Professional Documents

Culture Documents

Beltconv (1) - Is11592

Beltconv (1) - Is11592

Uploaded by

Taha ZiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beltconv (1) - Is11592

Beltconv (1) - Is11592

Uploaded by

Taha ZiaCopyright:

Available Formats

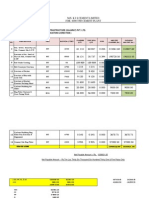

Date: 02nd June 1999 BELT CONVEYOR PROGRAM AS PER IS 11592

1.

DIMENSIONAL DETAILS OF A PROFILE :Calculations of effective tension for following six profiles can be worked out in t is progra!. ". #ori$ontal ii. "nclined

iii.

#ori$ontal % "nclined

iv.

"nclined % #ori$ontal

v.

#ori$ontal& "nclined % #ori$ontal

vi.

"nclined& #ori$ontal % "nclined

"n all t e above profiles& input para!eters suc as centre to centre lengt & lift % inclination 'if applicable(& ave to be entered. )fter receiving t ese inputs& t e progra! will give its output in t e for! of total developed lengt & total lift and inclination 'w atever applicable& respectivel*(. 2. ,-o& +arious options for troug ing angle& used in a progra! are 20 o& ,0o& .-o. /epose angles for various !aterials will be & wit respect to t eir '!aterial( c aracteristics and ence surc arge angle wit respect to repose angle will be as follows :Contd..20-

..2.. )ngle of /epose 0 - 20o o 21 - ,0o ,1o - .0o .1o % 5pwards )ngle of 1urc arge -o 10o 20o ,0o 2 /epose 1urc arge ,0 - ,---20o3 ,- - .0 ---2-o3 ".1. 4ut we ave in t e progra!& su!!ed up t e range in between as ',0o - .0o ---6 20o(

7 ere are six troug ing angles as per ".1.& sited above. 4ut generall* preferred are 20o& ,0o& ,-o % .-o 's all options be placed for all t e six possibilities 8(. ,. 9ow& to decide w et er t e !aterial being conve*ed is si$ed 0 unsi$ed to select t e proper belt widt :-

"f onl* capacit* % lu!p si$e is given& t en referring table back select 4.:. and proceed furt er wit t e elp of 4elt :idt . 1elect 5nsi$e as a Default % 1i$ed can also be selected&if given. e.g. as given below :Belt ( ! Width M"#$ L% & Si'e ( ! (M"#$ 100 1-0 200 2,0 ,,0 ,=0 .,0 -,0 <=0 =00

.00 -00 <00 <-0 =00 900 1000 1200 1.00 1<00

()i*+, Si'e ()-i'e (Si'ed! di e)-i+)! 0 ;0 ;< - 100 101 101 - 121-1 12201 12< - 1=0 2,1 1=1 - 200 ,,1 201 - 2-0 ,=1 2-1 - ,<0 .,1 ,<1 - ,=0 -,1 ,=1 - .10 <=1 -

"f capacit* % lu!psi$e > 190 ?rogra! will select unsi$ed as default i.e. 200 % select t e belt widt <00 !!. as

..,0-

..,.. DETERMINATION OF L(MP SI.E FACTOR /0 CONDITION 1. 2. ,. .. -. lu!p <. @u!p 1i$e @u!p 1i$e L(MP SI.E FACTOR 0 1 2 , .

A 10 !! A 2- !!

Buantit* of largest lu!p A20C of !ax. per!issible lu!p si$e Buantit* of largest lu!p A <0C of !ax. per!issible lu!p si$e 5nsi$ed '@argest lu!p si$e(

!ax. per!issible

1i$ed '@argest lu!p si$e(

!ax. per!issible lu!p

DETERMINATION OF ABRASIVENESS FACTOR /0 9on - )brasive Dildl* - )brasive )brasive +er* )brasive 1 2 , .

1peed factor )brasiveness

>

@u!psi$e

Eactor

Eactor

LIMITATIONS TO MA1IM(M BELT SPEEDS /0 1peed of t e !aterial to be conve*ed& is li!ited b* t e belt widt % seleceted speed factor as follows. "f we enter a speed on ig er side& t e progra! will displa* a !essage of not accepting it. S&eed F"3t+, 1 2 ,-. --< ;-= 455 2.2., 2.0 1.<1..555 2.2., 2.0 1.<1..655 ,.0 2.;2.,= 2.0 1.;BELT WIDT2 ( ! 655 755 955 1555 ,.0 2.;2.,= 2.0 1.;,.,.2 2.;2.,2.0,.,.2 2.;2.,2.0..0 ,.<,.12.<2.,125 5 ....12 ,.-,.0 2.<2 145 5 ....12 ,.-,.0 2.<2 1655 ....12 ,.-,.0 2.<2

.....

