Professional Documents

Culture Documents

Lecture 7 - Flexure: June 16, 2003 CVEN 444

Uploaded by

Raju SkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 7 - Flexure: June 16, 2003 CVEN 444

Uploaded by

Raju SkCopyright:

Available Formats

Lecture 7 - Flexure

June 16, 2003

CVEN 444

Lecture Goals

Doubly Reinforced beams

T Beams and L Beams

Pan Joist

Analysis of Flanged

Section

Floor systems with slabs and beams are placed

in monolithic pour.

Slab acts as a top flange to the beam; T-

beams, and Inverted L(Spandrel) Beams.

Analysis of Flanged

Sections

Positive and Negative Moment Regions in a T-beam

Analysis of Flanged Sections

If the neutral axis falls

within the slab depth

analyze the beam as a

rectangular beam,

otherwise as a T-beam.

Analysis of Flanged Sections

Effective Flange Width

Portions near the webs are more highly stressed than

areas away from the web.

Analysis of Flanged Sections

Effective width (b

eff

)

b

eff

is width that is stressed uniformly to give the same

compression force actually developed in compression

zone of width b

(actual)

ACI Code Provisions for

Estimating b

eff

From ACI 318, Section 8.10.2

T Beam Flange:

eff

f w

actual

4

16

L

b

h b

b

s

s +

s

ACI Code Provisions for

Estimating b

eff

From ACI 318, Section 8.10.3

Inverted L Shape Flange

( )

eff w

f w

actual w

12

6

0.5* clear distance to next web

L

b b

h b

b b

s +

s +

s = +

ACI Code Provisions for

Estimating b

eff

From ACI 318, Section 8.10

Isolated T-Beams

w eff

w

f

4

2

b b

b

h

s

>

Various Possible Geometries of

T-Beams

Single Tee

Twin Tee

Box

Analysis of T-Beam

Case 1: Same as rectangular section

Steel is yielding

under reinforced

Check

f

h a s

f

h a s

y s y s

Assume f f = > c c

Analysis of T-Beam

Case 1:

Equilibrium

f

h a s

s y

c eff

0.85

A f

T C a

f b

= =

'

Analysis of T-Beam

Case 1:

Confirm

f

h a s

y cu s

1

y s

c c c

|

c c

>

|

.

|

\

|

=

=

>

c

c d

a

c

Analysis of T-Beam

Case 1:

Calculate M

n

f

h a s

|

.

|

\

|

=

2

y s n

a

d f A M

Analysis of T-Beam

Case 2: Assume steel yields

f

h a >

( )

y s

w c w

f w c f

85 . 0

85 . 0

f A T

a b f C

h b b f C

=

'

=

'

=

Analysis of T-Beam

Case 2: Assume steel yields

f

h a >

( )

c w f

sf

y

0.85 f b b h

A

f

'

=

The flanges are considered to be equivalent

compression steel.

Analysis of T-Beam

Case 2: Equilibrium

f

h a >

( )

s sf y

f w

c w

0.85

A A f

T C C a

f b

= + =

'

Analysis of T-Beam

Case 2:

Confirm

f

h a >

f

1

s cu

0.005

a h

a

c

d c

c

|

c c

>

=

| |

= >

|

\ .

Analysis of T-Beam

Case 2:

Confirm

f

h a >

y

c

f f

1

1.18

or

f

f

d

h h a

=

=

|

=

'

s s

Analysis of T-Beam

Case 2:

Calculate nominal

moments

f

h a >

( )

n n1 n2

n1 s sf y

f

n2 sf y

2

2

M M M

a

M A A f d

h

M A f d

= +

| |

=

|

\ .

| |

=

|

\ .

Analysis of T-Beams

The definition of M

n1

and M

n2

for the T-Beam are given

as:

Analysis of T-Beams

The ultimate moment M

u

for the T-Beam are given as:

u n

M M

c

f

d

|

|

=

| |

=

|

\ .

