Professional Documents

Culture Documents

Glass Alkalinity: Your Company Information

Uploaded by

Shoaib Muhammad0 ratings0% found this document useful (0 votes)

98 views28 pagesOriginal Title

LEC 3 Glass Alkalinity

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

98 views28 pagesGlass Alkalinity: Your Company Information

Uploaded by

Shoaib MuhammadCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 28

Glass alkalinity

Your company information

Lecture 3(29-09-16)

learning objectives

• Explain how alkalinity develops in the glass?

• Describe the factors affecting alkalinity.

• Determine the effects of alkalinity on

Pharmaceutical dosage forms.

• "The capacity of water for neutralizing an

acid solution." - U.S. Geological Survey,

2010

• Alkalinity is a measure of the ability of a

solution to neutralize acids to the equivalence

point of carbonate or bicarbonate.

• Units: mEq/L (milliequivalent per liter).

• Commercially, ppm or parts per million.

• In all glass, the sodium and potassium oxides

are hygroscopic; the surface of glass absorbs

moisture from the air.

• Moisture and carbon dioxide in air causes the

Na2O or NaOH and K2O or KOH to convert to

sodium (Na2CO3) or potassium carbonate (K2CO3)

which are extremely hygroscopic.

• In salt water, the Na+ and K+ carbonates in

unstable glass may leach out, leaving only

fragile, porous hydrated silica (SiO2 ) network.

This causes the glass to fade, crack, pit and

gives surface of glass a frosty appear.

• Large surface areas

• Long contact times with the atmosphere

Effect of Glass Alkalinity on

Pharmaceutical Products

• Use of buffered solution (stability retained)

• Use of unbuffered solution (stability lost)

• Borosilicate glass (stability retained)

• Soda lime glass (stability lost)

• Alkalinity of a solution is the capacity of it

to react with a strong acid (usually H2SO4)

to a predetermined PH.

• The alkalinity of a solution is usually made

up of carbonate, bicarbonate, and

hydroxides.

• Similar to acidity, the higher the alkalinity

is, the more neutralizing agent is needed

to counteract it.

•The scanning electron micrographs showed

surprising differences in the appearance of the

surface region.

Sulfur treatment of ampoules was associated with

a pitting (abrasions) of the surface and the

presence of sodium sulfate crystals.

The sulfur treatment of vials altered the glass

surface in a characteristically different way

Test of alkalinity of glass

Alkalinity testing(chemical test)

1.Alkalinity test for whole glass

• Apparatus used:

Autoclave

Equipped with a thermometer, a pressure

gauge, a vent and a rack.

• Hardened-steel mortar and pestle.

o 8 Inch-sieves No. 20, 40 and 50 along with

the pan and cover

o 250ml conical flask and volumetric flask

made of resistant glass

• Special distilled water:

having a specific conductivity of 0.5 to1 Siemens.

• Methyl red solution:

Dissolve 24 mg of methyl red sodium in sufficient

purified water to make 100ml. if necessary,

neutralize the solution with 0.02 N NaOH.

• Take not less than 3 from each batch.

• Rinse twice the containers thoroughly with

distilled water.

• Fill each container to 90% of its overflow capacity

with the redistilled water.

• Cover the unsealed containers with crimped

pieces of new tin foil wash thoroughly with

acetone.

• Place the containers on in autoclave, close the

door, leaving the vent open.

• Heat until steam release vigorously from the vent

and continue heating for 10 min.

• Close the vent adjust the heating so that the

temperature rises 1°C/min until it reaches 121°C,

for 20- 25 min.

• Keep the temperature 121°C ± 0.5 °C for 1 hour.

• At the end decrease the supply of heat and cool

at the rate of 0.5 °C/min, until the internal

pressure is equal to the atmospheric pressure.

• Open the autoclave and allow the containers to

cool at 25 °C.

• Titration:

Transfer 100 ml of water from each container add 5

drops of methyl red solution, and titrate with 0.01 N

sulphuric acid.

• The time elapsing between opening the

autoclave and titrating should not exceed 60

minutes.

• Carry out Blank Test on 100 ml of water from the

same lot, and make the necessary correction.

