Professional Documents

Culture Documents

Vendor Document Epc CPF Phase 2

Uploaded by

Mohammed AbdallaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vendor Document Epc CPF Phase 2

Uploaded by

Mohammed AbdallaCopyright:

Available Formats

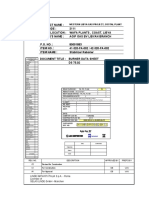

VENDOR DOCUMENT

EPC CPF PHASE 2

DOCUMENT DETAILS

EMPLOYER CONTRACT NO. : 090-13-BD-205-00

PROJECT : EPC CPF PHASE 2 AT BADRA OILFIELD, IRAQ

EMPLOYER : Gazprom Neft Badra B.V.

CONTRACTOR : Samsung Engineering Co. Ltd

CONTRACTOR PO NO. : 4500121975

PURCHASE ORDER

: Air Cooled Heat Exchanger

DESCRIPTION

SUPPLIER : Korea Heat Exchanger Ind. Co., Ltd

DOCUMENT NO. : GB090-4500121975-MS-E10-0006

VENDOR DOCUMENT NO. : N/A

REVISION NO. : 0 No. of pages (incl. sheet) : 9

: MOTOR DATA SHEET FOR LEAN SOLVENT AIR

DOCUMENT DESCRIPTION

COOLER

EQUIPMENT TAG NO.s : HC-29709/HC-29809

□ Code A : Approved

□ Code B : Approved with comment

□ Code C : Approved with comment and Resubmit

□ Code D : Rejected / Resubmit

□ Code R : Reviewed / Information Only

THIS APPROVAL OR REVIEW DOES NOT RELIEVE THE

VENDOR/SUBCONTRACTOR OF HIS RESPONSIBILITIES

TO MEET ALL OF THE SPECIFIED REQUIREMENTS OF

THE PURCHASE ORDER

ORIGINATOR CHECKED APPD(PR)

SIGN

DATE

SAMSUNG ENGINEERING CO., LTD

0 FOR FINAL 31/07/2015 S.A.PARK J.G.PARK M.G.HA

E FOR APPROVAL 13/03/2015 S.A.PARK J.G.PARK J.M.HUR

D FOR APPROVAL 02/10/2014 S.A.PARK J.G.PARK S.Y.PARK

C FOR APPROVAL 10/03/2014 S.A.PARK J.G.PARK S.R.SHIN

Rev Description Date Prepared Checked Approved

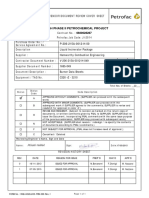

MOTOR DATA SHEET

LV INDUCTION MOTOR

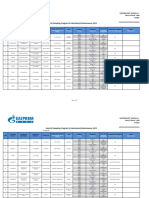

PROJECT: EPC CPF PHASE 2 AT BADRA OILFIELD, IRAQ DOC NO. REV SHEET NO.

