Professional Documents

Culture Documents

Fuel+Table+ +compactors

Uploaded by

Hopper GrassOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel+Table+ +compactors

Uploaded by

Hopper GrassCopyright:

Available Formats

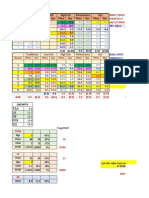

8 Hourly Fuel Consumption Tables Owning & Operating Costs

● Wheel Dozers/Soil Compactors/Landfill Compactors

WHEEL DOZERS/SOIL COMPACTORS/LANDFILL COMPACTORS

Model Low Medium High

liter U.S. gal liter U.S. gal liter U.S. gal

814F 21.0-25.0 5.5-6.5 26.0-30.0 7.0-8.0 36.0-40.0 9.5-10.5

815F 26.0-30.0 7.0-8.0 36.0-42.0 9.5-11.0 44.0-47.0 11.5-12.5

816F 26.0-30.0 7.0-8.0 36.0-42.0 9.5-11.0 44.0-47.0 11.5-12.5

824K 28.9-33.8 7.9-8.9 39.8-45.8 10.5-12.1 53.7-59.7 14.2-15.8

824K 37.8-43.8 10.0-11.6 53.7-67.3 14.2-17.8 63.7-69.7 16.8-18.4

826K 34.0-35.8 8.4-9.4 39.8-43.8 10.5-11.6 47.8-51.7 12.6-13.6

834K 34.6-43.4 9.1-11.4 48.2-52.2 12.7-13.8 67.6-74.0 17.8-19.5

836H 39.8-43.8 10.5-11.6 47.8-51.7 12.6-14.0 55.7-59.7 14.7-18.0

844K 42.0-50.0 11.0-13.0 54.0-62.0 14.0-16.0 65.0-73.0 17.0-19.0

854K 49.2-64.4 13.0-17.0 64.4-79.5 17.0-21.0 79.5-94.6 21.0-25.0

25

Wheel Dozers

Typical Application Description

(relative to work application)

Low Light utility and stockpile work. Pulling compactors. Dozing loose fill. Considerable idling

or travel with no load and no impact.

Medium Production dozing, push loading in clays, sands, silts, loose gravels. Shovel clean-up. Normal

compaction.

High Heavy production dozing in rock. Push-loading in rocky, bouldery borrow pits. Heavy landfill

compactor work. High impact conditions.

Load Factor Guide

(average engine load factor based on application description for each range)

Low 35%-50%

Medium 50%-65%

High 65%-80%

Soil Compactors/Landfill Compactors

Typical Application Description

(relative to work application)

Low No dozing or very light spreading on a flat or downhill surface. Machine has support equipment

dozing and spreading trash while compactor simply travels over flat surface multiple times.

Medium Compactor primary use is compacting already spread material. Compactor assists in dozing and

spreading during peak periods of day and possibly working slopes of no steeper than a 4:1.

High Compactor is possibly only machine for operation. Machine will doze and spread material

alone and then compact it with multiple passes working on steep slopes and possibly uphill.

Load Factor Guide

(average engine load factor based on application description for each range)