...0-

+olu!e bulk densit* 'lower value( is used to c eck capacit* and power densit* 'upper value( to deter!ine t e final power reGuire!ents.+alues of volu!e and power densities& angles of surc arge and repose can be c anged& if reGuried. CAPACITY CALC(LATIONS /0 4asic for!ula for calculating capacit* :Capacit* 'B( 7?# > )rea of Cross 1ection x 4elt 1peed x ,<00 x +ol. bulk densit* x "ncln. Eac '!2( '!0sec( '70!,(

H7

is co!es into picture onl* for conve*ors aving inclination % +alues are provided in t e progra! as per t e grap

in "1-11-92

'?g.1-(I. 7 e !ain t ree para!eters i.e. capacit*& 4elt 1peed and )rea '4elt :idt ( are dependent on eac ot er. )n* of t e two para!eters are known& t ird can be calcuated as per above for!ula. i. ii. iii. I* D"t" 8i9e) i- /0 Capacit* '7?#(& 4elt 1peed '!0sec.( 4elt :idt '!!(& Capacit* '7?#( 4elt :idt '!!(& 4elt 1peed '!0sec.( P,+8," :ill -ele3t Din. 4elt :idt '!!( Din. 4elt 1peed '!0sec.( Dax capacit* '7?#(

Calculations for area of cross-section as per "1-.;;< '?art - "(

: > ) F 10 4& : in !! & in degrees. 1 '!!( > 0.- '4-:( - '0.0- F 2-( / '!!( > 0.- : F 1 Cos 1 7otal )rea ')(> 10-< H1 1in ': F 1 Cos ( F 0.- /2 '2 - 1"9 2 I #ere is in radian i.e. !ultiple b* 01=0 ...-0-

..-.. Jg. 4 > =00 !!& :> ,1- F 10 > ,2- !!& > ,00& > 10 1 > 0.- '=00-,2-( - '0.0- x =00 F 2-( > 1;2.-0 !! / > 0.- x ,2- F 1;2.- Cos ,0( > 1;9<.<0 !! 1in 10 )rea ')(>10-<H1;2.- 1in ,0 ',2-F1;2.- Cos,0( F 0.- '1;9<.<( 2'2x10x 01=0 - 1in 20(I

)rea')( > 0.0-22 ! TABLE FOR W /0

Belt Width ( ! .00 -00 <00 <-0 =00 900 1000 1200 1.00 1<00

A (i$e$ R+lle, Le)8th! ( ! 1<200 2,2-0 ,1,-0 ,=0 .<-,0 <00

1tandard widt

of 4elt are as in !! :.00& -00& <00& <-0& =00& 900& 1000& 1200& 1.00 % 1<00

BELTING SELECTION /0 4elt selection i.e. rating& dut* will be as per Dunlop Catalogue. )s we know belt widt & we will c eck bot for adeGuate load support 'on basis of power densit*( and for adeGuate troug ing of e!pt* belt 'on basis of 7roug ing angle( w ic selects ?ri!ar* 4elt i.e. 4elt rating. ...<0-

...<... 4elt Daxi!u! designation reco!!ended working tension '+ulcanised 1plice( 7*pe Ge)e,"l D%t; /ating 2-002 ,1-0, .000, -000, <,00, <,00. =000. 10000. 12-00. 12-00. 1.0001<0001=000< 2-002 ,1-0, .000, -000, <,00, <,00. =000. Dut* > 'k90 !( 2,1 .0 -0 <, ;0 90 110 1.0 1.0 1-1=0 190 2,1 .0 -0 <, ;0 90 9o!inal carcass t ickness 9o!inal carcass weig t Dax. 4.:. Din. 4.:. '!!( for '!!( for adeGuate adeGuate load support troug ing of 'Dtrl e!pt* belt Densit* 70!,( 5pto 5pto 5pto 20 ,0 .- 1.0 1.- 2.idlers idlers idlers <-0 <00 .-0 .00 .00 .-0 1000 10-0 1200 1200 1.00 1<00 1=00 1=00 1=00 2000 2000 2000 900 1200 1200 1.00 1.00 1=00 1=00 =00 900 900 1000 1200 1.00 1.00 1<00 1=00 1=00 2000 2000 <-0 1000 1000 1200 1200 1.00 1<00 <-0 <-0 =00 =00 900 1000 1200 1.00 1<00 1=00 1=00 2000 -00 =00 =00 900 1000 1200 1.00 .00 -00 -00 -00 -00 -00 -00 <-0 <-0 <-0 =00 =00 .-0 -00 -00 -00 -00 -00 <-0 .-0 -00 -00 -00 -00 -00 <-0 <-0 =00 =00 900 900 .-0 -00 -00 -00 -00 <-0 =00 -00 -00 -00 -00 <-0 <-0 =00 =00 900 900 1000 1000 -00 -00 <00 <00 <-0 =00 900