EMPLOYER: Gazprom Neft Badra B.V. GB090-4500121975-MS-E10-0006 0 2/9

Rev

1 Item: HC-29709-FM01~FM06 / HC-29809-FM01~FM06 Quantity: 12sets

2 General specification: GB090-2614-250-EL-SP-0011 Standards, codes: IEC, ISO and as listed in specification

3

4 ENVIRONMENTAL CONDITIONS

5 Installation (indoor/outdoor) / Atmosphere outdoor marine dusty and corrosive

6 Ambient Design Temperature Max: + 55 °C Min: -5 °C

7 Altitude (if > 1000m)/Relative Humidity a.s.l.: + 66 m 81% at + 20 °C

8 Seismic Condition Seismic zone 3 (Acc. To UBC), Important Factor: Ip=1.25

9 Area Classification Zone 2, Gas Group II A

10

11 DRIVEN MACHINE DATA

12 Manufacturer/Machine Type (fan, pump, compressor,...) MOORE FAN

13 Maxi shaft power / Shaft power at operating point 19.19 kW 15.84 kW

14 Coupling type / To be designed for restarting HTD-BELT Yes No

15 Thrust (vertical) Up/Down Up N/A kg Down 186 kg

TO BE COMPLETED BY PURCHSER & BY DRIVEN MACHINE SUPPLIER

16 Driven Machine Inertia (WR2) 49.5 kg.m²

17 Brake torque curve / Required starting brake torque 593.3 N.m

18

19 MOTOR GENERAL CHARACTERISTICS

20 Rated power/ Number of Poles 22 Kw No: 4

21 Voltage/Frequency/Phases 400V (±10%) 50Hz (±5%) 3 Phase

22 Service Condition (S1, S2,…) S1

23 Mounting (IM1001,3001,3011,1011,...) V3

24 Protection degree: Enclosure / terminal box IP55 IP55

25 Protection : Motor in hazardous area / Terminal Box Ex (d) Ex (d)

26 Gas group (IIA, IIB, IIC or IIB + H2) / Temperature class (T3,...) IIC T4

27 Enclosure cooling (fan cooled, air to air, air to water,...) Fan cooled

28 Winding Connection (star, delta)/No terminals brought out Delta No: 6 ( 2ea / 1 phase)

29 Starting Method (loaded, unloaded / DOL, soft start,...) loaded V.V.V.F

30 Max. voltage drop at starting / Starting voltage 20 %

31 Max. Locked Rotor Current (Note 7) 670 %

32 No of consecutive starts within 1 hour Cold 3 Hot 2

33 Min.Insulation Class (B,F,...)/Max Temperature Rise Class F Class B

34 Direction of Rotation (looking at motor coupling) CW CCW Bidirectional

35 Position of Main / Auxiliary terminal box Main: IEC 160/180FR IIC Auxiliary: Ex d IIC/FR.90-280LL

36 Cable Type and Size on main terminal box Type: 0.6/1kv CU/XLPE/PVC/SWA or SWT/PVC Size: 3.5C x 35 mm²

37 Cable Entrance ISO metric thread

38 Terminal boxes provided with cable glands Yes No

39 Separated terminal box for anticondensation heater -

40 Separated terminal box for winding RTDs Required

41 Gland size (Main / Auxiliary) Main: M32 Auxiliary: M20

42 Anticondensation heaters (supply/voltage) - -

43 Anticondensation heater cable type and size Type: - Size: - mm²

44 Ground lug size 16 mm²

45 Painting (Mfr standard,... / color) Ral No 5017

46 Noise Level at 1 m 80 dB(A)

47 Winding material Copper

48

49

50

51

52

53

54

55

56

57

58

MOTOR DATA SHEET

LV INDUCTION MOTOR

PROJECT: EPC CPF PHASE 2 AT BADRA OILFIELD, IRAQ DOC NO. REV SHEET NO.

