Professional Documents

Culture Documents

Presentation ON Pre-Fabrication: Submitted To

Uploaded by

Harsimran Kaur0 ratings0% found this document useful (0 votes)

7 views30 pagesThis presentation discusses prefabrication in construction. Prefabrication involves assembling components of a structure in a factory and transporting them to the construction site. It aims to reduce costs, improve quality control, and speed up construction. Prefabricated structures are useful when normal construction is not feasible, such as in hilly areas, or when materials are not locally available. The process involves prefabricating walls, floors, and roofs in a factory and transporting them to assemble on site. Prefabrication is commonly used for concrete, steel, housing, and bridges. Its advantages include reduced construction time and costs through less formwork and on-site labor.

Original Description:

Original Title

Pre Fabrication

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis presentation discusses prefabrication in construction. Prefabrication involves assembling components of a structure in a factory and transporting them to the construction site. It aims to reduce costs, improve quality control, and speed up construction. Prefabricated structures are useful when normal construction is not feasible, such as in hilly areas, or when materials are not locally available. The process involves prefabricating walls, floors, and roofs in a factory and transporting them to assemble on site. Prefabrication is commonly used for concrete, steel, housing, and bridges. Its advantages include reduced construction time and costs through less formwork and on-site labor.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views30 pagesPresentation ON Pre-Fabrication: Submitted To

Uploaded by

Harsimran KaurThis presentation discusses prefabrication in construction. Prefabrication involves assembling components of a structure in a factory and transporting them to the construction site. It aims to reduce costs, improve quality control, and speed up construction. Prefabricated structures are useful when normal construction is not feasible, such as in hilly areas, or when materials are not locally available. The process involves prefabricating walls, floors, and roofs in a factory and transporting them to assemble on site. Prefabrication is commonly used for concrete, steel, housing, and bridges. Its advantages include reduced construction time and costs through less formwork and on-site labor.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 30

PRESENTATION

ON

PRE-FABRICATION

SUBMITTED TO: SUBMITTED BY:

AR. SULOCHANA DHIMAN ABHISHEK VERMA

AR. MANDEEP KAUR DARISHTI RAI

HAIZAL NAGPAL

HARSIMRAN KAUR

JYOTI GOYAL

PREFABRICATION P

R

• Prefabrication is the practice of assembling components of a structure in a factory or other

manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site E

where the structure is to be located. F

• Prefabricated building is the completely assembled and erected building, of which the structural parts

consist of prefabricated individual units or assemblies using ordinary or controlled materials.

A

• Prefabricated construction is a new technique and is desirable for large scale housing programmes.

B

R

I

C

A

T

I

O

N

PRINCIPLES: (AIMS) P

1) To effect economy in cost. R

2) To improve in quality as the components can be manufactured under controlled conditions.

E

3) To speed up construction since no curing is necessary.

F

4) To use locally available materials with required characteristics.

A

5) To use the materials which possess their innate characteristics like light weight, easy workability,

thermal insulation and combustibility etc. B

R

NEED FOR PREFABRICATION: I

C

o Prefabricated structures are used for sites which are not suitable for normal construction method such as

A

hilly region and also when normal construction materials are not easily available.

o PFS facilities can also be created at near a site as is done to make concrete blocks used in plane of

T

conventional knick. I

o Structures which are used repeatedly and can be standardized such as mass housing storage sheds, O

godowns, shelter, bus stand security cabins, site officers, fool over bridges, road bridges. Tubular

structures, concrete building blocks etc., are prefabricated structures. N

PROCESS OF PREFABRICATION P

• An example from house building illustrates the process of prefabrication. The conventional method of R

building a house is to transport bricks, timber, cement, sand, steel and construction aggregate etc. to the

site and to construct the house on site and to construct the house on site from these materials. E

• In prefabricated construction only the F

foundations are constructed in this way. A

While sections of walls floors and roof are

prefabricated structures with windows and B

door frame included and transported to the R

site lifted in to place by a crane and boiled

together. I

C

A

T

I

O

N

USES OF PREFABRICATION: P

R

The most widely used form of prefabrication building and civil engineering is the use of prefabrication

concrete & prefabricated steel section in structures where a particular part or form is repeated many

E

times. F

Pouring concrete section in a factory brings the advantages of being able to re-use moulds and the A

concrete can be mixed on the spot without having to be transported to and pumped wet on a congested

construction site. B

Prefabricating steel sections reduces on-site cutting and welding costs as well as the associated hazards. R

Prefabrication techniques are used in the construction of apartment blocks and housing developments I

with repeated housing units.