For a T-Beam with the

tension steel yielded using a

function c/d

Limitations on Reinforcement

for Flange Beams

Lower Limits

Flange in compression

c

y

s

min

w

y

3

larger of

200

f

f

A

b d

f

'

= =

Limitations on Reinforcement

for Flange Beams

Lower Limits

Flange in tension

'

'

=

d b

f

d b

f

f

d b

f

f

A

eff

y

eff

y

c

w

y

c

s(min)

200

3

of larger

6

of smaller

Limitations on Reinforcement

for Flange Beams

Lower Limits

If A

s(provided)

4/3 A

s(reqd)

based on analysis

then A

s(min)

is not required (i.e.)

|M

n

4/3M

u

for A

s(provided)

See ACI 10.5.3

>

>

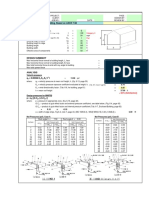

Example - T-Beam

Find M

n

and M

u

for T-Beam.

b

eff

= 54 in. h

f

= 3 in. b = 7 ft.

d = 16.5 in. A

s

= 8.5 in

2

f

y

= 50 ksi f

c

= 3 ksi

b

w

= 12 in L = 18 ft

Example of L-Beam

Confirm b

eff

( )

eff

f w

12 in.

18 ft

ft.

54 in.

4 4

16 16 3 in. 12 in.=60 in.

12 in.

7 ft. 84 in.

ft.

L

b

h b

b

| |

|

\ .

s = =

s + = +

| |

s = =

|

\ .

Example - T-Beam

( )( )

( )( )

2

s y

c eff

1

s

8.5 in 50 ksi

3.09 in.

0.85 0.85 3 ksi 54 in.

3.09 in

3.63 in.

0.85

16.5 in.

1 0.003 1 0.003 0.0106 0.005

3.63 in.

A f

a

f b

a

c

d

c

|

c

= = =

'

= = =

| | | |

= = = >

| |

\ . \ .

Compute the equivalent c value and check the strain

in the steel, c

s

Steel will yield in the tension zone.

Example - T-Beam

( )

( )( )

2

s

w

y

min min

c

y

8.5 in

0.0429

12 in. 16.5 in.

200 200

0.004

50000

0.004

3

3 3000

0.00329

50000

0.0429 0.004

A

b d

f

f

f

= = =

= =

= =

= =

>

Compute the reinforcement and check to make sure it

is greater than

min

Section works for minimum

reinforcement.

Example - T-Beam

( )( )

y

c

f

1

f

50 ksi

0.0429 0.7155

3 ksi

1.18 0.7155 16.5 in.

1.18

3 in. 16.388

0.85

3 in. 3.09 in.

f

f

d

h

h a

=

=

|

| |

= = =

|

'

\ .

s s =

s s

Compute e and check that the c value is greater than h

f

Analysis the beam as a T-beam.

Example - T-Beam

Compute e and check that the c value is greater than h

f

Compute a

( ) ( )( )( )

( )

c eff w f

sf

y

2

0.85 0.85 3 ksi 54 in. 12 in. 3 in.

50 ksi

6.426 in

f b b h

A

f

'

= =

=

( ) ( )

( )

( )( )

2 2

s sf y

c w

8.5 in 6.426 in 50 ksi

0.85 0.85 3 ksi 12 in.

3.889 in.

A A f

a

f b

= =

'

=

Example - T-Beam

Compute nominal moment components

( )

( )

2

f

n2 sf y

3 in.

6.426 in 50 ksi 16.5 in.

2 2

4819.5 k-in.

h

M A f d

| | | |

= =

| |

\ . \ .

=

( )

( )

( )

n1 s sf y

2 2

2

3.889 in.

8.5 in 6.426 in 50 ksi 16.5 in.

2

1535.34 k-in.

a

M A A f d

| |

=

|

\ .

| |

=

|

\ .

=

Example - T-Beam

Compute nominal moment

( )

u n

0.9 529.57 k-ft.

416.6 k-ft.

M M | = =

=

n n1 n2

1535.34 k-in. 4819.5 k-in.

6354.84 k-in. 529.57 k-ft.

M M M = +

= +

=

Compute ultimate moment

Example of L-Beam

Determine the

effective b for the

spandrel beam and

do the analysis.