'!!( 2.1 ,.1 ,., ,.; ,.9 ..9 -.< <.0 <.9 =.0 =.= 9.= 11.9 ,.2 ..2 ... ..; ..9 <.; ;.1

'kg0 !2( 2.1 ,.2 ,.. ,.= ..2 -.2 -.= <.<.9 =., =.= 9.= 11.9 ,.. ....; -.1 -.;.2 ;.;

E#t," D%t;

2e"9; D%t;

Keneral 0 Jxtra 0 #eav*

Eirst we select Keneral Dut*. "f rating is out of range of Keneral Dut*& progra! can go for anot er Dut*. ...;0-

..;.. 9ow to select Cover t ickness& 9irlon Catalogue is referred. :e ave loading C*cle > 2 x Conve*or Developed @engt '!( '1ec( 4elt 1peed '!0sec.( "f t is value lies in between 2 standard value& select lower value of loading c*cle w.r.t. !aterial abrasiveness % lu!p si$e '!!(. 7able gives for top cover t k. '!!( Kenerall* reco!!ended top cover gauge '!!( Daterial abrasiveness 9on-abrasive )brasive +er* abrasive

@oading c*cle '>2@( 2 '1econds(

@u!p si$e '!!(

-1F1 --0 ,.0 2.2.2.0 2.0 2.0 1.1.1.F-0 -1-0 -.0 ..0 ,.0 ,.0 2.2.2.0 2.0 2.0 F10 =.0 <.0 -.0 ..0 ,.0 ,.0 ,.0 ,.0 ,.0

@u!p si$e '!!(

-1,.0 ,.0 2.2.2.0 2.0 2.0 1.1.F1 --0 -.0 -.0 ..0 ..0 ,.0 ,.0 2.2.2.F-0 -1-0 <.0 <.0 -.0 -.0 ..0 ..0 ,.0 ,.0 ,.0 F10 9.=.0 ;.0 <.0 -.0 -.0 -.0 ..0 ..0

@u!p si$e '!!(

-1..0 ,.0 ,.0 2.2.2.0 2.0 2.0 2.0 F1 --0 <.0 <.0 -.0 -.0 ..0 ..0 ,.0 ,.0 ,.0 F-0 -1-0 =.0 =.0 ;.0 ;.0 <.0 <.0 -.0 -.0 ..0 F10 11.0 9.9.=.0 ;.0 ;.0 <.0 <.0 -.0

1,0 .<0 90 120 1=0 2.0 Lver 2.0

2.2.0 1.1.1.1.1.1.1.-

Eor 4otto! cover t ickness w.r.t. !aterial abrasiveness is 9on- abrasive : 1.- !! )brasive : 2 !! +er* )brasive : 2.- !! :e can also enter top0botto! cover t ickness as per reGuire!ent. 9ow& to calculate 4elt !ass :Db > Constant x 'top cover F botto! cover (F9o!inal carcass x 4elt :idt 'Mg.0!( factor t k'!!( t k '!!( :t. 'Mg0! 2( '!!( 1000 ..=0-

..=.. Constant Eactor 7able :Te e &e,"t%, ;120 1=0 200 -G,"de D2. #/ 1#/ 5#/ E/ F"3t+, *+, 3"l3%l"ti)8 <ette, "-1.1 1tandard +alue 1.21 > 10C > 1td. +alue 1.2<- > 1-C > ---N--1.,;- > 2-C > ---N--1.,2 > 20C > ---N---

Dass of !aterial is calculated as Dg 'Mg.0!( > 1000 B + > 4elt speed in !in.0sec. + B > +olu!etric Conv. Capacit* '!,0s( > 'c0s area( ) x +. > +ol. 4ulk densit* of !aterial 't0! ,( Driving Eorce Calculation: ?erip erial force reGuired on driving pulle* 's( 7J > / F /1 F /1? F /1@ used w en inclined conve*or used onl* w en @ A =0!( /> !ain resistance '9( > f.@.g HDc F Dr F '2D 4 F DK( Cos . H5sed onl* for inclined conva*or and"t is o!itted w en A 1=I : ere& f > artificial co-efficient or friction& usuall* 0.0, as a default /ange 0.01< - 0.0,0. "t can be fed !anuall* also. @'!( > conve*or lengt 'distance between centre( g '!0s2( > 9.=0<& )ccn. due to gravit*. Dc 'Mg0!( > Dass of revolving idler parts along carr*ing side of conve*or per !eter. Dr 'Mg0!( > Dass of revolving idler parts along return side of conve*or per !eter. 'Deg.( > )ngle of conve*or fro! ori$ontal line. 1. ...90-