C

The technique is also used in office blocks, warehouses and factory buildings.

A

Prefabricated steel and glass section are widely used for the exterior of large buildings.

T

Prefabricated bridge elements and systems offer bridge designers & contractors significant advantages in

terms of construction time safety environmental impact constructability and cost. I

Prefabrication can also help minimize the impact on transfer from bridge building. O

N

ADVANTAGES OF PREFABRICATION: P

R

Self supporting readymade components are used so the need for formwork shuttering and scaffolding is

greatly reduced. E

Construction time is reduced and buildings are completed sooner allowing on earlier return of the capital F

invested. A

On-site construction and congestion is minimized.

B

Prefabrication can be located where skilled labour, power materials space and overheads are lower.

R

Time spent in bad weather or hazardous environments at the construction site is minimized.

I

Materials for scaffolding is stored partly or in full and used.

C

Availability of precise structure and expect workmanship.

Work time is reduced.

A

Fewer expansion joints are required.

T

Interruptions in connecting can be omitted.

I

Work is done with a better technology. O

N

DISADVANTAGES OF PREFABRICATION: P

Careful handling of prefabricated components such as concrete panels or steel and glass panels is required. R

Attention has to be paid to the strength and corrosion-resistance of the joining of prefabricated sections to E

avoid failure of the joint. F

Similarly leaks can form at joints in prefabricated components.

A

Transportation costs may be higher for voluminous prefabricated sections than for the materials of which

they are made which can often be packed more efficiently.

B

Large prefabricated structures require heavy duty cranes & precision measurement and handling to place R

in position. I

Large groups of buildings from the same type of prefabricated elements tend to look drab and

monotonous.

C

Local Jobs are lost.

A

T

I

O

N

CHARACTERISTICS TO BE CONSIDERED: P

Easy availability.

R

Light weight for easy handling and transport, and to economies on sections and sizes of foundations.

Thermal insulation property

E

Easy workability

F

Durability in all weather conditions

A

Non-combustibility B

Economy in cost R

Sound insulation. I

C

A

T

I

O

N

MATERIALS TO BE USED IN PREFABRICATION P

SYSTEM: R

o Concrete E

o Steel F

o Treated Wood A

o Aluminium B

o Cellular Concrete R

o Light weight concrete elements

I

o Ceramic products etc.

C

A

T

I

O

N

PREFABRICATION SYSTEM: P

• The system of prefabricated construction depends on the extent of the use of prefab components, their

materials sizes and the technique adopted for their manufacture and use in building. R

E

F

A

B

R

I

C

A

T

I

O

N

VARIOUS PREFABRICATION SYSTEM: P

OPEN PREFAB SYSTEM

R

• This system is based on the use of the basic structural elements to form whole of part of a building.

The standard prefab concrete components which can be used are: E

o Reinforced concrete channel units, F

o Hollow core slabs, A

o Hollow blocks and battens,

B

o Precast planks and battens,

R

o Precast joists and tiles,

o Cellular concrete slabs,

I

o Prestressed/Reinforced concrete slabs, C

o Reinforced/Prestressed concrete beams, A

o Reinforced/Prestressed concrete columns, T

o Precast lintels and chajjas, I

o Reinforced concrete waffle slabs/shells,

O

o Room size reinforced/Prestressed concrete panels.

N

CATEGORIES OF OPEN PREFAB SYSTEM: P

• There are two categories of open prefab systems depending on the extent of prefabrication used in the

construction as given below:

R

Partial prefab open system E

Full prefab open system F

o PARTIAL PREFAB OPEN SYSTEM

A

This system basically emphasizes the use of precast roofing and

B

flooring components and other minor elements like lintels, chajjas, R

kitchen sills in conventional building construction. The structural

system could be in the form of in-situ framework or load bearing walls. I

o FULL PREFAB OPEN SYSTEM C

In this system almost all the structural components are prefabricated.