Use 4 #9 bars and

find the ultimate

moment capacity.

f

y

=50 ksi, f

c

= 3 ksi

Example of L-Beam

Compute b

eff

( )

eff w

f w

actual w

12

6

0.5* clear distance to next web

L

b b

h b

b b

s +

s +

s = +

Example of L-Beam

Compute b

eff

( )

( )

eff w

f w

actual w

12 in.

20 ft

ft

12 in. =32 in.

12 12

6 6 6 in. 12 in. = 48 in.

0.5* clear distance to next web

12 in.

12 in. + 0.5* 7 ft 54 i

ft

L

b b

h b

b b

| |

|

\ .

s + = +

s + = +

s = +

| |

| |

= =

| |

\ .

\ .

n.

Example of L-Beam

The value b

eff

and A

s

( )

eff

2 2

s

= 32 in.

4 1.0 in 4.0 in

b

A = =

Example - L-Beam

( )

( )

( )( )

2

s y

c eff

1

s

4.0 in 50 ksi

2.45 in.

0.85 0.85 3 ksi 32 in.

2.45 in

2.88 in.

0.85

24 in.

1 0.003 1 0.003 0.0220 0.005

2.88 in.

A f

a

f b

a

c

d

c

|

c

= = =

'

= = =

| | | |

= = = >

| |

\ . \ .

Compute the equivalent c value and check the strain

in the steel, c

s

Steel will yield in the tension zone.

Example - L-Beam

( )

( )( )

2

s

w

y

min min

c

y

4.0 in

0.0139

12 in. 24 in.

200 200

0.004

50000

0.004

3

3 3000

0.00329

50000

0.0139 0.004

A

b d

f

f

f

= = =

= =

= =

= =

>

Compute the reinforcement and check to make sure it

is greater than

min

Section works for minimum

reinforcement.

Example - L-Beam

( )( )

y

c

f

1

f

50 ksi

0.0139 0.2315

3 ksi

1.18 0.2315 24 in.

1.18

6 in. 7.71 in.

0.85

6 in. 2.45 in.

f

f

d

h

h a

=

=

|

| |

= = =

|

'

\ .

s s =

s s

Compute e and check that the c value is greater than h

f

Analysis the beam as a Singly reinforced beam.

False!

Example - L-Beam

Compute a

( )

( )

( )( )

2

s y

c

4.0 in 50 ksi

0.85 0.85 3 ksi 32 in.

2.451 in.

A f

a

f b

= =

'

=

Example - L-Beam

Compute nominal moment

( )

( )

n s y

2

2

2.451 in.

4.0 in 50 ksi 24.0 in.

2

4554.9 k-in. 379.58 k-ft.

a

M A f d

| |

=

|

\ .

| |

=

|

\ .

=

Example - L-Beam

( )

u n

0.9 379.58 k-ft.

341.62 k-ft.

M M | = =

=

Compute ultimate moment

Pan Joist Floor Systems

View of Pan Joist Slab from Below

Walter P. Moore & Assoc.

Pan Joist Floor Systems

View of Double Skip Joist Slab from Below

Walter P. Moore & Assoc.

Pan Joist Floor

Systems

Placing Reinforcement

for a Pan Joist Slab

Walter P. Moore & Assoc.

Pan Joist Floor Systems

General framing layout of

the pan joist system.

Pan Joist Floor

Systems

Pouring a Pan Joist Slab

Walter P. Moore & Assoc.

Pan Joist Floor Systems

Definition: The type of slab is also called a

ribbed slab. It consists of a floor slab, usually

2-4 in. thick, supported by reinforced

concrete ribs. The ribs are usually tapered

and uniformly spaced at distances that do not

exceed 30 in. The ribs are supported on

girders that rest on columns. In some ribbed

slabs, the space between ribs may be filled

with permanent fillers to provide a horizontal

slab soffit.

One-Way Joist

Construction

MacGregor, Fig. 10-28

Definition: Pan joist floor

systems are series of closely

spaced cast-in-place T-beams

or joists used for long-span

floors with relatively light

loads. Typically removable

metal forms (fillers or pans)

are used to form joists.

