Professional Documents

Culture Documents

FP e Article 20 Nov 2003

Uploaded by

mmsaleem19670 ratings0% found this document useful (0 votes)

12 views0 pagesvv vbbvb

Original Title

Fp e Article 20 Nov 2003

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentvv vbbvb

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views0 pagesFP e Article 20 Nov 2003

Uploaded by

mmsaleem1967vv vbbvb

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

Federal Pacific Panels Page 1 of 7

FPE Panels Hazard or Hype?

by Douglas Hansen

This article focuses on the controversy over

inspecting and reporting Federal Pacific

panels. It has been published in the maga-

zine for the California Real Estate Inspec-

tion Association and in other technical jour-

nals.

FPE Panels Hazard or Hype?

Federal Electric later known as Federal

Pacific Electric (FPE) was a popular

manufacturer of panels and breakers from

the mid-1950s until the early 1980s. Based

in New Jersey, their products were very

popular throughout the counry, and some

communities have FPE panels in almost

every home. For years, stories have circu-

lated about the hazards and defects unique

to this equipment, and the darker rumors

include tales of product recalls, fraudulent

manufacturing, and house fires resulting

from failed breakers. Inspectors and electri-

cians share tales of breakers falling out of

panels when the deadfront is removed, or

breakers failing to shut off when the handle

is operated. Home inspectors need the facts

so they can present their clients with accu-

rate information on which to base a decision

on accepting or replacing FPE panels.

Problems with FPE panels can be broken

down into 3 basic categories: First, there is

the simple fact that the equipment is old,

and manufactured to less stringent codes

and standards than modern equipment.

Electrical equipment is not something that

improves with age or use. Second, there

are problems unique to the design of the

FPE Stablok breakers, problems that are

not found in other equipment this age.

Third, there are issues of manufacturing

defects and circuit breaker failures. This last

issue causes the greatest concern; what

good is a circuit breaker that wont trip when

overloaded or shorted? What good is a

breaker that doesnt de-energize the circuit

when the handle is tripped?

Older isnt Better

Several of the problems found with FPE

panels are found in other brands of equip-

ment of the same age. There is less gutter

space in the panel than we find in modern

equipment. The result is crowding of the

wires in the panels. It is sometimes impos-

sible to see all of the terminals in an FPE

panel. The space for bending wires is also

less than required in modern panels. The

rules that proscribe minimum wire bending

space are found in the National Electrical

Code (NEC) in section 312.6 in the 2002

edition. Over the years, the required mini-

mum space has i ncreased, with the most

significant changes in the 1981 NEC, near

the very end of the days when FPE panels

were made. FPE manufactured some pan-

els with less clearance than the minimum

code rules by installing the lugs at an angle,

so the conductor was already parallel to the

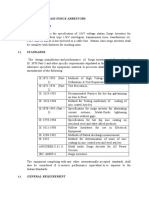

wall opposite the breaker terminal (figure 1).

However, the bends shown in figure 1 de-

feat the purpose of the angled lugs, and the

wire is bent too sharply.

Figure 1 Insufficient wire bending space

Federal Pacific Panels Page 2 of 7

The bus bars on several of the FPE models

were set on springs, with a depth adjust-

ment that enabled the position of the break-

ers to be moved forward or backward. For a

recessed panel, this feature allowed the

breakers to be brought out flush to the

deadfront cover even if the panel set too far

back into the wall. The code today does not

allow this, and states that bus bars must be

rigidly mounted (section 408.31). Rigid

mounting prevents the entire bus from mov-

ing when a single breaker handle is oper-

ated. Another problem with spring-mounted

bus bars is that the breakers sometimes

push against the deadfront cover, creating a

danger to the inspector when they remove

and put back the deadfront cover.

Since the 1984 edition of the NEC, breakers

that operate with their handles in a vertical

position must be on when in the up position,

and off in the down position. Prior to that

time, several manufacturers made equip-

ment such as that seen in figure 2, with a

row of breakers that was on when down and

off when up. The word on when upside

down is no. Inspectors encountering such

equipment might want to warn their clients

that these FPE breakers are on when facing

the outer edge of the panel, and off when

facing the center of the panel. It can be very

difficult to remove these covers without ac-

cidentally tripping a breaker.

