Professional Documents

Culture Documents

PART-4 (Stiffening System)

Uploaded by

yehia NasserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PART-4 (Stiffening System)

Uploaded by

yehia NasserCopyright:

Available Formats

Part- 4 Ship systems of construction

NAM162

Part(4) Stiffening Systems

Nasser 2020 07/31/2023 1

Marine Engineering Dep. Nasser Faculty of Engineering

Steel sections

Rolled and heavy sections

L shape

Offset bulb

I sections used as columns

Nasser 2020 07/31/2023 2

Different steel sections

Marine Engineering Dep. Nasser Faculty of Engineering

STEEL SECTIONS

Nasser 07/31/2023 3

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

1-Ship Plates 1 9 L

1-Deck plate

1-Sheer strake plates

3- Side plates

2

4-Bilge plates

5-Bottom plate

6-Garboard strakes

7-Keel plates

8-Tank top plates

9- Deck Stringer 3

10-Bulkhead plates

11-Margin

plate ?? 8

12-Shell plates are

all

4

5

6

7

2- Stiffeners (Long system)

L

1 Deck Longitudinal

2 Deck girders

3 Side Longitudinal

4Deck transvers (heave beam )

5- Bottom girders

6 Bottom Longitudinal

7 Floors

8 Side stringers

B/2

Nasser 2020 07/31/2023 4

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

3-Stiffeners (Trans system)

9- Beams

10-Frames L

11-Deck transverse

12-Side stringers

13- Web frame (heavy frames)

14-floors

B/2

B/2

4- Brackets

1. Knee

bracket

2. Tripping

brackets

3. Bilge

brackets

4. Side

brackets

5.Gusset bracket

6.

beam bracke

frame

Nasser 2020 07/31/2023 5

Part- 4 Ship systems of construction

Stiffening systems: A plate BxL is stiffened as

Frame space

From 0.8-1.2m

Heavy Heavy

sectio sectio

light

light

section

section

Frame

space

Transverse

space

B B

Transverse stiffening Longitudinal stiffening

Beams Longitudinals

Heavy beams(D transverse) Heavy beams(D transverse)

Girders Girders

Nasser 2020 07/31/2023 6

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Heavy stiffening members

Deck girders

Deck transverse

Side stringer

Bottom girders

1- Light stiffening members 2- Heavy stiffening

1- For transverse system For both transverse

Beams at deck and longitudinal

Frames at sides

systems

Inverse bottom frames

Bracket floor

Long deck girders

Deck transverse at each 3

frame space

Web frame at each 3 frames

2- For Longitudinal system Long. bottom girder

Deck Longs at deck Solid floor at each frame

Side Longs at side space

Bottom longs at bottom

Nasser 2020 (See above figure)

07/31/2023 7

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Stiffened plate panels

1- Side construction 2- Stiffened Deck

L

L

B

S stringer

Beams

D D. girder

Frames

Transverse Sys.

L

B

longitudinals

D D. Transverse

D. girder

Web frame

Nasser longitudinals 2020 07/31/2023 8

Longitudinal Sys.

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Systems of Construction

1-Transversly system of construction

This system is a series of closely spaced frames. This system

comprising frames, floors and longitudinal girders. The system is

suitable for small ships such as Tugs fishing vessels. The system is

supporting transverse and hydrostatic pressure loads.

Q1:Where, floors, inverse frames, web and ordinary frames , and

girders?

S stringer

Girders

2

Transverse system-

1- beams at deck and frames at side each (800- 1000mm)

2- inverse frames at bottom each (800- 1000mm)

Side stringers at side

Long. girders at deck and bottom

web frames +deck transvers + floors after 3 frames

Nasser 2020 07/31/2023 9

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Sections

Beams

Frames

Inverse frame

VT section at ordinary section

Deck transverse

Web frame

Solid floor

VT section at heavy section

Repeated each 3 ordinary frame

Nasser 2020 07/31/2023 10

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Transverse cycles

Nasser 2020 07/31/2023 11

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

2-Longitudinally system of construction

This system is a series of closely spaced longitudinal stiffeners. This system

comprising longitudinal , floors and widely deep transverse frames. This system

saving weight, give adequate longitudinal strength. This system is applied for

long ships where, acting bending moment is dominant loading. It is not applied

for G. Cargo ships.

Tankers, Container , passenger ships are adopted

Q2:Where, floors longitudinals, web, and girders?

Deck girder

Deck long

Side stringer

Side long

Bottom girder

Bottom long

Double side –bottom tanker

1-Longitudinals at deck , side and bottom each Long space

2-Long. girders at deck and bottom

3 Side stringers

Nasser 2020 07/31/2023 12

4 web frames +deck transvers + floors after 3frames

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Sections

Deck longitudinal

Side longitudinal

Bottom

longitudinal

VT section at ordinary frame

Deck transverse

Web frame

Solid floor

VT section at heavy section

Nasser 2020 07/31/2023 13

Repeated each 3 ordinary frame

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

3-Combined system of construction

This system has both advantages of the above systems.

The deck and bottom are longitudinally stiffened, while sides are

transversely stiffened. This system is mainly applied at bulk carriers and

passenger ships

The system combines advantages of long. and transverse systems

Q3:Difine advantages of each system and its applications and causes?

1- VT section at ordinary frames

2- VT section at web frames

Bulk carrier

1 Longitudinal at deck and bottom

2 Frames at sides

3 Side stringer at side

4 Long girders at deck and bottom

Nasser 2020 07/31/2023 14

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Deck longitudinal

Frame

Bottom

longitudinal

VT section at ordinary frame

Deck transvers

Web Frame

Solid floor

VT section at heavy section

Nasser 2020 07/31/2023 15

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

Functions of structural members

1. Bracket : support the girder, etc

2. Bulkheads : a vertical partition between compartments

3. Center girder : a heavy longitudinal member provide longitudinal

strength

4. Floor : A vertical member in the double-bottom along the breadth .

It will run from the center girder out to the margin plate on either

side of the vessel.

5. Frame : Internal support member for the side plating. It runs from

deck to bottom (along the depth)

6. Side stringer : A heavy long member sited in the side and connect

frames

7. Beam : An ordinary member support the deck along the breadth

8. Gusset : triangular plate for joining angle bar to a plate

9. Intercostals Side girder : A side longitudinal girder sited either side

of

i. the keel. Integral connection with the tank top and the ship’s

bottom plating and rigidly connected by floors

10.Keels : center line plate from stem to the stern frame.

Flat plate keels – Generally used keel. Center girder is

attached to the keel and inner bottom plating by continuous

welding and no scallops permitted

ii. Duct keels – a form of flat plate keel with tow center girder.

Often fitted between collision bulkhead and forward engine

room bulkhead to provide tunnel for pipes and additional

buoyancy.

11. Lightening holes – holes cut into floors or intercostals to reduce

weight and to provide access to tank areas

12..Bottom Longitudinal : A fore and aft strength member connecting

the athwartships floors. It must be continuous for ships.

13.Margin plate : a fore and aft plate sited at the turn of the bilge. The

upper edge is normally flanged to allow connection to the tank top

plating, while the opposite end is secured to the inside of the shell

plate by an angle-bar connection. It provides an end seal to the

double bottom tanks, having all the floors joining at right angles,

up to the collision bulkhead.

14.Panting beams : athwartships members in the forepart introduced

to reduce the in & out tendency of the shell plating, caused by

varying water pressure on the bow.

15.Panting stringers : internal horizontal plates secured to the shell

plating and braced athwartships by the panting beams.

16.Scantlings – used to indicate the thickness of plates, angles and

flanges.

Nasser 17.Sheer strake: the continuous row2020 of shell plates on a level with the 16

07/31/2023

uppermost continuous deck.

Marine Engineering Dep. Nasser Faculty of Engineering

Part- 4 Ship systems of construction

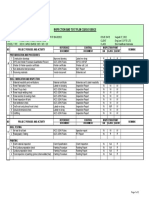

Members compensating stress

Heav Water Local Hog Dry-

Rackin y pressur & SF BM dockin Poundin Pantin

g g g

weig e Stres Sag g

ht s

Beam

knee

Beams

Bulkheads

Decks

Floors

Frames

Long'

girders

Pillars

Shell

plating

Nasser 2020 07/31/2023 17

Marine Engineering Dep. Nasser Faculty of Engineering

You might also like

- PART 4 (Stiffening System)Document18 pagesPART 4 (Stiffening System)MohamedMostafa100% (1)

- AMCRPS - AS 500 Design & Execution ManualDocument64 pagesAMCRPS - AS 500 Design & Execution Manualphilou6259No ratings yet

- Jiang Segmental LinerDocument68 pagesJiang Segmental LinerrodolfoNo ratings yet

- Structural Bracings 947.ppsDocument13 pagesStructural Bracings 947.ppsTuanQuachNo ratings yet

- Structural Bracings: Presentation by V. G. Abhyankar For Knowledge Sharing SessionsDocument13 pagesStructural Bracings: Presentation by V. G. Abhyankar For Knowledge Sharing Sessionssunil reddy100% (1)

- Design Principles of BreakwatersDocument97 pagesDesign Principles of BreakwatersShantanu Mandal0% (1)

- ITS - FTK - TL - Kuliah Tamu - Mooring and Riser Design - DD 23feb2018Document38 pagesITS - FTK - TL - Kuliah Tamu - Mooring and Riser Design - DD 23feb2018Ardi Ardiansyah100% (1)

- Time Line ADDplatformDocument4 pagesTime Line ADDplatformIlyas Rangga RamadhanNo ratings yet

- Project ReportDocument19 pagesProject ReportPAWANNo ratings yet

- Design of Plate Girder - Components of Plate GirderDocument11 pagesDesign of Plate Girder - Components of Plate Girdervijay kumarNo ratings yet

- Pipeline Instation Using Orcaflex Master Thesis 4 PDFDocument144 pagesPipeline Instation Using Orcaflex Master Thesis 4 PDFsamiransmita100% (3)

- A Comparative Study On Performance of Conventional and Pre-Engineered Steel Frames Subjected To Crane LoadDocument15 pagesA Comparative Study On Performance of Conventional and Pre-Engineered Steel Frames Subjected To Crane LoadIJRASETPublicationsNo ratings yet

- 11-Bcis Bearings - RLPDocument33 pages11-Bcis Bearings - RLPHugo SouzaNo ratings yet

- Eshan College of Engineering: Project Report On Pile Foundation (According To Practical Principals)Document7 pagesEshan College of Engineering: Project Report On Pile Foundation (According To Practical Principals)Salman QureshiNo ratings yet

- Design and Analysis of Floating Production Systems: Jinzhu XiaDocument21 pagesDesign and Analysis of Floating Production Systems: Jinzhu XiaAnonymous uUtULa7mJONo ratings yet

- ASBI Construction Practices Handbook For Concrete Segmental and Cable Supported Brdiges PDFDocument454 pagesASBI Construction Practices Handbook For Concrete Segmental and Cable Supported Brdiges PDFHema Chandra IndlaNo ratings yet

- Max Meyer - BDET Presentation - 5th JuneDocument62 pagesMax Meyer - BDET Presentation - 5th JuneSailaja VempatiNo ratings yet

- Module 4 NotesDocument95 pagesModule 4 NotesAKHIL.S1822 CE A 18-22No ratings yet

- TR 43 Post Tensioned Concrete Floors Design Handbook PDFDocument178 pagesTR 43 Post Tensioned Concrete Floors Design Handbook PDFWayne ChongNo ratings yet

- Chapter4 PDFDocument26 pagesChapter4 PDFvaibhav dahiwalkarNo ratings yet

- Bedplates Requirement:: K5106 - Marine Engineering Practice and LegislationDocument13 pagesBedplates Requirement:: K5106 - Marine Engineering Practice and Legislationdeevan rajNo ratings yet

- Mod Sea 101a 4Document9 pagesMod Sea 101a 4Denwil Vincent MoneraNo ratings yet

- PNA7 - Ship StructuresDocument25 pagesPNA7 - Ship Structurescujat123No ratings yet

- Ship Construction BY STOKOE PDFDocument92 pagesShip Construction BY STOKOE PDFMark Bhatti100% (1)

- Grillage Analysis ThesisDocument78 pagesGrillage Analysis ThesisAnonymous 0eBKSRNo ratings yet

- ASBI-Construction Practices Handbook For Concrete Segmental and Cable Supported BridgesDocument454 pagesASBI-Construction Practices Handbook For Concrete Segmental and Cable Supported BridgesGanesh PersaudNo ratings yet

- Tanks Examples-Oriented Reinforced Concrete Textbook According To ACI318, ASCE/SEI 7, ACI350.3, and ACI350Document8 pagesTanks Examples-Oriented Reinforced Concrete Textbook According To ACI318, ASCE/SEI 7, ACI350.3, and ACI350Cesar Paul Purihuaman MoraNo ratings yet

- Structural Design StudioDocument45 pagesStructural Design StudioIyappan AnithaNo ratings yet

- Ship Structure Committee - Case Study V - Container ShipDocument6 pagesShip Structure Committee - Case Study V - Container Shipreda redaNo ratings yet

- Analysis of Truss BridgeDocument83 pagesAnalysis of Truss Bridgeshaik sadikNo ratings yet

- Checklist For Preliminary Bridge DesignDocument2 pagesChecklist For Preliminary Bridge DesignbkgossNo ratings yet

- CE 312 Structural Analysis and Design Sessional-I (Lab Manual)Document73 pagesCE 312 Structural Analysis and Design Sessional-I (Lab Manual)julesNo ratings yet

- Dyform 8 PI: High Performance Crane Ropes BenefitsDocument2 pagesDyform 8 PI: High Performance Crane Ropes BenefitsKonstantinos SynodinosNo ratings yet

- Chapter B-4 Construction Plan, Cost Estimate and Implementation ProgramDocument53 pagesChapter B-4 Construction Plan, Cost Estimate and Implementation ProgramCrystel Joyce UltuNo ratings yet

- SLIPFORMDocument117 pagesSLIPFORMparamarthasom1974No ratings yet

- G12572 PDFDocument114 pagesG12572 PDFMURUGANANTHAMNo ratings yet

- Railway Sleepers Quality ControlDocument33 pagesRailway Sleepers Quality ControlRavi Teja100% (4)

- Industrial Building (Plate Girder)Document58 pagesIndustrial Building (Plate Girder)adnan-651358100% (1)

- Project No: Project Title: Section: Date Calcs For: by Sheet NoDocument2 pagesProject No: Project Title: Section: Date Calcs For: by Sheet Noahmad nafek august fouzyNo ratings yet

- A Study On The Behaviour of Double Layer Steel Braced Barrel VaultsDocument5 pagesA Study On The Behaviour of Double Layer Steel Braced Barrel VaultsSonit NemaNo ratings yet

- Fracture Project ReportDocument22 pagesFracture Project Reportsheldoncooper691017No ratings yet

- Design of RC BeamsDocument41 pagesDesign of RC BeamsNadeesh PriyashanNo ratings yet

- NS Beam-Brochure ENDocument19 pagesNS Beam-Brochure ENMartinNo ratings yet

- Analysis and Design of Mono-Rail Plate Girder Bridge - 2023Document67 pagesAnalysis and Design of Mono-Rail Plate Girder Bridge - 2023adnan-651358No ratings yet

- ASBI 2019-3rd - Edition - CP - HandbookDocument440 pagesASBI 2019-3rd - Edition - CP - Handbookarindam1508100% (1)

- ةحلسملا ةيناسرخلا تآشنملا ميمصت Design Of Reinforced Concrete StructuresDocument47 pagesةحلسملا ةيناسرخلا تآشنملا ميمصت Design Of Reinforced Concrete StructuresMohammed SalemNo ratings yet

- Modern Prestressed Bridges - Libby & PerkinsDocument256 pagesModern Prestressed Bridges - Libby & PerkinsRaghav chandraseskaranNo ratings yet

- Guidelines Code and Standard of Tunnel LinningDocument49 pagesGuidelines Code and Standard of Tunnel LinningChristin UrginoNo ratings yet

- Structure IV: Bachelor of Architecture Cosmos College of Management and TechnologyDocument86 pagesStructure IV: Bachelor of Architecture Cosmos College of Management and Technologysujan pokhrelNo ratings yet

- Chapter 8 Outline: CE 134-Design of Reinforced Concrete StructuresDocument14 pagesChapter 8 Outline: CE 134-Design of Reinforced Concrete StructuresJerome FabreroNo ratings yet

- Walker S ManaloDocument62 pagesWalker S ManaloVijay OfficialNo ratings yet

- Chapter 3-Compression MembersDocument41 pagesChapter 3-Compression MembersGamtesa EjetaNo ratings yet

- 1 IntroductionDocument7 pages1 Introductionroyko20000822No ratings yet

- S-Lay For DummiesDocument84 pagesS-Lay For DummiesjanuaingaranNo ratings yet

- Design Manual of Welded and Cold-Formed Hollow SectionsDocument128 pagesDesign Manual of Welded and Cold-Formed Hollow SectionstetrapetronNo ratings yet