• The quantity of 0.01N sulphuric acid used for

containers with a capacity of up to 100 ml should

be, not more than 0.5 ml and for containers of

capacity greater than 100ml, not more than 1.5

ml.

2.Powdered glass test

• Take a clean dry empty glass containers 6 or

more.

• crush it in mortar-pestle.

• Crushing and sieving.

• Excess of 10g, stored in closed container in

desiccator.

• Spread the sample on butter paper.

• Remove the iron particles from sample.

• Transfer sample in a 250ml conical flask

• wash it with 30 ml acetone,

• swirling 30sec,and decant the acetone.

• Dry the contents in flask in oven at 1400C for

20 minutes.

• Transfer this powder in another dried conical

flask and cool in desiccator.

• add 50ml of distilled water. (sample

preparation)

• In another conical flask (100ml) add 50ml of

distilled water. (for blank reading)

• Cover both flasks with paper and place in

oven at 1210C for 30minutes.

• Cool them in desiccators.

• Transfer distilled water from sample

containing flask in another flask.

• Wash glass powder residues with 15 ml

special distilled water 4times and

• transfer this water in a flask contain main

portion

• add 5 drops of methyl red.

• Titrate against 0.02N H2SO4 until color

changes to light pink.

• Titrate the distilled water for blank

determination in the same way.

• Note: Blank reading should be 0.1-0.2ml and

sample reading should be 0.7-0.8ml.

3.Water attack test

• Rinse thoroughly 3 or more containers, twice with

special distilled water.

• Fill each container 90% capacity with distilled water.

• Follow procedure of powered glass test except the time

of autoclaving =1hour

• In a 250ml conical flask, transfer 100ml water from

each container, small container combine contents will

be use.

• 5drops methyl red indicator will be used

• Titrate with 0.02N H2SO4.(0.2ml-0.7ml)

• Titrate 100ml of special dis. water for blank titration.

• Wash the glass thoroughly in running tap

water and then soak it in distilled water.

• Dry the glass in two baths of alcohol. This

treatment will retard the disintegration and

also improves the appearance of the glass.

• It does not however, always stop the

breakdown of the glass.

• If applicable, apply an organic lacquer (PVA

or Acryloid B-72) to impede disintegration.

• For assurance, store the glass in a dry

environment with the relative humidity not

higher than 40 %.

• Parentral glass container: Sulphur treatment

You might also like

- Alkalinity of GlassDocument16 pagesAlkalinity of Glassrm.umar001No ratings yet

- Determination of CalciumDocument2 pagesDetermination of Calciumcocomelon8454No ratings yet

- XII ChemistryDocument8 pagesXII ChemistryNilesh Kumar ChoudharyNo ratings yet

- Penentuan Kalsium Secara GravimetriDocument2 pagesPenentuan Kalsium Secara Gravimetrifitri_ana100% (1)

- lab 6 Gravimetric AnalysisDocument6 pageslab 6 Gravimetric Analysisw.balawi30No ratings yet

- Glass Container Chemical Resistance TestDocument4 pagesGlass Container Chemical Resistance Testamyn_sNo ratings yet

- Nickel Experiment XWDocument4 pagesNickel Experiment XWKhairul Anwar Abd HamidNo ratings yet

- Containers - Permeation 671Document12 pagesContainers - Permeation 671Kakon AhmedNo ratings yet

- USP 660 - 43 - Glass Grain TestDocument2 pagesUSP 660 - 43 - Glass Grain Testamitdi001_667397546No ratings yet

- 10 - Glass AmpulesDocument6 pages10 - Glass Ampulessupss2411No ratings yet

- Tests For GlassDocument4 pagesTests For GlassFera PermatasariNo ratings yet

- Ethanol PDFDocument2 pagesEthanol PDFokikwmNo ratings yet

- Hydrolysis of Methyl Salicylate ExpDocument7 pagesHydrolysis of Methyl Salicylate ExpPradeep100% (1)

- Organic vs Inorganic Compounds ExperimentDocument9 pagesOrganic vs Inorganic Compounds ExperimentSandra MacatangayNo ratings yet

- Making Magnesium Sulfate CrystalsDocument2 pagesMaking Magnesium Sulfate CrystalsHector CabezasNo ratings yet

- Stoichiometry and Gravimetric Analysis of Strontium CarbonateDocument4 pagesStoichiometry and Gravimetric Analysis of Strontium CarbonateIbelise MederosNo ratings yet

- Magnesium Aluminium SilicateDocument5 pagesMagnesium Aluminium SilicateWanguNo ratings yet

- Chemistry Content Based ExpirimentsDocument22 pagesChemistry Content Based ExpirimentsHari VaarthanNo ratings yet

- Group1 - RecrystallizationDocument51 pagesGroup1 - RecrystallizationNefren Roy Azurin LobitanaNo ratings yet

- Fractional Crystallization LabDocument5 pagesFractional Crystallization LabLuna Díaz AlvaNo ratings yet

- Dehydrate Cyclohexanol to Cyclohexene Using Phosphoric AcidDocument1 pageDehydrate Cyclohexanol to Cyclohexene Using Phosphoric AcidkalleecscottNo ratings yet

- Experiment No. 1 Gravimetric Determination of Calcium: ObjectivesDocument3 pagesExperiment No. 1 Gravimetric Determination of Calcium: ObjectivesIanaNo ratings yet

- Chemical Testkit: Chemical Laboratory "Dr. A. Verwey"Document7 pagesChemical Testkit: Chemical Laboratory "Dr. A. Verwey"romygmailNo ratings yet

- Calibrating Volumetric GlasswareDocument5 pagesCalibrating Volumetric GlasswareJazz DescalzoNo ratings yet

- Bleach AnalysisDocument6 pagesBleach AnalysisNartie MKH100% (1)

- Nickel Experiment XWDocument4 pagesNickel Experiment XWaween69No ratings yet

- Lab InstrumentsDocument19 pagesLab InstrumentsRAVIRAJ NAIK100% (1)

- Exp 3 - F23Document4 pagesExp 3 - F23s127886No ratings yet

- Complex Salts FormationDocument4 pagesComplex Salts FormationMayank AroraNo ratings yet

- Wall-Wash Tests On Chemical TankersDocument6 pagesWall-Wash Tests On Chemical TankersMoe Win AungNo ratings yet

- Biochemical Oxygen DemandDocument8 pagesBiochemical Oxygen DemandAngelMayMonteverdeNo ratings yet

- Test Report For Aluminim SulfateDocument3 pagesTest Report For Aluminim SulfateAbdur Rahim WaseemNo ratings yet

- Dry Ashing Procedure For Plant MaterialsDocument21 pagesDry Ashing Procedure For Plant MaterialsWaseem Hayat HaiderNo ratings yet

- Diffusion of Solutes in WaterDocument5 pagesDiffusion of Solutes in WaterThea Margaret GoNo ratings yet

- Water Soluble Matter Test & Mica PropertiesDocument9 pagesWater Soluble Matter Test & Mica Propertiesdineshdesai100% (1)

- Packaged Drinking Water Test ParametersDocument51 pagesPackaged Drinking Water Test Parameterslekshmi_remesh100% (2)

- Wall Wash TestDocument5 pagesWall Wash TestutkarshgahtoriNo ratings yet

- Total Carbs Protocol in 40 CharactersDocument4 pagesTotal Carbs Protocol in 40 CharactersknbiolabsNo ratings yet

- Gelatin Bloom StrengthDocument3 pagesGelatin Bloom StrengthmeongNo ratings yet

- Experiment 6 - Sem2Document4 pagesExperiment 6 - Sem2MUHAMMAD SYUKRI FITRI BIN MOHAMAD RAZALINo ratings yet

- Scope: CautionDocument7 pagesScope: CautionJavier Oswaldo Gonzalez AceroNo ratings yet

- Bleach Strength TestDocument8 pagesBleach Strength TestArslan ShaukatNo ratings yet

- Determination of Alcohol Content in Wines and Fermented MashesDocument2 pagesDetermination of Alcohol Content in Wines and Fermented MashesMike FidelisNo ratings yet

- Wall Wash Test Procedures on Chemical TankersDocument5 pagesWall Wash Test Procedures on Chemical Tankersutkarshgahtori100% (1)

- LMI Lab5 DeterminationClDocument3 pagesLMI Lab5 DeterminationClTim derzNo ratings yet

