Professional Documents

Culture Documents

Nozzle Calculations

Uploaded by

Baher ElsheikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle Calculations

Uploaded by

Baher ElsheikhCopyright:

Available Formats

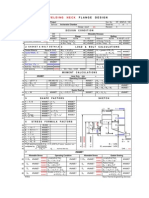

Prepared by: Baher EL Shaikh

ASME Code VIII Div. I Edition 2004, Addenda 2005 Page ( 6 / 41 ) Pressure Vessel Calculation

Nozzle (N1) (8") Sheet (1/2)

Head Data

SA-516 Gr 70 M :- Shell material.

138000 20,000 :- (Sv), Max. allowable stress -(Kpa, (psi))

1.00 :- (E1), efficiency of shell at nozzle.

mm in

14 0.551 :- (tv), wall thick, uncorroded

2.362 0.093 :- (tr), required wall thickness

914.5 36.0 :- (Rsi), inside radius of shell

4.000 0.157 :- (c), corrosion allowance

Nozzle Data:

SA-106 Gr. B M :- Nozzle material.

1.00 :- (E) Nozzle Efficiency.

1.00 :- (F) Correction factor.

12.5% :- (Utp), undertolerance of nozzle pipe.

88.9 3.500 :- (Do), Outside diameter - (mm, (in))

Kpa psig

118000.00

118000 00 17,100

1 100 (S ) M

:- (Sn), ll bl stress

Max. allowable t

358.73 51.0 : (P), (P=Pi+Ps) Internal Pressure

Nozzle Required Wall Thickness (trn) UG-27 (C)& Appendex 1-1

trn = P*(Do/2)/(Sn*E+0.4*P) =51*(3.5/2)/(17100*1+0.4*51)= 0.005 in 0.13 mm

By adding corrosion all. (AC)= trn+2*c =0.005+(2*0.157) = 0.163 in 4.13 mm

By adding pipe tolerance = AC+UTP*trn =0.163+0.125*0.005 = 0.163 in 4.15 mm

Use Nozzle 8" Sch120 B36.10M (tn) 0.719 in 18.26 mm

Variables:

Under tolerance(UT) = tn*UTp = 0.719 * 0.125 UT = 0.090 in 2.28 mm

Nozzle corroded thickness (tc) = tn-c-UT = 0.719-0.157-0.09 tc = 0.472 in 11.98 mm

Nozzle Inside corroded Diameter (d) = Do-2*tc = 3.5 - 2*0.472 d = 2.557 in 64.94 mm

Nozzle corroded inside raduis (Ron) = Do/2 = 2.557/2 Ron = 1.75 in 44.45 mm

Nozzle uncorroded inside raduis (Rn) = d/2 = 2.56/2 Rn = 1.28 in 32.47 mm

Vessle corroded thk.(t) = tv-c = 0.551 - 0.157 t= 0.394 in 10.00 mm

Nominal thk. of internal projection of nozzle wall (ti) =tn-2c =0.719-(2*0.157) = ti= 0.404 in 10.26 mm

Extension of nozzle beyond the inside surface of the vessel wall (h) = min. of {(2.5*tv),(2.5*ti)

h = Min.{(2.5*0.551),(2.5*0.404)= h= 1.010 in

fr1 = MIN(Sn/Sv,1) = MIN(17100/20000, 1) fr1 = 0.855

fr2 = MIN(Sn/Sv,1) = MIN(17100/20000, 1) fr2 = 0.855

fr3 = MIN(Sn/Sv,Sp/Sv,1) = MIN(17100/20000, 0/20000,1) fr3 = 0.000

fr4 = MIN(Sp/Sv,1) = MIN(0/20000,1) fr4 = 0.000

ASME Code VIII Div. I Edition 2004, Addenda 2005 Page ( 7 / 41 ) Pressure Vessel Calculation

Nozzle (N1) (8") Sheet (2/2)

Nozzle Neck Thickness (UG-45):

Wall thickness per UG-45(a) tr1=trn+c =0.005+0.157 = 0.163 in 4.13 mm

Wall thickness per UG-45(b) tr2=tr+c =0.093+0.157 = 0.250 in 6.36 mm

Wall thickness per UG-16(b) tr3=0.0625+c =0.0625+0.157 = 0.220 in 5.59 mm

Wall thickness per UG-45(b)(4) tr4=(t std -Utp)+c =0.189+0.157 = 0.346 in 8.80 mm