Figure 2 Breakers that are on when down

Prior to 1984, many manufacturers offered

split bus panels for residential use, such

as the panel in figure 3. These panels have

no main breaker. They do meet the rule re-

quiring no more than 6 disconnects, and

one of these disconnects feeds a separate

bus that typically contains the 15 and 20

amp 120 volt circuits. The advantages of a

split bus panel were purely economic. If the

largest breaker was the one feeding the

secondary bus, and it was rated at 50 amps,

it cost less than a single main 100 amp

breaker. In addition to the six disconnects

rule for service equipment, another rule also

applies to panels that are categorized as

lighting and appliance panels. These are

panels where more than 10% of the break-

ers are rated 30 amps or less and serve cir-

cuits with neutrals. These lighting and appli-

ance panels must be capable of having their

power disconnected by not more than 2

hand movements. Until 1984, the code ex-

empted these panels from the two-

disconnects rule when they served as resi-

dential service equipment. Today, the code

allows them to remain when they are exist-

ing service equipment, though it would not

allow a new installation of such a panel.

Figure 3 Split Bus Panel

Federal Pacific Panels Page 3 of 7

The panel in Figure 3 has 5 breakers at the

top. The 3 on the left control a water heater,

clothes dryer, and electric space heater.

The top right breaker controls the

range/oven circuit, and the one just below it

controls the lower bus section, with all the

lighting and appliance circuits. The wires

from this breaker to the lower bus section

are the sign that this is a split bus panel.

There are at least 5 design issues that are

no longer allowed by code; the gutter space,

the wire bending space, spring-mounted

bus, breakers that are on when down, and

the split bus service equipment. These is-

sues mean that a panel that has been sitting

on the hardware store shelf for 20 years

would not meet todays code, despite the

UL listing of the panel at the time it was

manufactured. Another even greater con-

cern is that older breakers of any brand

do not become more reliable with age. The

internal mechanical components can be-

come corroded or distorted, and the springs,

hinges, and levers inside the breaker might

not operate as designed after sufficient pas-

sage of time. Most breaker manufacturers

guarantee their products for only a year,

and for valuation purposes breakers are

considered fully depreciated after 15 years.

Figure 4 Overcrowded FPE panel with

wires obscuring terminals, neutral bar, and

bonding jumper. If the wires press against

the deadfront, it may pop out and trip the

breaker handles as soon as the panel

screws are removed.

The Unique FPE Design

Inspectors might find that their first problem

with FPE is the difficulty in removing the

deadfront cover without tripping the break-

ers. Several models of FPE panels have

breakers that are on when the handle is po-

sitioned toward the outside of the panels.

The handles stick out slightly over the dead-

front, past the twist-out opening for the

breaker. To remove the cover, it is neces-

sary to first lift it slightly away from the

panel, then slide it under the handles of one

row while lifting the cover off the other row.

If an inspector pulls the cover straight off, it

is likely that some of the breakers will acci-

dentally trip. The panels in figures 2, 3, and

4 have this problem.

Figure 5 Scorched Bus Bar

Most plug-in circuit breakers have a set of

jaws that fit over a bus bar, bringing the

metal of the jaw into a parallel position to

the bus bar. The FPE Stablok design is the

opposite; the breakers have a set of prongs

that are inserted into a slot in the bus bars

(figures 5 8). The result is a connection

between two pieces of metal that are at right

angles to each other, only touching at their

edges. One of the common FPE problems

is to find the breakers loose in the bus bars.

Good electrical connections require contact

pressure. If the FPE stab only touches one

edge of the opening in the bus, the lack of

contact pressure and the small contact area

will combine to produce arcing and over-

heating. If you remove the breakers from

the panel, it is not uncommon to find scorch

marks on FPE bus bars, as in figure 5.

