Professional Documents

Culture Documents

Anpsg 2001 Cips

Uploaded by

Eduardo MagallonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anpsg 2001 Cips

Uploaded by

Eduardo MagallonCopyright:

Available Formats

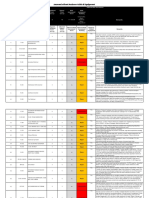

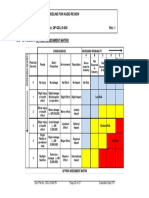

Frequency

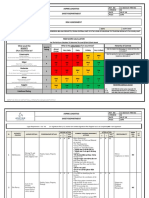

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site

Major on site

C4 HIGH SIGNIFICANT MODERATE

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Other

Minor on-plant

impact

C1 LOW

CIPS - Critical

NEGLIGIBLE

Instrument Protection

System

and what it means to me

David Hind Orica Carseland Works 1

Introduction

What is CIPS?

What Effect Will it Have?

David Hind Orica Carseland Works 2

What is CIPS

Critical

Last Resort

Must Work

Instrument

Involves valves, switches, transmitters, etc.

Protection

Security

Safety

System

Not just one thing, but many things.

David Hind Orica Carseland Works 3

What's Critical

Hazop Process

Identifies hazards & risks

Sets risk targets

CIPS Review

Defines how bad it could be

Consequence/frequency

Defines level of protection required

David Hind Orica Carseland Works 4

Example : AN Pumping System

90% AN

Tank

PUMP

David Hind Orica Carseland Works 5

Example : AN Pumping System

90% AN

Tank

PUMP

Are there any hazards????

David Hind Orica Carseland Works 6

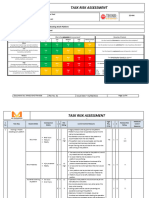

CIPS Decision Matrix

Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site C4 HIGH SIGNIFICANT MODERATE

Major on site

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

David Hind Orica Carseland Works 7

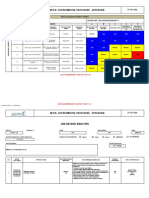

High Risk

Eliminate the risk mechanically

Fault Tree Analysis

Hard Wired

Safety PLC (Quadlog/Triconics)

Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site

Major on site

C4 HIGH SIGNIFICANT MODERATE

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

David Hind Orica Carseland Works 8

Significant Risk

Loop Analysis

FDT Calculations

Hard Wired

Safety PLC (Quadlog/Triconics)

Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site

Major on site

C4 HIGH SIGNIFICANT MODERATE

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

David Hind Orica Carseland Works 9

Moderate Risk

Good design practice

Hard Wired

Safety PLC (Quadlog/Triconics)

DCS

Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site

Major on site

C4 HIGH SIGNIFICANT MODERATE

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

David Hind Orica Carseland Works 10

Low Risk

Good design practice

DCS

Negligible Risk Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Do you really need it? Corporate/Site

Potential for off-

site impact or

Major on site

(including fatality)

C4 HIGH SIGNIFICANT MODERATE

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

David Hind Orica Carseland Works 11

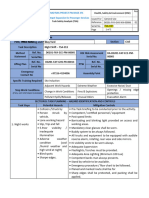

Example : AN Pumping System

Hazard :

Frozen AN line resulting

in dead heading pump,

heat build-up and pump

90% AN explosion

Tank

PUMP

David Hind Orica Carseland Works 12

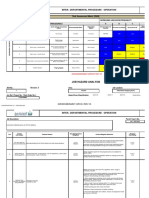

Example : AN Pumping System

Frequency

Consideration Rel. High Slight Very Slight

Hazard : Business SH&E W3 W2 W1

Frozen AN line resulting Potential for off-

site impact or

Corporate/Site C4 HIGH SIGNIFICANT MODERATE

Major on site

in dead heading pump, (including fatality)

heat build-up and pump

Major on plant

90% AN explosion Factory impact (incl. C3

Consequence

Serious injury)

Tank

Serious on-plant

Unit impact (including C2

PUMP MTI)

Minor on-plant

Other C1 LOW NEGLIGIBLE

impact

How Bad would a Pump Explosion Be?

How Frequent might it happen?

David Hind Orica Carseland Works 13

Instrumentation Design

Valves, Transmitters, Switches, Measuring Device

Reliability

Fail Safe/Failure Modes

Diagnostics

Redundancy

Hard Wired System vs Software System

Bypasses

David Hind Orica Carseland Works 14

Fault Tree Analysis

Frequency FDT

Low Level in D203 1

0.0125

LTLL 2202 Fails 0.0125 &

Suction

OR Problem

Pump Suction Blocked 0.02 0.02 0.0325

Flow

OR Problem

Line to AN Concentrator

Blocked 0.05 0.1925

XV2612 fails to open on

concentrator trip 0.01

OR Pump Dead Headed

Blocked Recycle Line 0.05 0.16

Line to AN Storage Blocked 0.05

David Hind Orica Carseland Works 15

Fraction Dead Time (FDT)

Calculating the amount of time an

instrumented trip system would not work

properly by examining the individual items

Data from tables, experience, etc.

David Hind Orica Carseland Works 16

Example : AN Pumping System

Hazard :

Frozen AN line resulting FSL E1

in dead heading pump,

heat build-up and pump

FIT

90% AN explosion

Tank

PUMP

Completed Fault Tree Analysis

Completed FDT Calculations

Complete Instrumentation Design

David Hind Orica Carseland Works 17

Protection System

Instrumentation System

Documentation System

Training & Procedures

Modification System (AWO)

Trip Testing

David Hind Orica Carseland Works 18

Documentation

How does it work and why.

P&IDs

Trip Matrix

CIPS Review Documents

Software Code

Instrument Index

Operating Procedures

David Hind Orica Carseland Works 19

Modification System (AWO)

System to allow it to change

Provides checks that change does not cause

disaster

David Hind Orica Carseland Works 20

Training & Procedures

Knowledge of how it works

Knowledge of why it works

Knowledge to keep it working

David Hind Orica Carseland Works 21

Trip Testing

Ensure the system will work when you want it to.

Method of testing

on line vs off line

Record Keeping

Frequency

based on acceptable dead time

David Hind Orica Carseland Works 22

No Testing

Device Fails

Operating

Failed

Time (months)

David Hind Orica Carseland Works 23

Testing Every Month

Device Fails

Working

Tested & Repaired

Failed

Time (months)

David Hind Orica Carseland Works 24

Testing Every 3 Months

Device Fails

Working

Failed

Tested and Repaired

Time (months)

David Hind Orica Carseland Works 25

CIPS and ME

More Documentation

Rules on Process Bypasses

Redundant Systems

More Complex

Safer System

David Hind Orica Carseland Works 26

More Documentation

P&IDs

Hazops

Trip Matrix

CIPS Review

FDT Calculations

Fault Tree Analysis

Trip Testing Records

More Information

Must keep it updated

David Hind Orica Carseland Works 27

Effect of CIPS

SaferSystem

Quantification of Risk Reduction

More/Better Documentation

Trip Testing & Record Keeping

More Complex Systems

Higher On line Time?

David Hind Orica Carseland Works 28

Frequency

Consideration Rel. High Slight Very Slight

Business SH&E W3 W2 W1

Potential for off-

site impact or

Corporate/Site

Major on site

C4 HIGH SIGNIFICANT MODERATE

(including fatality)

Major on plant

Consequence

Factory impact (incl. C3

Serious injury)

Serious on-plant

Unit impact (including C2

MTI)

Minor on-plant

Other

impact

C1 LOW NEGLIGIBLE

You might also like

- Business Expectations: Are You Using Technology to its Fullest?From EverandBusiness Expectations: Are You Using Technology to its Fullest?No ratings yet

- Hazard RegisterDocument47 pagesHazard RegisterJay Mark0% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDPa imanNo ratings yet

- 030 - Moving Machineries in Site PremisesDocument6 pages030 - Moving Machineries in Site PremisesPrem ChristianNo ratings yet

- Inherent Risk Assessment - Ammonia Plant - 12032020Document6 pagesInherent Risk Assessment - Ammonia Plant - 12032020Anonymous gWKgdUBNo ratings yet

- Finance Risk Assessment of CCSU ProjectDocument10 pagesFinance Risk Assessment of CCSU ProjectNavya RaturiNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- 04 IndustrialDocument14 pages04 IndustrialΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 1 - Construction SafetyDocument43 pages1 - Construction SafetyHawaiiChongNo ratings yet

- Alarm Philosophy Tata Steel IJmuidenDocument13 pagesAlarm Philosophy Tata Steel IJmuidenRaul GonzalezNo ratings yet

- Risk Assessment Risk Acceptable (Y/N) Severity of Harm(s) Likelihood of Occurance of Hazard (L) Risk Rating (S X L)Document6 pagesRisk Assessment Risk Acceptable (Y/N) Severity of Harm(s) Likelihood of Occurance of Hazard (L) Risk Rating (S X L)girijaNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- 038 - Working On Mobile Elevating Work PlatformDocument4 pages038 - Working On Mobile Elevating Work PlatformPrem ChristianNo ratings yet

- Safe Work Method Statement - Service: Date Created: Approved By: Review DateDocument2 pagesSafe Work Method Statement - Service: Date Created: Approved By: Review DateharmlesdragonNo ratings yet

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- TSA-020 - Concrete Core DrillDocument3 pagesTSA-020 - Concrete Core DrillMusadiq HussainNo ratings yet