The greater of tr2 or tr3 tr5 = =Max(0.25,0.22) = 0.250 in 6.36 mm

The lesser of tr4 or tr5 tr6 = =Min(0.346,0.25) = 0.250 in 6.36 mm

Required per UG-45 largest of tr1 or tr6 tr7= =Max(0.163,0.25) = 0.250 in 6.36 mm

tr7≤ tn-Utp*tn =0.25≤0.719-0.09 Ok

Calulating Size of Fillet Weld (Leg41,Leg42) used UW-16&Fig. UW-16:

tmin1= from UW-16(b) 0.750 in 19.05 mm

Between Nozzle and Shell

tmin= Min(tv,tn,tmin1) =MIN(0.551,0.719,0.75) 0.551 in 14.00 mm

Calulation of (tc) UW

UW-16(b)

16(b)

tc1 0.250 in 6.35 mm

tc2= 0.7*tmin =0.7*0.551 = 0.386 in 9.80 mm

tc= Min.(tc1,tc2) =Mim.(0.25,0.386) 0.250 in 6.35 mm

By considering equal fillet weld

Leg of outward nozzle weld = 21/2*tc =2^1/2*0.25 0.354 in 8.98 mm

use Leg41 = Leg43 0.472 in 12.00 mm

Between Reinforcing and Shell

tmin= Min(tv,te,tmin1) =MIN(0.551,0,0.75) 0.000 in 0.00 mm

Leg of outward nozzle weld = 21/2*tmin/2 =2^1/2*0/2 0.000 in 0.00 mm

Use Leg42 = 0.000 in 0.00 mm

MDMT for the nozzle :-

1- For W.N. flange B16.5

O O

MDMT W/O impact test {UCS-66(C)} -20 F -29 C

2- For nozzle pipe SA-106 Gr. B, curve B

O O

Min temp. at nominal thk. W/O impact test (UCS-66) 13 F -11 C

Nominal thk. of nozzle (tn) 0.719 in 18.263 mm

Required thk. of nozzle wall (trn) 0.005 in 0.13 mm

Ratno = trn * E / ( tn - c ) 0.01 < 0.35

Reduction in MDMT = (1 - ratio)*100 OF (Fig. UCS-66.1)

O

-99.07 O F -72.74 C

O

MDMT at required thk. W/O impact test (UCS-66.1) -86.07 O F -65.53 C

O O

MDMT for the nozzle (assembly) -20 F -29 C

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- UHX CalcsDocument5 pagesUHX CalcsJ.SIVIRA100% (2)

- Asme Viii D Table 2aDocument16 pagesAsme Viii D Table 2aJohakim974100% (1)

- Saddle Dimension CalculationDocument2 pagesSaddle Dimension Calculationrinabiswas50% (2)

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Pressure VesselDocument507 pagesPressure Vesselpradip11100% (1)

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Design Calculations For Pressure VesselsDocument24 pagesDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Trunnion Calc r6Document4 pagesTrunnion Calc r6Chirag Shah50% (2)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Weldstrength Calc ProgDocument10 pagesWeldstrength Calc ProgSajal KulshresthaNo ratings yet

- Navistar O & M ManualDocument56 pagesNavistar O & M ManualMushtaq Hasan95% (20)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Reinforcement Pad DesignDocument3 pagesReinforcement Pad DesignAkshat JainNo ratings yet

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- Heat Exchanger DesignDocument20 pagesHeat Exchanger Designpav270875% (4)

- Pipe Insulation THK CalculationDocument6 pagesPipe Insulation THK Calculationnitin_bir100% (2)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureDocument10 pagesDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Heat Exchanger DesignDocument7 pagesHeat Exchanger Designsiva sankarNo ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 pageOperating Case Trunnion Calculation Sheet: Input DataJagadish JasNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- WRC CalculationsDocument20 pagesWRC Calculationsanu radha50% (2)