The filler walls may be of bricks or any other local material.

A

T

I

O

N

LARGE PANEL PREFAB SYSTEM: P

• This system is based on the use of large prefab components. The components such as Precast concrete large

panels for walls, floors, roofs, balconies, staircase etc. The casting of the components could be at the site or

R

off the site. E

• These panels form a box like structure. Both vertical and horizontal panels resist gravity load. Wall panels are F

usually one storey high. Horizontal floor and roof panels span either as one-way or two-way slab.

A

WALL SYSTEMS B

• Structural scheme with precast large panel wall can be classified as:

o Cross wall system R

o Longitudinal wall system

I

Cross wall system C

o In this scheme the cross wall are load

bearing walls where as the façade wall are

A

non-loading bearing this system is suitable T

for high rise building.

Longitudinal wall system I

o In this case cross walls are non-load O

bearing whereas longitudinal walls are load

bearing walls. N

PRECAST FLOORS

o Precast flooring units could be homogeneous or non homogeneous. P

Homogeneous floors:

o Could be solid slabs, cored slabs, ribbed or waffle slabs.

R

Non-Homogeneous floors: E

o Could be multi-layered ones with combinations of light weight concrete or

reinforced/prestressed concrete, with filler blocks.

F

A

B

R

I

C

A

T

STAIRCASE SYSTEM I

o Staircase system could consist of single flights with in-built risers and treads in the element

only. The flights are normally unidirectional transferring the loads to supporting landing O

slabs or load bearing walls. N

BOX-TYPE CONSTRUCTION

o In this system, room size units are prefabricated and erected at site. Toilets and kitchen P

blocks also be similarly prefabricated and erected at site.

o This system derives its stability and stiffness from the box unit which are formed by the four R

adjacent walls. Walls are jointed to make rigid connections among themselves. The box unit E

rests on the plinth foundation which may be of conventional rests on the plinth foundation

which may be of conventional type or precast type. F

A

B

R

I

C

A

T

I

O

N

JOINTS: P

The joints should be provided in the light of their R

assessment with respect to the following considerations:

E

• Feasibility -The feasibility of joint shall be

determined by its loads carrying capacity in the F

particular situation in which the joints is to function. A

• Practicability -Practicability of joint shall be

determined by the amount and type of Material,

B

fabrication and erection and the time for fabrication R

and erection.

I

• Serviceability - Serviceability shall be determined

by the joints/expected behaviour to Repeated or C

possible overloading and exposure to climatic or A

chemical conditions.

• Fire-Proofing

T

• Appearance

I

O

N

JOINTS: P

• JOINT TECHNIQUES/MATERIALS

NORMALLY EMPLOYED ARE:

R

• Welding of cleats or projecting steel. E

• Overlapping reinforcement, loops and F

linking steel grouted by concrete. A

• Reinforced concrete ties all round a

slab.

B

• Prestressing.

R

• Epoxy grouting.(adhesive)

I

• Bolts and nuts connection. C

• A combination of the above. A

T

I

O

N

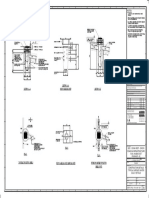

COMPONENTS FIXING AND JOINTING: P

R

E

F

A

B

R

I

C

A

T

I

O

N

INSTALLATION AND FIXING THE PRECAST P

FACADES INTO POSITION: R

E

F

A

B

R

I

C

A

T

I

O

N

PRECASTING METHODS: P

INDIVIDUAL MOULD METHOD

R

• Using mould which may be easily assembled

out of bottom and sides, transportable , if

E

necessary this may be either in timber or in steel F

using needle or mould vibrations and capable of

taking pre stressing forces. A

• Used in – Rib Slab, beams, Girders window B

panels, box type units and special elements. R

I

BATTERY FORM METHOD C

• Battery form method shuttering panels may be A

adjusted in the form of a battery at the required

distances equal to the thickness of the concrete T

members. I

• Used in – Interior Walls ( Panels, Shell elements, O

reinforced concrete, battens, rafters , purlines,

roof and floor slabs. N

STACK METHOD

P

• Used in – Floor and Roof slabs

panels. R

TILTING METHOD E

• Used in – Mould exterior Walls. F

LONG LINE PRESTRESSING BED A

METHOD

B

• Used in – Double tees, rib slabs,

purlins and beams. R

I

EXTRUSION METHOD C

• Long concrete mould with constant

cross section and vibration will be

A

done automatically just as in T

concrete roads.