..9.. 2. /s > 1econdar* resistance '9( > /a F /ska F /w F /b : ere /a '9( > B.1000. '+-+o( )ssu! +o > L !0s. 'Ken +o > + x Cos( - "nlet c ute angle wit belt > 90 Eriction resistance between andled !aterial and skirt plate in acceleration area& /ska > 2. B2 .1000 .g .la

(+

0.;

+ +L2 )

b1 2

2 >Co-efficient of friction between !aterial and skirt plate > 0.- to la > )cc lengt at loading area '!( > +2 - +o2

n

(0.< > Default )

2g.1 1 > Co-efficient of friction between !aterial and belt > 0.- to 0.; 0.< > Default b1 '!( > "nter skirt plate widt > 20, 4 'in !( /w'9( - :rap resistance between belt % pulle* '9( - Ero! below table : T"=e0%& 1crew +K7 #K7 P%lle; Ti8ht -ide 2,0 2,0 2,0 Sl"3= Side 1;1;1;Othe, &%lle; R:

1nub F > 1.0 -.1nub F 2 bend F take-up > 9<-<0 1nub F . bend F take-up > 1&2.=.0

/b > ?ulle* bearing resistance '9( > /w02 'assu!e( ,. /1p > 1p. /esistance '9(> /sp1 F /sp2 > /i F /sk F /bc : ere& /i > /esistance due to > g Ci 0 @i '!4 F !K( Cos 1ini idler tilting '9( Ci > 7roug > 0.. upto ,0 troug Eactor > 0.- above ,0 upto .- troug o > Co-efficient of friction between carr*ing idler % belts > 0., to 0.. > 0.,- default ..100-

..10.. @i '!( > @engt of installation eGuipped wit tilted idler > Developed conve*or lengt '!( i > gen 2 - option to be c anged. skirt /sk '9( > /esistance due to friction between andled !aterial and

plates > 22 B la 2. 1000 .g. lsk +2 b12 lsk > lengt of installation eGuipped wit skirt plate excluding la > ', - la('!( x no. of feed points in a conve*or. /bc '9( > Erictional resistance due to belt cleaners. > )1 ? , ? > ?ressure between belt cleaner % belt > , x 10 . to , x 10- 90!2 Default , > 0.< to 0.; between belt % belt cleaner. 0.<- Default. )1 > )rea of contact between belt % belt cleaner '! 2( > .. 10 x 4'!( 1000 F 2 x 10 x 4'!( 1000

/1@ > 1lope resistance in 9 > DK #g - "f conve*or is inclined. # '!( > @ift of conve*or between loading and disc arge end.

"f wrap angle over ead pulle* and ot er pulle* also are not specified& t en t e progra! will select t e following tabulated value. PROFILE NO$

1C/J: '1(

(I!

+K7 '+( #K7 '#( 1

(ii!

+ # 1

(iii!

+ # 1

(i9!

+ #

(9!

1 + # 1

(9i!

+ #

2e"d P%lle; A------------------------------------------1=0 ---------------------------------------6 "$ :>+ A------------------------------------------210 ---------------------------------------6 S)%< <$:ith S)%< S)%< A----------------------,0 Default % '20&,0&.0( options------------------------6 P%lle; Be)d ---90 90 -90 90 90 - 90 90 P%lle; F F F of of of

incln.

incln ..110-

incln

..11.. :rap angles for tail % take-up pulle* will be alwa*s eGual to 1=0 . 71 > 7J J F1 Default e-1 J > )cceleration co-efficient > 1.2 '/ange 1.2 - 2. 0( Default > Eriction co-efficient between driving& pulle* % belt > 0.. '0.. - 0..-( 9ow following ratio is c ecked and it s ould be less t an =0C 71 A =0C 4elt widt '!( x 7!ax Dunlop catalogue "f it exceeds =0C& t e progra! displa*s a !essage and goes on t e ig er side to select new rating. "f belting is not available in t at dut* t en c ange t e dut*& appearing on t e screen in belting !odule. 7 e procedure is continue till safe belting is selected. 9ow& wit t e belt widt of t is selected belting again 7e is calculated and c ecked w et er 7107!an is less t an =0C. Lnce t e belting is finalised& t en& depending on t e C value of 7107!ax& pulle* dia!eters are also decided in conOunction wit carcass t k. of selected belt as follows :C",3"-th=$ ( ! *,+ 0 %&t+ ? i)3l%di)8 2e" d (2! 2.= - ,.,.< - ... ..- - -.-.< - ;.0 ;.1 - =.= =.9 - 11.1 ,2, .00 -00 <,0 =00 1000 65 0 75@ A5 0 65 @ 5 0 A5@