- TSA-013 - Night ShiftDocument2 pagesTSA-013 - Night ShiftMusadiq HussainNo ratings yet

- QP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STDocument1 pageQP Guideline For Hazid Review: Doc File No.: GDL-S-040 R1 Page 22 of 27 Custodian Dept: STsanjayNo ratings yet

- 2 Accident Incident ReportingDocument28 pages2 Accident Incident ReportingBhaskar ShuklaNo ratings yet

- 29-JHA For Removal of Wooden PalletDocument4 pages29-JHA For Removal of Wooden PalletPradip Kumar ShaNo ratings yet

- Rehiraas (Odiya)Document1 pageRehiraas (Odiya)Ravie OuditNo ratings yet

- Hse Risk Assessment Matrix (Ram) : E4 E5 D1 D5 C1 C2 B1 B2 B3 A1 A2 A3 A4Document2 pagesHse Risk Assessment Matrix (Ram) : E4 E5 D1 D5 C1 C2 B1 B2 B3 A1 A2 A3 A4MOHD NAJMAN BIN MUDANo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument9 pagesKimanis Power Project: Job Safety Analysissimonsitompul25No ratings yet

- Dekra Leading Indicator For SIFDocument15 pagesDekra Leading Indicator For SIFsdurga1100% (2)

- Drypro832 Install (0921YF220E 070914 Fix) PDFDocument262 pagesDrypro832 Install (0921YF220E 070914 Fix) PDFКонстантин ПокидаевNo ratings yet

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaDocument10 pagesDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument25 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisFaraz KhalidNo ratings yet

- Compilation of Assessment Method For Criticality Equipment Rating Rev 2Document13 pagesCompilation of Assessment Method For Criticality Equipment Rating Rev 2Juristiawan FitriansyahNo ratings yet

- Project Risk RegisterDocument23 pagesProject Risk RegistersajinNo ratings yet

- Risk Assessment of WaterproofingDocument7 pagesRisk Assessment of WaterproofingAbdul MujeebNo ratings yet

- TSA-024 - Temporary WorksDocument4 pagesTSA-024 - Temporary WorksMusadiq HussainNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- Sil Assessment-Risk Graph and Lopa TrainingDocument40 pagesSil Assessment-Risk Graph and Lopa TrainingPravin GowardunNo ratings yet

- SIL ExplanationDocument40 pagesSIL ExplanationFernando De la RosaNo ratings yet

- Failure Modes, Effects and Diagnostic Analysis: Project: Plant-STOP 9469Document23 pagesFailure Modes, Effects and Diagnostic Analysis: Project: Plant-STOP 9469Ibrahim BenlakhdarNo ratings yet

- Risk Assessment Manhole CleaningDocument9 pagesRisk Assessment Manhole CleaningShah MuzzamilNo ratings yet

- Midmark 630 003-10431-99Document120 pagesMidmark 630 003-10431-99Camila MapuraNo ratings yet

- Hira For Crusher 1Document18 pagesHira For Crusher 1Aniket mhatreNo ratings yet

- Initial Incident Notification Form V9.Xls - Al-Karrar1 06-12-22Document1 pageInitial Incident Notification Form V9.Xls - Al-Karrar1 06-12-22Amjid GharkanNo ratings yet

- Job Hazard Analysis FORMDocument2 pagesJob Hazard Analysis FORMJerome EugeneNo ratings yet

- OHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEDocument21 pagesOHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEmohammed tofiqNo ratings yet

- 27.JHA For Collection and Disposal of Used Air Filter and Electronic WasteDocument4 pages27.JHA For Collection and Disposal of Used Air Filter and Electronic WastePradip Kumar ShaNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- DAIKIN MicrotechIII Remote User InterfaceDocument17 pagesDAIKIN MicrotechIII Remote User InterfaceNavin RamnauthNo ratings yet

- RA For Erection of Precast Elemenets For BOP Ref. No 3761800008-R-01-C-E-69047 - ADocument33 pagesRA For Erection of Precast Elemenets For BOP Ref. No 3761800008-R-01-C-E-69047 - ARAMY ABOU AL DAHABNo ratings yet

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- ABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsDocument5 pagesABC - ra.CWSS.19-HIRA-Erection of Precast Columns, BeamsShafie ZubierNo ratings yet

- General Maintenance Risk Assessment 2011Document9 pagesGeneral Maintenance Risk Assessment 2011Shannon MooreNo ratings yet

- Inter - Departmental Procedure Operation: IP-OPS-066Document10 pagesInter - Departmental Procedure Operation: IP-OPS-066AnuradheNo ratings yet

- ICM Rotec 2019Document54 pagesICM Rotec 2019Abu Yussif AlaboodiNo ratings yet

- Aspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Document6 pagesAspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Kevin ColmoNo ratings yet