Federal Pacific Panels Page 4 of 7

E-type Wafer Breaker

E-type Wafer Breaker

F-type Full Size Breaker F-type Full Size Breaker

Double E-type Breaker

Double E-type Breaker

Figure 6 E and F Breakers

Most panels accept two different sizes of

breakers full size and half size, or wafer

breakers. By using the half-size breakers,

the number of circuits in the panel can be

doubled. Because more circuit breakers and

more connected load will increase the heat

on the bus bars, manufacturers must install

some physical means of limiting the number

of breakers that can be installed in the

panel. Panels with an inherent limitation on

the number of breakers are referred to by

UL as Class CTL panels, and the breakers

that go into them will also be categorized as

Class CTL. Most panels can be completely

filled with wafer breakers without exceeding

the limits set by the UL standard, which as-

sumes 10 amps of load per breaker pole per

leg. By this formula, a 100 amp panel usu-

ally has a total of 20 bus stabs. An example

of something that is a half size breaker, and

not class CTL, would be certain models of

Square D piggyback breakers.

FPE found a unique way of designing their

wafer breakers and creating a limitation on

the number of them that could fit in a CTL

panel. Full size breakers have a stab that is

perpendicular to the direction the breaker

handle operates, and wafer breakers have a

stab parallel to the direction of the breaker

handle. The full size breakers stabs are re-

ferred to as F type, and the wafer breakers

as E stabs (figures 6&7). FPE has two dif-

ferent styles of bus opening. An E type

opening will allow either two E type break-

ers or one F type. An F type opening will

only allow one breaker, of either type. The

number of breakers that can fit in the panel

can therefore be limited by installing F

type openings, instead of E openings.

Figure 7 E & F bus slots

The problem with this arrangement is that

the E breaker stabs can be bent over and

jammed into an F socket, and the result is

another poor connection, as well as an

overcrowded panel. Figure 7 illustrates this

condition.

Federal Pacific Panels Page 5 of 7

Figure 8 Damaged E type breaker

Not only do E breakers make poor con-

nection to F sockets, forcing them into the

socket can damage them. The breaker may

split when shoved into the slot, with the bus

stab receding inside the breaker (figure 7).

Since it is now making a very loose contact

to the bus, the breaker might fall right out

when the deadfront cover is removed (figure

9). Inspectors can be forewarned of this

condition before taking off the cover. Simply

look at the label for the panel to see where

the E slots are located and whether any

E breakers have been inserted into F

slots. When finding that situation, there is no

need to remove the cover to know that the

breaker is in the wrong position.

Figure 9 Loose breaker

If a home inspector points out the hazards

of FPE breakers, there is a possibility they

will be contradicted by an electrician who

says he didnt see any problem in the panel.

However, if they havent taken the breakers

out of the panel, they havent really in-

spected it. While it is beyond the scope of a

home inspection for an inspector to remove

the breakers, an electrician could not make

the same claim. They cannot possibly know

if the bus is scorched or the breakers over-

heated unless they pull the breakers out

and look. Breakers burn out from the back

toward the front, not the other way around.

Product Defects

The Federal Pacific Electric company was

headquartered in New Jersey, and was ac-

quired by Reliance Electric Company in

1979. A 1982 financial statement from Reli-

ance indicated that they had learned that

previous UL listings on FPE products had

been obtained by deceptive means and

that as a result, most of the circuit protec-

tive products manufactured by Federal Pa-

cific, at some point thereafter, lost their UL

listing. Reliance claimed that the deceptive

practices ceased after their acquisition, and

asked the Consumer Product Safety Com-

mission (CPSC) to investigate. The CPSC

performed their own tests on FPE breakers,

and Reliance also hired their own inde-

pendent testing company. Additionally, Re-

liance initially stated that their own in-house

testing alerted them to potential problems

with 2-pole circuit breakers. Shortly after

these actions, the manufacture of FPE

Stablok breakers under that name ceased,

and for a time the breakers were manufac-

tured under the Challenger name. Mean-

while, lawsuits were initiated between the

purchasers and sellers of the prior company

in its various business manifestations.