Low 35%-50%

Medium 50%-65%

High 65%-80%

Edition 46 25-31

PHB-Sec25-16.indd 31 12/4/15 11:16 AM

Owning & Operating Costs 8 Hourly Fuel Consumption Tables

● Compaction Equipment

COMPACTION EQUIPMENT

Model Low Medium High

liter U.S. gal liter U.S. gal liter U.S. gal

SOIL COMPACTORS

CS-323C 8.0-13.0 2.0-3.5 11.0-15.0 3.0-4.0 11.0-19.0 3.0-5.0

CS34 4.9-6.1 1.3-1.6 6.1-9.1 1.6-2.4 9.1-12.9 2.4-3.4

CP-323C 8.0-13.0 2.0-3.5 11.0-15.0 3.0-4.0 11.0-19.0 3.0-5.0

CP34 4.9-6.1 1.3-1.6 6.1-9.1 1.6-2.4 9.1-12.9 2.4-3.4

CS-423E 4.5-6.4 1.2-1.7 6.4-9.5 1.7-2.5 9.5-12.9 2.5-3.4

CS-533E 5.7-9.5 1.5-2.5 9.5-13.2 2.5-3.5 13.2-17.0 3.5-4.5

CP-533E 5.7-9.5 1.5-2.5 9.5-13.2 2.5-3.5 13.2-17.0 3.5-4.5

CS44 5.8-7.8 1.5-2.1 7.8-11.9 2.1-3.1 11.9-15.7 3.1-4.2

CS44B 6.1-7.2 1.6-1.9 7.2-11.0 1.9-2.9 11.0-15.5 2.9-4.1

CP44 5.8-7.8 1.5-2.1 7.8-11.9 2.1-3.1 11.9-15.7 3.1-4.2

CP44B 6.1-7.2 1.6-1.9 7.2-11.0 1.9-2.9 11.0-15.5 2.9-4.1

CS54 5.7-9.5 1.5-2.5 9.5-13.2 2.5-3.5 13.2-17.0 3.5-4.5

CS56 7.6-9.5 2.0-2.5 9.5-15.1 2.5-4.0 15.1-22.7 4.0-6.0

CP56 7.6-9.5 2.0-2.5 9.5-15.1 2.5-4.0 15.1-22.7 4.0-6.0

CS64 7.6-9.5 2.0-2.5 9.5-15.1 2.5-4.0 15.1-26.5 4.0-7.0

CP64 7.6-9.5 2.0-2.5 9.5-15.1 2.5-4.0 15.1-26.5 4.0-7.0

CS74 9.5-11.4 2.5-3.0 11.4-15.1 3.0-4.0 15.1-26.5 4.0-7.0

CP74 9.5-11.4 2.5-3.0 11.4-15.1 3.0-4.0 15.1-26.5 4.0-7.0

CS76 11.4-13.3 3.0-3.5 13.3-17.0 3.5-4.5 17.0-26.5 4.5-7.0

CP76 11.4-13.3 3.0-3.5 13.3-17.0 3.5-4.5 17.0-26.5 4.5-7.0

CS76 XT 11.4-13.3 3.0-3.5 13.3-17.0 3.5-4.5 17.0-26.5 4.5-7.0

CS54B 6.3-10.5 1.7-2.8 10.5-14.5 2.8-3.9 14.5-18.7 3.9-5.0

CP54B 6.3-10.5 1.7-2.8 10.5-14.5 2.8-3.9 14.5-18.7 3.9-5.0

CS56B 8.4-10.5 2.2-2.8 10.5-16.6 2.8-4.4 16.6-25.0 4.4-6.6

CP56B 8.4-10.5 2.2-2.8 10.5-16.6 2.8-4.4 16.6-25.0 4.4-6.6

CS64B 6.3-10.5 1.7-2.8 10.5-14.5 2.8-3.9 14.5-18.7 3.9-5.0

CS66B 8.4-10.5 2.2-2.8 10.5-16.6 2.8-4.4 16.6-25.0 4.4-6.6

CS68B 8.4-10.5 2.2-2.8 10.5-16.6 2.8-4.4 16.6-29.2 4.4-7.7

CP68B 8.4-10.5 2.2-2.8 10.5-16.6 2.8-4.4 16.6-29.2 4.4-7.7

CS74B 10.5-12.5 2.8-3.3 12.5-16.6 3.3-4.4 16.6-29.2 4.4-7.7

CP74B 10.5-12.5 2.8-3.3 12.5-16.6 3.3-4.4 16.6-29.2 4.4-7.7

CS76B 12.5-14.9 3.3-3.9 14.9-18.7 3.9-5.0 18.7-29.2 5.0-7.7

CS78B 12.5-14.9 3.3-3.9 14.9-18.7 3.9-5.0 18.7-29.2 5.0-7.7

CS79B 12.5-14.9 3.3-3.9 14.9-18.7 3.9-5.0 18.7-29.2 5.0-7.7

25-32 Edition 46