T"il>T(> Be)d (T! 2;, ,2, .00 -00 <,0 =00

S)%<(! 219 2;, ,2, .00 -00 <,0

2 2;, ,2, .00 -00 <,0 =00

T 219 2;, ,2, .00 -00 <,0

S 219 219 2;, ,2, .00 -00

2 219 2;, ,2, .00 -00 <,0

T 219 2;, ,2, .00 -00 <,0

S 219 219 2;, ,2, .00 -00

?ulle* dia!eters are decided onl* after belting selection is finalised. ..120-

..12.. POWER REB(IREMENT /0 ?D? ?ower reGuired at driving pulle* 's( 'kw( ?D? 'M:( > 7J.+ option 1000 "f t is value ,0 0.;- '9or!al( )lso

> ,0 - 0.92- '#elical(

to c ange.

Dotor L0? power '1 aft( > ?D'M:( > ?D?0K4 > PPPPP M:. Dotor M: reGuired > ?D x Dotor service factor. '1.1- default value option open to c arge( )dopt !otor or next ig er rating 'M:( 7 is will be rated M:. GEAR BO1 SELECTION /0 7o consider perip eral speed of t e belt& w ile selecting gear box pulle* dia > 4are pulle* dia F 2 @agging t k F 'top F botto!( F carcass t k.

I

'!!( '!!( '!!(

> PPPPP !!01000 > PPPP !

Drive pulle* /?D > <0 x belt speed '!0sec( > PPPP rp! x pulle* dia '!( Kear 4ox ratio > 1..0 > Drive pulle* rp! 9ow as t e gearbox t*pe is selected& to arrive at proper si$e& t e progra! follows t e following pat .

..1,0-

...1,... GEAR BO1

:or! #elical 1olid s aft 1olid s aft #ollow s aft Eoot !td 1 aft !td #ollow s aft M490MC9 95 1DD Eoot !td E1D Eoot !td M4#0MC# "t will go downward 14901C9 1 aft !td w ile selecting. 1 aft !td M4)0MC) 14#01C9 14)01C) '7 is progra! will go fro! 4 to C i.e. fro! double to triple reduction to select correct K4 si$e and ratio(. ) separate gear box screen is introduced& w ic on getting t e correct data selects suitable gear box si$e. Default Kear box selection is based on - Lption " % "" 7*pe of Kear box - :or!& #elical& 4evel #elical 1 afting - 1olid % #ollow Eoot !ounting 1 aft !ounting 1ervice factor - 1.- 'Default option open to c ange. Lption ". !in. power reGuired for gear box > /ated M: x Kear box 1.E. 0.;> PPPPP #? / +, / )bsorbed kw > ?! x 2.- > PPPPPP #? Kreater of t e 2 will be 0.;selected /ated kw > /ated kw x 1.2- > PPPPP #? 0.;Din. power reGuired for K.4. > PPPPPPP x Kear box 1.E. 1.- default& option > PPPPPPP #? to c ange 8

4evel #elical

..1.0-

..1... 1$ WORM / 9ow& t e gear box ratio calculated will not be alwa*s eGual to or tall* wit standard ratios available. #ence& t e progra! alwa*s selects t e previous 0 lower gear box ratio. 9ow& wit respect to t is gear box ratio % !in. power reGuire!ent& t e progra! selects t e correct gear box si$e. Due to reduction in gear box ratio& belt speed of conve*or will rise. #ence t e conve*ing capacit* will increase for sa!e belt widt . 7 ere will also be a c ange in !otor power reGuire!ent w ic increases fro! its original value. #ence& gear box screen is continued wit : /eGuired gear box ratio Kear box si$e )ctuall* selected 0 standard gear box ratio --6 C ange in speed C ange in #?0new #? Capacit* increased0descreased #ere t e progra! will alwa*s displa* t e lower gear box ratio selected. 4ut if needed& we can select ig er ratio and c eck w et er t e capacit* get satisfied or not. )s we c ange ratio t e corresponding c anges will also be observed on t e screen. Lnl* t e ratios available in t at particular series will be displa*ed. 2ELICAL > BEVEL 2ELICAL /0 9ow& t e gear box ratio is selected % gear box si$e is also selected. C eck for t er!al capacit* i.e. eating effects. 1. Kear units wit out additional cooling w en Dotor M: ?K1 x E: '"f t is satisfies t en additional cooling is not reGuired or else it is reGuired.( ?K1 > 7 er!al capacit* wi tout additional cooling '?ower table( Ew > Eactor for a!bient te!perature '7able( 2. Kear unit wit fan possible w en& Dotor M: ?K2 x E: '"f t is satisfies t en fan cooling is sufficient or else fan cooling is not sufficient.( ?K2 > 7 er!al capacit* wit fan '?ower table( ..1-0-

..1-.. ,. Kear unit wit built in cooling coil possible w en Dotor Mw ?K, x E: '"f t is satisfies t en furt er cooling coil is sufficient or else furt er cooling is not sufficient.( ?K,> 7 er!al capacit* wit built-in cooling coil.

