Professional Documents

Culture Documents

Influence of Lightweight Aggregate On The Durability and Microstructure of Concretes

Influence of Lightweight Aggregate On The Durability and Microstructure of Concretes

Uploaded by

Wilmer Saith Catalan NoblesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Influence of Lightweight Aggregate On The Durability and Microstructure of Concretes

Influence of Lightweight Aggregate On The Durability and Microstructure of Concretes

Uploaded by

Wilmer Saith Catalan NoblesCopyright:

Available Formats

C-S-H

INFLUENCE OF LIGHTWEIGHT AGGREGATE ON THE DURABILITY AND

MICROSTRUCTURE OF CONCRETES

P. Vargas1, N. Marín Alzate2, J. I. Tobón3

1,2,3 Departamento de Materiales y Minerales, Grupo del Cemento y Materiales de Construcci ón, Universidad Nacional de Colombia, Colombia.

Email: pvargas@unal.edu.co

Q: Quartz, Silicon Oxide,

A: Albite, Aluminium oxide

ABSTRACT

AN Anorthite, Calcium aluminosilicate

H: Hematite , Iron oxide

High degree of

crystallinity

To fully appreciate lightweight concrete (LWC) is essential to

understand the intrinsic nature of lightweight aggregates (LWA) and A B

how they influence the properties of concrete made from them. The

LWA have within their mass an array of vesicles or air void. The size, Q: Quartz, Silicon Oxide,

A: Albite, Aluminium oxide

spacing and degree of interconnection of the vesicles make these Low degree of

aggregates capable of producing concrete with lower density of about crystallinity

1850 kg/m3, whit advantages such as increased thermal insulation, C D

extended moist curing and increased durability. Fig.1 . A) LWA aliven. B) SEM aliven,

This paper investigates the influence of sulfates attack on concrete (C) perlite, (d) SEM perlite Fig.2 . X-ray diffractogram

mineralogical composition

containing pumice, expanded clay (both coarse aggregate) and nano- A) perlite. B) aliven

RESULTS

silica (NS). The effects of LWA on the microstructure of the ITZ around

the lightweight aggregate, and how the NS improves the ITZ and

cement matrix and increase the resistance of sulfate attack.

METHODOLOGY

STAGE 1: STAGE 3:

STAGE 2: Fig.3 compressive strength of LWC at 7

Materials and Morphological evaluation Fig.4 Expansion LWC after 15 week

Evaluation of concretes and 28 days of curing sulfate attack

characterization LWC concrete

Chemistry (FRX) Morphology (SEM)

Mineralogy (XRD) Compressive strength Chemical composition

Morphology (SEM, Physics, density and

(EDS)

BET) water absorption Morphology, (optical

Physics, density and Sulfate attack

microscopy)

water absorption

Fig.5 Expansion sample PECS – 10 Fig.6 Expansion sample ALCS – 10

after sulfate attack after sulfate attack

MATERIALS AND CHARACTERIZATION

CS

C-S-H

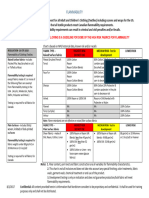

Table 1. Chemical composition of aggregates and cement TMS

C-S-H CS

Weight %

Chemical composition

Perlite Aliven OPC

Silicon Oxide (SiO2) 72.45 59.67 20.9 Fig.7 ITZ SEM micrograph sample Expansion Fig.8 ITZ SEM micrograph sample Expansion

Aluminum oxide (Al2 O3) 13.38 16.95 4.72 sample PECS – 10 after sulfate attack sample ALCS – 10 after sulfate attack

Iron oxide (Fe2 O3) 1.35 9.79 3.20

0.08 4.13 1.80

Magnesium oxide (MgO)

1.20 3.57 60.69 CONCLUSIONS

Calcium oxide (CaO)

3.40 2.07 0.37

Sodium oxide (Na2O)

2.92 0.75 3.68 The greater superficial area and porosity of perlite allows increased the water

Ignition losses at 1000°C

absorption on the aggregate surface causing further expansion in the

concrete, attributed to the direct migration of magnesium sulfate through the

Table 2. Physical properties of aggregates aggregate.

