Professional Documents

Culture Documents

Movimento Particulas No Inserto

Uploaded by

Jose ProenzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Movimento Particulas No Inserto

Uploaded by

Jose ProenzaCopyright:

Available Formats

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 1

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 2

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 3

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 4

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 5

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 6

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 7

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 8

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Illustrating the movement of small particles

inside a CJC Insert

Oct 2015, rev3 9

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Saturated CJC Insert

Cut through of used BG15/25

12 months of operation on WTG in Vestas 2 MW wind turbine

Insert is full of real particles. Close to max dirt holding capacity

and pressure (here 2.7 kg drained weight)

Oct 2015, rev3 Source: Test report Anders Damsgaard Serup 10

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

BG 15/25 - ISO 16889. Dirt holding Capacity

This is a ”full” BG 15/25 after

ISO 16889 multipass test.

MTD: 15 mg/l concentration.

=> Dirt Rate : 16 kg/year Test Dust only situated in outer surface of depth filter!

90% Dirt holding capacity still left.

Max DP reached, but is the insert saturated?

Oct 2015, rev3 Source: CJC Project Report 625 11

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

Guide for oil cleanliness

Recommendations for oil and fuel

ISO Code NAS 1638 Description Suitable for Dirt/year

ISO 14/12/09 NAS 3 Very clean oil All critical systems 7,5 kg *

ISO 16/14/11 NAS 5 Clean Oil Servo valves, high pressure hydraulics, 17 kg *

Common rail diesel injection

ISO 17/15/12 NAS 6 Light contaminated oil Standard hydraulics, lube oil systems 36 kg *

ISO 19/17/14 NAS 8 New unfiltered oil Low loaded gears, low pressure 144 kg *

systems

ISO 22/20/17 NAS 11 Very contaminated oil Not suitable for oil systems > 570 kg *

*Weight of solid particles passing the system pump yearly at the given ISO code. Based on: 200 l/min, 20 h/day, 300 days/year

ISO 14/12/10 equals approx 0,1 mg/l of solids

ISO 17/15/12 approx 0.5 mg/l

ISO 19/17/14 approx 2 mg/l

ISO 22/20/17 approx 8 mg/l

Oct 2015, rev3 12

CJC

CJC vs.

vs. Pleated

Pleated Inserts

Inserts

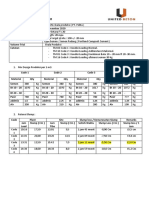

Cleanliness Level

ISO Codes, Complete

Expected Cleanliness level (ISO Code)

Current Machine

Cleanliness (ISO

Code) 21/19/16 20/18/15 19/17/14 18/16/13 17/15/12 16/14/11

16/14/11

16/14/11 15/13/10 14/12/9 13/11/8 12/10/7

2 1.6 3 2 4 2.5 6 3 7 3.5 8 4 >10 5 >10 6 >10 7 >10 >10

24/22/19 1.8 1.3 2.3 1.7 3 2 3.5 2.5 4.5 3 5.5 3.5 7 4 8 5 10 5.5 >10 8.5

1.5 1.5 2 1.7 3 2 4 2.5 5 3 7 3.5 9 4 >10 5 >10 7 >10 10

23/21/18 1.5 1.3 1.8 1.4 2.2 1.6 3 2 3.5 2.5 4.5 3 5 3.5 7 4 9 5.5 10 8

22/20/17

1.3 1.2

1.2 1.05

1.6

1.5

1.5

1.3

2

1.8

1.7

1.4

3

2.3

2

1.7

4

3

2.5

2

5

3.5

3

2.5

7

5

4

3

Example:

9

6

5

4

>10

8 5.5

7 >10

10

9

7

21/19/16

21/19/16

1.3

1.2

1.2

1.1

1.6

1.5

1.5

1.3

2

1.8

1.7

1.5

3

2.2

2

1.7

4

33

2.5

2.5 5 3 By increasing

7 4 oil

9 cleaniness

6 >10 8

21/19/16 22 3.5 2.5 5 3.5 7 4.5 9 6

1.3 1.2

1.2 1.6 1.5 2 1.7 3 2 4 2.5

from 5

ISO3

code:7 4.6 >10 6

20/18/15 1.2 1.1 1.5 1.3 1.8 1.5 2.3 1.7 3 2 3.5 2.5 5.5 3.7 8 5

1.2 1.1

1.3 1.2 1.6 1.5 2 1.7 3 2 4 2.5 6 3 8 5

19/17/14 1.2 1.1 1.5 1.3 1.8 1.5 2.3 1.7 3 2 4 2.5 6 3.5

1.3 1.2 1.6 1.5 2 1.7 3 2 4 3.5 6 4

18/16/13 1.2 1.1 1.5 1.3 1.8 1.5 16/14/11

2.3 1.8 3.7 21/19/16

3 4.5 3.5

Hydraulics

Hydraulics Rolling

Rolling Elements

Element

Elements

and

and Diesel

Diesel Engines

Engines Bearings

Bearings 1.3 1.2 1.6 1.5 2 1.7 3 2 4 2.5

17/15/12 1.2 1.1 1.5 1.4

Hydraulic

1.8 1.5

component

2.3 1.8 3 2.2

Journal

JournalBearings

Journal Bearing Gear

Gear Boxes

Gear Boxes 1.3 1.3 1.6 1.6 2 1.8 3 2

1.2lifetime increase

1.9 41.5times2.3

16/14/11 Bearing Boxes

and

and Turbo

Turbo Machinery

Machinery and

and others

others 1.3 1.6 1.4 1.8

1.4 1.2 1.8 1.5 2.5 1.8

15/13/10

Oct 2015, rev3 1.2 1.1 1.6 1.3 2 1.6 13

You might also like

- SsangYong Actyon Service Manual PDFDocument2,172 pagesSsangYong Actyon Service Manual PDFVictor Abel Ovalle Retamal94% (35)

- Toyota ForkliftDocument423 pagesToyota ForkliftMarco Antonio Aduviri Fernandez83% (12)

- Manual No.114101 (V-150)Document530 pagesManual No.114101 (V-150)opasv100% (9)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- 2000 Nissan Frontier VG33E EMDocument60 pages2000 Nissan Frontier VG33E EMDavid Cervantes100% (2)

- Using Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsDocument7 pagesUsing Mesh Obscuration Technology To Determine The Cleanliness of Internal Combustion LubricantsJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- Maxitrol 325 7AL 1 1 4 BrochureDocument8 pagesMaxitrol 325 7AL 1 1 4 BrochureAlberto GrullonNo ratings yet

- CurvesDocument49 pagesCurvesSAMBHAVNo ratings yet

- 325L 2psi Lever Acting DesignDocument9 pages325L 2psi Lever Acting DesignLexNo ratings yet

- Till 11th OctoberDocument14 pagesTill 11th OctoberNM2104TE06 PRATHURI SUMANTHNo ratings yet

- Errata-2016_RCC-CW-2015_ENDocument113 pagesErrata-2016_RCC-CW-2015_ENahmedalshawiNo ratings yet

- Vendor DataDocument6 pagesVendor DatasubudhiprasannaNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Economics of Gas Gathering CashflowDocument83 pagesEconomics of Gas Gathering CashflowDerrick GloverNo ratings yet

- MicrometricaDocument2 pagesMicrometricaEsteban Vargas RosasNo ratings yet

- Gasometor Ritter mgc10Document15 pagesGasometor Ritter mgc10Edwin Andres Flor MatallanaNo ratings yet

- APEL Aqua Patch Test Data 6e8ded7733Document10 pagesAPEL Aqua Patch Test Data 6e8ded7733Adelina GeorgianaNo ratings yet

- All_you_need_to_know_about_Bentonite_in_cement_slurries_Article_Reading_handoutDocument6 pagesAll_you_need_to_know_about_Bentonite_in_cement_slurries_Article_Reading_handoutVicente FreitasNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Sae J51-2015Document11 pagesSae J51-2015NastyNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- Detailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsDocument33 pagesDetailed Studies of The Impact of EEDI On VLCC Design and CO2 EmissionsGeorgios PapakostasNo ratings yet

- Heating, Ventilation & Air ConditioningDocument95 pagesHeating, Ventilation & Air ConditioningmiguelNo ratings yet

- 19 Manual Chain HoistsDocument1 page19 Manual Chain HoistsJimSpockNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Plumbing & Sanitary Slides PDFDocument27 pagesPlumbing & Sanitary Slides PDFShahril ShahibullahNo ratings yet