..

Kear unit wit built-in cooling coil % fan possible % also put oil cooler neccesar*. Dotor M: ?K. x E: ?K. > 7 er!al capacit* wit built-in cooling coil % fan. "f t is satisfies t en& cooling coil % fan is reGuired or else t en& external oil cooler is necessar*. 7 is portion is explained as follows :/eGuired gear box ratio : 1..00D 1elected one : PPPP 'let it be x( Drpurp! c anged : 1..00x 1peed c anged : x Dr dia x Drpurp! c anged 0 <0 M: c anged '"f an*( : 7e'9( x speed c anged 0 1000 Capacit* increased > )rea x increased speed x ,000 x bulk densit* xk f CO(PLING SELECTION /0 ". dela* "nput coupling : ', t*pes - fluid& pin % bus % geared( a. Eluid coupling - c eck& w et er t e coupling is wit or wit out c a!ber. 1ee !otor M: selected. 1elect t e coupling wit rating eGual to or greater t an t e above !otor M: at 1.-0 rp!. b. ?in % bus 0 Keared coupling :"nput coupling torGue > ;1< x rated !otor #? x Cplg. 1.E. x 9.=19! 1..0 1.- default& option can be c anged 1elect t e greater value a!ong !otor s aft dia % gear box input s aft dia :./.7. t is greater value decides t e ke*wa* portion in ub as per t e table given below :...1<0-

..1<.. S,$ N+$ 1$ 2. ,. .. -. <. ;. =. 9. 10. 11. 12. 1,. 1.. 1-. Sh"*t di" ( ! (F,+ 0 %&t+ ? i)3l%de-! 2, - ,0 ,1 - ,= ,9 - .. .- - -0 -1 - -= -9 - <<< - ;;< - ==< - 99< - 110 111 - 1,0 1,1 - 1-0 1-1 - 1;0 1;1 - 200 201 - 2,0 Ce; :"; &+,ti+) i) h%< ( ! ,., ,., ,., ,.= .., ... ..9 -.9 -.. <.. ;.. =.. 9.. 10.. 11..

Eollowing two conditions are c ecked :1 aft dia at !otor as well as i0p gear box s ould be !in. bore of coupling. !ake it round figure !ax -------N ---------9ow& 'ke*wa* portion F10 !!( x2 F Kreater value a!ong A #ub outside dia in ub t e 2 s aft dia 7 is value is entered in t e cplg. database. 7 e progra! will select& t e correct coupling si$e satisf*ing above , conditions of torGue !in % !ax. bore % ub outside dia criterion. II$ O%t&%t 3+%&li)8 /0

L0? coupling torGue > ;1< x rated !otor #? x Cplg. 1.E. x 9.=1-9! 1..0 0 K.4. ratio 1.- default& option can be c anged. 1elect t e coupling wit greater torGue& next to calculated above and displa* t e si$e.

You might also like

- Dates Processing Plant: Agriculture Business Division, LahoreDocument23 pagesDates Processing Plant: Agriculture Business Division, LahoreTaha ZiaNo ratings yet

- 3 Ton Load Calculation of Cargo LiftDocument2 pages3 Ton Load Calculation of Cargo LiftTaha ZiaNo ratings yet

- Design of ChainDocument9 pagesDesign of ChainArun Pravin APNo ratings yet

- PSC Design (Aashto-Lrfd Tyu07) TutorialDocument44 pagesPSC Design (Aashto-Lrfd Tyu07) TutorialMohammad Tawfiq WaraNo ratings yet

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaNo ratings yet

- ASME Horizontal Vessel AnalysisDocument16 pagesASME Horizontal Vessel AnalysisAsep Darojat100% (1)

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- Ec PDFDocument1,232 pagesEc PDFChristiam OrtegaNo ratings yet

- Rotary Kiln SimulatorDocument10 pagesRotary Kiln SimulatorPassmore DubeNo ratings yet

- Unique Conveyor Problems and SolutionsDocument20 pagesUnique Conveyor Problems and SolutionsPaul MaposaNo ratings yet

- Windows Mixed Reality Documentation PDFDocument1,550 pagesWindows Mixed Reality Documentation PDFIpeleng DubeNo ratings yet

- Sample Calculation of Exp 4Document3 pagesSample Calculation of Exp 4Yeaminul IslamNo ratings yet