Surface area Shape index Density Water Pores area REFERENCES

Aggregate

(m2/g) (%) (kg/m3) absorption (%) DIP (%) Collepardi, M. 2003. A state-of- the-art review on delayed ettringite attack on concrete.

Perlite 2.10 21.2 304.8 44.0 63.2 Lee, S. T., H. Y. Moon, and R. N. Swamy, 2005, Sulfate attack and role of silica fume in

Aliven 1.13 23.9 519.9 10.3 70.5 resisting strength loss

* Particle size 7,5 mm Lo, T. Y., H. Z. Cui, W. C. Tang, and W. M. Leung, 2008, The effect of aggregate absorption

on pore area at interfacial zone of lightweight concrete

CEMENT AND BUILDING MATERIALS GROUP, UNIVERSIDAD NACIONAL DE COLOMBIA

You might also like

- Estimating Standard ManualDocument75 pagesEstimating Standard ManualNino Gabriel Esguerra100% (5)

- New Concession Stand Roofing Siding EstimateDocument5 pagesNew Concession Stand Roofing Siding EstimateFerdinand UbaldoNo ratings yet

- Astm B584Document6 pagesAstm B584Lucas Mlb100% (1)

- Drawings: Md. Habib Naukhez Gulf Asia Saudi ArabDocument13 pagesDrawings: Md. Habib Naukhez Gulf Asia Saudi ArabRaheel JibranNo ratings yet

- E381-22 - Standard Method of Macroetch Testing Steel Bars, Billets, Blooms, and ForgingsDocument8 pagesE381-22 - Standard Method of Macroetch Testing Steel Bars, Billets, Blooms, and ForgingsAlejandro Valdés Rojas100% (3)

- Castable Refractory ConcreteDocument23 pagesCastable Refractory Concretemnaziria6612100% (3)

- Electrodeposition of Nanocrystalline Nickel - Cobalt Binary Alloy Coatings: A ReviewDocument9 pagesElectrodeposition of Nanocrystalline Nickel - Cobalt Binary Alloy Coatings: A ReviewHaydee VNo ratings yet

- Characteristics of A Thermally Activated Alumino-Silicate Pozzolanic Material and Its Use in ConcreteDocument13 pagesCharacteristics of A Thermally Activated Alumino-Silicate Pozzolanic Material and Its Use in ConcreteDIAZCORDOBANo ratings yet

- CARACTERIZACIÓN y EVALUACIÓN Electrodeposición, Caracterización y ComportamientoDocument10 pagesCARACTERIZACIÓN y EVALUACIÓN Electrodeposición, Caracterización y ComportamientoLucia OsmaNo ratings yet

- Construction and Building Materials: P. Vargas, Oscar Restrepo-Baena, Jorge I. TobónDocument9 pagesConstruction and Building Materials: P. Vargas, Oscar Restrepo-Baena, Jorge I. TobónHamada Shoukry MohammedNo ratings yet

- Applied Geochemistry: Tiziana Missana, Ursula Alonso, Ana María Fernández, Miguel García-GutiérrezDocument8 pagesApplied Geochemistry: Tiziana Missana, Ursula Alonso, Ana María Fernández, Miguel García-GutiérrezDan StefanNo ratings yet

- 11-Potential Use of Volcanic Pumice As A Construction Materialhossain2004Document7 pages11-Potential Use of Volcanic Pumice As A Construction Materialhossain2004afzal taiNo ratings yet

- Experimental Study On Flexural Behaviour of Reinforced Geopolymer Concrete Beam With Steel FiberDocument43 pagesExperimental Study On Flexural Behaviour of Reinforced Geopolymer Concrete Beam With Steel Fiberkarthiksamp100% (1)

- Cement and Concrete Composites: SciencedirectDocument8 pagesCement and Concrete Composites: SciencedirectrakeshNo ratings yet

- CONICET Digital Nro. ADocument11 pagesCONICET Digital Nro. ANora al-anssariNo ratings yet

- Investigations of Supplementary Cementing Materials For Reducing Alkali-Aggregate ReactionsDocument10 pagesInvestigations of Supplementary Cementing Materials For Reducing Alkali-Aggregate ReactionsIsrael VenkatNo ratings yet