I

• Used in – roof slabs, concrete walls,

panels and beams.

O

N

ON-SITE PREFABRICATION: P

In this scheme, prefabricated components are produced at site or near the site of work as possible.

R

This system is normally adopted for a specific job order for a limited period. Though there is definite

economy with respect to cost of transportation, this system suffers from basic drawback of its non- E

suitability to any high degree of mechanization and no elaborate arrangements for quality control. Normal

benefits of continuity of work is not available in this system of construction. Under this category there are

F

two types that is semi-mechanized and fully-mechanized. A

• Semi-mechanized B

The work is normally carried out in open space with locally available labour force. The equipment R

machinery used may be minor in nature and moulds are of mobile or stationary in nature.

I

• Fully-mechanized

The work carried out under shed with skilled labour.The equipments used are similar to one of factory

C

production. This type of precast yards will be set up for the production of precast components of high A

quality, high rate of production.

T

I

O

N

OFF-SITE PREFABRICATION: P

FACTORY PREFABRICATION R

Factory prefabrication is resorted to in a factory for the commercial production for the

manufacture of standardized components on a long-term basis. It is a capital intensive production E

where work is done throughout the year preferably under a closed shed to avoid effects of

seasonal variations. High level of mechanization can always be introduced in this system where

F

the work can be organized in a factory-like manner with the help of a constant team of workmen. A

B

R

I

C

A

T

I

O

N

PREFAB BUILDING COMPONENTS: P

• Flooring R

• Roofing E

• Beams F

• Columns A

• Walls B

• Staircase R

• Lintels I

• Sunshade/Chajja

C

projections

A

T

I

O

N

COLUMNS: P

A column is a vertical member carrying the beam and floor loadings to the foundation.

R

It is a compression member and therefore the column connection is required to be proper.

E

The main principle involved in making column connections is to ensure continuity and this can be

achieved by a variety of methods. F

A

B

R

I

C

A

T

I

O

N

Column to Column Connection

BEAMS: P

Beams can vary in their complexity of design and reinforcement from the very simple beam formed over R

an isolated opening to the more common encountered in frames where the beams transfer their loadings

to the column.

E

F

Methods of connecting beams and columns are

A precasting concrete haunch is cast on to the column with a locating dowel or stud bolt to fix the A

beam.

A projecting metal corbel is fixed to the column and the beam is bolted to the corbel.

B

Column and beam reinforcement, generally in the form of hooks, are left exposed. The two members R

are hooked together and covered with insitu concrete to complete the joint.

This is as shown in the figure.

I

C

A

T

I

O

N

P

R

E

F

A

B

R

I

C

A

T

I

O

N

WAFFLE UNIT FOR FLOORING/ROOFING: P

The saving achieved is not much. Also Shuttering are complicated and costly.

R

Time consumption for construction is less. E

These are suitable for roofs / floors spanning in two directions. F

They are laid in a grid pattern. A

These units are cast in moulds. B

R

I

C

A

T

I

O

N

P

R

E

F

A

B

R

I

C

A

T

I

O

SLAB TO BEAM CONNECTION N

THANK YOU

You might also like

- DetailedEstimatesAndProgramOfWorks JOSDocument4 pagesDetailedEstimatesAndProgramOfWorks JOSJhoe SamNo ratings yet

- Material WeldingDocument1 pageMaterial WeldingDebashish ChatterjeeNo ratings yet

- Masonry Support Systems and LintelsDocument36 pagesMasonry Support Systems and LintelsAchilleas21No ratings yet

- Standard Operating Procedure Top DownDocument6 pagesStandard Operating Procedure Top DownHakimHaron100% (1)

- Reinforcement Steel SpecificationsDocument1 pageReinforcement Steel SpecificationsvishalNo ratings yet

- Willis TowerDocument1 pageWillis TowerReshanth Vangalapudi100% (2)

- Manual of Standard Practice - DefaultDocument1 pageManual of Standard Practice - DefaultShane0% (4)