- Mintz Berg Ten School of Thought For Strategy FormationDocument3 pagesMintz Berg Ten School of Thought For Strategy FormationNawafZaferNo ratings yet

- Conveyor Gallery - Structural Design ParameterDocument21 pagesConveyor Gallery - Structural Design Parametershailendra rathoreNo ratings yet

- Sis 05 5900Document11 pagesSis 05 5900Taha Zia50% (2)

- Racecar Engineering 2013 05 PDFDocument100 pagesRacecar Engineering 2013 05 PDFfreddyonnimiNo ratings yet

- Haskal ImpDocument2 pagesHaskal ImpTaha ZiaNo ratings yet

- Mixing Mixing: ENVE 301 Environmental Engineering Unit OperationsDocument47 pagesMixing Mixing: ENVE 301 Environmental Engineering Unit OperationsTaha ZiaNo ratings yet

- FormulaDocument60 pagesFormulaYhaneNo ratings yet

- Sprocket Guide123456789Document17 pagesSprocket Guide123456789Ramsai ChigurupatiNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- Tools For Assembly and Service 01 DesbloqueadoDocument60 pagesTools For Assembly and Service 01 Desbloqueadodanielzepeda_235851No ratings yet

- ATOX Raw Mill. Weekly ReportDocument7 pagesATOX Raw Mill. Weekly ReportDilnesa EjiguNo ratings yet

- Measuring Smart Mobility Readiness IndexDocument7 pagesMeasuring Smart Mobility Readiness IndexAndry Redima KurniawanNo ratings yet

- Mechanical Size Reduction SLIDEDocument26 pagesMechanical Size Reduction SLIDEaziziNo ratings yet

- Technical Specifications For RAW Mill-KILN BAG HOUSE SectionDocument3 pagesTechnical Specifications For RAW Mill-KILN BAG HOUSE SectionRajmohan KushwahaNo ratings yet

- Nit CHP Silo PDFDocument495 pagesNit CHP Silo PDFGenci GjergjaniNo ratings yet

- Infinity Bucket Elevator ComponentsDocument19 pagesInfinity Bucket Elevator ComponentsKumar Jbs100% (3)

- SS448 ManualDocument8 pagesSS448 ManualkikoNo ratings yet

- M/S. K J S Cement Limited For-6000 TPD Cement PlantDocument22 pagesM/S. K J S Cement Limited For-6000 TPD Cement Plantvinod_eicsNo ratings yet

- CFMDocument13 pagesCFMaliNo ratings yet

- M1.Creating LED Champions - Course DesignDocument124 pagesM1.Creating LED Champions - Course DesignFatimi SantiagoNo ratings yet

- Chapter 1Document56 pagesChapter 1Surbhi JainNo ratings yet

- V6 EngineeringDocument252 pagesV6 Engineeringcrengifo1726No ratings yet

- Plant Eng Part 2 - ConveyorsDocument30 pagesPlant Eng Part 2 - ConveyorsLehlohonoloNo ratings yet

- Maintenance Practices in Cement IndustryDocument12 pagesMaintenance Practices in Cement IndustryHarshil AdodariyaNo ratings yet

- 1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4Document67 pages1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4anand7602No ratings yet

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IDocument6 pagesFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraNo ratings yet

- Fluidised Bed SeederDocument11 pagesFluidised Bed SeederAmritanshu ManuNo ratings yet

- Axial Transport and Residence Time of MSW in Rotary KilnsDocument11 pagesAxial Transport and Residence Time of MSW in Rotary Kilnsjimmy_burgos_11No ratings yet

- Girth Gear Work OrderDocument3 pagesGirth Gear Work OrderDgk RajuNo ratings yet

- Is Code List - ConveyorDocument4 pagesIs Code List - Conveyorpinksp5No ratings yet

- Essential Formulae: Number and AlgebraDocument7 pagesEssential Formulae: Number and AlgebraShinigami01001No ratings yet

- 20 TPH Bucket ElevatorDocument4 pages20 TPH Bucket ElevatorAlok NayakNo ratings yet

- Bag Filter Load DesignDocument2 pagesBag Filter Load DesignPrakasam VenkatamuraliNo ratings yet

- Cyclone Design 7 PDF FreeDocument6 pagesCyclone Design 7 PDF FreeSatish KumarNo ratings yet

- Pro Wearflex2000ht UkDocument1 pagePro Wearflex2000ht UkJagadeesh GuttiNo ratings yet

- Cement Kiln CapacityDocument2 pagesCement Kiln Capacityemad sabriNo ratings yet

- Mobile Lubrication Bijur DelimonDocument12 pagesMobile Lubrication Bijur DelimonFAVIONo ratings yet