PHB-Sec25-16.indd 32 12/4/15 11:16 AM

8 Hourly Fuel Consumption Tables Owning & Operating Costs

● Compaction Equipment

COMPACTION EQUIPMENT

Model Low Medium High

liter U.S. gal liter U.S. gal liter U.S. gal

ASPHALT COMPACTORS

CB-434D 5.7-7.6 1.5-2.0 7.6-11.4 2.0-3.0 11.4-15.2 3.0-4.0

CB-534D 5.7-7.6 1.5-2.0 7.6-11.4 2.0-3.0 11.4-15.2 3.0-4.0

CB-534D XW 5.7-7.6 1.5-2.0 7.6-11.4 2.0-3.0 11.4-15.2 3.0-4.0

CB-564D 8.6 2.3 10.4 2.8 13.3 3.5

CB54 8.5 2.2 9.4 2.5 11.0 2.9

CB54 XW 8.2 2.2 9.4 2.5 11.0 2.9

CB64 8.5 2.2 9.4 2.5 12.9 3.4

CB44B 6.8 1.8 8.3 2.2 10.2 2.7

CD44B 6.8 1.8 8.3 2.2 10.2 2.7

CB54B 7.9 2.1 9.5 2.5 10.9 2.9

25

CD54B 6.8 1.8 8.3 2.2 10.2 2.7

CB64B 8.2 2.2 9.4 2.5 11.0 2.9

CB66B 8.5 2.2 9.4 2.5 12.9 3.4

CB68B 8.5 2.2 9.4 2.5 12.9 3.4

PNEUMATIC TIRED COMPACTORS

PS-150C 8.0-11.0 2.0-3.0 11.0-13.0 3.0-3.5 13.0-15.0 3.5-4.0

PS-300C 13.0-15.0 3.5-4.0 15.0-17.0 4.0-4.5 17.0-23.0 4.5-6.0

PF-300C 13.0-15.0 3.5-4.0 15.0-17.0 4.0-4.5 17.0-23.0 4.5-6.0

PS-360C 7.4-9.8 1.9-2.6 9.8-12.4 2.6-3.3 12.4-14.5 3.3-4.6

CW14 8.0-11.0 2.1-2.9 11.0-13.0 2.9-3.4 13.0-15.0 3.4-4.0

CW34 7.4-9.8 2.0-2.6 9.8-12.4 2.6-3.3 12.4-14.5 3.3-3.8

Edition 46 25-33

PHB-Sec25-16.indd 33 12/4/15 11:16 AM

You might also like

- Fuel+Table+ +compactorsDocument3 pagesFuel+Table+ +compactorsHopper GrassNo ratings yet

- Fuel Consumption KomatsuDocument8 pagesFuel Consumption Komatsukukuh sugiyatnoNo ratings yet

- Excerpt of Spec & Application Handbook Ed 27Document9 pagesExcerpt of Spec & Application Handbook Ed 27jaime bolivarNo ratings yet

- Fuel Consumption Tables and Load Factor Guides Track-Type TractorsDocument2 pagesFuel Consumption Tables and Load Factor Guides Track-Type TractorsJamarx MarkNo ratings yet

- Piloting Vessels With AcdsDocument18 pagesPiloting Vessels With Acdspa.irurtiagarciaNo ratings yet

- Proje TakvimiDocument4 pagesProje TakvimiYalçın ÖzaygünNo ratings yet

- Fuel ConsumtionDocument1 pageFuel ConsumtionAgung ArdhanaNo ratings yet

- Fuel+Table+ +Articulated+TrucksDocument1 pageFuel+Table+ +Articulated+TrucksphannaNo ratings yet

- Air CondenserDocument40 pagesAir CondenserAlvaro DiazNo ratings yet

- STRATEGY OPTIMIZATIONDocument83 pagesSTRATEGY OPTIMIZATIONyog sNo ratings yet

- Valve Pressure TemperatureDocument3 pagesValve Pressure Temperaturesales3No ratings yet