- 2 Finishing Works Method Statement For Building ConstructionDocument15 pages2 Finishing Works Method Statement For Building ConstructionElxao XanNo ratings yet

- Calculation Pressure DropDocument9 pagesCalculation Pressure DropdasubhaiNo ratings yet

- Martensite and The Control of Retained AusteniteDocument6 pagesMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNo ratings yet

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNo ratings yet

- CorenDocument19 pagesCorenRaymond ChristmasNo ratings yet

- Construction Method Statement-GeneralDocument6 pagesConstruction Method Statement-GeneralShakila Nishani100% (1)

- 2 - Buildability and ConstructabilityDocument32 pages2 - Buildability and ConstructabilityGr3Y zØN3 (呆呆的恶魔)No ratings yet

- Contoh Inspection Test PlansDocument8 pagesContoh Inspection Test PlansImam Syafni L100% (2)

- BS 1722 - FenceDocument2 pagesBS 1722 - Fence11 Sqn RERNo ratings yet

- F.K.I TowerDocument8 pagesF.K.I Towermegha madhuNo ratings yet

- Prefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaDocument25 pagesPrefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaSwapnil JainNo ratings yet

- QP Protection Structures Gates and Fences Elements and Details Sheet 4 of 5Document1 pageQP Protection Structures Gates and Fences Elements and Details Sheet 4 of 5raghebomNo ratings yet

- Aashka PosterDocument1 pageAashka PosterAashka BhattNo ratings yet

- Mivan TechnologyDocument38 pagesMivan TechnologyNayana P BabuNo ratings yet

- Research - The Process of Design For CommunitiesDocument10 pagesResearch - The Process of Design For CommunitiesKathleen Kaye MenoriasNo ratings yet

- 16.precast ConstructionDocument15 pages16.precast ConstructionSamson TseNo ratings yet

- Peb PDFDocument1 pagePeb PDFAriel GasangNo ratings yet

- Structure Structure: Magazine MagazineDocument3 pagesStructure Structure: Magazine MagazineRoel Pepito Sepat Jr.No ratings yet

- Installation of Drainage SysytemDocument37 pagesInstallation of Drainage Sysytemqwertykey3991No ratings yet

- CIG 704 Make Up Exam WS14 15 MADocument12 pagesCIG 704 Make Up Exam WS14 15 MAZeyad ElhoutNo ratings yet

- Executive Summary - ADDITIONAL WORKS ON PROJECTSDocument4 pagesExecutive Summary - ADDITIONAL WORKS ON PROJECTSrj22yzht6pNo ratings yet

- P R E C A S T: What Is Precast StructureDocument31 pagesP R E C A S T: What Is Precast StructureMohammed ThanveerNo ratings yet

- Welding Work & TechniquesDocument34 pagesWelding Work & Techniquesqwertykey3991No ratings yet

- Building Construction Model ExamDocument14 pagesBuilding Construction Model ExamTadesse MegersaNo ratings yet

- Ques BANK CTP CIE 1Document3 pagesQues BANK CTP CIE 1Rajha RajeswaranNo ratings yet

- Prefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil EngineeringDocument15 pagesPrefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil Engineeringनोलराज पौडेलNo ratings yet

- Tilt-Up Building Seismic Design - Precast or Cast-In PlaceDocument3 pagesTilt-Up Building Seismic Design - Precast or Cast-In PlacealexitomichaelNo ratings yet

- Chapter10 Structureconstructionsagil 131112092928 Phpapp02Document25 pagesChapter10 Structureconstructionsagil 131112092928 Phpapp02ZorbaNo ratings yet

- Tilt-Up Construction Method (Additional Slides) 7.28.20Document35 pagesTilt-Up Construction Method (Additional Slides) 7.28.20Beverly luthe MorteraNo ratings yet

- (MTC Imperio) Corporate BrochureDocument11 pages(MTC Imperio) Corporate BrochureMeng WaiNo ratings yet

- Screw Conveyor History and General Application: FOR DistributionDocument3 pagesScrew Conveyor History and General Application: FOR DistributionHARSH PATELNo ratings yet

- T5.3 Gnida Formworks PDFDocument63 pagesT5.3 Gnida Formworks PDFsmishra2222No ratings yet

- Prefabrication StructureDocument18 pagesPrefabrication StructureNatty Wap Jr.No ratings yet

- Civil-Engineering-High Rise Apartment BuildingDocument204 pagesCivil-Engineering-High Rise Apartment BuildingDivino Edgar LacambraNo ratings yet

- Site Selection & Civil ConstructionDocument14 pagesSite Selection & Civil ConstructionPRIYANKA GADENo ratings yet

- Specifications 1 14Document35 pagesSpecifications 1 14Sonny John SantosNo ratings yet

- National Case StudyDocument49 pagesNational Case StudyNIDHI SINGHNo ratings yet

- 7 2-PrecastConstructionDocument142 pages7 2-PrecastConstructionsolano21No ratings yet

- Eldad Profile 2016 PDFDocument32 pagesEldad Profile 2016 PDFMillion GemechuNo ratings yet

- Soil Permeability and Seepage: Permeability (Ability To Permeate)Document17 pagesSoil Permeability and Seepage: Permeability (Ability To Permeate)Mark Charles S. MartinezNo ratings yet

- Proposed Design, Built and Completion of Amwaj Towers at Umm Al Quwain On Lot 2, Umm Al Quwain, United Arab EmiratesDocument2 pagesProposed Design, Built and Completion of Amwaj Towers at Umm Al Quwain On Lot 2, Umm Al Quwain, United Arab EmiratesmsfayasNo ratings yet

- EN FlexiBowl 500 C CC DatasheetDocument2 pagesEN FlexiBowl 500 C CC DatasheetSuavi YıldırımNo ratings yet

- Bored Compaction Pile Foundation: Central Building Research Institute RoorkeeDocument1 pageBored Compaction Pile Foundation: Central Building Research Institute RoorkeePramukh Test houseNo ratings yet

- Health HorizonDocument19 pagesHealth HorizonshivajoshiniNo ratings yet

- 141-148p-EPS Fill in The Dovercourt Bypass EmbankmentDocument8 pages141-148p-EPS Fill in The Dovercourt Bypass EmbankmentVa Ni SkyNo ratings yet

- MLCP Infosys Project PuneDocument159 pagesMLCP Infosys Project PuneG Ravi Kumar Reddy50% (2)

- Material Board and SpecificationsDocument3 pagesMaterial Board and Specificationskobe manubayNo ratings yet

- Notes:: - DW016 ATK SW 7201 P02Document1 pageNotes:: - DW016 ATK SW 7201 P02Balaji NaikNo ratings yet

- Internship ReportDocument23 pagesInternship ReportMrTacitVideoNo ratings yet

- Plan 1a: NotesDocument1 pagePlan 1a: NotesErika Faye GutierrezNo ratings yet

- Imran Ahmed CV (Civil - Structural Engineer, 17 Years Experience3)Document4 pagesImran Ahmed CV (Civil - Structural Engineer, 17 Years Experience3)Imran AhmedNo ratings yet

- CIG-704-Midterm-Exam WS14 15 MADocument8 pagesCIG-704-Midterm-Exam WS14 15 MAZeyad ElhoutNo ratings yet

- Construc Tion: The Fullerton Bay HotelDocument1 pageConstruc Tion: The Fullerton Bay HotelDanny EspinosaNo ratings yet

- Imran Ahmed CV (Civil - Structural Engineer, 17 Years Experience2) - RevDocument4 pagesImran Ahmed CV (Civil - Structural Engineer, 17 Years Experience2) - RevImran AhmedNo ratings yet

- Group 7 Project PlanDocument46 pagesGroup 7 Project PlanJian yiNo ratings yet

- REPORT On PrefabricationDocument11 pagesREPORT On Prefabricationharshita sethiNo ratings yet

- SteelDocument51 pagesSteelrahul sulakheNo ratings yet

- Project Management With Pert & CPMDocument26 pagesProject Management With Pert & CPML'HOMME Business PlanNo ratings yet

- Lab 5B - P4-10Document1 pageLab 5B - P4-10Nacho BusinessNo ratings yet

- Multicriteria Selection For An Alumina-Cement Plant Location in East Azerbaijan Province of IranDocument8 pagesMulticriteria Selection For An Alumina-Cement Plant Location in East Azerbaijan Province of Irantuing2ing4982No ratings yet

