100% found this document useful (2 votes)

10K views26 pagesPattern Making Introduction

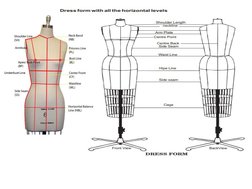

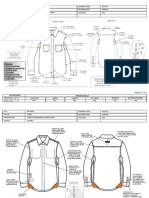

Pattern making involves accurately measuring the human body and transforming those measurements into paper patterns that can be used to construct garments. It is a complex task due to variations in human bodies. Patterns include all necessary information for cutting and production, such as seam allowances, notches, and grain lines. Key terminology includes blocks/slopers, which are basic pattern pieces used to create other patterns, and darts, triangular shapes that control fit. Pattern making is the foundation for mass producing consistent, well-fitting garments.

Uploaded by

sonamanand2008Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

10K views26 pagesPattern Making Introduction

Pattern making involves accurately measuring the human body and transforming those measurements into paper patterns that can be used to construct garments. It is a complex task due to variations in human bodies. Patterns include all necessary information for cutting and production, such as seam allowances, notches, and grain lines. Key terminology includes blocks/slopers, which are basic pattern pieces used to create other patterns, and darts, triangular shapes that control fit. Pattern making is the foundation for mass producing consistent, well-fitting garments.

Uploaded by

sonamanand2008Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd