Professional Documents

Culture Documents

Supercut Engineering Works: Process Flow Diagram

Supercut Engineering Works: Process Flow Diagram

Uploaded by

Mary Frazier0 ratings0% found this document useful (0 votes)

6 views1 page1. The document is a process flow diagram for part number SI-217-3 describing the manufacturing process for a part used in Hero Honda motorcycles.

2. The process involves cold forging, chamfering, centreless grinding, cleaning, final inspection, packaging, and dispatch.

3. Key steps include receiving wire/rod, drawing, annealing, forging, rough and finish grinding, final inspection, packaging, and dispatching the finished parts.

Original Description:

Original Title

Hero Honda Pfd

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document is a process flow diagram for part number SI-217-3 describing the manufacturing process for a part used in Hero Honda motorcycles.

2. The process involves cold forging, chamfering, centreless grinding, cleaning, final inspection, packaging, and dispatch.

3. Key steps include receiving wire/rod, drawing, annealing, forging, rough and finish grinding, final inspection, packaging, and dispatching the finished parts.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageSupercut Engineering Works: Process Flow Diagram

Supercut Engineering Works: Process Flow Diagram

Uploaded by

Mary Frazier1. The document is a process flow diagram for part number SI-217-3 describing the manufacturing process for a part used in Hero Honda motorcycles.

2. The process involves cold forging, chamfering, centreless grinding, cleaning, final inspection, packaging, and dispatch.

3. Key steps include receiving wire/rod, drawing, annealing, forging, rough and finish grinding, final inspection, packaging, and dispatching the finished parts.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

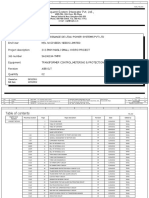

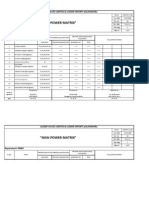

SUPERCUT ENGINEERING WORKS

21/4, MATHURA NEAR GURGAON CANAL BALLABHGARH,FARIDABAD(HR.)

FORMAT NO.: REV NO.:Effe. Date:PAGE NO 1 OF 1

FM/22 03 16.11.2012

PROCESS FLOW DIAGRAM

Supplier Code:~ Part No.:~ SI-217-3 PART DESCRIPTION:~ HERO HONDA DIRECTION :- Used as Movement symbol can be in either direction as Appropriate PROCESS :- COLD FORGING, CHAMFERING (BOTH SIDES)CENTRE LESS GRINDING, CLEANING, FINAL INSP, PACKING, DISP. Drawing Rev.No.:~02

DATE :~ 02.03.2013

CUSTOMER :- M/S FEDRAL MOGUL GOETZE INDIA LTD. PATIALA OPERATION STEP MOVE STORE INSPECT PROCESS DESCRIPTION REMARKS

RECEIVING WIRE / WIRE ROD FROM RAW MATERIAL SUPLLIER

1

RECEIVING INSPECTION (WIRE / WIRE ROD) STORAGE OF WIRE ROD

5

2

MOVE WIRE ROD TO DARWING OPERATION TO DESIRED OD

2

DRAWING (PATROL INSPECTION) MOVED TO ANEELING OF WIRE ROD

7

3

PATROL INSPECTION MOVE TO FORGING PART FORM FIVE STATION , ( PARTING ,TOTAL LENGTH, DRILLING, FINISHED ID AS PER FORGED SPECIFICATION ) PATROLING INSPECTION

10

11

MOVED TO ROUGH OD GRINDING

12

PATROLING INSPECTION MOVE TO CNC ( FACING, COUNTER , TOTAL LENGTH)

13

6

6

14

PATROLING INSPECTION MOVED TO FINISH OD GRINDING

15

PATROLING INSPECTION

16

8 8

MOVED TO FINAL INSPECTION FINAL INSPECTION MOVED FOR PACKAGING SECTION PACKAGING

9i

17

9

18

9

19

20

MOVED TO WARE HOUSE (OPTIONAL) DISPATCH

21

9ii

PREPARED BY:

APPROVED BY :

You might also like

- Game of Coaching EbookDocument97 pagesGame of Coaching EbookasklorraineNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- S705 E-43 (A) 6E2831101 MAIN GENERATORDocument24 pagesS705 E-43 (A) 6E2831101 MAIN GENERATORSagar TamhankarNo ratings yet

- SDAG - Project Technical GlossaryDocument80 pagesSDAG - Project Technical GlossaryAnna MiropolskayaNo ratings yet

- Pulpal Anatomy and Access Preparations: Appendix ADocument60 pagesPulpal Anatomy and Access Preparations: Appendix AHassan Tantawy100% (4)

- Weld Summary ReportDocument80 pagesWeld Summary ReportBinu SulochananNo ratings yet

- TMFR PanelDocument42 pagesTMFR PanelVarun SharmaNo ratings yet

- Turbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1Document34 pagesTurbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1yuliantoNo ratings yet

- Coffee Marketing PlanDocument24 pagesCoffee Marketing PlanAnkit Goswami100% (1)

- ITP For PilingDocument9 pagesITP For PilingAntonio Tomas Gonzalez Losa100% (2)

- VA1 YEA 02100 I I1 PID 0001 - RevA PDFDocument7 pagesVA1 YEA 02100 I I1 PID 0001 - RevA PDFAnonymous JtYvKt5XENo ratings yet

- Pallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance PlanDocument13 pagesPallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance Planp kishorNo ratings yet

- Excavation Along Jalan Belfield: Method Statement ForDocument37 pagesExcavation Along Jalan Belfield: Method Statement ForSyerifaizal Hj. Mustapha100% (1)

- 11 - 62 - 95 - 9601 - RevB-IOM LoadingDocument12 pages11 - 62 - 95 - 9601 - RevB-IOM Loadingsgagaga2095No ratings yet

- Sri Saundarya LahariDocument2 pagesSri Saundarya Laharisathi23138% (8)

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- D 1 1Document956 pagesD 1 1karthi82887No ratings yet

- 315 Me DS 083 D3Document6 pages315 Me DS 083 D3mihailspiridonNo ratings yet

- Saudi Electricity Company تاموسرلا طبض ةحفص: Drawing Control SheetDocument4 pagesSaudi Electricity Company تاموسرلا طبض ةحفص: Drawing Control Sheetbsenthilraj1550No ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- HTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsDocument22 pagesHTTPS://FR - Scribd.com/doc/294639869/method Statement For Cable Pulling and ConnectionsCripoNo ratings yet

- Appendix - Propgress Report IDocument406 pagesAppendix - Propgress Report IFebri Ramdani NugrahaNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Green Operate Fresh GrantedDocument677 pagesGreen Operate Fresh GrantedcrusieerNo ratings yet

- PO - 22004 Valve & Pressure GaugesDocument1 pagePO - 22004 Valve & Pressure Gaugessabir aliNo ratings yet

- Level Gauge-Bicolor DrumDocument4 pagesLevel Gauge-Bicolor DrumJKKNo ratings yet

- DatasheetDocument8 pagesDatasheetSales SES OmanNo ratings yet

- Rotary GurgaonDocument1 pageRotary GurgaonArindom KunduNo ratings yet

- 01.pneumatic Diagram Carton Sealer HotmeltDocument2 pages01.pneumatic Diagram Carton Sealer HotmeltFuad EfendiNo ratings yet

- Final Certticate 508Document1 pageFinal Certticate 508Rahul MoottolikandyNo ratings yet

- Est Etp RC 201 - R0Document1 pageEst Etp RC 201 - R0Shankar HirapureNo ratings yet

- Bolt Torquing Reference - 2Document5 pagesBolt Torquing Reference - 2DILSHAD AHEMADNo ratings yet

- PAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001Document44 pagesPAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001karthickeyanclass4No ratings yet

- Tega - Lining Part List: Mill Lining Division Tega Industries Limited Kolkata, IndiaDocument4 pagesTega - Lining Part List: Mill Lining Division Tega Industries Limited Kolkata, IndiaSilvio Veragua GallardoNo ratings yet

- Vendor Drawing Comments - Flow TeeDocument9 pagesVendor Drawing Comments - Flow TeeVeena NageshNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- Metro Link Express For Gandhinagar & Ahmedabad: 220724/ENTRY-ROOF/STR/RBCY-2Document1 pageMetro Link Express For Gandhinagar & Ahmedabad: 220724/ENTRY-ROOF/STR/RBCY-2Ankit KhuranaNo ratings yet

- Albion: Index - Alb522MbDocument18 pagesAlbion: Index - Alb522MbShauna MooreNo ratings yet

- MFG Certificate 79Document2 pagesMFG Certificate 79Hoshiar BaghelNo ratings yet

- CDPL-EEL-SNM-PUMP-DS-0001 - Mainline Pump Data Sheet 4PD-47939 - R1Document7 pagesCDPL-EEL-SNM-PUMP-DS-0001 - Mainline Pump Data Sheet 4PD-47939 - R1Amit KumarNo ratings yet

- Est Etp RC 202 - R0Document1 pageEst Etp RC 202 - R0Shankar HirapureNo ratings yet

- Renk Gearbox PDFDocument1 pageRenk Gearbox PDFMuzzammil NazeerNo ratings yet

- Delhi G 2013 10Document36 pagesDelhi G 2013 10Ashish RanaNo ratings yet

- Welders Identity Card: Project: Sharjah Cement Factory Customer: PhotoDocument1 pageWelders Identity Card: Project: Sharjah Cement Factory Customer: Photoayoki100% (1)

- Q01152 Bawan Tengah SDPDocument26 pagesQ01152 Bawan Tengah SDPReedzuanAbdulRazakNo ratings yet

- Mac LS 0 002 0Document4 pagesMac LS 0 002 0arifayee-1No ratings yet

- V-2158-103-A-851 - 4 ITP For PumpDocument4 pagesV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasNo ratings yet

- Plate - ADocument9 pagesPlate - ASumit SinghNo ratings yet

- Heat Treatment Procedure For Coil Header:::::: Purchaser End-User Project Name Location Item No. &service NameDocument2 pagesHeat Treatment Procedure For Coil Header:::::: Purchaser End-User Project Name Location Item No. &service NameGábor BacsaNo ratings yet

- Handling ToolsDocument21 pagesHandling ToolsMehmet SoysalNo ratings yet

- Man Power Matrix (M&S)Document3 pagesMan Power Matrix (M&S)Gourav SharmaNo ratings yet

- 546 List of Finished Machinery)Document17 pages546 List of Finished Machinery)stelianivan1964No ratings yet

- STD Water MonitorDocument5 pagesSTD Water MonitorAlvin SmithNo ratings yet

- List of Finished PlansDocument27 pagesList of Finished Plansalexandru911111No ratings yet

- Mirn KNPGBDocument635 pagesMirn KNPGBRudren Eswaran KrishnanNo ratings yet

- MPPDocument5 pagesMPPalokbdasNo ratings yet

- Ultrasonic Test Report: Tested by Industrial Engineering Services.19/1-D, Tolarbagh, MirpurDocument4 pagesUltrasonic Test Report: Tested by Industrial Engineering Services.19/1-D, Tolarbagh, MirpurAmit HasanNo ratings yet

- Indra: Total SheetDocument633 pagesIndra: Total SheetPHAM PHI HUNGNo ratings yet

- RD CocDocument1 pageRD CocPamungkasNo ratings yet

- Ug Alignment CENTRE LINEDocument15 pagesUg Alignment CENTRE LINEnorbu karbuluNo ratings yet