A company acquires a UL listing for its

product, along with the right to use the UL

insignia, by two basic steps. First, the

manufacturer submits the product to UL for

testing to a known standard of safety (for

circuit breakers, the standard is UL 489). UL

then tests the product against the foresee-

able hazards outlined in the standard of

safety.

Federal Pacific Panels Page 6 of 7

The second step is for the manufacturer to

allow unannounced field inspections from

UL representatives to assure that the prod-

uct is still being manufactured to the same

specifications as those submitted for testing.

Rather than repeating rumors about what

may have occurred that constituted obtain-

ing the listing by deceptive means, the test

results themselves are the next item to ex-

amine.

The CPSC documents show the results

from testing 122 2-pole breakers in 1982.

The breakers were obtained directly from

FPE as well as some that were purchased

retail or taken from existing installations.

The failure rate was higher after mechanical

operations of the breakers, which seems

contradictory to the recommendation that

many inspectors make that breakers should

be routinely operated to prevent them from

freezing in place. Under UL 489 test con-

ditions, the rate of failure to trip greatly ex-

ceeded the tolerances allowed by the stan-

dard. The full document showing the CPSC

results is posted at the web site maintained

by Dan Friedman (see below). At the same

time the CPSC tests were performed, Reli-

ance conducted their own testing, and dis-

agreed with the results from the CPSC.

They claimed a lower failure rate than the

CPSC test results.

Considering that there was such a high fail-

ure rate in the CPSC tests, why were they

not recalled? The answer, as with most

such considerations, is tied up with the eco-

nomics of the situation. The CPSC stated

that they had insufficient data to accept or

refute the claims from Reliance, and that it

would cost several million dollars to conduct

the necessary studies to determine if a re-

call was warranted. Their budget for 1983

was only 34 million, and they simply did not

have the funds to pursue the issue. FPE

was one of the most popular products of its

time, and it is not the only old product that

would merit such attention if we lived in a

perfect world.

FPE also is not without its defenders. A 2-

page letter in the May/June 1999 issue of

IAIE News, the magazine of the Interna-

tional Association of Electrical Inspectors,

defended FPE breakers. The article claimed

that all listings of FPE equipment were valid,

and that home inspectors calling the equip-

ment hazardous were making unsupported

recommendations.

One of the major sources of information on

FPE failures, with documentation in the form

of stories from the field and photographs of

fires associated with FPE, is the web site

maintained by Dan Friedman, at

www.inspect-ny/fpe/fpepanel.htm. When we

look at documentation on this subject, it is

important to consider the source. Mr.

Friedman has no economic interest in the

FPE controversy, though he does have a

long history of consumer advocacy. The let-

ter defending FPE was published anony-

mously, with the author only being identified

as the former quality manager of FPE.

Replacement Breakers

If the breakers themselves are the problem,

should homeowners consider replacing the

breakers and keeping the panel? At various

times over the last 2 decades, different

manufacturers have made after-market

products designed to fit FPE panels. In

some cases, these breakers have been

made in Canada, Mexico, or China. Sal-

vaged old FPE breakers are also available

from specialty dealers. The breakers sold

under the American brand (figure 10) are

no longer UL listed, though they are listed

by ETL, another nationally recognized test-

ing laboratory. In all cases, replacement

breakers are very expensive, with a single-

pole 15 amp breaker costing as much as

$50. If one wanted to replace all the break-

ers in a panel, they could spend a great

deal more than it would cost to replace the

panel with modern listed equipment.

Federal Pacific Panels Page 7 of 7

Figure 10 Replacement Stablok breaker

Another consideration is the desire to install

GFCI or AFCI breakers. GFCI breakers can

sometimes be found in the specialty supply

houses, and they are very expensive. Since

GFCI protection can also be provided by

receptacle outlets and other feed-through

devices, the lack of available GFCI breakers

is not a major issue. As of this writing, no

listed AFCI breakers are available for FPE

panels.

In Canada, a similar product, under the

name Federal Pioneer is still available.

