Professional Documents

Culture Documents

Clufix M10 - FHO - NC

Uploaded by

Sagar Kumar0 ratings0% found this document useful (0 votes)

11 views5 pagesThe document analyzes three cases of using rivet nuts of size M10. Case 1 uses existing rivets that protrude 0.6mm above the plate. Case 2 uses new rivets that protrude 1.12mm without drilling. Case 3 also uses new rivets, but with drilling and countersinking that results in rivets protruding 0.3mm. Controlling drilling depth accuracy and repeatability for larger lots is challenging.

Original Description:

Original Title

clufix M10_FHO_NC

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document analyzes three cases of using rivet nuts of size M10. Case 1 uses existing rivets that protrude 0.6mm above the plate. Case 2 uses new rivets that protrude 1.12mm without drilling. Case 3 also uses new rivets, but with drilling and countersinking that results in rivets protruding 0.3mm. Controlling drilling depth accuracy and repeatability for larger lots is challenging.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views5 pagesClufix M10 - FHO - NC

Uploaded by

Sagar KumarThe document analyzes three cases of using rivet nuts of size M10. Case 1 uses existing rivets that protrude 0.6mm above the plate. Case 2 uses new rivets that protrude 1.12mm without drilling. Case 3 also uses new rivets, but with drilling and countersinking that results in rivets protruding 0.3mm. Controlling drilling depth accuracy and repeatability for larger lots is challenging.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 5

RIVET NUT M10 FHO type - ANALYSIS

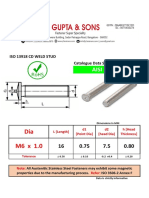

Case 1: Rivet M10 from JC Gupta

1) Used existing Rivets from JC Gupta –

AHO type

2) Head height protruded above the

plate is 0.6 mm observed.

3) Process - Hexagonal hole in laser cut

+ rivet crimping

Case 2: M10 Rivet from CLUFIX without any drilling operation

1) Used new Rivet from Clufix – FHO

type as per the drawing

2) Head height protruded above the

plate is 1.12 mm observed.

3) Process - Hexagonal hole in laser cut

+ rivet crimping

Case 3: M10 Rivet from CLUFIX with drilling (countersunk) operation

1) Used new Rivet from Clufix – FHO type

as per the drawing

2) Head height protruded above the plate

is 0.3mm observed.

3) Process - Hexagonal hole in laser cut +

Drill+ rivet crimping

4) Drill size – 16 dia. and Drill depth – 1.4

Challenges to be discussed by projects, quality and engineering team

before finalizing.

• Controlling the depth of drilling (countersunk) operation with the available

machine at BFGM is not accurate and tolerance variation at 0.3mm.

• Repeatability of the same results in bigger lot size

• Fixturing the parts on drill bed for counter sunk operation

You might also like

- Design and Fabrication of Multi-Purpose MachineDocument48 pagesDesign and Fabrication of Multi-Purpose MachineglisoNo ratings yet

- CSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetDocument4 pagesCSWIP 3.0 Practical Fillet Welded T Joint Instruction SheetOnur Altuntaş100% (2)

- Mold Design Important Features Part 3Document21 pagesMold Design Important Features Part 3Jesus hernandez floresNo ratings yet

- Cubex Peter CorcoranDocument18 pagesCubex Peter CorcoranSriram Nambi100% (2)

- MULTI-PURPOSE MACHINE ReportDocument48 pagesMULTI-PURPOSE MACHINE Reportganesh86% (7)

- 1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHIDocument17 pages1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHICarlos Soler100% (1)

- 1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFDocument14 pages1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFAnonymous oRXzylDPNNo ratings yet

- Deburring MultiTool - WZ68enDocument12 pagesDeburring MultiTool - WZ68enBebe Ionuț AnițaNo ratings yet

- July 2017: Understanding The Basics of Hand Taps and Carbide TapsDocument24 pagesJuly 2017: Understanding The Basics of Hand Taps and Carbide TapswinasharNo ratings yet

- Chapter 7 - Abrasive Waterjet MillingDocument39 pagesChapter 7 - Abrasive Waterjet MillingMonglafru MogNo ratings yet

- Tunneling in Soft StrataDocument8 pagesTunneling in Soft StrataPooja RautNo ratings yet

- Katalog Mikroskop Biologi (N) PDFDocument13 pagesKatalog Mikroskop Biologi (N) PDFindra_f04100% (1)