- Caterpillar DozerDocument1 pageCaterpillar DozerAgung ArdhanaNo ratings yet

- Products That Perform...By People Who CareDocument16 pagesProducts That Perform...By People Who CareFalak KhanNo ratings yet

- Stream Engine Micro Hydro Power SystemsDocument21 pagesStream Engine Micro Hydro Power SystemsGreen Action Sustainable Technology GroupNo ratings yet

- 04 Excel File - Capsim Capstone - Best Strategy - COMPETITION 5.0Document78 pages04 Excel File - Capsim Capstone - Best Strategy - COMPETITION 5.0Rocío QuijadaNo ratings yet

- Capsim Capstone - Best Strategy - Free Excel File - COMPETITION 5.0Document75 pagesCapsim Capstone - Best Strategy - Free Excel File - COMPETITION 5.0Somil GuptaNo ratings yet

- CATERPILLAR Fuel ConsumptionDocument22 pagesCATERPILLAR Fuel ConsumptionScribdTranslationsNo ratings yet

- EIL Piping Support StandardsDocument152 pagesEIL Piping Support Standardsriturishi717No ratings yet

- Valve Pressure TemperatureDocument3 pagesValve Pressure TemperatureDannis AnantoNo ratings yet

- Kolver Usa CatalogoDocument24 pagesKolver Usa CatalogoMartin DavilaNo ratings yet

- Traditional Low End High End Performance Size Sweet Spots Strategy TableDocument76 pagesTraditional Low End High End Performance Size Sweet Spots Strategy TableVidhi Sharma0% (1)

- aFX Dockleveler: Installation and Owner's ManualDocument34 pagesaFX Dockleveler: Installation and Owner's ManualElizabeth OrNo ratings yet

- Traditional Low High Performance Size Sweet SpotsDocument74 pagesTraditional Low High Performance Size Sweet SpotsJared FenleyNo ratings yet

- Mroy Metering Pumps Data Sheet - 2022Document5 pagesMroy Metering Pumps Data Sheet - 2022Ricardo VeraNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Hourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersDocument2 pagesHourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersphannaNo ratings yet

- Capsim Capstone - Best Strategy - COMPETITION 5.0Document80 pagesCapsim Capstone - Best Strategy - COMPETITION 5.0Divesh VashistNo ratings yet

- Tecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Document8 pagesTecumseh RD 0003 e - Rev 1 Service Guidelines HCFC r22 To HFC Blends - Oct2017Bazin TsegayeNo ratings yet

- Industrial 50 HZ 4 Pole: Avr Controlled 40°C Ambient Temperature Class "H" Temp Rise 125°C (Base Continuous Rating)Document3 pagesIndustrial 50 HZ 4 Pole: Avr Controlled 40°C Ambient Temperature Class "H" Temp Rise 125°C (Base Continuous Rating)Simba WahyudiNo ratings yet

- PermaCylDocument2 pagesPermaCylJosePsdNo ratings yet

- Workpack LabelDocument14 pagesWorkpack LabelbanglvhNo ratings yet

- Tfa - Bit TriconeDocument2 pagesTfa - Bit Triconekmf serviceNo ratings yet

- Dayton Lite DutyDocument44 pagesDayton Lite DutyMiyer Gonzalo Montenegro Lizarazo100% (1)

- DOZERDocument2 pagesDOZERJackson PhinniNo ratings yet

- Pumping Log and Rate LogDocument32 pagesPumping Log and Rate LogStefan ManolacheNo ratings yet

- HDPEWaterSupply 05OCT2021 05 04 2022Document52 pagesHDPEWaterSupply 05OCT2021 05 04 2022MaithamNo ratings yet

- CI2400 BS2400 Product DataDocument6 pagesCI2400 BS2400 Product DataDaniel BrownNo ratings yet

