Professional Documents

Culture Documents

1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1

Uploaded by

Fatin Johar0 ratings0% found this document useful (0 votes)

32 views34 pagesOriginal Title

1- Chapter 6 - 1 - 1 Material Removal Process - introduction 21-1

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views34 pages1 - Chapter 6 - 1 - 1 Material Removal Process - Introduction 21-1

Uploaded by

Fatin JoharCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 34

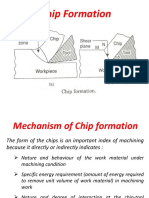

How chips are produced during machining.

Factors involved in temperature rise and its

effects.

How cutting tools wear and fail.

Surface finish and integrity of parts produced

by machining.

Machinability of materials.

Cutting processes remove material from the surface of a

workpiece by producing chips. Some of the more common cutting

processes are as follow:

1. Turning, in which the workpiece is rotated and a cutting tool

removes a layer of material as it moves to the left.

2. Cutting-off operation, where the cutting tool moves radially

inward and separates the right piece from the bulk of the

blank.

3. Slab-milling operation, in which a rotating cutting tool

removes a layer of material from the surface of the

workpiece.

4. End-milling operation, in which a rotating cutter travels along

a certain depth in the workpiece and produces a cavity.

Fig 21.1 shows some examples of common

machining operations.

Fig 21.2 shows the schematic illustration of the turning

operation showing various features.

The factors that influence the cutting process are outlined in

Table 21.1.

In order to appreciate the contents of this table, let’s now

identify the major independent variables in the cutting process

as follows:

◦ (a) tool material and coatings;

◦ (b) tool shape, surface finish, and sharpness;

◦ (c) workpiece material and condition;

◦ (d) cutting speed, feed, and depth of cut;

◦ (e) cutting fluids;

◦ (f) characteristics of the machine tool; and

◦ (g) workholding and fixturing.

Dependent variables in cutting are those that

are influenced by changes in the independent

variables listed above, and include: (a) type of

chip produced, (b) force and energy dissipated

during cutting, (c) temperature rise in the

workpiece, the tool, and the chip, (d) tool wear

and failure, and (e) surface finish and surface

integrity of the workpiece.

A typical question posed is which of the

independent variables should be changed first,

and to what extent, if (a) the surface finish of

the workpiece being cut is poor and

unacceptable, (b) the cutting tool wears rapidly

and becomes dull, (c) the workpiece becomes

very hot, and (d) the tool begins to vibrate and

chatter.

The four main types are:

1. Continuous

2. Built-up edge

3. Serrated or segmented

4. Discontinuous

Continuous chips

Continuous chips usually are formed with ductile

materials, machined at high cutting speeds

and/or high rake angles.

The deformation of the material takes place

along a narrow shear zone called the primary

shear zone.

Continuous chips may develop a secondary

shear zone because of high friction at the tool–

chip interface; this zone becomes thicker as

friction increases.

Deformation in continuous chips also may take

place along a wide primary shear zone with

curved boundaries.

This problem can be alleviated with chip

breakers (to follow) or by changing

parameters, such as cutting speed, feed, depth

of cut, and by using cutting fluids.

Built-up edge chips

A built-up edge (BUE) consists of layers of

material from the workpiece that gradually are

deposited on the tool tip—hence the term

built-up.

Built-up edge commonly is observed in

practice.

It is a major factor that adversely affects

surface finish, however, a thin, stable BUE

usually is regarded as desirable because it

reduces tool wear by protecting its rake face.

Built-up edge chips

The tendency for BUE formation can be

reduced by one or more of the following

means:

1. Increase the cutting speeds

2. Decrease the depth of cut

3. Increase the rake angle

4. Use a sharp tool

5. Use an effective cutting fluid

6. Use a cutting tool that has lower chemical

affinity for the workpiece material

Serrated chips are semicontinuous chips with

large zones of low shear strain and small

zones of high shear strain, hence the latter

zone is called shear localization.

Metals with low thermal conductivity and

strength that decreases sharply with

temperature (thermal softening) exhibit this

behavior, most notably titanium.

Discontinuous chips

Discontinuous chips consist of segments that may be

attached firmly or loosely to each other.

Discontinuous chips usually form under the following

conditions:

1. Brittle workpiece materials, because they do not have

the capacity to undergo the high shear strains involved

in cutting.

2. Workpiece materials that contain hard inclusions and

impurities or have structures such as the graphite

flakes in gray cast iron.

3. Very low or very high cutting speeds

4. Large depths of cut.

5. Low rake angles.

6. Lack of an effective cutting fluid.

7. Low stiffness of the toolholder or the machine

tool, thus allowing vibration and chatter to

occur.

Because of the discontinuous nature of chip

formation, forces continually vary during

cutting.

