Professional Documents

Culture Documents

Heating Hot Water System Schematic: Sequence of Operation

Uploaded by

Fadzil SafuanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heating Hot Water System Schematic: Sequence of Operation

Uploaded by

Fadzil SafuanCopyright:

Available Formats

HEATING HOT WATER SYSTEM SCHEMATIC

FLOW SWITCH TO BE HARD-WIRED INTO BOILER START CIRCUIT PER MFRS INSTRUCTIONS (TYP. FOR BOTH BOILERS)

SEE DRAWINGS FOR LOCATION

AI Flow Switch (by mfr.) Hot Water Supply Temp Pump 1 HWS Pump 3 Pump 1 Enable BOILER 1 Boiler 1 Enable Boiler 1 Status BO BI Pump 3 Enable Pump 3 Status STARTER BO BI Pump 1 Status VFD Signal (0-10vdc) VFD Pump 2 120vac Flow Switch (by mfr.) Pump 2 Enable Pump 4 Pump 2 Status VFD Signal (0-10vdc) BOILER 2 Boiler 2 Enable Boiler 2 Status BO BI Pump 4 Enable Pump 4 Status STARTER BO BI BO BI AO VFD Digital Control Panel BO BI AO Hot Water Return Temp TO SYSTEM AI

Diff Press

LOW HI

HWS

AI

HWR

HWR

SEQUENCE OF OPERATION: HEATING WATER PLANT: The Heating Water System shall be enabled to run anytime the outside air temperature is below 85F (adj.). The lead Boiler Pump (P-3 or P-4), and the lead System Hot Water Pump (P-1 or P-2) shall be enabled. Once the lead pumps are proven to be on, then the lead Boiler (B-1 or B-2) shall be enabled. SYSTEM HOT WATER PUMPS (P-1 & P-2): Lead and lag system pump assignment shall be initialized automatically by the FMS based upon day-of-month strategy. Between the first day of any given month and through the (15th) day, P-1 shall be the lead pump (with P-2 in stand-by mode), from the 16th day to the last day of the month, P-2 shall be the lead pump (with P-1 in stand-by mode). Failure of the lead pump shall cause the stand-by pump to operate and an alarm generated through the FMS. The FMS operator shall be able to override or bypass the switchover assignment from the user interface graphic screen. The System Pump VFDs shall be modulated to maintain the differential pressure setpoint of 10 PSI (adj.) measured between the supply and return lines at the location indicated on the drawings. BOILER PUMPS (P-3 & P-4): Before a boiler is fired, its associated circulating pump shall be commanded on. Once the circulating pump is proven to be on through a current sensing switch then the boiler shall be allowed to fire. BOILERS (B-1 & B-2): Lead and lag boiler assignment shall be initialized by the FMS based upon day-of-month strategy. Between the first day of any given month and through the (15th) day, B-1 shall be the lead boiler (with B-2 in stand-by mode), from the 16th day to the last day of the month, B-2 shall be the lead pump (with B-1 in stand-by mode). Failure of the lead boiler to maintain the hot water supply temperature setpoint shall cause the stand-by boiler to operate. The FMS operator shall be able to override or bypass the switchover assignment from the user interface graphic screen. HOT WATER SUPPLY TEMPERATURE RESET: Measurements of hot water supply temperature shall be taken over a 10 minute (adj.) floating window to determine the average temperature. The FMS shall inversely reset the supply water temperature with the outside air temperature. Initially, the HWS-T setpoint shall be 180F at OAT=20F and below and 160F at OAT=75F and above. The lead boiler (and lag boiler if necessary) shall be fired to maintain the HWS-T setpoint.

Outside Air Temp Outside Air Humidity

AI AI

MOUNT OA TEMP./HUMIDITY SENSOR ON NORTH FACING WALL IN SHADED AREA.

You might also like

- HPBP Writeup Dadri-IIDocument17 pagesHPBP Writeup Dadri-IIrajan_me083No ratings yet

- ELS10-8HV-B700-SIE-S06-F4001-A-Sequence of OperationDocument21 pagesELS10-8HV-B700-SIE-S06-F4001-A-Sequence of OperationMohamed AshrafNo ratings yet

- Chiller Operating SequenceDocument3 pagesChiller Operating Sequencejomy_pj8106No ratings yet

- PWPS MultiDrive PotablePump Control Sequence-Rev3Document5 pagesPWPS MultiDrive PotablePump Control Sequence-Rev3md_rehan_2No ratings yet

- Sequence of Operation ChillerDocument2 pagesSequence of Operation ChillerOoi Tze Hoong60% (5)

- Practica CDocument2 pagesPractica CAlejandroCalleRuizNo ratings yet

- Analog Control SystemDocument11 pagesAnalog Control SystemYoginder KumarNo ratings yet

- Operating Philosophy - Conveying SystemDocument6 pagesOperating Philosophy - Conveying SystemAmit JainNo ratings yet

- Testing and Commissioning of Fire Fighting System Hose Reel and Sprinkler SystemDocument3 pagesTesting and Commissioning of Fire Fighting System Hose Reel and Sprinkler SystemgaineyskNo ratings yet

- 2.1 Purpose of The GCTDocument6 pages2.1 Purpose of The GCTsml mptNo ratings yet

- PWR Pressure Control Training Text PP20-24Document5 pagesPWR Pressure Control Training Text PP20-24lassekjaersgaardNo ratings yet

- Testing and Commissioning of Water Supply Piping System Network PDFDocument4 pagesTesting and Commissioning of Water Supply Piping System Network PDFHumaid ShaikhNo ratings yet

- AV6+ BypassGeneralDescriptionDocument14 pagesAV6+ BypassGeneralDescriptionGaurav ChauhanNo ratings yet

- Testing and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemDocument4 pagesTesting and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemHumaid ShaikhNo ratings yet

- Sequence of OperationsDocument12 pagesSequence of Operationseyad100% (2)

- 2 .1.1. Pre-Start Operations: Check Out The Fuel Oil Supply System StateDocument7 pages2 .1.1. Pre-Start Operations: Check Out The Fuel Oil Supply System StateJonas NordvikNo ratings yet

- PP10CC 00 Lab MR Abc 001Document7 pagesPP10CC 00 Lab MR Abc 001anbesivam87No ratings yet

- Complex InstDocument13 pagesComplex InstJHANSINo ratings yet

- Chilled Water Sequence of OperationDocument8 pagesChilled Water Sequence of OperationRaulSaavedra100% (1)

- Sequence of Operation For Constant Air Volume Air Conditioning SystemDocument7 pagesSequence of Operation For Constant Air Volume Air Conditioning SystemDong VanraNo ratings yet

- Chilled Water System Sequence of OperationsDocument6 pagesChilled Water System Sequence of Operationsmeeng2014No ratings yet

- Boiler LogicsDocument42 pagesBoiler LogicsSupratim Pal100% (1)

- Capricorn Modul Hidraulic Fisa Tehnica 14.03.2013 NA enDocument7 pagesCapricorn Modul Hidraulic Fisa Tehnica 14.03.2013 NA envalentin proseanchinNo ratings yet

- Pump Logic - Variable PrimaryDocument1 pagePump Logic - Variable PrimaryVISHNU PRABHAKARNo ratings yet

- MultipleDocument3 pagesMultipleHumaid ShaikhNo ratings yet

- HGU ManualDocument15 pagesHGU ManualGarvit ChopraNo ratings yet

- PDC Question BankDocument15 pagesPDC Question BankHardik PatoliyaNo ratings yet

- Chilled Water Installations, Dubai, UAE 23.05.2016Document14 pagesChilled Water Installations, Dubai, UAE 23.05.2016coolth2100% (3)

- Boiler Operating Sequence-Rev1Document11 pagesBoiler Operating Sequence-Rev1Ran NNo ratings yet

- Final Backup System Control Philosophy Rev4Document9 pagesFinal Backup System Control Philosophy Rev4AhmedNo ratings yet

- Project: Associated Equipment: - AHU - Thru - CHWP - Thru - VFD For CHWP - B-T Station - (Document4 pagesProject: Associated Equipment: - AHU - Thru - CHWP - Thru - VFD For CHWP - B-T Station - (carlcrowNo ratings yet

- Hattersley PICV Brochure 16pp V2 LO RESDocument16 pagesHattersley PICV Brochure 16pp V2 LO RESmymikeymikesNo ratings yet

- Intercooler, Aftercooler and Antisurge Control: 1. One CasingDocument3 pagesIntercooler, Aftercooler and Antisurge Control: 1. One CasingFouad TachiNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul_choubey_9100% (1)

- Drun Level ControlDocument12 pagesDrun Level ControlAshvani ShuklaNo ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- Boiler ControlsDocument27 pagesBoiler ControlsMY NAME IS NEERAJ..:):)No ratings yet

- LP Bypass SystemDocument7 pagesLP Bypass SystemJackSparrow86No ratings yet

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Control & Automation For Super Critical UnitsDocument46 pagesControl & Automation For Super Critical Unitsbsiva9No ratings yet

- GS ControlsDocument2 pagesGS Controlsashu0470No ratings yet

- KPCL - Steam Blowing ProcedureDocument7 pagesKPCL - Steam Blowing ProcedureAtiqur RahmanNo ratings yet

- Improved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric LocomotivesDocument38 pagesImproved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric Locomotivesjohn peter100% (11)

- Write Up On Aux PrdsDocument6 pagesWrite Up On Aux PrdsYousuf AliNo ratings yet

- Operation & Control Philosophy-Rev-3Document9 pagesOperation & Control Philosophy-Rev-3Amit BalotNo ratings yet

- Manual Steering EngDocument24 pagesManual Steering Engghiocel apinteiNo ratings yet

- Hydraulic Control System CompactDocument4 pagesHydraulic Control System CompactEmi MariniNo ratings yet

- BMS Sequence of OperationDocument29 pagesBMS Sequence of Operationmohmmad alam Khan100% (1)

- Operation of Condensate and Feed Water System HPDocument8 pagesOperation of Condensate and Feed Water System HPlp mishraNo ratings yet

- Boiler Control and InstrumentationDocument9 pagesBoiler Control and Instrumentationkvmurugan1976No ratings yet

- Product Information: Variable Flow Application Engineering BulletinDocument4 pagesProduct Information: Variable Flow Application Engineering BulletinEmrah aliçayNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul ranaNo ratings yet

- O&M Manual DraftDocument28 pagesO&M Manual Draftmahroof mkuttyNo ratings yet

- 18 Control PhilosophyDocument13 pages18 Control PhilosophyWael WaelNo ratings yet

- Sop HRSGDocument23 pagesSop HRSGshameer_febi100% (1)

- Functional Description of The Vacuum Pump Set-1Document8 pagesFunctional Description of The Vacuum Pump Set-1jigneshluharNo ratings yet

- TURBINE Logics and InterlocksDocument62 pagesTURBINE Logics and Interlockskalyanm20351586% (7)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 2018, API, API SN PLUS Requirements PDFDocument5 pages2018, API, API SN PLUS Requirements PDFtehnicar1No ratings yet

- Paccar MX 11 ENGINE Operators Manual 2018Document104 pagesPaccar MX 11 ENGINE Operators Manual 2018ddi1150% (2)

- Block 1-Data Handling Using Pandas DataFrameDocument17 pagesBlock 1-Data Handling Using Pandas DataFrameBhaskar PVNNo ratings yet

- Parallel Port InterfacingDocument34 pagesParallel Port InterfacingKingsprincessNo ratings yet

- Balika I 2020Document15 pagesBalika I 2020Kiran SomayajiNo ratings yet

- Allotted List Round 2 PDFDocument370 pagesAllotted List Round 2 PDFASHOKNo ratings yet

- QSX15-G9: EPA NSPS CertifiedDocument3 pagesQSX15-G9: EPA NSPS CertifiedMarcos Batista Dos SantosNo ratings yet