- LUG TableDocument17 pagesLUG TableSeth Madhusudan RathiNo ratings yet

- TS B3 SeriesDocument4 pagesTS B3 SeriesGuadalupe CondoriNo ratings yet

- Forecasting ExcelDocument60 pagesForecasting ExcelViswanath NihanNo ratings yet

- Process IndicatorDocument51 pagesProcess Indicatorgestapo78No ratings yet

- Consumo de Combustivel de CarregadeirasDocument1 pageConsumo de Combustivel de CarregadeirasJoão MariaNo ratings yet

- IMS APEX Manual Final LOCODocument64 pagesIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- Taxation Trends in The European Union - 2012 216Document1 pageTaxation Trends in The European Union - 2012 216d05registerNo ratings yet

- Quality Management Process CapabilityDocument24 pagesQuality Management Process Capabilityabhimanyu ratheeNo ratings yet

- Hangcha A Series 1-5t Electrical Four-Wheel Forklift Truck Service Manual 2019.08Document47 pagesHangcha A Series 1-5t Electrical Four-Wheel Forklift Truck Service Manual 2019.08kirk sutherlandNo ratings yet

- Tabla de Tiempos DanielsDocument13 pagesTabla de Tiempos DanielsSebastian RobaynaNo ratings yet

- Vickers Vane v10 v20 PDFDocument24 pagesVickers Vane v10 v20 PDFTom TraviNo ratings yet

- Line Sizing and Fluid VelocityDocument3 pagesLine Sizing and Fluid VelocitynitantharaniNo ratings yet

- Kirloskar Kos Openwell Submersible Pumps PDFDocument1 pageKirloskar Kos Openwell Submersible Pumps PDFSuraj SNo ratings yet

- Allrig Lifting ChainDocument14 pagesAllrig Lifting ChainAwanNo ratings yet

- Performance_manual_Exc_B_Series[1][1] RENDIMIENTO VOLVODocument20 pagesPerformance_manual_Exc_B_Series[1][1] RENDIMIENTO VOLVOsergioNo ratings yet

- KirloskerDocument36 pagesKirloskerArup NathNo ratings yet

- MA - Spray Ball - 3A - V3 - EN-250726Document6 pagesMA - Spray Ball - 3A - V3 - EN-250726Hoàng Nguyễn VănNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Fuel+Table+ +Motor+GradersDocument2 pagesFuel+Table+ +Motor+GradersHopper GrassNo ratings yet

- Fuel+Table+ +excavatorsDocument4 pagesFuel+Table+ +excavatorsHopper GrassNo ratings yet

- Hourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersDocument2 pagesHourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersphannaNo ratings yet

- Fuel+Table+ +Motor+GradersDocument2 pagesFuel+Table+ +Motor+GradersHopper GrassNo ratings yet

- Hourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersDocument2 pagesHourly Fuel Consumption Tables Wheel Loaders and Integrated ToolcarriersphannaNo ratings yet

- Fuel+Table+ +excavatorsDocument4 pagesFuel+Table+ +excavatorsHopper GrassNo ratings yet

- Tools For Community Risk Assessments: Partners For Resilience Philippines September 2011 Version: Final DraftDocument39 pagesTools For Community Risk Assessments: Partners For Resilience Philippines September 2011 Version: Final DraftNurul pattyNo ratings yet

- BH 102 PDFDocument1 pageBH 102 PDFPriodeep ChowdhuryNo ratings yet

- VIII National ParksDocument1 pageVIII National ParksGabriela FloreaNo ratings yet

- Hydrologic CycleDocument41 pagesHydrologic CyclePatricia Sofia DizonNo ratings yet

- Eapp Week 2 Summarization and Precise WritingDocument16 pagesEapp Week 2 Summarization and Precise WritingBrian NiceNo ratings yet

- How Melting Snow and Dams Can Cause Devastating FloodsDocument3 pagesHow Melting Snow and Dams Can Cause Devastating FloodscalebNo ratings yet