One-Way Joist Construction

Details of ribbed floor

with removable steel

pans.

Ribbed-floor cross

sections.

One-Way Joist

Construction

The design of a ribbed floor

with steel pan forms and

average weight of the floor.

One-Way Joist Construction

The design of a ribbed floor with steel pan forms and

average weight of the floor.

One-Way Joist Construction

Joist Details

Pan Joist Floor Systems

ACI Requirements for Joist Construction

(Sec. 8.11, ACI 318-02)

Slabs and ribs must be cast monolithically.

Ribs must be spaced consistently

Ribs may not be less than 4 inches in width

Pan Joist Floor Systems

ACI Requirements for Joist Construction (cont.)

(Sec. 8.11.2, ACI 318-02)

Depth of ribs may not be more than 3.5

times the minimum rib width

Clear spacing between ribs shall not exceed

30 inches.

** Ribbed slabs not meeting these

requirements are designed as slabs and

beams. **

Pan Joist Floor Systems

Slab Thickness

(ACI Sec. 8.11.6.1)

t 2 in. for joints formed with 20 in. wide

pans

t 2.5 in. for joints formed with 30 in. wide

pans (1/12 distance)

>

>

Pan Joist Floor Systems

Slab Thickness (cont.)

Building codes give minimum fire resistance

rating:

1-hour fire rating: in. cover, 3-3.5 slab

thickness

2-hour fire rating: 1 in. cover, 4.5 slab

thickness

Pan Joist Floor

Systems

Standard

Removable Form

Dimensions

Note the shapes

Pan Joist Floor Systems

Standard Removable Form Dimensions

Standard Widths: 20 in. & 30 in.

(measured at bottom of ribs)

Standard Depths: 6, 8, 10, 12, 14, 16 or

20 in.

Pan Joist Floor Systems

Standard Removable Form Dimensions

(cont.)

End Forms: one end is closed (built-in) to

form the supporting beam

Tapered End Forms: provide additional shear

capacity at ends of joists by tapering ends to

increase rib width.

Pan Joist

Slabs

Standard Pan Joist

Form Dimensions

Ref. CECO Concrete

Construction Catalog

Pan Joist

Slabs

Standard Pan Joist

Form Dimensions

Ref. CECO Concrete Construction

Catalog

Pan Joist Floor Systems

Laying Out Pan Joist Floors

Rib/slab thickness

Governed by strength, fire rating,

available space

Overall depth and rib thickness

Governed by deflections and shear

Pan Joist Floor Systems

Laying Out Pan Joist Floors (cont.)

Typically no stirrups are used in joists

Reducing Forming Costs:

Use constant joist depth for entire floor

Use same depth for joists and beams

(not always possible)

Pan Joist Floor Systems

Distribution Ribs

Placed perpendicular to joists*

Spans < 20 ft.: None

Spans 20-30 ft.: Provided a midspan

Spans > 30 ft.: Provided at third-points

At least one continuous #4 bar is provided at top

and bottom of distribution rib.

*Note: not required by ACI Code, but typically used

in construction

Member Depth

ACI provides minimum member depth and

slab thickness requirements that can be used

without a deflection calculation (Sec. 9.5 ACI

318)

Useful for selecting preliminary member

sizes

Member Depth

ACI 318 - Table 9.5a:

Min. thickness, h (for beams or ribbed one-way

slab)

For beams with one end continuous: L/18.5

For beams with both ends continuous: L/21

L is span length in inches

Table 9.5a usually gives a depth too shallow for

design, but should be checked as a minimum.

Member

Depth

ACI 318-99: Table 9.5a

Member Depth

Rule of Thumb:

h

b

(in.) ~ L (ft.)

Ex.) 30 ft. span -> h

b

~ 30 in.

May be a little large, but okay as a start to

calc. DL

Another Rule of Thumb:

w

DL

(web below slab) ~ 15% (w

SDL

+ w

LL

)

Note: For design, start with maximum

moment for beam to finalize depth.