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDocument15 pagesReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodNo ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Reinforcement of Openings On Tori-Dish (Trial)Document23 pagesReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- 93 Qc20 J 414 Inlet NozzleDocument6 pages93 Qc20 J 414 Inlet NozzleHgagselim SelimNo ratings yet

- Pvelite PruebaDocument6 pagesPvelite PruebaLuis Cordova RamonNo ratings yet

- WRC 297Document9 pagesWRC 297akisdassasNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Samb Expand End PlateDocument5 pagesSamb Expand End PlateArbiNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Clean Water Tank - Id - 7200x10900 HDocument208 pagesClean Water Tank - Id - 7200x10900 HWilly SastraleksanaNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNo ratings yet

- Buffer Tank DesignDocument1 pageBuffer Tank DesignSuresh Damu BhadNo ratings yet

- Heat Exchangers Course Baher Part02Document21 pagesHeat Exchangers Course Baher Part02Baher ElsheikhNo ratings yet

- Clamp Design Baher 1651934316Document10 pagesClamp Design Baher 1651934316Muhammad Zun Nooren BangashNo ratings yet

- Heat Exchangers Course Baher Part04Document32 pagesHeat Exchangers Course Baher Part04Baher ElsheikhNo ratings yet

- Heat Exchangers Part 6 - Common Tube DefectsDocument13 pagesHeat Exchangers Part 6 - Common Tube DefectsBaher ElsheikhNo ratings yet

- Heat Exchangers Course Baher Part03Document18 pagesHeat Exchangers Course Baher Part03Baher ElsheikhNo ratings yet

- Key Changes in API 571-2020 Part 1Document66 pagesKey Changes in API 571-2020 Part 1Raghavan Venkatraman100% (4)

- Stainless Steel Tubing-Related FiresDocument1 pageStainless Steel Tubing-Related FiresBaher ElsheikhNo ratings yet

- Codes and Standards: Petroleum Engineering Technology (Pet) Department Polytechnic Abu Dhabi (Adpoly)Document37 pagesCodes and Standards: Petroleum Engineering Technology (Pet) Department Polytechnic Abu Dhabi (Adpoly)Baher Elsheikh100% (2)

- Heat Exchangers Course - Baher - Part 01Document24 pagesHeat Exchangers Course - Baher - Part 01Baher ElsheikhNo ratings yet

- Utility Boiler Condition AssessmentDocument12 pagesUtility Boiler Condition AssessmentBaher ElsheikhNo ratings yet

- Static Equipment Awarness Session - 02Document156 pagesStatic Equipment Awarness Session - 02Baher Elsheikh100% (2)

- CreepDocument26 pagesCreepOsu AmpawanonNo ratings yet

- FSA Gasket Handbook - June 2017Document138 pagesFSA Gasket Handbook - June 2017Dijin MaroliNo ratings yet

- Supercritical and Ultra-Supercritical Power Plants - SEA's Vision or Reality?Document23 pagesSupercritical and Ultra-Supercritical Power Plants - SEA's Vision or Reality?anupam789No ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- RR 253Document47 pagesRR 253hpmonNo ratings yet

- Parker Fittings IomDocument120 pagesParker Fittings IomAgustin CesanNo ratings yet

- FSA Gasket Handbook - June 2017Document138 pagesFSA Gasket Handbook - June 2017Dijin MaroliNo ratings yet

- Original Gasket Technology GuideDocument40 pagesOriginal Gasket Technology GuideAtty AttyNo ratings yet

- Flange and Gasket Detail PDFDocument74 pagesFlange and Gasket Detail PDFumar_hazrad8219No ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- 3E Plus V4 Users ManualDocument60 pages3E Plus V4 Users ManualManikanda PrabhuNo ratings yet

- 5.david - .Spencer - Air Cooled HE TTSDocument6 pages5.david - .Spencer - Air Cooled HE TTSBaher ElsheikhNo ratings yet

- Nureg 6007Document122 pagesNureg 6007Baher ElsheikhNo ratings yet

- GasketsDocument58 pagesGasketsdroessaert_stijnNo ratings yet

- Classification of Heat ExchangersDocument77 pagesClassification of Heat Exchangers4605566vivek100% (1)

- 3-34C-5 Tube To Tubesheet Welds IntegrityDocument5 pages3-34C-5 Tube To Tubesheet Welds IntegrityBaher ElsheikhNo ratings yet