- Acr and Compressive StrengthDocument11 pagesAcr and Compressive StrengthjorgecarrascoreyesNo ratings yet

- Corrosion of Uncoated and Oxide-Coated Basalt Fibre in Different Alkaline Media 2016Document7 pagesCorrosion of Uncoated and Oxide-Coated Basalt Fibre in Different Alkaline Media 2016Ping GeNo ratings yet

- Giúdice, 2004, Combinational Use of Extenders With Lamellar ZincDocument14 pagesGiúdice, 2004, Combinational Use of Extenders With Lamellar Zinccyclo DreamNo ratings yet

- Bainite Obtaining CIDocument6 pagesBainite Obtaining CIashokjkhannaNo ratings yet

- IUST v7n4p16 enDocument9 pagesIUST v7n4p16 enhuseynfiruzyNo ratings yet

- Enhanced Seawater Corrosion Resistance of Reinforcement in Nanophase Modified Fly Ash ConcreteDocument12 pagesEnhanced Seawater Corrosion Resistance of Reinforcement in Nanophase Modified Fly Ash ConcreteYogaNo ratings yet

- Corrosion Science: Jianqiang Wei, Siwei Ma, D'Shawn G. ThomasDocument15 pagesCorrosion Science: Jianqiang Wei, Siwei Ma, D'Shawn G. ThomasFabiano AmorimNo ratings yet

- Construction and Building Materials: P. Štukovnik, V. Bokan Bosiljkov, M. MarinšekDocument12 pagesConstruction and Building Materials: P. Štukovnik, V. Bokan Bosiljkov, M. MarinšekManuel AceroNo ratings yet

- (A6) Durability of Concrete With Different Mineral Admixtures A ReviewDocument12 pages(A6) Durability of Concrete With Different Mineral Admixtures A ReviewAbd El-nour RamdNo ratings yet

- Copper SlagDocument13 pagesCopper Slagjohn davidNo ratings yet

- Experimental Investigation of Thin Tungsten Films As Corrosion Barriers For Liquid Metal DivertorDocument6 pagesExperimental Investigation of Thin Tungsten Films As Corrosion Barriers For Liquid Metal Divertorantonio ScacchiNo ratings yet

- Corrosion Brass, Steel and Brass Coated WiresDocument13 pagesCorrosion Brass, Steel and Brass Coated WiresMichaela JoanidisovaNo ratings yet

- Adai Al-Farttoosi 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012106Document12 pagesAdai Al-Farttoosi 2021 IOP Conf. Ser. Mater. Sci. Eng. 1090 012106shivanand hippargaNo ratings yet

- Production and Properties of Silicon Carbide Particles Reinforced Aluminium Alloy CompositesDocument4 pagesProduction and Properties of Silicon Carbide Particles Reinforced Aluminium Alloy CompositesAlina JumoleaNo ratings yet

- IJETR042328Document7 pagesIJETR042328erpublicationNo ratings yet

- 1 s2.0 S0950061815300817 Main PDFDocument9 pages1 s2.0 S0950061815300817 Main PDFMarden Rengifo RuizNo ratings yet

- Kup Wade Patil 2011Document12 pagesKup Wade Patil 2011JHON WILMAR CARDENAS PULIDONo ratings yet

- Study On Durability Properties of Limestone Powder Concrete Incorporated With Steel FibresDocument10 pagesStudy On Durability Properties of Limestone Powder Concrete Incorporated With Steel FibresNiou MekkiNo ratings yet

- 1 s2.0 S187638041560012X MainDocument8 pages1 s2.0 S187638041560012X MainemefakoveNo ratings yet

- 2020 in Situ Seismic Investigations For Evaluating Geotechnical Properties and Liquefaction Potential of Fine Coal TailingsDocument14 pages2020 in Situ Seismic Investigations For Evaluating Geotechnical Properties and Liquefaction Potential of Fine Coal TailingsS R Kumar KonathalaNo ratings yet

- Geopolymer Concrete Strength DevelopmentDocument7 pagesGeopolymer Concrete Strength DevelopmentMasi NuriNo ratings yet

- K Hjort 1994 J. Micromech. Microeng. 4 001Document14 pagesK Hjort 1994 J. Micromech. Microeng. 4 001Hazel Chavez MartinezNo ratings yet