- Vendor Document Epc CPF Phase 2Document9 pagesVendor Document Epc CPF Phase 2Mohammed AbdallaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Unit 3 - Programming Multi-Core and Shared MemoryDocument100 pagesUnit 3 - Programming Multi-Core and Shared MemorySupreetha G SNo ratings yet

- Role / Responsibility of Operation ManagersDocument12 pagesRole / Responsibility of Operation ManagersDhruvil ShahNo ratings yet

- Shakil2014 BangladeshDocument5 pagesShakil2014 BangladeshAbir Rashid, 170011004No ratings yet

- Trenton Mayor Writes To Starbucks CEO About Store ClosingDocument2 pagesTrenton Mayor Writes To Starbucks CEO About Store ClosingThe TrentonianNo ratings yet

- Molecular Features and Cooking Behavior of Pasta FDocument12 pagesMolecular Features and Cooking Behavior of Pasta Fanand agarwalNo ratings yet

- Ecologic ModelDocument3 pagesEcologic ModelHazel Regencia RodriguezNo ratings yet

- Method Statement: Site Set Up: Compound, Parking & Material StorageDocument19 pagesMethod Statement: Site Set Up: Compound, Parking & Material StorageVICTORNo ratings yet

- Text FileDocument104 pagesText FileVictor TanasescuNo ratings yet

- Kubernetes and The Enterprise: Brought To You in Partnership WithDocument54 pagesKubernetes and The Enterprise: Brought To You in Partnership Withmiguel_murillo2No ratings yet

- Answer Key: Neet Booster Test Series (NBTS) For Neet-2021 Test - 6Document14 pagesAnswer Key: Neet Booster Test Series (NBTS) For Neet-2021 Test - 6anita tripathiNo ratings yet

- Yoga and World PeaceDocument6 pagesYoga and World Peacepaper_yoga100% (1)

- 4.2 A Quantum Dot WireDocument9 pages4.2 A Quantum Dot Wireraunak guptaNo ratings yet

- PFN1223 - Financial Management - Set C 2020Document14 pagesPFN1223 - Financial Management - Set C 2020alya farhanaNo ratings yet

- How To Write A Spelling CorrectorDocument9 pagesHow To Write A Spelling CorrectorafboterosNo ratings yet

- Energy Science Engineering - 2014 - S Nchez - Nuclear Fusion As A Massive Clean and Inexhaustible Energy Source For TheDocument12 pagesEnergy Science Engineering - 2014 - S Nchez - Nuclear Fusion As A Massive Clean and Inexhaustible Energy Source For ThekowshikNo ratings yet

- OWG007101 IGWB Hardware and Principle ISSUE 1.0Document35 pagesOWG007101 IGWB Hardware and Principle ISSUE 1.0anujgujjarNo ratings yet

- Advances in Topographic Mapping ProgrammeDocument2 pagesAdvances in Topographic Mapping ProgrammeMiloš BasarićNo ratings yet

- Alalalal LuaDocument53 pagesAlalalal Luarenato soporteNo ratings yet

- Arham 2010Document19 pagesArham 2010Mouhamad BigwantoNo ratings yet

- Walking With Dinosaurs IELTS Question With Answers PDFDocument8 pagesWalking With Dinosaurs IELTS Question With Answers PDFtrường ngôNo ratings yet

- Esei DeforestationDocument6 pagesEsei DeforestationSharinaZuhairNo ratings yet

- Beginner Listening PracticeDocument18 pagesBeginner Listening PracticeAhmad JanbeinNo ratings yet

- Profit RatesDocument1 pageProfit RatesMuzaffar AliNo ratings yet

- Ug 5th LCPWMDocument2 pagesUg 5th LCPWMBabbu DograNo ratings yet

- 4final REPORT - 1-62Document64 pages4final REPORT - 1-62Jyoti YadavNo ratings yet

- Product DetailsDocument215 pagesProduct DetailsEric MagnayeNo ratings yet