- PackagingDocument18 pagesPackagingAli HNo ratings yet

- NaOCl Test ProcedureDocument11 pagesNaOCl Test ProcedureTrivik BhavnaniNo ratings yet

- CHM 212 Experiment 5 - Gravimetric Determination of Calcium As ...Document2 pagesCHM 212 Experiment 5 - Gravimetric Determination of Calcium As ...Shante MorganNo ratings yet

- Science EXPERIMENT For Class 9Document21 pagesScience EXPERIMENT For Class 9HEMRAJ SONINo ratings yet

- Wall Wash Test ProceduresDocument5 pagesWall Wash Test Proceduresrabi4457No ratings yet

- ENV SessonalDocument31 pagesENV SessonalBelal HosenNo ratings yet

- Preparation of IodoformDocument3 pagesPreparation of Iodoformjerry green100% (2)

- Wall Wash Test Procedures On Chemical TankersDocument3 pagesWall Wash Test Procedures On Chemical TankersPavel Viktor100% (1)

- ENVIRONMENTAL EngineeringDocument16 pagesENVIRONMENTAL EngineeringSALMANNo ratings yet

- Experiment 12 Preparation of Adipic Acid From CyclohexeneDocument6 pagesExperiment 12 Preparation of Adipic Acid From Cyclohexenesaransh1994No ratings yet

- Experiment 2 Analysis of An Unknown Vinegar Sample ObjectivesDocument5 pagesExperiment 2 Analysis of An Unknown Vinegar Sample ObjectivesVirginia DukeNo ratings yet

- Hydrolysis of Methyl SalicylateDocument6 pagesHydrolysis of Methyl SalicylateNguyen Son Tung100% (1)

- Crude Oil DesaltingDocument25 pagesCrude Oil DesaltingNaumanNo ratings yet

- Sterlization of Water Using Bleaching Powder PDFDocument20 pagesSterlization of Water Using Bleaching Powder PDFradha krishnanNo ratings yet

- Young's Demonstrative Translation of Scientific Secrets: Or, A Collection of Above 500 Useful Receipts on a Variety of SubjectsFrom EverandYoung's Demonstrative Translation of Scientific Secrets: Or, A Collection of Above 500 Useful Receipts on a Variety of SubjectsNo ratings yet

- LEC 5 PQMDocument20 pagesLEC 5 PQMShoaib MuhammadNo ratings yet

- Lecture 6Document14 pagesLecture 6Shoaib MuhammadNo ratings yet

- Lec 4-Toxicity and Identification TestDocument46 pagesLec 4-Toxicity and Identification TestShoaib MuhammadNo ratings yet

- Glass Alkalinity: Your Company InformationDocument28 pagesGlass Alkalinity: Your Company InformationShoaib MuhammadNo ratings yet

- Miscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueDocument28 pagesMiscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueShoaib Muhammad100% (1)

- LEC 5 PQMDocument20 pagesLEC 5 PQMShoaib MuhammadNo ratings yet

- Lecture 6Document14 pagesLecture 6Shoaib MuhammadNo ratings yet

- Lec 4-Toxicity and Identification TestDocument46 pagesLec 4-Toxicity and Identification TestShoaib MuhammadNo ratings yet

- Miscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueDocument28 pagesMiscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueShoaib Muhammad100% (1)

- WCH01 01 Que 20180110Document24 pagesWCH01 01 Que 20180110Yuan XintongNo ratings yet

- Qualitative Test For Ephedrine and Its DerivativesDocument5 pagesQualitative Test For Ephedrine and Its Derivatives11113432No ratings yet

- Chemical Bonding - Practice Questions: Identify The Choice That Best Completes The Statement or Answers The QuestionDocument3 pagesChemical Bonding - Practice Questions: Identify The Choice That Best Completes The Statement or Answers The Questionasti dNo ratings yet

- 1-Atoms and Molecules - 2022Document50 pages1-Atoms and Molecules - 2022riva rizkianaNo ratings yet

- Rakchem Industries: Chemical Manufacturer ProfileDocument12 pagesRakchem Industries: Chemical Manufacturer ProfileRohith KommuNo ratings yet