- 2014 Maintenance Robotics in TBM TunnellingDocument8 pages2014 Maintenance Robotics in TBM TunnellingTrainingNo ratings yet

- Crane GirderDocument1 pageCrane GirderPawan ShettyNo ratings yet

- Chip Evacuation of PCB Micro-Drilling and High-Speed PhotographyDocument7 pagesChip Evacuation of PCB Micro-Drilling and High-Speed PhotographyChethan GowdaNo ratings yet

- Tank Inspection PP09 - Tank#16 (1) - CompressedDocument455 pagesTank Inspection PP09 - Tank#16 (1) - CompressedVPN NetworkNo ratings yet

- Product Information Technical Data Country of Origin Project ReferenceDocument22 pagesProduct Information Technical Data Country of Origin Project ReferenceJacky LeongNo ratings yet

- Rapid Fabrication of Nylon Surgical Sutures by 3D PrintingDocument5 pagesRapid Fabrication of Nylon Surgical Sutures by 3D PrintingjournalNo ratings yet

- Submittal Asset Doc Loc 5695806 (Hst3 2021)Document17 pagesSubmittal Asset Doc Loc 5695806 (Hst3 2021)Luen HopNo ratings yet

- Submittal-ASSET-DOC-LOC-5695806 (HST3)Document16 pagesSubmittal-ASSET-DOC-LOC-5695806 (HST3)Luen HopNo ratings yet

- Workability of Concrete by Slump Cone TestDocument2 pagesWorkability of Concrete by Slump Cone Testsri082000No ratings yet

- Flex MasterDocument9 pagesFlex MastervanillalavenderNo ratings yet

- Medupi Units 6 Shutdown Daily Update.: Unit: 6Document1 pageMedupi Units 6 Shutdown Daily Update.: Unit: 6Mbalekelwa MpembeNo ratings yet

- The Connection For Predictable BiologyDocument28 pagesThe Connection For Predictable BiologyRonaldoNo ratings yet

- Thread Cutting and Knurling To Make Nut and BoltDocument3 pagesThread Cutting and Knurling To Make Nut and BoltHassan AliNo ratings yet

- Sample Compaction: Technical SpecificationsDocument1 pageSample Compaction: Technical SpecificationsDilhara WickramaarachchiNo ratings yet

- 70.00.00 Standard Practices - InspectionDocument2 pages70.00.00 Standard Practices - InspectionTimoteo Molina RomeroNo ratings yet

- Test Coupon SizeDocument1 pageTest Coupon SizeSARSAN NDTNo ratings yet

- Ischebeck Present Jan2024Document41 pagesIschebeck Present Jan2024Thomas GlasbyNo ratings yet

- Oyu Tolgoi Project Technical Specification Overview - Underground Explosives Updated March 2017Document10 pagesOyu Tolgoi Project Technical Specification Overview - Underground Explosives Updated March 2017Julliana SilvaNo ratings yet

- Annexure A 1432024226Document6 pagesAnnexure A 1432024226Abas AbedNo ratings yet

- Schulung Premium Flow EnglischDocument15 pagesSchulung Premium Flow EnglischВячеслав ШапочкаNo ratings yet

- Perio PosterDocument3 pagesPerio Posterrupak biswasNo ratings yet

- TCXD 206-1998 Bored Pile-Requirements For Quality of ConstructionDocument20 pagesTCXD 206-1998 Bored Pile-Requirements For Quality of ConstructionWee Keat SimNo ratings yet

- Acero 10-2-GK23A UMB Manual 20140711Document16 pagesAcero 10-2-GK23A UMB Manual 20140711gonzalo hernandez aguilarNo ratings yet

- The Advantages of Broaching Have Been Stated As UnderDocument3 pagesThe Advantages of Broaching Have Been Stated As UnderNishit ParmarNo ratings yet

- Закладные элементы IMTEC imtec-thread-inserts-for-in-moulding-en-0225Document8 pagesЗакладные элементы IMTEC imtec-thread-inserts-for-in-moulding-en-0225AndreyNo ratings yet

- Metfloor 60 - Composite Deck Slab Concrete VolumeDocument4 pagesMetfloor 60 - Composite Deck Slab Concrete VolumeHardeo Dennis ChattergoonNo ratings yet

- UNIT 8: High Energy Rate Forming (HERF) ProcessesDocument9 pagesUNIT 8: High Energy Rate Forming (HERF) ProcessesLeo Dev WinsNo ratings yet