Select b as a function of d

b ~ (0.45 to 0.65) (d)

You might also like

- Earthquake Load Calculation (Base Shear Method) : Rigid FrameDocument4 pagesEarthquake Load Calculation (Base Shear Method) : Rigid FrameJohn Rheynor MayoNo ratings yet

- Concrete Beam Design Flow ChartDocument16 pagesConcrete Beam Design Flow Chartdicktracy11No ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- HSE Inspection Report-07Document32 pagesHSE Inspection Report-07najihahNo ratings yet

- Software Verification: AISC-360-16 Example 003Document5 pagesSoftware Verification: AISC-360-16 Example 003alejandro mantillaNo ratings yet

- Body Wash Base Guide Recipe PDFDocument2 pagesBody Wash Base Guide Recipe PDFTanmay PatelNo ratings yet

- Ahriman's Prophecy Walk ThroughDocument106 pagesAhriman's Prophecy Walk ThroughAngga Nata100% (1)

- Mathcad - Punching ShearDocument4 pagesMathcad - Punching ShearMa'rruf AmarNo ratings yet

- C5. Bolted-Simple Connection-SupplementDocument9 pagesC5. Bolted-Simple Connection-SupplementKURONo ratings yet

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Document2 pagesWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldNo ratings yet

- US Stair oDocument3 pagesUS Stair oRenvil PedernalNo ratings yet

- Isolated Footing Design Based On ACI 318-02Document15 pagesIsolated Footing Design Based On ACI 318-02Wintun73No ratings yet

- Design of FootingDocument13 pagesDesign of Footingeco protectionNo ratings yet

- Chapter 5 Torsion BucklingDocument68 pagesChapter 5 Torsion BucklingMalik Rehan SyedNo ratings yet

- RC Column - Axially Loaded - NSCP by RGCEDocument3 pagesRC Column - Axially Loaded - NSCP by RGCEJet ToledoNo ratings yet

- One Way SlabDocument5 pagesOne Way SlabShoaib Mohammad Quraishi100% (2)

- Flexural Analysis of Singly Reinforced Beam Using Mathcad PrimeDocument1 pageFlexural Analysis of Singly Reinforced Beam Using Mathcad PrimeYan YanNo ratings yet

- Pega DevOps Release Pipeline OverviewDocument200 pagesPega DevOps Release Pipeline OverviewArun100% (1)

- ASCE7 Wind For Cladding CN8 Block BDocument4 pagesASCE7 Wind For Cladding CN8 Block BCheng KoNo ratings yet

- 425-Doubly Reinforced Beam Design-S11Document45 pages425-Doubly Reinforced Beam Design-S11Kaye MamisaoNo ratings yet

- CE 579 Lecture 6 Stability - Differential Equations-TorsionDocument16 pagesCE 579 Lecture 6 Stability - Differential Equations-TorsionbsitlerNo ratings yet

- ACI318-08 Columns Circular BiaxialDocument6 pagesACI318-08 Columns Circular Biaxialazamislam726537No ratings yet

- Deflection of T BeamDocument3 pagesDeflection of T BeamMayoo LaxmanNo ratings yet

- Introduction To Plant Physiology!!!!Document112 pagesIntroduction To Plant Physiology!!!!Bio SciencesNo ratings yet

- Introduction To Cavitation in Pumps and Their TypesDocument12 pagesIntroduction To Cavitation in Pumps and Their TypesMujadid Khawaja100% (1)

- Lateral Earth PressureDocument27 pagesLateral Earth PressureJommarVocalTagalogNo ratings yet

- Short Columns by CharifDocument21 pagesShort Columns by CharifMiski45No ratings yet

- SX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSDocument9 pagesSX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSWNo ratings yet

- AISI Appendix BDocument9 pagesAISI Appendix Brk_vijay81No ratings yet

- Recruitment of Officers in Grade B' (General) - DR - By-2019Document2 pagesRecruitment of Officers in Grade B' (General) - DR - By-2019Shalom NaikNo ratings yet

- Analysis and Design of T-BeamDocument28 pagesAnalysis and Design of T-BeamhuyxpkissNo ratings yet

- Lec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFDocument8 pagesLec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFဒုကၡ သစၥာNo ratings yet

- Flexural Analysis of Singly Reinforced Beams-ExampleDocument2 pagesFlexural Analysis of Singly Reinforced Beams-ExampleFahad Areeb100% (1)

- 7.continuous BeamsDocument35 pages7.continuous BeamsTareck BOU JAOUDENo ratings yet

- Steel 2022 BeamDocument26 pagesSteel 2022 BeamRaven Von DizonNo ratings yet

- Beam ExampleProblemsDocument10 pagesBeam ExampleProblemsApril IngramNo ratings yet

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMayur PatelNo ratings yet

- CIV 4235 ExamDocument9 pagesCIV 4235 Exammalumius100% (2)

- Purlin DesignDocument4 pagesPurlin DesignIfkar AzmiNo ratings yet

- RCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFDocument14 pagesRCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFEduard Joseph Dela CruzNo ratings yet

- FormulasDocument5 pagesFormulasPremNo ratings yet

- Two-Way-Concrete-Slab-Floor-With-Drop-Panels-Design-Detailing 01-26-2018 PDFDocument81 pagesTwo-Way-Concrete-Slab-Floor-With-Drop-Panels-Design-Detailing 01-26-2018 PDFBizimenyera Zenza TheonesteNo ratings yet

- Slender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounDocument8 pagesSlender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounMike2322100% (1)

- Joint DesignDocument44 pagesJoint DesignMuhammad ImranNo ratings yet

- 1.plastic Analysis Theory & ProblemsDocument47 pages1.plastic Analysis Theory & ProblemsJack HaamboteNo ratings yet

- Method of Design - SLAB & BEAMDocument19 pagesMethod of Design - SLAB & BEAMসামিউলইসলামNo ratings yet

- Ultimate Strength Design (Doubly)Document17 pagesUltimate Strength Design (Doubly)C.j. CaparasNo ratings yet

- Examples in Column's ChapterDocument12 pagesExamples in Column's Chapterrd radenNo ratings yet

- WSD Method - BeamsDocument4 pagesWSD Method - BeamsCharlette SolanoNo ratings yet

- STEP OF Square Footing DesignDocument10 pagesSTEP OF Square Footing DesignPhreetzi ÜnseenNo ratings yet

- 05 04 Chap GereDocument12 pages05 04 Chap GereDipNdra SharmaNo ratings yet

- Tension Members SampleDocument6 pagesTension Members SampleTachooNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Analysis and Design of SlabsDocument3 pagesAnalysis and Design of Slabsdhanya1995100% (1)

- TR 334 Tutorial-1Document5 pagesTR 334 Tutorial-1Adaminovic MrishoNo ratings yet

- Chapter 3 Lateral Earth PressureDocument47 pagesChapter 3 Lateral Earth PressureJiregna Tesfaye100% (2)

- 5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputDocument27 pages5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputNH SyzlnNo ratings yet

- Soil Mechanics Formula p1 To p3Document5 pagesSoil Mechanics Formula p1 To p3Arjie RecarialNo ratings yet

- Quiz 2Document4 pagesQuiz 2Jerome M. GuetaNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Reinforced Concrete Design ProblemsDocument3 pagesReinforced Concrete Design ProblemsLimuel Milo LebiosNo ratings yet

- CIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringDocument52 pagesCIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringHakuna MatataNo ratings yet

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsDocument8 pagesAxial Load Capacity For Deep Foundations Piles: Sand Input Resultsacidrisamuel2656No ratings yet

- Base Plate DesignDocument3 pagesBase Plate Designyangmeme32No ratings yet

- Elementos de Concreto ArmadoDocument41 pagesElementos de Concreto ArmadoVictor Rene H. R.No ratings yet

- Chap 8 1 T-BeamDocument10 pagesChap 8 1 T-Beamatherton625No ratings yet

- Torsion Tension and Column (11-16)Document33 pagesTorsion Tension and Column (11-16)2011kumarNo ratings yet

- Seepage Control and LiningDocument16 pagesSeepage Control and Liningnickdash09No ratings yet