Consequently, the stiffness or rigidity of the

cutting-tool holder, the workholding devices,

and the machine tool are important in cutting

with serrated chips as well as with

discontinuous chips.

Chip Curl

In all cutting operations performed on metals,

as well as nonmetallic materials such as

plastics and wood, chips develop a curvature

(chip curl) as they leave the workpiece surface.

Among factors affecting the chip curl are:

1. The distribution of stresses in the primary and

secondary shear zones.

2. Thermal effects.

3. Work-hardening characteristics of the workpiece

material.

4. The geometry of the cutting tool

5. Cutting fluid

Generally, as the depth of cut decreases, the

radius of curvature decreases; that is, the chip

becomes curlier.

Also, cutting fluids can make chips become

more curly, thus reducing the tool–chip contact

area and concentrating the heat closer to the tip

of the tool. As a result, tool wear increases.

Chip Breakers

Continuous and long chips are undesirable as

they tend to become entangled and severely

interfere with machining operations and also

become a potential safety hazard.

Fig 21.7(a) shows the schematic illustration of

the action of a chip breaker. Note that the chip

breaker decreases the radius of curvature of

the chip and eventually breaks it. (b) Chip

breaker clamped on the rake face of a cutting

tool. (c) Grooves in cutting tools acting as chip

breakers. Most cutting tools used now are

inserts with built-in chip-breaker features.

Chip breakers have traditionally been a piece of

metal clamped to the tool’s rake face, which bend

and break the chip.

However, most modern cutting tools and inserts

now have built-in chip-breaker features of various

designs.

Fig 21.8 shows the chips produced in turning: (a)

tightly curled chip; (b) chip hits workpiece and

breaks; (c) continuous chip moving radially away

from workpiece; and (d) chip hits tool shank and

breaks off.

In interrupted-cutting operations (such as milling),

chip breakers generally are not necessary, since

the chips already have finite lengths.

Controlled contact on tools

Cutting tools can be designed so that the tool–chip

contact length is reduced by recessing the rake

face of the tool some distance away from its tip.

This reduction in contact length affects chip-

formation mechanics.

Primarily, it reduces the cutting forces and, thus,

the energy and temperature.

Determination of an optimum length is important

as too small a contact length would concentrate

the heat at the tool tip, thus increasing wear.

Cutting nonmetallic materials

A variety of chips are encountered in cutting

thermoplastics, depending on the type of

polymer and process parameters, such as

depth of cut, tool geometry, and cutting

speed.

Many of the discussions concerning metals

also are applicable generally to polymers.

Because they are brittle, thermosetting plastics

and ceramics generally produce discontinuous

chips.

The majority of machining operations involve

tool shapes that are three-dimensional, thus

the cutting is oblique.

Whereas in orthogonal cutting, the chip slides

directly up the face of the tool, in oblique

cutting, the chip is helical and at an angle i,

called the inclination angle.

Fig 21.9(a) shows the schematic illustration of

cutting with an oblique tool. Note the direction

of chip movement. (b) Top view, showing the

inclination angle, i. (c) Types of chips produced

with tools at increasing inclination angles.

Fig 21.10(a) shows the schematic illustration

of a right-hand cutting tool. The various

angles on these tools and their effects on

machining.

Although these tools traditionally have been

produced from solid tool-steel bars, they have

been replaced largely with Fig 21.10(b) inserts

made of carbides and other materials of

various shapes and sizes.

Shaving and skiving

Thin layers of material can be removed from

straight or curved surfaces by a process similar

to the use of a plane to shave wood.

Shaving is useful particularly in improving the

surface finish and dimensional accuracy of

sheared parts and punched slugs.

Skiving = Shave for long material. Shave with

sharp cutting tool that moves tangentially

across the length of the piece

You might also like

- Machining by CuttingDocument4 pagesMachining by CuttingSiddhi JainNo ratings yet

- Cutting Speed OptimizationDocument14 pagesCutting Speed OptimizationCharles OndiekiNo ratings yet

- Manufacturing Process - Module4.0Document18 pagesManufacturing Process - Module4.0Fiza KamaNo ratings yet

- Production Engineering Lecture 2Document16 pagesProduction Engineering Lecture 2AINAMANI AMOSNo ratings yet

- Unit I 4 Types of ChipsDocument6 pagesUnit I 4 Types of ChipsvelladuraiNo ratings yet

- Lecture 2 - 4 - Fundametals of MachiningDocument58 pagesLecture 2 - 4 - Fundametals of MachiningAINAMANI AMOSNo ratings yet

- ch21 Fundamentals of MachiningDocument25 pagesch21 Fundamentals of MachiningBaatar Zorigt100% (1)

- Sheet Production TechnologyDocument23 pagesSheet Production TechnologyOmar AlyNo ratings yet

- Me1008 Unit 3 Theory of Metal CuttingDocument39 pagesMe1008 Unit 3 Theory of Metal CuttingPruthviraj rathodNo ratings yet