- ISO 4406 Cleanliness CodeDocument2 pagesISO 4406 Cleanliness CodeVILLANUEVA_DANIEL2064No ratings yet

- Ringkasan Trial Mix BetonDocument10 pagesRingkasan Trial Mix BetonyohanesfernandoNo ratings yet

- Analysis On The Human Resources EmployedDocument10 pagesAnalysis On The Human Resources EmployedTanmay VivekNo ratings yet

- 1MW Solar PV Templet Surendranagar Rev2 RealisticDocument2 pages1MW Solar PV Templet Surendranagar Rev2 Realisticmysoulfrnd5208100% (1)

- Commissioning Sheet 1Document1 pageCommissioning Sheet 1ABHISHEK SHARMANo ratings yet

- d601000258 Man 001Document24 pagesd601000258 Man 001Oswaldo VillarroelNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- DPM CHECKLISTDocument1 pageDPM CHECKLISTShiftinchargeengineer dadri coalNo ratings yet

- GBK GFK Um en PDFDocument68 pagesGBK GFK Um en PDFYeabsra YonasNo ratings yet

- DVU Selection GuideDocument4 pagesDVU Selection GuideSebastian MartinelliNo ratings yet

- Dgs Report NewDocument678 pagesDgs Report NewVíctor Hugo Morales CurayNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Target ISO Cleanliness CodesDocument0 pagesTarget ISO Cleanliness CodesRaghavendra DeshpandeNo ratings yet

- Operation Manual for Diesel Oil Storage and Transfer SystemsDocument26 pagesOperation Manual for Diesel Oil Storage and Transfer SystemsVraja KisoriNo ratings yet

- IMS APEX Manual Final LOCODocument64 pagesIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- CL DG Complex Aeroplanes Iss 02 Rev 01Document61 pagesCL DG Complex Aeroplanes Iss 02 Rev 01sunitaNo ratings yet

- Interlink TenacityDocument7 pagesInterlink TenacitySameera SampathNo ratings yet

- CC IntroDocument86 pagesCC IntroLuis HuirseNo ratings yet

- Intro ME-GI - Dual FuelDocument37 pagesIntro ME-GI - Dual FuelamasrurNo ratings yet

- Equipment testing and waste management recordsDocument10 pagesEquipment testing and waste management recordsTHIYAGARAJAN ANo ratings yet

- Cleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingDocument1 pageCleaner Fluid, Longer Component & Fluid Life, More Uptime!: Roller Contact BearingfrankNo ratings yet

- Ext. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)Document1 pageExt. No. Type Capacity Ext. Mfg. Date HPT Done On HPT Due On Refill Done On Refill Due On Remarks (If Any Life Span Expires)srimathiNo ratings yet

- Cat engine cutout test resultsDocument3 pagesCat engine cutout test resultsPILAR MARTINEZ100% (1)

- Dispenser Data Gathering - Basic Requirements (260522)Document15 pagesDispenser Data Gathering - Basic Requirements (260522)ags alfNo ratings yet

- Anti Fouling & Trap Corrosion System (M.G.P.S.) Log SheetDocument2 pagesAnti Fouling & Trap Corrosion System (M.G.P.S.) Log Sheetஎன்றும் அன்புடன் கலைNo ratings yet

- Lubricating Oil Consumption and Acceptable LimitsDocument18 pagesLubricating Oil Consumption and Acceptable LimitststkupdhNo ratings yet

- Both Well CatelogDocument60 pagesBoth Well CatelogArmağan DemirelNo ratings yet

- Series G1070, GP1070 Specification SheetDocument2 pagesSeries G1070, GP1070 Specification SheetWattsNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- WCC.10002MG (Tanjung Bin)Document10 pagesWCC.10002MG (Tanjung Bin)keymal9195No ratings yet

- Fuel Consumption KomatsuDocument8 pagesFuel Consumption Komatsukukuh sugiyatnoNo ratings yet

- Polyester Resin ManufactureDocument49 pagesPolyester Resin ManufactureGreg Voloshenko100% (9)

- Australia LNG Concession - CalcDocument308 pagesAustralia LNG Concession - CalcJulian Ee Zhi HowNo ratings yet