- Class40 Rules 2021Document24 pagesClass40 Rules 2021Nadezhda ValmountNo ratings yet

- Design of Columns (2020)Document37 pagesDesign of Columns (2020)Trevor LingNo ratings yet

- SIN Beam Technical Guide PDFDocument141 pagesSIN Beam Technical Guide PDFIvan KlyuchkaNo ratings yet

- TRIAGE AND LIFEBOAT ETHICS'pptDocument11 pagesTRIAGE AND LIFEBOAT ETHICS'pptyumikoNo ratings yet

- Daniel Riski Nama Deck Officer Class IVDocument1 pageDaniel Riski Nama Deck Officer Class IVsaleh umbalakNo ratings yet

- Shipbuilding ApprovalsDocument5 pagesShipbuilding ApprovalslucasNo ratings yet

- ShipbuildingDocument15 pagesShipbuildingvzagkasNo ratings yet

- Equipment Sheet: Trailing Suction Hopper DredgerDocument2 pagesEquipment Sheet: Trailing Suction Hopper DredgerGerardo AmbuludiNo ratings yet

- Container Logistics and Maritime TransportDocument41 pagesContainer Logistics and Maritime TransportHasnae BlNo ratings yet

- Port Hedland LoadingDocument3 pagesPort Hedland LoadingAsif Siddiqui50% (2)

- Inspection and Test Plan Cargo Barge: Page 1 of 2Document2 pagesInspection and Test Plan Cargo Barge: Page 1 of 2ferdyNo ratings yet

- A-Class - Vessel DescriptionDocument2 pagesA-Class - Vessel DescriptionEnrique Domínguez DomínguezNo ratings yet

- Dwg. No. 19 - 42 12 023 - EL3-ModelDocument1 pageDwg. No. 19 - 42 12 023 - EL3-ModelRamadhian EkaputraNo ratings yet

- Conan D20 1e Pirate IslesDocument129 pagesConan D20 1e Pirate IslesJonathan Segura100% (4)

- Pre Arrival Checklist (EXAMPLE)Document11 pagesPre Arrival Checklist (EXAMPLE)elfrinaNo ratings yet

- Across The Sea To IrelandDocument1 pageAcross The Sea To IrelandKintyre On RecordNo ratings yet

- Logistics Final ExamDocument7 pagesLogistics Final ExamJeidi Emerald100% (1)

- CAE Reading Multiple Choice - Flagging OutDocument3 pagesCAE Reading Multiple Choice - Flagging OutCristina CBNo ratings yet

- IMO ConventionDocument95 pagesIMO ConventionJoselito Ramos Cawagas Jr.No ratings yet

- ANDES Vessel Particular: As of March 2006Document20 pagesANDES Vessel Particular: As of March 2006ankit_chauhan100% (1)

- UAEDocument2 pagesUAEHemaNo ratings yet

- Cebu Salvage Corp V Phil. Home AssuranceDocument1 pageCebu Salvage Corp V Phil. Home Assurancejudith_marie1012100% (2)

- Curiculum Vitae: Document TravelDocument2 pagesCuriculum Vitae: Document TravelNavoleon AlfaridhoNo ratings yet

- Sistership MaulDocument11 pagesSistership MaulArdiani Samti Nur AzizahNo ratings yet

- JudulDocument5 pagesJudulriduan100% (1)

- Test 2: ListeningDocument7 pagesTest 2: ListeningRully Purnama Aji100% (1)

- Class 1Document36 pagesClass 1Aktarojjaman MiltonNo ratings yet

- MS Notice 92 - Application For An Endorsement Attesting Recognition of A CoC - Doc - 20140625083943Document2 pagesMS Notice 92 - Application For An Endorsement Attesting Recognition of A CoC - Doc - 20140625083943Tanmoy MandalNo ratings yet

- Principles of Ship HandlingDocument10 pagesPrinciples of Ship HandlingGlen MacNo ratings yet

- The Inland Water Transport of Bangladesh and I2Document3 pagesThe Inland Water Transport of Bangladesh and I2Syed Mubashir Ali H ShahNo ratings yet

- BV NR 467Document280 pagesBV NR 467teacgNo ratings yet

- NSCV C6a July2018Document112 pagesNSCV C6a July2018taddeoNo ratings yet

- Maritime TerminologyDocument16 pagesMaritime TerminologysaifulNo ratings yet