- Repair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerDocument7 pagesRepair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerBaher ElsheikhNo ratings yet

- 54521Document29 pages54521Alok DubeyNo ratings yet

- 5 Shell-And-tube Heat Exchanger - EckrichDocument22 pages5 Shell-And-tube Heat Exchanger - EckrichAshley JacksonNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- AD AUSAT Reviewer - Dimensions: Study Online atDocument2 pagesAD AUSAT Reviewer - Dimensions: Study Online atGrace ComiaNo ratings yet

- Appendix EDocument51 pagesAppendix Earif_rubinNo ratings yet

- GVAR210 Exploded ViewDocument4 pagesGVAR210 Exploded ViewUEENo ratings yet

- Questions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGDocument8 pagesQuestions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGMina MagdyNo ratings yet

- Guidelines Using Thermal Mass Concrete BuildingsDocument12 pagesGuidelines Using Thermal Mass Concrete Buildingsnatalia_campelo100% (1)

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- Metode Kerja Umum PDA Test - 2021Document23 pagesMetode Kerja Umum PDA Test - 2021WannNo ratings yet

- 12 BY8 ShedplanDocument30 pages12 BY8 Shedplanhaheq100% (1)

- Casagrand Grandio BrochureDocument53 pagesCasagrand Grandio BrochureJoshikha MNo ratings yet

- HVAC Load CalculationDocument5 pagesHVAC Load Calculationthanh_79No ratings yet

- QSE Experiment No 2Document4 pagesQSE Experiment No 2Neeraj Kumar ThakurNo ratings yet

- Plastic Design GuidelinesDocument241 pagesPlastic Design Guidelines2023ht30006No ratings yet

- DEUTZ FL912 Engine Overhaul Part ListDocument12 pagesDEUTZ FL912 Engine Overhaul Part ListTong Hai WangNo ratings yet

- Material Consumption Norms For Various Civil Works - Civil4MDocument1 pageMaterial Consumption Norms For Various Civil Works - Civil4MAnubhav NautiyalNo ratings yet

- Stress Assessment of Skew Composite Steel I-Girder Bridge: Kapil Kumar Gupta, Shashivendra DulawatDocument9 pagesStress Assessment of Skew Composite Steel I-Girder Bridge: Kapil Kumar Gupta, Shashivendra DulawatkapilshwetaNo ratings yet

- A Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteDocument5 pagesA Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Work Instruction Page 1 of 2 Contiguous Bored Piles InstallationDocument7 pagesWork Instruction Page 1 of 2 Contiguous Bored Piles InstallationMuhammad Syahmi Adli SamNo ratings yet

- Full Public Roads Act - 2002Document52 pagesFull Public Roads Act - 2002Jonas Kañombi MukwatuNo ratings yet

- Architecture Vernacular Terms 2Document2 pagesArchitecture Vernacular Terms 2Christian James TuazonNo ratings yet

- Article 352 Rigid Polyvinyl Chloride Conduit: Type PVC: CodeDocument1 pageArticle 352 Rigid Polyvinyl Chloride Conduit: Type PVC: CodeSharik KhanNo ratings yet

- Forest EngineeringDocument78 pagesForest EngineeringPrakash KaniveNo ratings yet

- G 962 1188 - BomDocument8 pagesG 962 1188 - BomDibyendu ChakrabortyNo ratings yet

- SPAN Part H - Particular Construction...Document8 pagesSPAN Part H - Particular Construction...ang.xicongNo ratings yet

- ASTM D3689 (Prueba de Carga en Traccion)Document11 pagesASTM D3689 (Prueba de Carga en Traccion)Josh ClaureNo ratings yet

- By: Aldub NationDocument23 pagesBy: Aldub NationKenneth Paul OlinanNo ratings yet

- Tank-A Tank-B Tank-C: Bus BayDocument4 pagesTank-A Tank-B Tank-C: Bus BayMohit AgarwalNo ratings yet

- Chemdur - 42 RHDocument3 pagesChemdur - 42 RHICPL-RWPNo ratings yet

- Registration CRDocument5 pagesRegistration CRnandha gopalNo ratings yet