- 19BCG1077 - Swarup DebDocument1 page19BCG1077 - Swarup DebUX ༒CONQUERERNo ratings yet

- SLC Twin Rt2 0,7.. 10 kVA: User ManualDocument48 pagesSLC Twin Rt2 0,7.. 10 kVA: User Manualsomae AbbasNo ratings yet

- Declaration of Conformity: TP-Link Technologies Co., LTDDocument21 pagesDeclaration of Conformity: TP-Link Technologies Co., LTDBianca Maria PopescuNo ratings yet

- 3D Construction Printing: Technical Specifications 2021Document3 pages3D Construction Printing: Technical Specifications 2021Camilo Sebastián Romero VivancoNo ratings yet

- LogDocument130 pagesLogZaheerabbas KhanNo ratings yet

- Coolmay: MX2N Series PLC Programming ManualDocument32 pagesCoolmay: MX2N Series PLC Programming ManualAbel G AbelNo ratings yet

- Application Development - SMART CARD: Software Architecture and Dataflow DiagramDocument2 pagesApplication Development - SMART CARD: Software Architecture and Dataflow DiagramAnonymous MSAAwrZC5No ratings yet

- Netscreen Concepts and ExamplesDocument476 pagesNetscreen Concepts and ExamplesKeshri SekhonNo ratings yet

- Q Cells Data Sheet Q.peak Duo-G8 345-360 Global 2019-05 Rev02 enDocument2 pagesQ Cells Data Sheet Q.peak Duo-G8 345-360 Global 2019-05 Rev02 envijayNo ratings yet

- Machine SolutionDocument337 pagesMachine SolutionSumon SarkerNo ratings yet

- IBM Sterling Warehouse Management System: Increase Warehouse Productivity and Reduce CostsDocument5 pagesIBM Sterling Warehouse Management System: Increase Warehouse Productivity and Reduce CostsRishard MohamedNo ratings yet

- Cp15 Semester 6Document16 pagesCp15 Semester 6mithunprayag0% (1)

- IBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773Document762 pagesIBM Tivoli Provisioning Manager V7.1.1 Deployment and IBM Service Management Integration Guide Sg247773bupbechanhNo ratings yet

- 10264A - Developing Web Applications With Microsoft Visual Studio 2010 - Vol1 PDFDocument506 pages10264A - Developing Web Applications With Microsoft Visual Studio 2010 - Vol1 PDFRODRIGO SAMPAIONo ratings yet

- DS-2TD2617-3/V1 Thermal & Optical Network Bullet Camera: Smart Function (Thermal Imaging)Document5 pagesDS-2TD2617-3/V1 Thermal & Optical Network Bullet Camera: Smart Function (Thermal Imaging)Dávid DobóNo ratings yet

- What Is A StartupDocument3 pagesWhat Is A StartupArun SoniNo ratings yet

- File Upload XSS - Hack 2 LearnDocument12 pagesFile Upload XSS - Hack 2 LearnTech HelpNo ratings yet

- Dell PowerEdge RAID Controller H330Document2 pagesDell PowerEdge RAID Controller H330danxl007No ratings yet

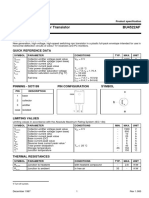

- Datasheet 3Document7 pagesDatasheet 3محمدعليNo ratings yet

- CA4500 - 4 Reader Access Control Board: NEW - The Control Board May Require Setting S2 DIPDocument2 pagesCA4500 - 4 Reader Access Control Board: NEW - The Control Board May Require Setting S2 DIPLuis Huerta100% (1)

- LS Retail Training Manual Version 4.2Document170 pagesLS Retail Training Manual Version 4.2MOHAMMED AARIFNo ratings yet

- Discussion NTM2Document2 pagesDiscussion NTM2neenoonaaNo ratings yet

- Eee111 Experiment 4Document6 pagesEee111 Experiment 4Amirul 0205No ratings yet