- Trimo 2967 Trimo Assembly SNVDocument14 pagesTrimo 2967 Trimo Assembly SNVBogdan RuxandaNo ratings yet

- Appendix 1: Quality Standards For Structural WorksDocument2 pagesAppendix 1: Quality Standards For Structural WorkskaranNo ratings yet

- CSWIP 3 0 Practical Fillet Welded T Joint Instruction SheetDocument4 pagesCSWIP 3 0 Practical Fillet Welded T Joint Instruction SheetAslanNo ratings yet

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument6 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialIorga AlexandruNo ratings yet

- Sample Report For Rebar ScanningDocument1 pageSample Report For Rebar ScanningRahul AgarwalNo ratings yet

- HSFG BoltsDocument30 pagesHSFG BoltsJeyakumar JamesNo ratings yet

- Repot FoundryDocument14 pagesRepot FoundryMuhd HazwanNo ratings yet

- Data Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Document2 pagesData Sheet Multi-Channel Duct: Doc. No. DIPL-M/QA/PDS/FPF/693 Rev. 00, Issue: 1 - Issue Date: 09 - Aug, 2017Murali KrishnaNo ratings yet

- Supplement To The Operating Manual: Punch and Multi-Purpose MachinesDocument18 pagesSupplement To The Operating Manual: Punch and Multi-Purpose MachinesRomanProfilNo ratings yet

- Chime and Multiskip InspectionDocument10 pagesChime and Multiskip InspectionVignesh VelNo ratings yet

- Rapid Manufacturing Process GuidelineDocument7 pagesRapid Manufacturing Process Guidelinemuhammad haidar razan hilmiNo ratings yet

- EVCO O RingeDocument24 pagesEVCO O RingeteresamcabralNo ratings yet

- Engineering Academy: Civil Engineering ESE Conventional Revision TEST - VDocument6 pagesEngineering Academy: Civil Engineering ESE Conventional Revision TEST - Vsaxenaarpita41No ratings yet

- Company ProfileDocument20 pagesCompany ProfileTung Bui ThanhNo ratings yet

- CoroPlusToolGuide Report 2019-12-01 PDFDocument5 pagesCoroPlusToolGuide Report 2019-12-01 PDFIorga AlexandruNo ratings yet

- FTM CIF Quotation of 250TPH Mobile Crushing PlantDocument15 pagesFTM CIF Quotation of 250TPH Mobile Crushing PlantPT. SULAWESI BERLIAN JAYANo ratings yet

- 1.3 Technical Condition Timber Formwork BeamDocument8 pages1.3 Technical Condition Timber Formwork BeamEng. Mahmoud Al shafeyNo ratings yet

- Process Specification: Machining of FRP ComponentsDocument9 pagesProcess Specification: Machining of FRP Componentss0l1v3r18No ratings yet

- Precast Reinforced Concrete Pile Drawing No: PLIB/1 & PLIB/2 Taking-Off List Plant and EquipmentDocument3 pagesPrecast Reinforced Concrete Pile Drawing No: PLIB/1 & PLIB/2 Taking-Off List Plant and EquipmentCHEE CHEONG KONGNo ratings yet

- Approved Independent Calibration Laboratories As of 31 May 2020Document6 pagesApproved Independent Calibration Laboratories As of 31 May 2020Sagar KumarNo ratings yet

- Magnelis Certification FCIDocument1 pageMagnelis Certification FCISagar KumarNo ratings yet

- ISO 13918 CD Weld Stud B4E2106016 SS 304Document1 pageISO 13918 CD Weld Stud B4E2106016 SS 304Sagar KumarNo ratings yet

- LWF1000 - Technical Proposal-HGTECHDocument6 pagesLWF1000 - Technical Proposal-HGTECHSagar KumarNo ratings yet

- Handheld Laser Welding Machine HW-A - 2022Document10 pagesHandheld Laser Welding Machine HW-A - 2022Sagar KumarNo ratings yet

- UntitledDocument1 pageUntitledSagar KumarNo ratings yet

- MSDS - VK Dip & VK Dip - SoftDocument3 pagesMSDS - VK Dip & VK Dip - SoftSagar KumarNo ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- Blind Nuts Semi Hex RHDocument1 pageBlind Nuts Semi Hex RHSagar KumarNo ratings yet

- Nelson NCD 1000T 1600T Operating ManualDocument35 pagesNelson NCD 1000T 1600T Operating ManualSagar KumarNo ratings yet