EMPLOYER: Gazprom Neft Badra B.V. GB090-4500121975-MS-E10-0006 0 3/9

Rev

59 MOTOR MANUFACTURER'S DATA

60 Manufacturer type / Frame Size / - HL-XD 180 -

61 Winding Connection (star, delta)/No terminals brought out Delta No: 6 (2ea / 1 Phase)

62 Full Load Speed 1475 rpm

63 Rated Current / No load current / Locked Rotor Current 41.8 A 10.8 A 670 %

64 Starting Time (% of Voltage) at full load 100%: 2 s 80%: 3 s

65 Allowable Locked Rotor withstand Time Cold: 23 s Hot: 17 s

66 Thermal Time Constant Cooling: 23 s Heating: 17 s

TO BE COMPLETED BY MANUFACTURER

67 Efficiency 4/4 91.6 % 3/4 91.8 % 2/4 91.1 %

68 Power Factor 4/4 0.830 3/4 0.810 2/4 0.740

69 Locked Rotor Power Factor 0.18

70 Full load Torque 142.1 N.m

71 Locked/Pull Up/Breakdown Torque L: 160 % PU: 120 % BD: 230 %

72 Rotor Motor Inertia (WR2) 0.18 kg.m²

73 Bearing Type (Drive End/Non Drive End) DE : 6312ZZC3 NDE : 6310ZZC3

74 Lubrication Type/Interval PERMANENT TYPE hours

75 Anticondensation heaters (power / voltage) Yes No - kW - V

76 Ground lug size 16 mm²

77 Motor Weight 260 kg

78 Certifying authority / certificate No ATEX Baseefa10ATEX0107X/2

79 Motor restart with full opposite residual voltage possible 30 %

80 No load power requirements 0.53 kW

81 First / Second critical speed 11,803 RPM 33,229 RPM

82 Bearing RTDs (Type / Qty) N/A No: -

83 Winding RTDs (Type / Qty) PTC Thermister 1 EA/Ph

84 Set for alarm / shut down - mm/s - mm/s

85

86

87

88

89

90

91 Notes:

92 1. Utilization Voltage for Motor

93 A) Motor capacity ≥ 200 kW : 11kV, 3Ph, 50Hz

94 B) Motor capacity < 200 kW : 400V, 3Ph, 50Hz

95 2. Terminal boxes shall be located at the top in a way that the cable connection can be made from four sides at 90°C.

96 3. For VSD (Variable Speed Drive)

97 A) The motor shall be of special design suitable for operation with the specified type of frequency converter.

98 B) Motor shall be equipped with 3 nos. temperature detectors of the thermistor type (one per phase) connected

99 to a separate junction box.

100 C) For motors rated < 7.5kW, the terminals of the motor and of the temperature detectors (themistors)

101 may be mounted in on terminal box with partitions.

102 4. Operational life time for all LV induction motors shall be 25 years minimum.

103 5. Vendor shall submit the following curve.

104 a) Speed -Torque curve for 100%, 80% Voltage

105 b) Speed -Current curve for 100%, 80% voltage

106 c) Time-Current Thermal Curve for 100%, 80% Voltage

107 6. Delete

108 7. The locked rotor apparent power shall comply with IEC 60034-12.

109 However, for motors with rated output in excess of 55 kW, the starting current shall be less than or equal 6.5 times of the rated current

110 of the motor (including IEC tolerance).

111

112

CURVE NO.

HYUNDAI PERFORMANCE CURVE

HEAVY INDUSTRIES CO., LTD

P-3941252-9

TYPE : HL-XD 22 kW 4P 50 Hz

FULL LOAD TORQUE : 14.5 kg.m RATED SPEED : 1475 rpm

2

J OF MOTOR : 0.180 kg.m VOLTAGE 400 V

J OF Load : 1.482 kg.m 2 RATED CURRENT 41.8 A

SPEED VS TORQUE & CURRENT CURVE

350 800

A

300 700

C 600

250

CURRENT IN %

TORQUE IN %

500

200

B 400

150

300

D

100

200

50 100

Load

0 0

0 10 20 30 40 50 60 70 80 90 100

SPEED IN %

A : SPEED VS CURRENT CURVE AT FULL VOLTAGE STARTING.

B : SPEED VS TORQUE CURVE AT FULL VOLTAGE STARTING.

C : SPEED VS CURRENT CURVE AT 80% OF FULL VOLTAGE STARTING.

D : SPEED VS TORQUE CURVE AT 80% OF FULL VOLTAGE STARTING.

E : SPEED VS TORQUE CURVE OF PUMP

OUTPUT VS EFF., P.F & CURRENT CURVE

100 200

EFF

90 180

80 160

70 P.F 140

EFF. & P.F IN %

CURRENT IN %

60 120

50 100

40 80

30 60

CURRENT

20 40

10 20

0 0

0 25 50 75 100 125

LOAD IN %

RM-P251-133 A4(210mm x 297mm)

CURVE NO.