- Final ReportDocument28 pagesFinal Reportsnekanvns344No ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- 5 Storage Tips For Oil & Gas Equipment - Cat - CaterpillarDocument3 pages5 Storage Tips For Oil & Gas Equipment - Cat - CaterpillarJose ProenzaNo ratings yet

- 10 - CCJ Marketing Mining Focus - Branding & Communication - July 2019Document31 pages10 - CCJ Marketing Mining Focus - Branding & Communication - July 2019Jose Proenza100% (1)

- Clean Oil GuideDocument36 pagesClean Oil GuidesppramNo ratings yet

- Contamination Codes PDFDocument25 pagesContamination Codes PDFMohan RaoNo ratings yet

- HusqvarnaDocument85 pagesHusqvarnasdgddNo ratings yet

- 11 - 009 - Series 1600 New Interface - Smart ConnectDocument3 pages11 - 009 - Series 1600 New Interface - Smart ConnectMichaels SanclementeNo ratings yet

- Tolerancias de RodamientosDocument3 pagesTolerancias de Rodamientospaolo88No ratings yet

- ShapperDocument5 pagesShapperUsman AyyubNo ratings yet

- Fatima Michael College Question Bank on Automotive TransmissionDocument10 pagesFatima Michael College Question Bank on Automotive TransmissionrajmehaNo ratings yet

- CV Yeshwanth Konduru HVAC ManagerDocument5 pagesCV Yeshwanth Konduru HVAC ManagerShankker KumarNo ratings yet

- ABS wiring diagram breakdownDocument9 pagesABS wiring diagram breakdownSergio HL100% (1)

- SKF SYSTEM 24 Single Point Automatic Lubricator LAGD 125 and LAGD 60 - 012732Document3 pagesSKF SYSTEM 24 Single Point Automatic Lubricator LAGD 125 and LAGD 60 - 012732Olawale John AdeotiNo ratings yet

- Te 2 SyllabusDocument3 pagesTe 2 SyllabusPolireddi Gopala KrishnaNo ratings yet

- 2 Three-Phase AC Motor Architecture PDFDocument15 pages2 Three-Phase AC Motor Architecture PDFFRANCISCO JAVIER MEJIA TASCONNo ratings yet

- Techgen CPL AtplDocument4 pagesTechgen CPL AtplPierre BouvierNo ratings yet

- Ventrack Control Valve TesterDocument4 pagesVentrack Control Valve TesterStudent ForeignNo ratings yet

- Torito Crom Z Gasolina (Referencial) (1) - 1-82-41-82Document42 pagesTorito Crom Z Gasolina (Referencial) (1) - 1-82-41-82Darwin PeñaNo ratings yet

- Instruction Manual Zoje ZJ9813Document32 pagesInstruction Manual Zoje ZJ9813MaskusyaniNo ratings yet

- ASME Standard ListDocument2 pagesASME Standard ListAdamNo ratings yet

- Design of Power ScrewsDocument19 pagesDesign of Power ScrewsSOURAV JADHAVNo ratings yet

- Orbit27999 Manual PDFDocument32 pagesOrbit27999 Manual PDFDanno NNo ratings yet

- High voltage wound-rotor motors series guideDocument21 pagesHigh voltage wound-rotor motors series guideAmazonas ManutençãoNo ratings yet

- Ingenious Mechanisms Vol.3 Jones 1930Document272 pagesIngenious Mechanisms Vol.3 Jones 1930RobertoDlCruzLaraNo ratings yet

- ML e C1Document38 pagesML e C1helmi_69No ratings yet

- Pizza-Ovens-Electrolux 201311251502 LFDocument24 pagesPizza-Ovens-Electrolux 201311251502 LFEngh E MostafaNo ratings yet

- Zico Descarga Dump ValveDocument12 pagesZico Descarga Dump ValveJanusNo ratings yet

- Functional Description AlrarDocument57 pagesFunctional Description Alrarnabil160874No ratings yet

- 62 305 454 30 Ed 01 EN Creemers KompressorDocument28 pages62 305 454 30 Ed 01 EN Creemers KompressorsebastianNo ratings yet

- Legend:-: Above Ground Pipe Under Ground Pipe Butt Welded Ball Valve Butt Welded Plug ValveDocument9 pagesLegend:-: Above Ground Pipe Under Ground Pipe Butt Welded Ball Valve Butt Welded Plug ValveShalenddra SinghNo ratings yet