Professional Documents

Culture Documents

Cause & Effect Diagram PDF

Uploaded by

Jetesh Devgun0 ratings0% found this document useful (0 votes)

49 views1 pageSample of cause & effect diagram

Original Title

Cause & effect diagram.pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSample of cause & effect diagram

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views1 pageCause & Effect Diagram PDF

Uploaded by

Jetesh DevgunSample of cause & effect diagram

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MAN

Proper program selected or not Trained of milling process

CAUSE AND EFFECT DIAGRAM (ISHIKAWA)

know how of identification for rubber compound Perventive maintenance of m/c done Check machine for any malfunctioning Check Chilled water flow/rotameter Machine stop due to power cut

8D Ref NO

MACHINE

Water leakage from ram Carbon leakage from gland Excess oil flow Chilled water tempreature as per spec (16-22)

know how of identifications for rubber, oil, carbon, chemicals & scanning/tracebility Trained to run intermix (both m/c & computer operations) Trained to run rheometer

Trained to run milling machine

Check Air pr 6-7 bar

Check RPM of rotor

callibration of rheometer/viscom eter

Check RPM of roller with stop watch

Machine stop due to unwanted brake applied Trained to make/test hardness button

water tempreature on small mill, temp difference less than 10C

Working of stock blender

Chilled water tempraeture in big mill (16-22)

Proper selection of compound code programme Dumping tempreature as per spec Dump energy as per spec Dump time as per spec

Check Raw material qty on weight balance

Batch Failed

Check Quality certificate of Raw material & incoming inspection report

Raw polymer viscosity shelf life of raw material

Batch struked in mixer method to check rheometry properties followed method to check Hardness followed

check master batch weight

MATERIAL

Tempreature of rubber compound nip gap adjustment

Batch struked in mill

METHOD

You might also like

- Westerman TableDocument86 pagesWesterman TableDipak88% (17)

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- SA Crane Operator Daily Inspection ChecklistDocument1 pageSA Crane Operator Daily Inspection Checklistshaikh_nazar75% (8)

- Audi q7 Suspension and BrakesDocument48 pagesAudi q7 Suspension and BrakesUlpiano100% (2)

- Lecture - 3 Design LoadsDocument62 pagesLecture - 3 Design Loadshammads88No ratings yet

- Hydraulic Solar Tracking SystemDocument37 pagesHydraulic Solar Tracking Systemdivyesh67% (3)

- Flexible Grouted ClampDocument14 pagesFlexible Grouted ClampMiroslav AleksicNo ratings yet

- Air Dryer PDFDocument112 pagesAir Dryer PDFPrateekSinghBaghelNo ratings yet

- PM Check ListDocument6 pagesPM Check ListsaifulbachriNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Heavy Duty Gas Turbine Maintenance From GEDocument36 pagesHeavy Duty Gas Turbine Maintenance From GEJitu Jena100% (3)

- Komatsu PC160LC 7Document20 pagesKomatsu PC160LC 7Virgil Cenariu100% (3)

- FMEA PDocument6 pagesFMEA Pparu1982No ratings yet

- Genie GS-3268 RT Service ManualDocument183 pagesGenie GS-3268 RT Service ManualBosko100% (3)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Transmission and Transfer Case: Manual Transmission - G56 - Service InformationDocument68 pagesTransmission and Transfer Case: Manual Transmission - G56 - Service InformationRyanNo ratings yet

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekDocument8 pagesWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoNo ratings yet

- 3500 Start Up and Commissioning ChecklistDocument23 pages3500 Start Up and Commissioning Checklistlquinter75100% (2)

- Wet GranulationDocument18 pagesWet GranulationRafeek Shaikh100% (1)

- APQPDocument38 pagesAPQPJetesh DevgunNo ratings yet

- Cpi Gtr50 Service ManualDocument43 pagesCpi Gtr50 Service ManualKlara PataiNo ratings yet

- Master Form Standar PPM PC 2000-8Document3 pagesMaster Form Standar PPM PC 2000-8Burhan Mburine UdinNo ratings yet