T-3-941-252-009

Type : HL-XD 22 kW 4P 50 Hz

FULL LOAD TORQUE : 14.5 kg.m RATED SPEED : 1475 rpm

J OF LOAD : 1.482 kg.m2 VOLTAGE 400 V

J OF MOTOR : 0.180 kg.m2 RATED CURRENT 41.8A

10000

1000

Time(sec)

100

10

1

100 200 300 400 500 600 700 800

Current(%)

THERMAL LIMIT CURVE AT COLD CONDITION

THERMAL LIMIT CURVE AT HOT CONDITION

TIME VS. CURRENT CURVE AT RATED VOLTAGE STARTING

TIME VS. CURRENT CURVE AT 80% OF RATED VOLTAGE STARTING

STARTING TIME SAFE STALL TIME

2 sec. at rated voltage starting 17 sec. at Hot condition

at Cold condition

3 sec. at 80% of rated voltage starting 23 sec. at Cold condition

RM P251 133

RM-P251-133 A4(210mm x 297mm)

You might also like

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- FM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetDocument8 pagesFM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetAmr TarekNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- API 610 Vertical Centrifugal PumpDocument7 pagesAPI 610 Vertical Centrifugal PumpNAHASALI11No ratings yet

- Indra: Firm Up No.3 Api Oil Separator Project (Civil & Building Work)Document9 pagesIndra: Firm Up No.3 Api Oil Separator Project (Civil & Building Work)sajay2010No ratings yet

- Gunasekar Ramesh-External 2023.01.21 10:09:29 +05'30'Document106 pagesGunasekar Ramesh-External 2023.01.21 10:09:29 +05'30'Satish KumarNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Data Book P-8A01 FinalDocument129 pagesData Book P-8A01 FinalRUBEN ACOSTANo ratings yet

- Level Gauge-Bicolor DrumDocument4 pagesLevel Gauge-Bicolor DrumJKKNo ratings yet

- LNG Booster Pump DatasheetDocument7 pagesLNG Booster Pump DatasheetsswahyudiNo ratings yet

- IC#9 HBL Inspection Waiver ProfomaDocument2 pagesIC#9 HBL Inspection Waiver ProfomaAashish MoyalNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- KG D6 Ruby: Geostationary DBB Valves SpecificationDocument35 pagesKG D6 Ruby: Geostationary DBB Valves SpecificationMaffone NumerounoNo ratings yet

- Plant TS PVB El Evd LPF 001 00Document18 pagesPlant TS PVB El Evd LPF 001 00rahul rNo ratings yet

- Boiler Performance Test Report Rev0Document73 pagesBoiler Performance Test Report Rev0mvrk19650% (1)

- Spare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Document78 pagesSpare Parts Catalog: 4 WG-200 Case Material Number: 4644.024.131Teknik MakinaNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- Sok0929245 PDFDocument17 pagesSok0929245 PDFLeonardo Basante HerreraNo ratings yet

- Za 6Document21 pagesZa 6Yashvant NayarNo ratings yet

- Indra: Total SheetDocument633 pagesIndra: Total SheetPHAM PHI HUNGNo ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- MY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentDocument48 pagesMY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentkelburnNo ratings yet

- 30001-Technical Specification Sheet (Datasheet)Document6 pages30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- CWC Mec DTS P002abDocument8 pagesCWC Mec DTS P002abAlonso1593No ratings yet

- SFCCL Reformer DCI R1Document38 pagesSFCCL Reformer DCI R1maheshNo ratings yet

- Failure of 9FA Gas Turbine Compressor - A Unique Experience. D.Nandi (AGM-OS/GT) K.R.C.Murty (AGM-OS/GT)Document10 pagesFailure of 9FA Gas Turbine Compressor - A Unique Experience. D.Nandi (AGM-OS/GT) K.R.C.Murty (AGM-OS/GT)Thanapaet RittirutNo ratings yet

- VD V220 BSL DWG 0015 - eDocument26 pagesVD V220 BSL DWG 0015 - eabdulNo ratings yet

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- Pressure Switch DatasheetDocument1 pagePressure Switch DatasheetMohamed El MaadawyNo ratings yet