- Study of Cemented Rock Fill MaterialsDocument9 pagesStudy of Cemented Rock Fill MaterialsAlvydas PeldžiusNo ratings yet

- 1 s2.0 S0950061823002155 MainDocument25 pages1 s2.0 S0950061823002155 MainsakhirNo ratings yet

- Materials: Ffect of Fibre Material and Fibre Roughness OnDocument21 pagesMaterials: Ffect of Fibre Material and Fibre Roughness OnDilshod AbdazovNo ratings yet

- A Comparative Study Between ASTM C1567 and ASTM C227 To Mitigate Alkali-Silica ReactionDocument8 pagesA Comparative Study Between ASTM C1567 and ASTM C227 To Mitigate Alkali-Silica ReactionMARLON ESPINOZANo ratings yet

- Performance of Self Compacting Concrete Exposed To Marine EnvironmentDocument16 pagesPerformance of Self Compacting Concrete Exposed To Marine EnvironmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Basalt Rock FibreDocument8 pagesBasalt Rock FibreAditya MittalNo ratings yet

- J Cemconcomp 2003 09 003Document10 pagesJ Cemconcomp 2003 09 003shaik chandiniNo ratings yet

- Study On Mechanical Properties of Basalt Fiber Reinforced ConcreteDocument5 pagesStudy On Mechanical Properties of Basalt Fiber Reinforced ConcreteTohidNo ratings yet

- (2020) Zhan PDFDocument14 pages(2020) Zhan PDFDaniela Gonzalez BetancurNo ratings yet

- Structure Formation During Processing Short Carbon Fiber-Reinforced Aluminum Alloy Matrix CompositesDocument5 pagesStructure Formation During Processing Short Carbon Fiber-Reinforced Aluminum Alloy Matrix CompositesjohnrsunilNo ratings yet

- Surface Treatments of Dental Ceramics: The State of The ArtDocument13 pagesSurface Treatments of Dental Ceramics: The State of The ArtBouthaina maftouhNo ratings yet

- Charge Separation and Catalytic Activity of Ag@Tio Core Shell Composite Clusters Under Uv IrradiationDocument7 pagesCharge Separation and Catalytic Activity of Ag@Tio Core Shell Composite Clusters Under Uv IrradiationQuynh Anh NguyenNo ratings yet

- Meyyappan 2019 IOP Conf. Ser. Mater. Sci. Eng. 561 012064Document7 pagesMeyyappan 2019 IOP Conf. Ser. Mater. Sci. Eng. 561 012064shivanand hippargaNo ratings yet

- Effect of Superplasticizer and Silica Fume On Properties of ConcreteDocument3 pagesEffect of Superplasticizer and Silica Fume On Properties of ConcretemajedsalehNo ratings yet

- Corrosion Resistance in NaCl Environment of Fiber Metal Laminates Based On Aluminum and Titanium Alloys With Carbon and Glass FibersDocument14 pagesCorrosion Resistance in NaCl Environment of Fiber Metal Laminates Based On Aluminum and Titanium Alloys With Carbon and Glass FibersSharamito AkaritoNo ratings yet

- Krizan 2002Document8 pagesKrizan 2002Vidyadhara VNo ratings yet

- Huang 2004Document5 pagesHuang 2004Oğuzhan AtmacaNo ratings yet

- Seminar 1 Presentation by Indar ChavanDocument17 pagesSeminar 1 Presentation by Indar ChavanIndar ChavanNo ratings yet

- Geomechanical Properties of A Conglomerate From Iran: ARMA 08-053Document8 pagesGeomechanical Properties of A Conglomerate From Iran: ARMA 08-053Julian RamírezNo ratings yet

- ART1 jcdc16-2Document25 pagesART1 jcdc16-2Dibit SabanNo ratings yet

- Novel Redesign of Welded Pressure Leach Autoclaves For The Platinum IndustryDocument5 pagesNovel Redesign of Welded Pressure Leach Autoclaves For The Platinum IndustryHabram Miranda AlcantaraNo ratings yet