- Data For Atlas Honda Shekupura InternshipDocument9 pagesData For Atlas Honda Shekupura InternshipEmziarNo ratings yet

- Gas Turbine Maintenence AspectsDocument38 pagesGas Turbine Maintenence Aspectsprasad5034100% (1)

- Overview of ACMV Design PDFDocument23 pagesOverview of ACMV Design PDFJojo TangalinNo ratings yet

- CENT Condition Monitoring PresentationDocument28 pagesCENT Condition Monitoring PresentationmkpqNo ratings yet

- Compressor Maintenance Water WashingDocument30 pagesCompressor Maintenance Water WashingMajid Motahari100% (1)

- Maintenance RecommendationsDocument15 pagesMaintenance Recommendationsmsalem730% (1)

- Insp Checklist - LO FlushingDocument3 pagesInsp Checklist - LO Flushingaanouar7750% (2)

- GBH Enterprises, LTD.: GBHE-EDG-MAC-1030Document24 pagesGBH Enterprises, LTD.: GBHE-EDG-MAC-1030Jay ShahNo ratings yet

- Pump DatasheetDocument10 pagesPump DatasheetPaulusIwan100% (1)

- Selecting Target ISO Cleanliness CodesDocument4 pagesSelecting Target ISO Cleanliness CodesluaguNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Checklist For Preventive Maintenance Machine: Rotary Cambering Machine Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ADocument2 pagesChecklist For Preventive Maintenance Machine: Rotary Cambering Machine Machine Code: Frequency: Monthly / Quarterly / Annually Checks M Q ASanjay Malhotra100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Eita Elevators General Function GuideDocument6 pagesEita Elevators General Function GuideLewKarKeong100% (1)

- Presentation On MSA by TS16949 Auditors From UL IndiaDocument16 pagesPresentation On MSA by TS16949 Auditors From UL IndiaJetesh DevgunNo ratings yet

- TQMDocument42 pagesTQMJetesh Devgun0% (1)

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocument15 pagesB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoNo ratings yet

- Maintenance of Plastics Processing & Testing Machinery Unit 1Document41 pagesMaintenance of Plastics Processing & Testing Machinery Unit 1Mohsin Alam100% (5)

- Cat Compact Start Up and Commissioning ChecklistDocument19 pagesCat Compact Start Up and Commissioning ChecklistAnonymous aufoLkcwhZ100% (1)

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

- Applied Mechanics SopDocument2 pagesApplied Mechanics Sopneerajmohanvp100% (3)

- Ti Nspire CX Cas If97 DocuDocument23 pagesTi Nspire CX Cas If97 DocuJohan GalloNo ratings yet

- Target ISO Cleanliness CodesDocument0 pagesTarget ISO Cleanliness CodesRaghavendra DeshpandeNo ratings yet

- 2010 - Real Time SimulationDocument23 pages2010 - Real Time SimulationpaufrioNo ratings yet

- Machine Condition Report WA700-1: United Tractors TBKDocument24 pagesMachine Condition Report WA700-1: United Tractors TBKhandoyoNo ratings yet

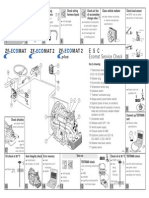

- Esc-Ecomat Service Check: Key To DrawingDocument2 pagesEsc-Ecomat Service Check: Key To DrawingCarlosNo ratings yet

- BMGS1740 ContainerizedDocument4 pagesBMGS1740 ContainerizedDimas KurniadiNo ratings yet

- SAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil SystemDocument3 pagesSAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil Systemবিপ্লব পালNo ratings yet

- Inspección Equipo BM 2000 2200 - 2013 - enDocument3 pagesInspección Equipo BM 2000 2200 - 2013 - enCesarNo ratings yet

- CustomerDocument3 pagesCustomerKumar RajadhyakshNo ratings yet

- F-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuideDocument1 pageF-Super Duty/Excursion 2004 - Early Build 6.0L Power Stroke Diesel Engine Performance Diagnostic GuidevixentdNo ratings yet

