA90Document2 pagesSEA90truthfulventuresNo ratings yet

- Periodic Table & PropertiesDocument16 pagesPeriodic Table & PropertiesAYUSH GOSWAMINo ratings yet

- Handbook of Batteries (3rd Edition)Document9 pagesHandbook of Batteries (3rd Edition)camilianus0% (1)

- The Development of The Periodic TableDocument95 pagesThe Development of The Periodic TableSherren NalaNo ratings yet

- Complexometry 7199 1Document9 pagesComplexometry 7199 1Admiral General AmanNo ratings yet

- IodometryDocument4 pagesIodometryRenol ArnevNo ratings yet

- Titanium and Its Role in Dentistry: ArticleDocument8 pagesTitanium and Its Role in Dentistry: ArticleBruna GomesNo ratings yet

- Effect of Elements in SteelDocument3 pagesEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Groups and Periods in The Periodic TableDocument24 pagesGroups and Periods in The Periodic TableAngelica CamilonNo ratings yet

- Atoms From The Eyes of The PhilosophersDocument2 pagesAtoms From The Eyes of The Philosopherskimchen edenelle63% (8)

- Class 10 Chemistry Chapter 7 Revision NotesDocument5 pagesClass 10 Chemistry Chapter 7 Revision NotesAn SaNo ratings yet

- 1.1 PowerofamagnetDocument20 pages1.1 PowerofamagnetEngelo CaroNo ratings yet

- Worksheet - 01 The Solid State: ChemistryDocument2 pagesWorksheet - 01 The Solid State: ChemistryAbhyudith BharadwajNo ratings yet

- Ionic Bonding Dot and Cross WorksheetDocument2 pagesIonic Bonding Dot and Cross WorksheetBasra AbdillahiNo ratings yet

- GATE Chemistry Study Material Book 4 Inorganic Chemistry 2Document9 pagesGATE Chemistry Study Material Book 4 Inorganic Chemistry 2Sudhanshu PandeyNo ratings yet

- PublicationDocument251 pagesPublicationJariya Srisawat81% (48)

- Periodic Table of ElementsDocument1 pagePeriodic Table of Elementsteknologipangan bthNo ratings yet

- Writing and Naming CompoundsDocument3 pagesWriting and Naming CompoundsChennille Ann Bleu GundayaoNo ratings yet

- Lab Report 5 Hanif Ashran DLM 1aDocument10 pagesLab Report 5 Hanif Ashran DLM 1aHanif AshranNo ratings yet

- Water Analysis - Lab ReportDocument16 pagesWater Analysis - Lab ReportRibka Kristania Hadhiwaluyo100% (3)

- Lecture 1Document18 pagesLecture 1Arslan Anjum100% (1)

- Law of Definite Proportions Lab ReportDocument3 pagesLaw of Definite Proportions Lab Reportrinkeanmark50% (2)

- Activity ZoneDocument4 pagesActivity ZoneSK CreationsNo ratings yet

- MCQ Questions For Class 10 Science CH - 2 Acids, Bases, and SaltsDocument12 pagesMCQ Questions For Class 10 Science CH - 2 Acids, Bases, and SaltsMiss none of your businessNo ratings yet

- Identification of Cations, Anions and GasesDocument2 pagesIdentification of Cations, Anions and GasesMustufa FerozNo ratings yet

- Selective Leaching Type CorrosionDocument14 pagesSelective Leaching Type CorrosionRifqi MumtazNo ratings yet

- Namma Kalvi 12th Chemistry Unit 1 To 4 Loyola Ec Guide em PDFDocument114 pagesNamma Kalvi 12th Chemistry Unit 1 To 4 Loyola Ec Guide em PDFAakaash C.K.No ratings yet