- SMBI - IN.FI12 REV02 Motor Insulation Resistance Test ReportDocument3 pagesSMBI - IN.FI12 REV02 Motor Insulation Resistance Test Reporteugene mejidana100% (1)

- Rabigh Phase Ii Petrochemical Project: Michael HaddadDocument22 pagesRabigh Phase Ii Petrochemical Project: Michael HaddadsonalisabirNo ratings yet

- 2 CQC Trienergy 5000027066 50506 - Data SheetDocument4 pages2 CQC Trienergy 5000027066 50506 - Data SheetIgor HernandezNo ratings yet

- Me-692 Pump Starter Data Sheet: GeneralDocument3 pagesMe-692 Pump Starter Data Sheet: GeneralPaul MaragoniNo ratings yet

- First Article Inspection Report: Form QCS 16Document16 pagesFirst Article Inspection Report: Form QCS 16bondo2011No ratings yet

- Pump DatasheetDocument4 pagesPump Datasheetbmanojkumar16No ratings yet

- Hot Water Generator (HW) : Rabigh II Project Interconnecting Package (UO1)Document18 pagesHot Water Generator (HW) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Ns2-Yt01-p0gcf-120002-Ab (Water Treatment Plant) - Motor Data SheetDocument196 pagesNs2-Yt01-p0gcf-120002-Ab (Water Treatment Plant) - Motor Data Sheettrong ngoc PhanNo ratings yet

- VP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPDocument10 pagesVP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPMinh PhamNo ratings yet

- E 001B1 MotorDocument2 pagesE 001B1 MotorBhihi RajaNo ratings yet

- Camy Plants: Shell Long Seam Back-Chip D.P. Test ReportDocument5 pagesCamy Plants: Shell Long Seam Back-Chip D.P. Test Reportnarendra vermaNo ratings yet

- 3 PDFDocument1 page3 PDFPrabhu SampathNo ratings yet

- Chpprint 2Document1 pageChpprint 2Prabhu SampathNo ratings yet

- TXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitDocument4 pagesTXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitMiguel Jiménez FloresNo ratings yet

- 3 PDFDocument1 page3 PDFPrabhu SampathNo ratings yet

- MD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationDocument30 pagesMD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationTran KhuynhNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument7 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Ibrahim T60CS Commissioning ContinuedDocument18 pagesIbrahim T60CS Commissioning ContinuedOmar Khaled100% (1)

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- Hook Ups PDFDocument8 pagesHook Ups PDFAnonymous d7Jde8No ratings yet

- VJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDocument19 pagesVJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDucNo ratings yet

- Mohammed Abdalla - Rotating Equipment Engineer BN PDFDocument12 pagesMohammed Abdalla - Rotating Equipment Engineer BN PDFMohammed AbdallaNo ratings yet

- Hoffmann Bearings DirectoryDocument4 pagesHoffmann Bearings DirectoryMohammed AbdallaNo ratings yet

- Forcing SQL Studio Manager To Attach A DatabaseDocument3 pagesForcing SQL Studio Manager To Attach A DatabaseMohammed AbdallaNo ratings yet

- Setting Up An @ptitude Analyst / OPC Connection: Quick Start GuideDocument8 pagesSetting Up An @ptitude Analyst / OPC Connection: Quick Start GuideMohammed AbdallaNo ratings yet

- How To Attach A SQL Server Database (Using Skfuser - MDF File)Document6 pagesHow To Attach A SQL Server Database (Using Skfuser - MDF File)Mohammed AbdallaNo ratings yet

- Collection Status Report: Source: GD-22301CDocument5 pagesCollection Status Report: Source: GD-22301CMohammed AbdallaNo ratings yet

- Collection Status Report: Source: U-26202BDocument4 pagesCollection Status Report: Source: U-26202BMohammed AbdallaNo ratings yet

- U-23203-P03 Spectral Plot ReportDocument15 pagesU-23203-P03 Spectral Plot ReportMohammed AbdallaNo ratings yet