- The Ozone Layer: Formation and Depletion: By-Ramen Gogoi Imsc 9 Sem Roll No 16Document43 pagesThe Ozone Layer: Formation and Depletion: By-Ramen Gogoi Imsc 9 Sem Roll No 16Ramen KukoiNo ratings yet

- Hsu2019 PDFDocument11 pagesHsu2019 PDFBryan Roncal LlajarunaNo ratings yet

- Synthesis and Reactions of Cobalt Complexes PDFDocument3 pagesSynthesis and Reactions of Cobalt Complexes PDFRoberto SousaNo ratings yet

- Changes in MatterDocument29 pagesChanges in MatterThisari GunasingheNo ratings yet

- Investigating Silver Nitrate Titrations: + (Aq) (Aq) (S)Document4 pagesInvestigating Silver Nitrate Titrations: + (Aq) (Aq) (S)Elisa PattonNo ratings yet

- Jovanovic 1966Document5 pagesJovanovic 1966Fuad AmrillahNo ratings yet

- Periodic TableDocument44 pagesPeriodic TableAlaa AlkababjiNo ratings yet

- Finishes Chart for Architectural Hardware MaterialsDocument1 pageFinishes Chart for Architectural Hardware MaterialsRey Eduard Q. UmelNo ratings yet

- Rubidium - WikipediaDocument12 pagesRubidium - WikipediakamaalNo ratings yet

- Chemistry SongDocument3 pagesChemistry SongJobasces Medallada MarinNo ratings yet

- EChem ExerciseDocument23 pagesEChem ExerciseWilliam ChongNo ratings yet

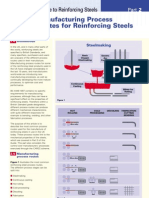

- Manufacturing Process Routes For Reinforcing Steels: CaresDocument6 pagesManufacturing Process Routes For Reinforcing Steels: CaresMustafaNo ratings yet

- Periodic Table Part 1 HandoutDocument8 pagesPeriodic Table Part 1 HandoutChristopher Jr TundagNo ratings yet

- Iwaki America Chemical Compatibility Chart DataDocument5 pagesIwaki America Chemical Compatibility Chart DataDeepak patilNo ratings yet

- Chemical Analysis of Nickel, Cobalt, and High-Temperature AlloysDocument38 pagesChemical Analysis of Nickel, Cobalt, and High-Temperature AlloysLuigi HernándezNo ratings yet

- Methods of Sulphuric AcidDocument18 pagesMethods of Sulphuric AcidKrushit PatelNo ratings yet

- As-Level Paper 1 Pp12Document16 pagesAs-Level Paper 1 Pp12faith mNo ratings yet

- 01 Bs 3692 Grade 88 Bolt Nut CompressDocument1 page01 Bs 3692 Grade 88 Bolt Nut Compresssssaiyed786yahoo.com ShoebNo ratings yet

- Chemistry Class XI Unsolved Sample Paper 1Document4 pagesChemistry Class XI Unsolved Sample Paper 1s.shaw71101No ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document20 pagesCambridge IGCSE: Chemistry 0620/22jad obaidNo ratings yet

- Agua de Mar en Lixiviacion de CalcopiritaDocument8 pagesAgua de Mar en Lixiviacion de CalcopiritaMatias Varas AlarconNo ratings yet

- High Performance Stainless Takes The Gall: Properties & General DataDocument2 pagesHigh Performance Stainless Takes The Gall: Properties & General Datajoker63000No ratings yet

- Physical Science: First Quarter - Module 6: StoichiometryDocument38 pagesPhysical Science: First Quarter - Module 6: StoichiometryLee Arne BarayugaNo ratings yet

- Manidhanaeyam Free Ias AcademyDocument32 pagesManidhanaeyam Free Ias AcademyNathiyaNo ratings yet

- What Is Steel?: 1. Integrated (Blast Furnace and Basic Oxygen Furnace) - 2. Electric Arc Furnace (EAF)Document6 pagesWhat Is Steel?: 1. Integrated (Blast Furnace and Basic Oxygen Furnace) - 2. Electric Arc Furnace (EAF)Prabhakar KattulaNo ratings yet