- Unit-I Theory of Metal CuttingDocument73 pagesUnit-I Theory of Metal CuttingSarvesh Kumarasamy100% (1)

- Theory of Metal Cutting PDFDocument47 pagesTheory of Metal Cutting PDFEmmanuel KutaniNo ratings yet

- Theory of Metal CuttingDocument29 pagesTheory of Metal Cuttingvishnu anandNo ratings yet

- Metal Cutting ProcessDocument26 pagesMetal Cutting Processমুকসেতিন আল রাজী রিফাতNo ratings yet

- Experiment No.2 PDFDocument6 pagesExperiment No.2 PDFGest Account 08No ratings yet

- Effect of Metal Cutting Parameters On Chip Reduction Co-EfficientDocument7 pagesEffect of Metal Cutting Parameters On Chip Reduction Co-EfficientDebarshibiswasNo ratings yet

- Model Answers On Some QuestionsDocument18 pagesModel Answers On Some QuestionsCharles OndiekiNo ratings yet

- Unit I ' Theory of Metal CuttingDocument19 pagesUnit I ' Theory of Metal CuttingThulasi RamNo ratings yet

- Basic of Cutting ToolsDocument26 pagesBasic of Cutting Toolssiva kumarNo ratings yet

- Sheet Metal FormingDocument53 pagesSheet Metal Formingvinod100% (1)

- Unit One Material and Geometry of Cutting Tools 2015Document46 pagesUnit One Material and Geometry of Cutting Tools 2015elnat feyisa100% (1)

- Key 2Document22 pagesKey 2Jury.rahulNo ratings yet

- Mechanical Manufacturing Report 2 (Cutting)Document11 pagesMechanical Manufacturing Report 2 (Cutting)席拉茱No ratings yet

- Ch21 Fundamentals of CuttingDocument56 pagesCh21 Fundamentals of CuttingImGlobalCitizenNo ratings yet

- Ch21 Fundamentals of Cutting2Document70 pagesCh21 Fundamentals of Cutting2manojc68No ratings yet

- Theory of Metal Cutting 2Document39 pagesTheory of Metal Cutting 2Anonymous p0mg44x100% (1)

- Fundamentals of Cutting Mechanics Chip FormationDocument26 pagesFundamentals of Cutting Mechanics Chip FormationMerchant Ali100% (1)

- TDD-Metal Cutting & Special ToolsDocument27 pagesTDD-Metal Cutting & Special ToolsGS RathoreNo ratings yet

- Theory of Metal Cutting 2Document39 pagesTheory of Metal Cutting 2Ravichandran G67% (6)

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranNo ratings yet

- Ipe 332Document19 pagesIpe 332S. M. Hasibur RahmanNo ratings yet

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument62 pagesDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc Le100% (1)

- Fundamentals of Cutting: Chapter-20Document26 pagesFundamentals of Cutting: Chapter-20Venu Gopal AnneNo ratings yet

- Unit I ': Theory of Metal CuttingDocument14 pagesUnit I ': Theory of Metal CuttingramtwinsmeNo ratings yet

- Fundamentals of Cutting: Chapter-20Document26 pagesFundamentals of Cutting: Chapter-20rameshNo ratings yet

- Unit 2 12102019Document16 pagesUnit 2 12102019Satish SatiNo ratings yet

- Cutting Tool Materials & Theory of Metal CuttingDocument11 pagesCutting Tool Materials & Theory of Metal Cuttingrkscad11No ratings yet

- Q. What Is Metal Cutting?Document12 pagesQ. What Is Metal Cutting?ThenarasumohanveluNo ratings yet

- Chip Formation: Manufacturing Technology-IiDocument20 pagesChip Formation: Manufacturing Technology-IiSachin BharadwajNo ratings yet

- Production TechnologyDocument22 pagesProduction TechnologyOmar AlyNo ratings yet

- MT II - 2 Marks With AnswersDocument40 pagesMT II - 2 Marks With AnswersArulNo ratings yet

- Hard Machining GuideDocument51 pagesHard Machining GuideMuthu KumarNo ratings yet

- Mechanics of The Cutting ProcessDocument19 pagesMechanics of The Cutting ProcessdawitNo ratings yet

- Experiment No. To Study The Chip Breaker in Machining: Instructional ObjectivesDocument2 pagesExperiment No. To Study The Chip Breaker in Machining: Instructional Objectivespurushottam prajapatiNo ratings yet

- Tool engineering guide for metal cutting processesDocument89 pagesTool engineering guide for metal cutting processesYashraj patilNo ratings yet

- Machining Process IntroductionDocument9 pagesMachining Process Introductionirinuca12No ratings yet

- Theory of Metal Machining ProcessesDocument111 pagesTheory of Metal Machining ProcessesYuvraaj Singh100% (1)

