0% found this document useful (0 votes)

271 views20 pagesQ Hatt: Heat Transfer From Finned Surfaces

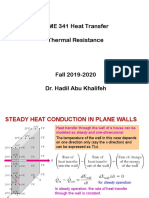

Finned surfaces increase heat transfer by increasing surface area. The fin equation describes heat transfer along a fin under steady conditions. Boundary conditions like specified temperature or adiabatic tip determine the temperature distribution solution. Fin efficiency compares actual to ideal heat transfer. Effectiveness compares heat transfer with and without fins. Proper fin length maximizes heat transfer within a material and geometry. Common heat transfer problems use shape factors to model two-surface conduction.

Uploaded by

Mobashawir AlamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

271 views20 pagesQ Hatt: Heat Transfer From Finned Surfaces

Finned surfaces increase heat transfer by increasing surface area. The fin equation describes heat transfer along a fin under steady conditions. Boundary conditions like specified temperature or adiabatic tip determine the temperature distribution solution. Fin efficiency compares actual to ideal heat transfer. Effectiveness compares heat transfer with and without fins. Proper fin length maximizes heat transfer within a material and geometry. Common heat transfer problems use shape factors to model two-surface conduction.

Uploaded by

Mobashawir AlamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd