Professional Documents

Culture Documents

04 JSA - Welding Works

Uploaded by

syed khaja misbhuddinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 JSA - Welding Works

Uploaded by

syed khaja misbhuddinCopyright:

Available Formats

JSA – Job Safety Analysis JSA No: 04

SWMS Title: Welding Works Revision : 04

Submitted by:

Contractor: INFINITI BUILDINH SOLUTIONS PVT LTD Prepared by:

Contact Name SURESH KUMAR Contact Position: SITE ENGINEER

Contact Signature: Contract Phone No:

Project Details & JSA Task Description:

Project: DRPL-PHASE-2 Location

Bldg/Area DRPL-PHASE-2

Task / Activity: Welding Works :Level UPPERBASE

Zone/Room

Trades Involved:

FITTER, WELDER, HELPERS, ENGINEER

Major Equipment to be used

List PPE required for this task:

for this task: HARD HAT, SAFETY SHOE, HAND GLOVES,

*All equipment listed has has been cleared for use on site and is maintained in

accordance with the manufacturers recommendations. FACE SHEILD, NOSE MASK, EAR PLUG

List any Hazardous WELDING MACHINES, CUTTING AND

HOT AND GENERAL WORK PERMIT

Substances, Materials or GRINDING MACHINES List Permits to Work required to

Dangerous Goods to be used: commence this Task:

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

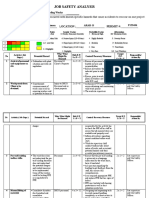

Risk Matrix & Ranking

Likelihood / Probability

Level Description of Consequence or Impact Consequence M

L U

Moderat

Likely Unlikely

e

H (1) Potential death, permanent disability or major structural failure/damage. Off-site environmental H (1)

1 1 2

(High level of harm) discharge/release not contained and significant long-term environmental harm. (High)

M (2) Potential temporary disability or minor structural failure/damage.

M (2)

(Medium level of On-site environmental discharge/release contained, minor remediation required, short-term 1 2 3

(Medium)

harm) environmental harm.

Incident that has the potential to cause persons to require first aid.

L (3) L (3)

On-site environmental discharge/release immediately contained, minor level clean up with no 2 3 3

(Low level of harm) (Low)

short-term environmental harm.

Level Likelihood / Probability

Likely Could happen frequently

Moderate Could happen occasionally

Unlikely May occur only in exceptional circumstances

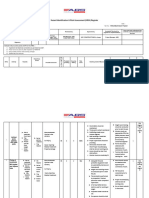

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

# Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Area to be barricaded and display Hot

work/Lifting signages.

Appropriate barrication and training to

workers.

Injury to trespassers.

1 Area barrication Isolating the lifting area from other all

Obstruction to other

activities.

activities.

Area to be cleared from Combustable and

Flammable materials. Injury due to fall of

objects hitting tresspassers and nearby

activity workers.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

# Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Cables to be double insulated and

connections to be insulated

without any openings

Cables to be secured/protected

Electrical Hazards from damages by Mobile

scaffolding any other means of

2 Verifying Welding Machine Electrocution, Burns, damages all

Fabrillation, Irregular

Heartbeat Connections to be made by a

Certified Electrician

Cables to be run from Dry Area

and not to be in contact with metal

surfaces

Health Hazards

Welder to be well equipped with

Welding Shield, Mask, Leather

Falls, slips, trips

gloves and Apron

3 Welding Works all

Vapours may cause

if possible Welding Screens to be

suffocation in enclosed

used, Intervals to be taken to

areas and UV rays effect

avoid Ergonomically Hazards

our vision

As monitoring is the crucial

element in the activity, it should

be exercised by a competent

Major injury or fatality person and all the wire ropes will

4 Underlying Hazards due to load failure or be unhooked using Boom Lift

equipment failure.

Competent and experienced

supervisor should execute the

activity.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

# Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Ensure hot particles or sparks cannot

lodge in fissures crevices or any

combustible material

Keep connection point clear of

flammable materials

Fire Make sure appropriate welding rods

are used

Burns Use only insulated cable for the

welding and return leads

5 Carry out welding Fumes DO NOT hold electrode under the all

arm pit while changing them

Radiation DO NOT drag live welding leads to

the work

Electric shock

DO not use leaking water- cooled

equipment

Keep clothing and gloves dry from

preparation

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Hazards Identification & Control Measures

Risk Class Responsibility

Item Job steps Hazards Controls

Refer risk matrix Who will do it

# Break the job down into sequential steps List what can harm you How can you make the job as safe as possible

Use mechanical aids, get help, use

correct lifting technique

Manual handling

Clean up and store all leads and equipment

6 Damage to all

equipment Store equipment so that leads and

connections are protected from

damage

JSA Induction Verification. To be signed by all participants in the task prior to commencement.

I have read this SWMS, understand its content and acknowledge its conditions and my responsibilities :

Print Names: Title / Trade Classification Signatures: Dates:

JSA Review & Approval to Proceed.

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

Review Date

Status

Rejected Resubmit Approved

Commnets:

This JSA has been reviewed and the works may proceed based on compliance with the requirements outlined in this SWMS , respective permits to work issued, applicable

EH&S legislation, codes and specifications.

Reviewer: Company: Title: Signed: Date: Time:

Cushman & Wakefield Regional Template. Revision A. 10/02/2014

You might also like

- 1866 Lee Animal Magnetism and Magnet Lucid SomnambulismDocument354 pages1866 Lee Animal Magnetism and Magnet Lucid SomnambulismtvosNo ratings yet

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- Permanent Facilities Storage ProtectionDocument2 pagesPermanent Facilities Storage ProtectionMOHAMMED RIYAN TNo ratings yet

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

- Excavation & Backfilling Risk - AssessmentDocument9 pagesExcavation & Backfilling Risk - AssessmentKashif RehmanNo ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- AHA-004, Earth Work Site PrepDocument6 pagesAHA-004, Earth Work Site PrepBuddhikaNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- Hazard Identification & Risk Assessment FormDocument3 pagesHazard Identification & Risk Assessment FormChandra Shekar EmaniNo ratings yet

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Risk Assessment for Installation of Exhaust FansDocument4 pagesRisk Assessment for Installation of Exhaust FansehteshamNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- Asphalt Paving JsaDocument2 pagesAsphalt Paving Jsanabeel100% (1)

- Hydro Static Test: Risk AssessmentDocument10 pagesHydro Static Test: Risk Assessmentmohammed a hseNo ratings yet

- De-Shuttering Risk Assisment SICAST ProjectDocument3 pagesDe-Shuttering Risk Assisment SICAST ProjectKashif RehmanNo ratings yet

- Risk assessment form for painting workDocument1 pageRisk assessment form for painting workNarender BhardwajNo ratings yet

- Weekly HSE Inspection Closeout Report - 01Document2 pagesWeekly HSE Inspection Closeout Report - 01niyas100% (1)

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- 19.17 (SWMS) All Work HvacDocument17 pages19.17 (SWMS) All Work Hvacsyed khaja misbhuddinNo ratings yet

- Risk Assessment For DemolitionDocument10 pagesRisk Assessment For Demolitionadeniyi abiolaNo ratings yet

- Block Work and PlasteringDocument7 pagesBlock Work and Plasteringmohammed sohailNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- SCP109 - Risk Assessment For Glass Partition EditedDocument4 pagesSCP109 - Risk Assessment For Glass Partition EditedamenmohdNo ratings yet

- Hira Carpentry WorkDocument2 pagesHira Carpentry WorkAtiq ShaikhNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- HSE Close-Out Report for PRM Lounge ExpansionDocument3 pagesHSE Close-Out Report for PRM Lounge ExpansionVijayakumar KarunanidhiNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Risk Assessment Lifting Operations PDFDocument6 pagesRisk Assessment Lifting Operations PDFkim alfonsoNo ratings yet

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- HSE Close Out ReportDocument4 pagesHSE Close Out ReportVijayakumar KarunanidhiNo ratings yet

- NYC Chocolate Chip Cookies! - Jane's PatisserieDocument2 pagesNYC Chocolate Chip Cookies! - Jane's PatisserieCharmaine IlaoNo ratings yet

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- Safety Committee Minutes of MeetingDocument4 pagesSafety Committee Minutes of MeetingMichael BejigaNo ratings yet

- Hira - Excavation, PCC, RCCDocument6 pagesHira - Excavation, PCC, RCCPrithika AnbuNo ratings yet

- James M. Buchanan - Why I, Too, Am Not A Conservative PDFDocument121 pagesJames M. Buchanan - Why I, Too, Am Not A Conservative PDFHeitor Berbigier Bandas100% (2)

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- EnCORE V13.5 en EnglishDocument138 pagesEnCORE V13.5 en EnglishRommel SaavedraNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- 25 Mosquito Facts and TriviaDocument3 pages25 Mosquito Facts and Triviamara_hahaNo ratings yet

- Enscape Tutorial GuideDocument27 pagesEnscape Tutorial GuideDoroty CastroNo ratings yet

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- Chapter 7 Portfolio Theory: Prepared By: Wael Shams EL-DinDocument21 pagesChapter 7 Portfolio Theory: Prepared By: Wael Shams EL-DinmaheraldamatiNo ratings yet

- OYO Case Study SolutionDocument4 pagesOYO Case Study SolutionVIKASH GARGNo ratings yet

- Demoltion Work Risk AssesmentDocument2 pagesDemoltion Work Risk AssesmentBijin BalakrishnanNo ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- Site Specific Health Safety Environment Plan HvacDocument74 pagesSite Specific Health Safety Environment Plan Hvacsyed khaja misbhuddin100% (1)