- Pathways rw3 2e U4 TestDocument12 pagesPathways rw3 2e U4 Testdieuanh100% (2)

- Eia Report On DamoderDocument249 pagesEia Report On DamoderRiya SharmaNo ratings yet

- You Will Find The Instructions and Maps Here:: Part 1: Glacial Landforms, A Map Reading ExerciseDocument4 pagesYou Will Find The Instructions and Maps Here:: Part 1: Glacial Landforms, A Map Reading Exercisenick2020100% (1)

- Faheem Shah ThesisDocument47 pagesFaheem Shah ThesisFaheem ShahNo ratings yet

- Gravity SurveyDocument14 pagesGravity SurveyMelannie AdanteNo ratings yet

- Written Assessment - Reading & WritingDocument4 pagesWritten Assessment - Reading & WritingMadalina DogaruNo ratings yet

- NSSA eDNA SurveyDocument20 pagesNSSA eDNA SurveyNeville CrabbeNo ratings yet

- In Situ Stresses - CH 9Document36 pagesIn Situ Stresses - CH 9waleed khalidNo ratings yet

- Lesson Plan in MonsoonsDocument2 pagesLesson Plan in MonsoonsDrew ReignNo ratings yet

- Rev 2-EIA - NHCTL Vol 1-EIA Report 28.08.2019Document274 pagesRev 2-EIA - NHCTL Vol 1-EIA Report 28.08.2019Dheeraj Chowdary DhanekulaNo ratings yet

- State of The Climate in Europe 2022 enDocument40 pagesState of The Climate in Europe 2022 enDavide FalcioniNo ratings yet

- IGBC Green Factory Buildings - Addenda - August 2011Document2 pagesIGBC Green Factory Buildings - Addenda - August 2011chakka nagendra subrahmanyamNo ratings yet

- Geo SbaDocument16 pagesGeo SbaBrittaniaNo ratings yet

- Presentation On Water ResourcesDocument21 pagesPresentation On Water ResourcesGaurav MorghareNo ratings yet

- Sea Wave Energy FinalDocument26 pagesSea Wave Energy FinalKieth Daryl CampanerNo ratings yet

- A Map Is A Diagrammatic Representation of An Area of Land or Sea Showing Physical FeaturesDocument8 pagesA Map Is A Diagrammatic Representation of An Area of Land or Sea Showing Physical FeaturesGgayi JosephNo ratings yet

- Assessment of Deep Well As Water SupplyDocument22 pagesAssessment of Deep Well As Water SupplyLezil O. CalutanNo ratings yet

- A Review On Effects of Stabilizing AgentsDocument7 pagesA Review On Effects of Stabilizing AgentsGabriel SalgadoNo ratings yet

- Tracking Fluid Exhaust From Polymetallic Carbonate Rock-Hosted Ore Deposits: Examples From Central PerúDocument4 pagesTracking Fluid Exhaust From Polymetallic Carbonate Rock-Hosted Ore Deposits: Examples From Central PerúHarrison RamosNo ratings yet

- Understanding Plate TectonicsDocument44 pagesUnderstanding Plate TectonicsSiena Joy MangaoangNo ratings yet

- Drilling Log for Batang ProjectDocument3 pagesDrilling Log for Batang ProjectDyah Arintha DewiNo ratings yet

- Water Supply: Section 4Document56 pagesWater Supply: Section 4groksurfNo ratings yet

- Geological Controls On Fluid Flow and Seepage in Western Svalbard Fjord, NorwayDocument62 pagesGeological Controls On Fluid Flow and Seepage in Western Svalbard Fjord, NorwaykingcoffeeNo ratings yet

- A Fascination With Levada Walking On Madeira IslandDocument8 pagesA Fascination With Levada Walking On Madeira IslandNavega BemNo ratings yet

![Performance_manual_Exc_B_Series[1][1] RENDIMIENTO VOLVO](https://imgv2-2-f.scribdassets.com/img/document/723643111/149x198/2b6c9e36dd/1713285243?v=1)