- Analyst - SQL Server Performance TuningDocument20 pagesAnalyst - SQL Server Performance TuningMohammed AbdallaNo ratings yet

- Lube Oil Sampling Mechanical-2023 Rev0Document10 pagesLube Oil Sampling Mechanical-2023 Rev0Mohammed AbdallaNo ratings yet

- Collection Status Report: Source: HC-21201A-FM02Document1 pageCollection Status Report: Source: HC-21201A-FM02Mohammed AbdallaNo ratings yet

- Job Safety Analysis: Vibration Analyzer, RagDocument1 pageJob Safety Analysis: Vibration Analyzer, RagMohammed AbdallaNo ratings yet

- Collection Status Report: Source: U-23203-P14Document1 pageCollection Status Report: Source: U-23203-P14Mohammed AbdallaNo ratings yet

- Fresh Oil Report 157 - HPU TRSVDocument1 pageFresh Oil Report 157 - HPU TRSVMohammed AbdallaNo ratings yet

- Collection Status Report: Source: P-28553Document1 pageCollection Status Report: Source: P-28553Mohammed AbdallaNo ratings yet

- Ref PKG Coupling OrdersDocument3 pagesRef PKG Coupling OrdersMohammed AbdallaNo ratings yet

- Collection Status Report: Source: HC-21001C-FM02Document3 pagesCollection Status Report: Source: HC-21001C-FM02Mohammed AbdallaNo ratings yet

- Collection Status Report: Source: HC-21001C-FM01Document4 pagesCollection Status Report: Source: HC-21001C-FM01Mohammed AbdallaNo ratings yet

- Collection Status Report: Source: P-21401ADocument4 pagesCollection Status Report: Source: P-21401AMohammed AbdallaNo ratings yet

- Vendor Document Epc CPF Phase 2Document4 pagesVendor Document Epc CPF Phase 2Mohammed AbdallaNo ratings yet

- Collection Status Report: Source: P-21002ADocument3 pagesCollection Status Report: Source: P-21002AMohammed AbdallaNo ratings yet

- Collection Status Report: Source: F-29502ADocument2 pagesCollection Status Report: Source: F-29502AMohammed AbdallaNo ratings yet

- Rotex ZS-DKM-SH Flexible Jaw Couplings: Double-Cardanic Shaft Coupling With SPLIT HubsDocument2 pagesRotex ZS-DKM-SH Flexible Jaw Couplings: Double-Cardanic Shaft Coupling With SPLIT HubsMohammed AbdallaNo ratings yet

- Document DetailsDocument2 pagesDocument DetailsMohammed AbdallaNo ratings yet

- Salam Murshidi CVDocument4 pagesSalam Murshidi CVMohammed AbdallaNo ratings yet

- Confined Space Rescue Plan: Closed Drain Area Closed Drain Drum Pit, Work PlatformDocument1 pageConfined Space Rescue Plan: Closed Drain Area Closed Drain Drum Pit, Work PlatformMohammed AbdallaNo ratings yet

- Job Safety Analysis: Vibration Analyzer, RagDocument1 pageJob Safety Analysis: Vibration Analyzer, RagMohammed AbdallaNo ratings yet

- Equipment Risk and Equipment ReliabilityDocument28 pagesEquipment Risk and Equipment ReliabilityMohammed AbdallaNo ratings yet

- P20 - 083 - AES Solutions Guide Updates - KL - r8 - Digital-V5a PDFDocument12 pagesP20 - 083 - AES Solutions Guide Updates - KL - r8 - Digital-V5a PDFad80083No ratings yet

- Catalogo NovoconDocument62 pagesCatalogo NovoconfernandoNo ratings yet

- BC80 Catalogue: Type Description/Technical Data Stock Code PictureDocument16 pagesBC80 Catalogue: Type Description/Technical Data Stock Code PictureDinesh Chauhan100% (1)