- Metal Matrix Composites: I. Kostikov A N D KilinDocument16 pagesMetal Matrix Composites: I. Kostikov A N D Kilinsupriyo1970No ratings yet

- Fabrication Technique and Characterization of AluminumDocument7 pagesFabrication Technique and Characterization of Aluminumaguilera.santiago18No ratings yet

- Characteristics of Lightweight Concrete Containing Mineral AdmixturesDocument5 pagesCharacteristics of Lightweight Concrete Containing Mineral Admixturestimtoihochoi1No ratings yet

- Cement & Concrete Composites: Lisa K. Spainhour, Isaac A. WoottonDocument9 pagesCement & Concrete Composites: Lisa K. Spainhour, Isaac A. Woottonandri.kusbiantoro9761No ratings yet

- Factors Affect Color Fastness of Dyed TextilesDocument3 pagesFactors Affect Color Fastness of Dyed TextilesRezaul Karim Tutul100% (2)

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish ANo ratings yet

- Rapplon Selection G Rapplon - Selection - Guide - 2012uide 2012 - RydellDocument8 pagesRapplon Selection G Rapplon - Selection - Guide - 2012uide 2012 - RydellValentin AndreiNo ratings yet

- 1D Thermal Static Analysis of Composite WallDocument1 page1D Thermal Static Analysis of Composite WallNaushad AhmadNo ratings yet

- Department of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIDocument22 pagesDepartment of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIswarup babalsureNo ratings yet

- Sugarcane Leaves As A Food ContainerDocument3 pagesSugarcane Leaves As A Food ContainerRolen Crysty IINo ratings yet

- Design and Manufacturing of Personal Protective Equipment (Ppe) in NepalDocument20 pagesDesign and Manufacturing of Personal Protective Equipment (Ppe) in NepalKrishna KumarNo ratings yet

- BOQ Packet C Aetrio BuildconDocument145 pagesBOQ Packet C Aetrio BuildconSrikanth BhaskaraNo ratings yet

- LongoriaDocument31 pagesLongoriaIELCANo ratings yet

- SALT ANALYSIS-sunriseDocument6 pagesSALT ANALYSIS-sunrisegeorge josephNo ratings yet

- 12 MCQDocument3 pages12 MCQAmsha HegdeNo ratings yet

- 1504 Metals From MWIBA R. BungeDocument68 pages1504 Metals From MWIBA R. BungemhdsolehNo ratings yet

- 9963 FlyerDocument3 pages9963 FlyerDeltalube TangerangNo ratings yet

- PropertyDocument2 pagesPropertyHaresh BhanushaliNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- TDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Document1 pageTDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Tanpreet SinghNo ratings yet

- Flammability Chart For HIGH RISK FABRICS - August 2017Document1 pageFlammability Chart For HIGH RISK FABRICS - August 2017Rao Fahim NazarNo ratings yet

- INDOKOTE Company Profile-4Document8 pagesINDOKOTE Company Profile-4AvijitSinghNo ratings yet

- High-pH-Magnesium Coagulation-Flocculation in Wastewater TreatmentDocument16 pagesHigh-pH-Magnesium Coagulation-Flocculation in Wastewater TreatmentAJITH SNo ratings yet

- trm-2 AssignmentDocument9 pagestrm-2 AssignmentBoier Sesh PataNo ratings yet

- Alnus - Cordata - Dressmaking - Group (1) - Copy Redo Protoype 1Document17 pagesAlnus - Cordata - Dressmaking - Group (1) - Copy Redo Protoype 1Catherine HattsNo ratings yet

- GFJDocument4 pagesGFJWoon Tian LiNo ratings yet

- Microbial Corrosion: Presented By: Jarar Haider (170301032) Osama Daniyal (170301030)Document12 pagesMicrobial Corrosion: Presented By: Jarar Haider (170301032) Osama Daniyal (170301030)Jarar HaiderNo ratings yet

- Recommendations For Design and Construction of Ultra High Strength Concrete Structures, - DraftDocument4 pagesRecommendations For Design and Construction of Ultra High Strength Concrete Structures, - DraftMashfiqul IslamNo ratings yet

- Sikagard - 552 W AquaprimerDocument3 pagesSikagard - 552 W AquaprimerAndrei GheoNo ratings yet