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Height Pass and Vertigo Test Report FormatDocument2 pagesHeight Pass and Vertigo Test Report Formatsyed khaja misbhuddin67% (3)

- Standard JKR Spec For Bridge LoadingDocument5 pagesStandard JKR Spec For Bridge LoadingHong Rui ChongNo ratings yet

- T2-1 MS PDFDocument27 pagesT2-1 MS PDFManav NairNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- Hazard Identification & Risk Analysis for Civil ReworksDocument3 pagesHazard Identification & Risk Analysis for Civil ReworksHARSHADNo ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Vibration Risk Assessment: (Site/ Building/ Room)Document3 pagesVibration Risk Assessment: (Site/ Building/ Room)Him SiwakotiNo ratings yet

- 01 JSA - Material ShiftingDocument5 pages01 JSA - Material Shiftingsyed khaja misbhuddinNo ratings yet

- PPE's Check ListDocument1 pagePPE's Check Listsyed khaja misbhuddinNo ratings yet

- JSA - Scissor - Lift 2023Document4 pagesJSA - Scissor - Lift 2023syed khaja misbhuddinNo ratings yet

- HIRA Insullation URCDocument12 pagesHIRA Insullation URCsyed khaja misbhuddinNo ratings yet

- JSA - Lifting Shifting PhoenixDocument5 pagesJSA - Lifting Shifting Phoenixsyed khaja misbhuddinNo ratings yet

- ABS HIRA For Store ConstructionDocument6 pagesABS HIRA For Store Constructionsyed khaja misbhuddinNo ratings yet

- Robert Laughton Memo Re Job Safety Analysis - 8-2-17Document29 pagesRobert Laughton Memo Re Job Safety Analysis - 8-2-17syed khaja misbhuddinNo ratings yet

- Scissor Lift Safety PlanDocument24 pagesScissor Lift Safety Plansyed khaja misbhuddinNo ratings yet

- JSA - Lifting Shifting PhoenixDocument5 pagesJSA - Lifting Shifting Phoenixsyed khaja misbhuddinNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Weekly EHS StatisticsDocument1 pageWeekly EHS Statisticssyed khaja misbhuddinNo ratings yet

- Strawberry GenerationDocument2 pagesStrawberry GenerationImat12No ratings yet

- Basic Electronic ComponentsDocument28 pagesBasic Electronic ComponentsJafar ShaikhNo ratings yet

- LogDocument15 pagesLogandrew_hm925635No ratings yet

- Economics of Power GenerationDocument32 pagesEconomics of Power GenerationKimberly Jade VillaganasNo ratings yet

- Group ActDocument3 pagesGroup ActRey Visitacion MolinaNo ratings yet

- Filipino Nationalism LessonDocument24 pagesFilipino Nationalism LessonIan Jay TumulakNo ratings yet

- My Demo DemoDocument19 pagesMy Demo DemoAlex LopezNo ratings yet

- wizBRAINeng20 2Document4 pageswizBRAINeng20 2Deepika AgrawalNo ratings yet

- Examining The Structural Relationships of Destination Image, Tourist Satisfaction PDFDocument13 pagesExamining The Structural Relationships of Destination Image, Tourist Satisfaction PDFAndreea JecuNo ratings yet

- Automation of Banking Service - EBL & EXIM BankDocument32 pagesAutomation of Banking Service - EBL & EXIM BankShaffyNo ratings yet

- What Is Mean?: Extrapolation InterpolationDocument2 pagesWhat Is Mean?: Extrapolation InterpolationVinod SharmaNo ratings yet

- Overview of Research ProcessDocument31 pagesOverview of Research Processprema balusamyNo ratings yet

- Fee Structure 2023-2024Document10 pagesFee Structure 2023-2024Emmanuel NjogellahNo ratings yet

- HL-1060 User, Parts, and Service Manual 02Document6 pagesHL-1060 User, Parts, and Service Manual 02วรพงษ์ กอชัชวาลNo ratings yet

- F 83179Document6 pagesF 83179pcmfilhoNo ratings yet

- Combining Singing and PsycologyDocument6 pagesCombining Singing and PsycologyAna luciaNo ratings yet

- MPX English Final Version VOLUME 3Document878 pagesMPX English Final Version VOLUME 3Adrian MacayaNo ratings yet

- SMD 40kHz Ultrasonic Transducer MA40H1SR RevGMay 7 2014Document9 pagesSMD 40kHz Ultrasonic Transducer MA40H1SR RevGMay 7 2014robert wengerNo ratings yet

- ORPHEUS by GRS Mead - Electronic Text EditionDocument199 pagesORPHEUS by GRS Mead - Electronic Text EditionMartin EuserNo ratings yet

- Yingli CS Centrale-Poggiorsini EN 062011-1 PDFDocument2 pagesYingli CS Centrale-Poggiorsini EN 062011-1 PDFZvonko Trajkov100% (1)