- Rimt - Coa: Mandi GobindgarhDocument28 pagesRimt - Coa: Mandi GobindgarhHarsimran KaurNo ratings yet

- Rimt-College of Architecture: Sirhind Side, Mandi GobindgarhDocument33 pagesRimt-College of Architecture: Sirhind Side, Mandi GobindgarhHarsimran KaurNo ratings yet

- Disaster Manangement: Submitted To: Ar. Geetanjali KapoorDocument54 pagesDisaster Manangement: Submitted To: Ar. Geetanjali KapoorHarsimran KaurNo ratings yet

- Building EconomicsPresentation1!26!10 16Document58 pagesBuilding EconomicsPresentation1!26!10 16Harsimran KaurNo ratings yet

- Resfoam 1 KM GBDocument3 pagesResfoam 1 KM GBMahesh Chandra SinghNo ratings yet

- Manufacturing TechniquesDocument18 pagesManufacturing TechniqueskdasrkmsNo ratings yet

- Ef3 Englisch 04 14 08052014Document20 pagesEf3 Englisch 04 14 08052014PiPradoNo ratings yet

- Astm A0194 A0194mDocument12 pagesAstm A0194 A0194mndt_inspectorNo ratings yet

- Test Specimens and Mechanical Testing Procedures For Materials W2Document10 pagesTest Specimens and Mechanical Testing Procedures For Materials W2utsmanheruNo ratings yet

- Overview of The Current Aerospace IndustryDocument3 pagesOverview of The Current Aerospace IndustryRamNo ratings yet

- Concrete Products-Manufacture: Quality and CompetenceDocument4 pagesConcrete Products-Manufacture: Quality and Competencedanv68@gmail.comNo ratings yet

- Buehler-Sum-Met Sample Preparation TechniqueDocument136 pagesBuehler-Sum-Met Sample Preparation TechniquesgarrabNo ratings yet

- PVC Pipes: Complete PVC Piping SystemDocument2 pagesPVC Pipes: Complete PVC Piping SystemSyed Shariq HassanNo ratings yet

- Wictec 50Sg Structural Glazing Curtain Wall: Technical PerformanceDocument1 pageWictec 50Sg Structural Glazing Curtain Wall: Technical PerformancehisambergNo ratings yet

- Type 1 Floor and Wall Tile Adhesive: Tilegrab IDocument1 pageType 1 Floor and Wall Tile Adhesive: Tilegrab IYASHICA VAITTIANATHANNo ratings yet

- Engtex DI Pipe SpanDocument2 pagesEngtex DI Pipe SpanArif ZukriNo ratings yet

- Vector - Galvashield XP DSP 2019 - Form B Rev00 v2.06dmDocument4 pagesVector - Galvashield XP DSP 2019 - Form B Rev00 v2.06dmFernando EscriváNo ratings yet

- Metric Thread - Extended Thread Size RangeDocument17 pagesMetric Thread - Extended Thread Size RangeM DhafinNo ratings yet

- Cws100 Data SheetDocument3 pagesCws100 Data SheetGuntur SaputroNo ratings yet

- Mosaic & Glass Collection - Cotto ThailandDocument24 pagesMosaic & Glass Collection - Cotto ThailandTuan QuangNo ratings yet

- Limestone Deposit of Nimbahera Area of Chittorgarh DistrictDocument9 pagesLimestone Deposit of Nimbahera Area of Chittorgarh DistrictVijay Pratap SinghNo ratings yet

- Lecture 5 Sheet Metal FormingDocument98 pagesLecture 5 Sheet Metal FormingAnand P DwivediNo ratings yet

- Building For Future LTD.: Project:JhumkolotaDocument2 pagesBuilding For Future LTD.: Project:JhumkolotahelalNo ratings yet

- Amperit Thermal Spray PowdersDocument16 pagesAmperit Thermal Spray PowdersSergeyNo ratings yet

- Building BrochureDocument44 pagesBuilding BrochureBelal AlrwadiehNo ratings yet

- Jenka System 866 0Document20 pagesJenka System 866 0lutcusNo ratings yet