They are a subsidiary of the parent com-

pany of Square D. Their web site did not

include information on whether there is a

third-party listing for the breakers, and they

are limited to the Canadian market. Their

site is

http://www.schneider-

electric.ca/www/txt/products/stab-

lok/html/cb.htm.

The Canadian company does make an

AFCI breaker, though without an American

third-party listing it would not be practical to

install them in an old FPE panel. Federal

Pioneer did issue a recall of circuit breakers

manufactured between August 1, 1996 and

June 11, 1997. In the words of the manufac-

turer In some circumstances these break-

ers may not trip.

The Home Inspectors Dilemna

Given this set of facts, what can inspectors

say to their clients? In general, product de-

fects and recalls are beyond the scope of a

home inspection. Even if the CPSC were to

request a recall of the product, such infor-

mation would exceed the minimum standard

of care for a home inspector. However,

home inspectors who say nothing about it

could find themselves with angry clients

who wish that something had been said. If a

purchaser calls an electrical contractor, and

the contractor refuses to work on the sys-

tem because it has an FPE panel, the cli-

ents could well blame the home inspector. I

personally was not a believer until I wit-

nessed a multiple failure of FPE breakers in

a dead short. The branch circuit breaker,

the feeder to the subpanel, and the main

breaker all failed to open while a dead short

carrying thousands of amps ran through the

breakers. Those of us conducting the ex-

periment heard a violent shaking that nearly

tore the panel out of the wall, and the ser-

vice wires whipped in the air from the mag-

netic fields created by the high currents go-

ing through the breakers. That experience

was convincing. I continue to hear stories

from the field, and Dan Friedman is always

adding new ones to the web site.

I suggest that inspectors at least tell their

clients that there is widespread information

on defects with this product, and refer them

to the CPSC data and other information on

Dan Friedmans web site.

Thanks to Jay Balin for his editorial assis-

tance, and to Mark Cramer for his usual

keen perspective and for figure 5. Thanks to

John McComas and Alan Block for bringing

this safety issue to our attention. Portions of

this article are taken from Electrical Inspec-

tion of Existing Dwellings, by Douglas Han-

sen, Redwood Kardon, and Michael Casey.

You might also like

- RootCauseAnalysis of Machine Stator Failures Electric MotorsDocument13 pagesRootCauseAnalysis of Machine Stator Failures Electric MotorsJAVIER ARTURO CORREA LOAIZANo ratings yet

- Alternator ProblemsDocument8 pagesAlternator ProblemskellechaiNo ratings yet

- AlternatorDocument16 pagesAlternatorjeevapillay100% (1)

- Problems With Modern Air-Cooled Generator STATOR WINDING INSULATIONDocument8 pagesProblems With Modern Air-Cooled Generator STATOR WINDING INSULATIONBasu Deo BhomiaNo ratings yet

- Standard Operating Procedure - HT Panel - V01 - 022.04.2011Document5 pagesStandard Operating Procedure - HT Panel - V01 - 022.04.2011Karthik Mandya100% (1)

- Generator LiteratureDocument10 pagesGenerator LiteratureHetal LakhaniNo ratings yet

- Basic Residential Electrical Wiring Circuits Rough in and Codes GuideDocument10 pagesBasic Residential Electrical Wiring Circuits Rough in and Codes Guidejohnnywalker2000No ratings yet

- How To Replace C52 KefDocument7 pagesHow To Replace C52 KefSheena CotterillNo ratings yet

- Corona Protection in Rotating High Voltage MachinesDocument6 pagesCorona Protection in Rotating High Voltage MachinesLaplaceFourier100% (1)

- Biblio MotorsDocument11 pagesBiblio MotorsMuhammad KaleemNo ratings yet

- Biblio MotorsDocument11 pagesBiblio MotorsMuhammad KaleemNo ratings yet

- Preventing Failures in Isolated Phase Bus TimperleyDocument48 pagesPreventing Failures in Isolated Phase Bus TimperleyMagoroku D. YudhoNo ratings yet