- IPE-4102-Machine Tool SessionalDocument29 pagesIPE-4102-Machine Tool SessionalNafiz AlamNo ratings yet

- CH-1 MachiningDocument29 pagesCH-1 MachiningAbreham DerejeNo ratings yet

- Drilling Hole Quality and Cutting Fluid Cost OptimizationDocument45 pagesDrilling Hole Quality and Cutting Fluid Cost Optimizationidris_ali_7No ratings yet

- Temperature, Tool WearDocument36 pagesTemperature, Tool WearNimish JoshiNo ratings yet

- Types of Chips in Metal CuttingDocument5 pagesTypes of Chips in Metal CuttingMUKIIBI GERALDNo ratings yet

- 5 - Pembentukan GeramDocument21 pages5 - Pembentukan GeramHizkia OswariNo ratings yet

- ME2252 - Manufacturing Technology-IiDocument40 pagesME2252 - Manufacturing Technology-Iiraoli411No ratings yet

- 1 Mechanics of MachiningDocument47 pages1 Mechanics of MachiningRAJEEV KHANDELWALNo ratings yet

- Metal Cutting Forces and Chip FormationDocument38 pagesMetal Cutting Forces and Chip FormationcrazynupNo ratings yet

- Me8451 QB2Document32 pagesMe8451 QB2Jayaram R S [MECH]No ratings yet

- Metal Cutting TechnologyDocument22 pagesMetal Cutting Technologydema_diasNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Seminar Application of Nitrous Oxide in AutomobilesDocument20 pagesSeminar Application of Nitrous Oxide in AutomobilesSaikat BadyakarNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- Chapter-1: Introduction of The StudyDocument21 pagesChapter-1: Introduction of The StudyViswanathanNo ratings yet

- Barney's Great Adventure - Barney Wiki - WikiaDocument2 pagesBarney's Great Adventure - Barney Wiki - WikiachefchadsmithNo ratings yet

- Kyle 106 - 119 - 131 - 141Document1 pageKyle 106 - 119 - 131 - 141Gerson SouzaNo ratings yet

- The Picture of Dorian GrayDocument137 pagesThe Picture of Dorian GrayАнгелаС.No ratings yet

- Meralco Bill 330370940102 04142023Document2 pagesMeralco Bill 330370940102 04142023Jha CruzNo ratings yet

- 9709 s15 QP 12Document4 pages9709 s15 QP 12Abrar JahinNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- Engineering StudiesDocument4 pagesEngineering StudiesSamuel PhegelloNo ratings yet

- Essotherm 500 PDFDocument8 pagesEssotherm 500 PDFdonyaNo ratings yet

- 5988-4082EN Designers GuidDocument82 pages5988-4082EN Designers GuidAndreaNo ratings yet

- Musical Siren Project Report Under 40 CharactersDocument10 pagesMusical Siren Project Report Under 40 Charactersvinod kapateNo ratings yet

- Air release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorDocument1 pageAir release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorshravan Kumar SinghNo ratings yet

- MFJ-854 RF MeterDocument5 pagesMFJ-854 RF MeterHappyJoeNo ratings yet

- Factory made uPVC windows installationDocument2 pagesFactory made uPVC windows installationAmit Singh100% (2)

- B Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Document3 pagesB Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Rrr KkkNo ratings yet

- Petford & Atherton., 1996Document31 pagesPetford & Atherton., 1996Ivan Hagler Becerra VasquezNo ratings yet

- Studyguide TracksDocument75 pagesStudyguide TracksAnonymous FabB2WJl485% (13)

- QRP Yu1lm SDR-RX TXDocument299 pagesQRP Yu1lm SDR-RX TXD BNo ratings yet

- Postmodern EthicsDocument1 pagePostmodern Ethicsgeorge elerickNo ratings yet

- Mass DisasterDocument70 pagesMass DisasterJoseph RadovanNo ratings yet

- 1 Proforma of Allotment LetterDocument32 pages1 Proforma of Allotment LetterGovind SandhaNo ratings yet

- Permeability Test Constant Head MethodDocument10 pagesPermeability Test Constant Head MethodLouise LuyNo ratings yet

- Galactic Handbook and Synchronized MeditationsDocument91 pagesGalactic Handbook and Synchronized Meditationslapiton100% (10)

- Free Printable House Cleaning Schedule Template PDFDocument1 pageFree Printable House Cleaning Schedule Template PDFclear100% (1)

- Terpin Hydrate Oral SolutionDocument1 pageTerpin Hydrate Oral SolutionAbelard Maria EscrivaNo ratings yet

- Mathematics 6 LAS Q4Document127 pagesMathematics 6 LAS Q4Jake Padua100% (1)

- With Machine Room - GAD-01Document1 pageWith Machine Room - GAD-01Nagarajan SNo ratings yet