- ShearDocument6 pagesShearRaju SkNo ratings yet

- Punching Shear Tests On Column FootingsDocument23 pagesPunching Shear Tests On Column FootingsRaju SkNo ratings yet

- Ch7notes PDFtyDocument71 pagesCh7notes PDFtyRaju SkNo ratings yet

- Training Workshop For Evaluators From National Medicines Regulatory Authorities in East African CommunityDocument30 pagesTraining Workshop For Evaluators From National Medicines Regulatory Authorities in East African CommunityRaju SkNo ratings yet

- Uncracked Section Example: QuestionsDocument8 pagesUncracked Section Example: QuestionsRaju SkNo ratings yet

- Eq09 IitrkDocument66 pagesEq09 IitrkSuhas NatuNo ratings yet

- Chapter-6 Structure and Layout: 6.1 GeneralDocument14 pagesChapter-6 Structure and Layout: 6.1 GeneralRaju SkNo ratings yet

- Chapter-6 Structure and Layout: 6.1 GeneralDocument14 pagesChapter-6 Structure and Layout: 6.1 GeneralRaju SkNo ratings yet

- ApartmentsDocument49 pagesApartmentsRichard Marl AbbugaoNo ratings yet

- MAF 451 Suggested Solutions - A) I) Process 1Document9 pagesMAF 451 Suggested Solutions - A) I) Process 1anis izzatiNo ratings yet

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Document186 pagesDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671No ratings yet

- Monster Energy v. Jing - Counterfeit OpinionDocument9 pagesMonster Energy v. Jing - Counterfeit OpinionMark JaffeNo ratings yet

- Eimco Elecon Initiating Coverage 04072016Document19 pagesEimco Elecon Initiating Coverage 04072016greyistariNo ratings yet

- Lecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceDocument7 pagesLecture Notes 1 - Finance - Principles of Finance Lecture Notes 1 - Finance - Principles of FinanceKim Cristian MaañoNo ratings yet

- Board of DirectorsDocument2 pagesBoard of DirectorsjonahsalvadorNo ratings yet

- Executing and Releasing Value (V4.0.4.1) - A4Document27 pagesExecuting and Releasing Value (V4.0.4.1) - A4V100% (1)

- Shock Cat 2009Document191 pagesShock Cat 2009gersonplovasNo ratings yet

- Debit Note and Credit NoteDocument2 pagesDebit Note and Credit Noteabdul haseebNo ratings yet

- Swot Ananlysis of Fintech CompaniesDocument7 pagesSwot Ananlysis of Fintech CompaniesUyen Le VuNo ratings yet

- Phyto Pharmacy: Current Concepts and GMP NormsDocument22 pagesPhyto Pharmacy: Current Concepts and GMP NormsSunitha Katta100% (1)

- SCI Annual Report 2017Document32 pagesSCI Annual Report 2017The Seamen's Church Institute100% (2)

- Safety Data Sheet: Section 1. IdentificationDocument10 pagesSafety Data Sheet: Section 1. IdentificationAnonymous Wj1DqbENo ratings yet

- 1. Mạch điện đồng hồ santafe 2014-2018Document5 pages1. Mạch điện đồng hồ santafe 2014-2018PRO ECUNo ratings yet

- InflibnetDocument3 pagesInflibnetSuhotra GuptaNo ratings yet

- Materials Science and Engineering-Chapter 11Document3 pagesMaterials Science and Engineering-Chapter 11JurgenNo ratings yet

- Krunker SettingsDocument2 pagesKrunker SettingsArsyad DanishNo ratings yet

- The Messenger 190Document76 pagesThe Messenger 190European Southern ObservatoryNo ratings yet

- SPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Document14 pagesSPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Daniel FelipeNo ratings yet

- (FORD) Manual de Propietario Ford Ranger 1998Document160 pages(FORD) Manual de Propietario Ford Ranger 1998Marly Salas GonzalezNo ratings yet

- 16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsDocument14 pages16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsThereNo ratings yet

- 08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Document89 pages08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Middle EastNo ratings yet

- Kbli 2017 - 1Document50 pagesKbli 2017 - 1Putri NadiaNo ratings yet