- Premature Failure of Modern GeneratorsDocument8 pagesPremature Failure of Modern GeneratorsSelva ManianNo ratings yet

- Bushing Failures in Medium VoltageDocument4 pagesBushing Failures in Medium VoltageDunstan AmaratungaNo ratings yet

- Ćuk ConverterDocument4 pagesĆuk ConverterSuneet Kumar RathNo ratings yet

- Electronic Components: Symbols & FunctionsDocument6 pagesElectronic Components: Symbols & FunctionsAlexander San Juan92% (113)

- Examples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsDocument4 pagesExamples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsstarkopeteNo ratings yet

- SEW MDX Inverter Operating InstructionsDocument232 pagesSEW MDX Inverter Operating InstructionsIker BasqueadventureNo ratings yet

- Chapter 3Document19 pagesChapter 3Mei QiiNo ratings yet

- Causes of Cable FailuresDocument14 pagesCauses of Cable FailuresDenzil D'SouzaNo ratings yet

- Failure of Modern GeneratorsDocument6 pagesFailure of Modern GeneratorsJose Calvo100% (1)

- Earthing (Grounding) and Bonding Guidelines For Uniprise Solutions F/UTP Cabling SystemDocument11 pagesEarthing (Grounding) and Bonding Guidelines For Uniprise Solutions F/UTP Cabling Systemcharleselitb92No ratings yet

- Failure of MV CablesDocument5 pagesFailure of MV CablesselvamNo ratings yet

- Electrical System Upgrade Ground Training: TCTO 1C-130-1339Document33 pagesElectrical System Upgrade Ground Training: TCTO 1C-130-1339Djiby TouréNo ratings yet

- Top Five Causes of Switchgear FailureDocument3 pagesTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- IEEE Standard 142 - Foundation For GroundingDocument4 pagesIEEE Standard 142 - Foundation For GroundingrajuanthatiNo ratings yet

- Electrical: Er Transit Service ManualDocument76 pagesElectrical: Er Transit Service ManualArmando HernandezNo ratings yet

- Progress Report On Failures of High Voltage Bushings With Draw LeadsDocument16 pagesProgress Report On Failures of High Voltage Bushings With Draw Leads'Suazo StreetboyNo ratings yet

- Edium-Voltage Able Accessories: Special FeatureDocument5 pagesEdium-Voltage Able Accessories: Special FeatureMohamedHussein MohamedHusseinNo ratings yet

- 17 electricalOKservmanDocument78 pages17 electricalOKservmaninge dieselNo ratings yet

- The Zl2bmi DSB Transceiver Introduction 2Document9 pagesThe Zl2bmi DSB Transceiver Introduction 2jlnlimaNo ratings yet

- Alewine Wind Turbine Generator Failure ModesDocument5 pagesAlewine Wind Turbine Generator Failure ModesKevin AlewineNo ratings yet

- Bushing Failures in Medium Voltage Switchgear - Coetzee Van HeerdenDocument16 pagesBushing Failures in Medium Voltage Switchgear - Coetzee Van HeerdenJorge CáceresNo ratings yet

- Screened SUBCAB Cable Connection Recommendations and EMC Guideline PDFDocument12 pagesScreened SUBCAB Cable Connection Recommendations and EMC Guideline PDFEduardo Mendoza SanchezNo ratings yet

- A Fish Tape Is Used To Pull Stranded or Solid Wire Through Metal or PVC ConduitDocument23 pagesA Fish Tape Is Used To Pull Stranded or Solid Wire Through Metal or PVC ConduitthewhiteeagleNo ratings yet

- Multi Battery Isolator InstructionsDocument4 pagesMulti Battery Isolator InstructionsBrian Rice100% (1)

- Maintenance Eps: Febrianto W. U - 2209 100 010Document18 pagesMaintenance Eps: Febrianto W. U - 2209 100 010Diogenes HardoriNo ratings yet