- 2006trans13 CDocument26 pages2006trans13 Ceurospeed2No ratings yet

- Maintenance Checklist: Macan/S/GTS/Turbo (2015-On)Document2 pagesMaintenance Checklist: Macan/S/GTS/Turbo (2015-On)edk34100% (1)

- 2006 File 7Document22 pages2006 File 7eurospeed2No ratings yet

- 60 - HPHT ChecklistsDocument8 pages60 - HPHT Checklistsgplese0No ratings yet

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- CPDocument26 pagesCPAhmed Khalid RasheedNo ratings yet

- Control Plan Extrusion of Tyre TreadsDocument4 pagesControl Plan Extrusion of Tyre TreadsChetan MetkarNo ratings yet

- Smart ExDocument6 pagesSmart ExekoyonatanNo ratings yet

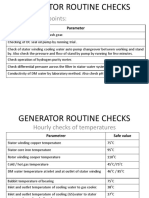

- Generator Routine ChecksDocument5 pagesGenerator Routine ChecksankitNo ratings yet

- PS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Document19 pagesPS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Fatra JuliandNo ratings yet

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- VMC ChecklistDocument5 pagesVMC Checklistprojects.fameautoNo ratings yet

- Nema Frame Motors (17-Samss-503) Pages (1-3) : Saudi Aramco Pre-Commissioning FormDocument13 pagesNema Frame Motors (17-Samss-503) Pages (1-3) : Saudi Aramco Pre-Commissioning FormHaleem Ur Rashid Bangash100% (1)

- Satr B 4001Document3 pagesSatr B 4001mahdi_gNo ratings yet

- GeneratorDocument35 pagesGeneratorUmair BeygNo ratings yet

- Maintenance Intervals (16-2523C)Document4 pagesMaintenance Intervals (16-2523C)HassanSadiq100% (1)

- Lubricant Analysis Report: Missing InformationDocument3 pagesLubricant Analysis Report: Missing InformationRaúl GarcíaNo ratings yet

- R1600G LHDDocument53 pagesR1600G LHDIvan ColqueNo ratings yet

- Furnace Cleaning Rev 1Document1 pageFurnace Cleaning Rev 1Jetesh DevgunNo ratings yet

- Shishu Niketan Model Sr. Sec. School: Sector 22-D, ChandigarhDocument1 pageShishu Niketan Model Sr. Sec. School: Sector 22-D, ChandigarhJetesh DevgunNo ratings yet

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartDocument33 pagesIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunNo ratings yet

- Worksheet in SQ Checksheet Part1Document50 pagesWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- Ticket: Terms & ConditionsDocument1 pageTicket: Terms & ConditionsJetesh DevgunNo ratings yet

- Date Sheet Dec 2015 PDFDocument126 pagesDate Sheet Dec 2015 PDFamandeep651No ratings yet

- Terms Conditions For Apy FinalDocument3 pagesTerms Conditions For Apy FinalJetesh DevgunNo ratings yet

- REVISION Master - GM Customer Specifics - Rev141212 - FINALDocument34 pagesREVISION Master - GM Customer Specifics - Rev141212 - FINALJetesh DevgunNo ratings yet

- Site Assessment HandbookDocument18 pagesSite Assessment HandbookJetesh DevgunNo ratings yet

- Presentation On 7 Tools of Q.C.Document25 pagesPresentation On 7 Tools of Q.C.Jetesh DevgunNo ratings yet

- 17-11-2015 M Tech Cse 2015Document21 pages17-11-2015 M Tech Cse 2015Jetesh DevgunNo ratings yet

- Process CapabilityDocument18 pagesProcess CapabilitysigmasundarNo ratings yet

- Software Engineering Projects in Distant TeachingDocument8 pagesSoftware Engineering Projects in Distant TeachingJetesh DevgunNo ratings yet

- BrochureDocument1 pageBrochureJetesh DevgunNo ratings yet

- ISO TS 16949 2009 ChangesDocument9 pagesISO TS 16949 2009 ChangesfolorNo ratings yet