- Initial Incident Notification Form V9.Xls - Al-Karrar 06-12-22Document1 pageInitial Incident Notification Form V9.Xls - Al-Karrar 06-12-22Amjid GharkanNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Warehouse - Store-Laydown Yard Rev.2021Document12 pagesOHS-PR-09-03-F02 HIRA - 001 Warehouse - Store-Laydown Yard Rev.2021sayed fida hussainNo ratings yet

- The Faculty of Language: What Is It, Who Has It and How Did It Evolve?Document4 pagesThe Faculty of Language: What Is It, Who Has It and How Did It Evolve?Aman GuptaNo ratings yet

- How To Write Your Novel Study EssayDocument27 pagesHow To Write Your Novel Study EssayTimon WilsonNo ratings yet

- A Service Response To The Pandemic: Open Circle and Restorative Justice During COVID-19Document3 pagesA Service Response To The Pandemic: Open Circle and Restorative Justice During COVID-19Gabriel RochaNo ratings yet

- Markham College School Profile 2022 2023Document2 pagesMarkham College School Profile 2022 2023lskdfjNo ratings yet

- Ambetronics Engineers PVT LTD: Questionnaire FormDocument2 pagesAmbetronics Engineers PVT LTD: Questionnaire FormGovind RaoNo ratings yet

- TRASCO ES Couplings PDFDocument16 pagesTRASCO ES Couplings PDFAlvaro Felipe CharlinNo ratings yet

- MECH 2 Module 3 Unit 1 Newton's Second Law of MotionDocument19 pagesMECH 2 Module 3 Unit 1 Newton's Second Law of MotionIya AsperinNo ratings yet

- 13.2 Biotic & Abiotic FactorsDocument3 pages13.2 Biotic & Abiotic FactorsOmar AlwaerNo ratings yet

- HPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Document9 pagesHPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Đoàn Lê Thuý HiềnNo ratings yet

- Ssdeandpv Vartak: On The Speed of LightDocument8 pagesSsdeandpv Vartak: On The Speed of LightdhaataaNo ratings yet

- CBSE-Class-4-Maths-Worksheet SubtractDocument6 pagesCBSE-Class-4-Maths-Worksheet Subtractkomaltagra0% (1)

- Group Activity: International Trade: Topics ResultsDocument6 pagesGroup Activity: International Trade: Topics ResultsGround ZeroNo ratings yet

- Mechanical Properties of Solids NewDocument32 pagesMechanical Properties of Solids NewVijyata DhankharNo ratings yet

- Le Chatelier's PrincipleDocument15 pagesLe Chatelier's PrincipleAldrick VeranoNo ratings yet

- San 310CTRDocument2 pagesSan 310CTRNguyễn Hồng NamNo ratings yet

- 2.0 Cegeotech2 Lec m1 (Intro)Document19 pages2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaNo ratings yet

- Module 4 AssignmentDocument4 pagesModule 4 AssignmentSophia June NgNo ratings yet

- Making A Poster Rubric 1Document1 pageMaking A Poster Rubric 1Kimberly Ann Dureza RedmanNo ratings yet

- درجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةDocument26 pagesدرجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةAbdallah HamedNo ratings yet

- BISE MCQs-I (Microsoft Forms)Document3 pagesBISE MCQs-I (Microsoft Forms)Ghulam FaridNo ratings yet

- Uk EssaysDocument7 pagesUk Essaysvotukezez1z2100% (2)

- 04mindset2 Unit3 Test OralProductionDocument2 pages04mindset2 Unit3 Test OralProductionAndrea David MartínezNo ratings yet

- Franklin 1988Document16 pagesFranklin 1988Verônica VieiraNo ratings yet

- Poptropica English Islands My Language Kit 5Document58 pagesPoptropica English Islands My Language Kit 5Alex8mR40% (5)

- Ko 2015Document22 pagesKo 2015Mudavath Babu RamNo ratings yet

- COVID-19 Weekly Report: Oregon's Weekly Surveillance Summary Novel Coronavirus (COVID-19)Document8 pagesCOVID-19 Weekly Report: Oregon's Weekly Surveillance Summary Novel Coronavirus (COVID-19)KGW NewsNo ratings yet

- IELTS Listening Practice 01Document16 pagesIELTS Listening Practice 01ENGLISH LANGUAGE TUTORINGNo ratings yet

- Stat 130 Module 1 B SlidesDocument16 pagesStat 130 Module 1 B SlidesambonulanNo ratings yet

- Statistics and StatisticDocument11 pagesStatistics and Statisticmaria69No ratings yet

- Chemistry I Equation Sheet: Solubility Rules Polyatomic IonsDocument1 pageChemistry I Equation Sheet: Solubility Rules Polyatomic IonsbanatinoNo ratings yet