- Electrical PanelsDocument4 pagesElectrical PanelsShahin G KhatriNo ratings yet

- Large HV Machine Repair: Repair Options & Rewind Good Practice With Examples of More Unusual RepairsDocument9 pagesLarge HV Machine Repair: Repair Options & Rewind Good Practice With Examples of More Unusual RepairsmersiumNo ratings yet

- Avoiding Common Code Mistakes: John WilesDocument3 pagesAvoiding Common Code Mistakes: John WilesKaher AlyteemNo ratings yet

- Distribution BoardDocument7 pagesDistribution BoardmuralichandrasekarNo ratings yet

- Infra Red Camera LectureDocument9 pagesInfra Red Camera LectureNuru TwahaNo ratings yet

- Reliability Aspects of MV XLPE Cable Joints and TerminationsDocument15 pagesReliability Aspects of MV XLPE Cable Joints and TerminationsAnonymous bau06xStTNo ratings yet

- Heater Fan Switch WorkaroundDocument3 pagesHeater Fan Switch WorkaroundJack MarlowNo ratings yet

- Coaxial Power ConnectorDocument12 pagesCoaxial Power ConnectorSo BorathNo ratings yet

- Transformer Basics To Those Unfamiliar With Transformer Manufacturing, Terms Such As Fish, Kraft, NaturalDocument6 pagesTransformer Basics To Those Unfamiliar With Transformer Manufacturing, Terms Such As Fish, Kraft, NaturalluroguitaNo ratings yet

- Jad AcDocument2 pagesJad AcFrancisco LeonNo ratings yet

- What Will MV Switchgear Look Like in The Future?: by Jean-Marc BiasseDocument16 pagesWhat Will MV Switchgear Look Like in The Future?: by Jean-Marc BiasseMilcov ConstantinNo ratings yet

- HV EarthingDocument3 pagesHV EarthingarunbavaNo ratings yet

- To-92 - Transistor InfoDocument3 pagesTo-92 - Transistor Infod4nk4rNo ratings yet

- TransformerDocument8 pagesTransformersbpathiNo ratings yet

- The Zl2bmi DSB Transceiver Introduction 2Document9 pagesThe Zl2bmi DSB Transceiver Introduction 2NickEglezosNo ratings yet

- Electromagnetic Compatibility (EMC) and Variable Speed DrivesDocument2 pagesElectromagnetic Compatibility (EMC) and Variable Speed Drivessopan saNo ratings yet

- Cable SelectionDocument8 pagesCable SelectionaramirezbenitesNo ratings yet

- Begin With The End in Mind - Proper VFD Cable Termination PDFDocument4 pagesBegin With The End in Mind - Proper VFD Cable Termination PDFGauravNo ratings yet

- Frequently Asked Questions (Faqs)Document16 pagesFrequently Asked Questions (Faqs)Pamela BradleyNo ratings yet

- Quiet Down FCC Emissions-1Document6 pagesQuiet Down FCC Emissions-1oflorez72No ratings yet

- Ugly ConstructionDocument14 pagesUgly ConstructionRudik WidNo ratings yet

- Fc-s8 Designing With Planar Ferrite CoresDocument12 pagesFc-s8 Designing With Planar Ferrite CoresemilfrancuNo ratings yet

- Firefly PCB Guide 8Document16 pagesFirefly PCB Guide 8Renier Orlando BlancoNo ratings yet

- Under Floor Trunking SystemsDocument218 pagesUnder Floor Trunking SystemsChia Woon LimNo ratings yet

- Molex ConnectorDocument5 pagesMolex Connectorcarlosxxx1234No ratings yet

- 450 Watt 6m Amplifier: Chris, G3WOS - July 1993Document10 pages450 Watt 6m Amplifier: Chris, G3WOS - July 1993Adrian DrakesNo ratings yet

- FT-817 Mods: Battery Mod For ft-817Document43 pagesFT-817 Mods: Battery Mod For ft-817Arturo MejiaNo ratings yet

- SECTION 16160 PanelboardsDocument7 pagesSECTION 16160 Panelboardsno nameNo ratings yet

- Requirements ModelingDocument70 pagesRequirements ModelingMuhammad KaleemNo ratings yet