- Detailed Advt CWE Clerks VDocument33 pagesDetailed Advt CWE Clerks VRahul SoniNo ratings yet

- LL VNT.F,) SCRNF - L I: No.: " NoDocument2 pagesLL VNT.F,) SCRNF - L I: No.: " NoJetesh DevgunNo ratings yet

- MITC July4Document7 pagesMITC July4Jetesh DevgunNo ratings yet

- It's Time To Take A Smart Step!Document2 pagesIt's Time To Take A Smart Step!Jetesh DevgunNo ratings yet

- Software Engineering Projects in Distant TeachingDocument8 pagesSoftware Engineering Projects in Distant TeachingJetesh DevgunNo ratings yet

- SynopsisDocument15 pagesSynopsisMeenu ChauhanNo ratings yet

- Home Policy WordingsDocument10 pagesHome Policy WordingsJetesh DevgunNo ratings yet

- SCRCyberReceipt13 09 2015Document1 pageSCRCyberReceipt13 09 2015Jetesh DevgunNo ratings yet

- TATA GarageList (Updated 16.07.2013)Document768 pagesTATA GarageList (Updated 16.07.2013)Jetesh DevgunNo ratings yet

- PPAP File - 1-Ilovepdf-Compressed.2Document1 pagePPAP File - 1-Ilovepdf-Compressed.2Jetesh DevgunNo ratings yet

- It's Time To Take A Smart Step!Document2 pagesIt's Time To Take A Smart Step!Jetesh DevgunNo ratings yet

- Hydraulic Jet PumpDocument3 pagesHydraulic Jet Pumpvictor javier nuñezNo ratings yet

- Thermal Conductivity Using Searle's ApparatusDocument10 pagesThermal Conductivity Using Searle's ApparatusShlôkä Jõshï86% (7)

- Relative AccelerationDocument3 pagesRelative AccelerationJanaka PriyalalNo ratings yet

- W 1000064Document24 pagesW 1000064Adrian RodriguesNo ratings yet

- BHFQ22P1517 ImDocument14 pagesBHFQ22P1517 ImAlberto Bravo SánchezNo ratings yet

- Prestressed Concrete Assignment TU DelftDocument4 pagesPrestressed Concrete Assignment TU DelfttimsykiNo ratings yet

- Product Sheet 2002-2111 DN32-DN350Document2 pagesProduct Sheet 2002-2111 DN32-DN350Justin ReyesNo ratings yet

- Vibration Testing Theory and PracticeDocument31 pagesVibration Testing Theory and PracticeDilara Çınarel0% (3)

- Royal Military College of Science - Cranfield University: ReliabilityDocument4 pagesRoyal Military College of Science - Cranfield University: ReliabilitySanjay MehrishiNo ratings yet

- EXPERIMENTDocument4 pagesEXPERIMENTBholenath BhaktNo ratings yet

- Numerical Modelling and Computation Methods of Concrete Face Rockfill DamDocument2 pagesNumerical Modelling and Computation Methods of Concrete Face Rockfill DamTony ChanNo ratings yet

- 2008 Carter 12Document38 pages2008 Carter 12PiousNo ratings yet

- Double Wall Corrugated Pipes (DWC) HDPE PipesDocument15 pagesDouble Wall Corrugated Pipes (DWC) HDPE Pipesdesign teamNo ratings yet

- Ficha Cat Excavadorahidraulica 324DLDocument32 pagesFicha Cat Excavadorahidraulica 324DLAnthony Arturo Mestiza SalinasNo ratings yet

- CWCH4IN Instal Manual WebDocument39 pagesCWCH4IN Instal Manual WebEnrique ScibiliaNo ratings yet

- 19 Series - Safety Valve: Installation, Operation, & MaintenanceDocument6 pages19 Series - Safety Valve: Installation, Operation, & MaintenanceADAN CESSANo ratings yet

- Fluid Mechanics 3 - 4: Incompressible Potential FlowsDocument28 pagesFluid Mechanics 3 - 4: Incompressible Potential FlowsDrEmadEl-SaidNo ratings yet