- 08u 1Document31 pages08u 1Anonymous G1iPoNOKNo ratings yet

- Stryker High Flow 40 Liter Insufflator L Service ManualDocument44 pagesStryker High Flow 40 Liter Insufflator L Service ManualUbirajaraNo ratings yet

- K 90 9048 - PrintDocument1 pageK 90 9048 - PrintcchristtNo ratings yet

- 650m Electrical SchematicDocument4 pages650m Electrical SchematicEl PerroNo ratings yet

- ELM1085DG: Bipolar 3A LDO Voltage RegulatorDocument3 pagesELM1085DG: Bipolar 3A LDO Voltage RegulatorCleiton SilvaNo ratings yet

- Faa StandartDocument13 pagesFaa StandartBagas SaputraNo ratings yet

- L2 - 1 - Insulation Materials Used in TransformersDocument2 pagesL2 - 1 - Insulation Materials Used in TransformersPartha RayNo ratings yet

- Catalogo DanfossDocument8 pagesCatalogo DanfossJovany SegoviaNo ratings yet

- CO2CELL 170 - en - Ns 0301 - MMM - V1.0Document22 pagesCO2CELL 170 - en - Ns 0301 - MMM - V1.0gigel1980No ratings yet

- Denon AVRX3100W Avr Sm2Document212 pagesDenon AVRX3100W Avr Sm2João BatistaNo ratings yet

- Question Bank For DSSDocument7 pagesQuestion Bank For DSSNyamatulla PatelNo ratings yet

- Códigos de Avería Genéricos y Específicos SsangyongDocument8 pagesCódigos de Avería Genéricos y Específicos SsangyongJorge Antonio Guillen50% (2)

- Ultrasound Modulation and Codification For Localization SystemsDocument12 pagesUltrasound Modulation and Codification For Localization SystemsNguyen Tuan DanhNo ratings yet

- Product Data: Aquazone™ 50PCH, PCV, PCD007-070 Compact Water Source Heat Pumps With Puron Refrigerant (R-410A)Document72 pagesProduct Data: Aquazone™ 50PCH, PCV, PCD007-070 Compact Water Source Heat Pumps With Puron Refrigerant (R-410A)Jesus DavalosNo ratings yet

- American International University-Bangladesh (Aiub) : Faculty of EngineeringDocument7 pagesAmerican International University-Bangladesh (Aiub) : Faculty of EngineeringRifat RudroNo ratings yet

- 0001 PDFDocument20 pages0001 PDFPVelozoNo ratings yet

- 95 8723 U5015Document20 pages95 8723 U5015Jorge Isaac Lara RamosNo ratings yet

- Cbse Class 12 Sample Paper 2022 23 PhysicsDocument14 pagesCbse Class 12 Sample Paper 2022 23 PhysicsHacker MNo ratings yet

- R.V.R. PTXLCDDocument79 pagesR.V.R. PTXLCDFreeFM100% (3)

- Must 24 PV3000 LVHMDocument1 pageMust 24 PV3000 LVHMDuverlis Medina de HoyosNo ratings yet

- Guerra Residence: Lighting Layout PlanDocument1 pageGuerra Residence: Lighting Layout PlanKiarah GuerraNo ratings yet

- Antenna 2.1mDocument4 pagesAntenna 2.1mnoelNo ratings yet

- Schedule of STTP Seies-I 1st To 6th March-2021Document2 pagesSchedule of STTP Seies-I 1st To 6th March-2021muqthiarNo ratings yet

- Science 10 - Quarter 2 - Module 4Document8 pagesScience 10 - Quarter 2 - Module 4jennifer paneloNo ratings yet

- Sony Manual LCD x52 x72 x82Document180 pagesSony Manual LCD x52 x72 x82arrachetoiNo ratings yet

- Parallel Inverter: Power ElectronicsDocument10 pagesParallel Inverter: Power ElectronicsKiran SmathNo ratings yet

- TL3842PDocument18 pagesTL3842PjoelpalzaNo ratings yet