- Agent Networks FullDocument25 pagesAgent Networks FullMuhammad KaleemNo ratings yet

- Soap 2Document79 pagesSoap 2Asesh MandalNo ratings yet

- 11Kv Voltage Class Surge ArrestorsDocument16 pages11Kv Voltage Class Surge ArrestorsSandip AhireNo ratings yet

- To Construct A Portable Mobile ChargerDocument5 pagesTo Construct A Portable Mobile ChargerADARSH TECHY PRADHANNo ratings yet

- RMxprt12使用指南Document481 pagesRMxprt12使用指南Latisha CarterNo ratings yet

- 2.electricity Wiring Regulations-807Document139 pages2.electricity Wiring Regulations-807Saleesh PindiyedathNo ratings yet

- Okok Sony - kv-2197m3 - Cxp85220a - Tda8375 - str-6707 - La7830 - Ta8248k PDFDocument13 pagesOkok Sony - kv-2197m3 - Cxp85220a - Tda8375 - str-6707 - La7830 - Ta8248k PDFAloui Zakaria100% (1)

- Ame 55QMDocument4 pagesAme 55QMJaison MacorimNo ratings yet

- Proximity Sensor: Types of Sensor Circuits IR SensorsDocument5 pagesProximity Sensor: Types of Sensor Circuits IR SensorsgobimohanNo ratings yet

- Data Sheet: BZT03 SeriesDocument9 pagesData Sheet: BZT03 Seriesdrain rainNo ratings yet

- Co Sensor - KMD300 - EDocument2 pagesCo Sensor - KMD300 - EArmin IranfarNo ratings yet

- Completo FMF 2023 Vf2 BCDocument180 pagesCompleto FMF 2023 Vf2 BCIván QuirozNo ratings yet

- DatasheetDocument4 pagesDatasheetqwertyuiNo ratings yet

- Smart Power Console Installation Manual - V1.1 (English) PDFDocument2 pagesSmart Power Console Installation Manual - V1.1 (English) PDFAllan Soldevilla Biton100% (1)

- WL005 - WL10: Silicon Bridge Rectifiers WOBDocument3 pagesWL005 - WL10: Silicon Bridge Rectifiers WOBtarpinoNo ratings yet

- Configuration of Transistor Circuit: CB, CE, CC Configuration Input and Output CharacteristicsDocument8 pagesConfiguration of Transistor Circuit: CB, CE, CC Configuration Input and Output CharacteristicsRai SenNo ratings yet

- Ub 8000 PDFDocument2 pagesUb 8000 PDFEduardo PerottiNo ratings yet

- EE6702 PSG Important Question November December 19Document1 pageEE6702 PSG Important Question November December 19WwweeeNo ratings yet

- Fanuc Alpha Ac Servo AlimentationDocument40 pagesFanuc Alpha Ac Servo AlimentationSamuel DaboinNo ratings yet

- MS12 Digital Pressure Switch / Transmitter: ApplicationDocument4 pagesMS12 Digital Pressure Switch / Transmitter: ApplicationOchoa Para La BandaNo ratings yet

- Project: JBM EVCS: Delhi & Mumbai: Equipment/Job Details Remarks Date of Supply Invoice Date of Project CommissioningDocument1 pageProject: JBM EVCS: Delhi & Mumbai: Equipment/Job Details Remarks Date of Supply Invoice Date of Project CommissioningkamaleshsNo ratings yet

- Three Phase Synchronous MachinesDocument14 pagesThree Phase Synchronous MachinesMohdFirdausNo ratings yet

- Qse 93af600 DataDocument9 pagesQse 93af600 DataPutraAdityaNo ratings yet

- CCSD ExuDocument3 pagesCCSD ExurahulNo ratings yet

- Manual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El SotanoDocument3 pagesManual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El Sotanodiego rotpeNo ratings yet

- 6.101 Analog Electronics Final Project Report Variable Power SupplyDocument28 pages6.101 Analog Electronics Final Project Report Variable Power SupplyDavid PredovanNo ratings yet