- EAU-1,19000 CFM at 75 MM StaticDocument1 pageEAU-1,19000 CFM at 75 MM StaticdesignhvacNo ratings yet

- Twin Flue MEPL ReferenceDocument3 pagesTwin Flue MEPL ReferenceDurjoy ChakrabortyNo ratings yet

- The Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxDocument24 pagesThe Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxSURAJ MAHATONo ratings yet

- Chapter Four: FuelsDocument40 pagesChapter Four: Fuelsbiruk1No ratings yet

- Screw Feeder CalculationDocument5 pagesScrew Feeder CalculationHirenNo ratings yet

- Hangers Hanger BearingsDocument10 pagesHangers Hanger BearingsDouglas BatistellaNo ratings yet

- JK Lakshmi Cement LTD: 10 National Award For Excellence in Energy Management-2009Document25 pagesJK Lakshmi Cement LTD: 10 National Award For Excellence in Energy Management-2009albeta01No ratings yet

- Atox Gear PresentationDocument27 pagesAtox Gear PresentationMujahid BalochNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- Powder Cooler - BrochureDocument4 pagesPowder Cooler - BrochureAnonymous Cxriyx9HIX50% (2)

- Screw Conveyor WorksheetDocument30 pagesScrew Conveyor WorksheetAkshay RaskarNo ratings yet

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocument3 pagesA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresNo ratings yet

- Bag Filter Cage InspectionDocument3 pagesBag Filter Cage InspectionAhmad Nil ForoushanNo ratings yet

- Air SlideDocument3 pagesAir SlideMuhamad FadzirNo ratings yet

- Design of Machine Elements ReviewDocument2 pagesDesign of Machine Elements ReviewSuraj WodeyarNo ratings yet

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNo ratings yet

- Geas Mod 18Document2 pagesGeas Mod 18Denaiya Watton LeehNo ratings yet

- Design of Main GirderDocument58 pagesDesign of Main GirderovikbasuNo ratings yet

- Elementary Tutorial: Fundamentals of Linear VibrationsDocument51 pagesElementary Tutorial: Fundamentals of Linear VibrationsfujinyuanNo ratings yet

- Coal Miners SuitDocument4 pagesCoal Miners SuitSudipta BainNo ratings yet

- Kilncooler: Control Your Kiln Shell TemperatureDocument2 pagesKilncooler: Control Your Kiln Shell TemperatureSafrin SangiaNo ratings yet

- Motor and Inertia LoadDocument4 pagesMotor and Inertia LoadKiran Kumar K TNo ratings yet

- Beltconv (1) - CemaDocument45 pagesBeltconv (1) - CemaGuiidoo' Churairaa'No ratings yet

- Lec # 9 V-Belt DriveDocument46 pagesLec # 9 V-Belt DriveEl LordNo ratings yet

- Mondelez-Rework U Mixer - Insepction & Repair ReportDocument9 pagesMondelez-Rework U Mixer - Insepction & Repair ReportTaha ZiaNo ratings yet

- Mondelez-Junction Box - SC # 05 - Insepction & Repair ReportDocument5 pagesMondelez-Junction Box - SC # 05 - Insepction & Repair ReportTaha ZiaNo ratings yet

- DWT 260 C LVS User ManualDocument11 pagesDWT 260 C LVS User ManualTaha ZiaNo ratings yet

- Atex Load Cell Instruction ManualDocument9 pagesAtex Load Cell Instruction ManualTaha ZiaNo ratings yet

- Final Above Ground Quotation Tank (With Drawing)Document4 pagesFinal Above Ground Quotation Tank (With Drawing)Taha ZiaNo ratings yet

- Silicon Bronze: (Ercusi-A)Document1 pageSilicon Bronze: (Ercusi-A)Taha ZiaNo ratings yet

- Activity - Activating and Using The Assembly NavigatorDocument3 pagesActivity - Activating and Using The Assembly NavigatorTaha ZiaNo ratings yet

- AISC/AWS Fabricator Program InformationDocument1 pageAISC/AWS Fabricator Program InformationTaha ZiaNo ratings yet

- The Color Coding System For Shop SafetyDocument4 pagesThe Color Coding System For Shop SafetyjEmAhLiCiOuSNo ratings yet

- Heat Exchanger: F I L eDocument1 pageHeat Exchanger: F I L eTaha ZiaNo ratings yet

- Silicone Conveyor Belts: - Adhesive - Flexible - Antiadhesive EffectDocument1 pageSilicone Conveyor Belts: - Adhesive - Flexible - Antiadhesive EffectTaha ZiaNo ratings yet

- Chemical ProcessingDocument13 pagesChemical ProcessingTaha ZiaNo ratings yet

- Vacuum Test Individual Tubes For Pin Hole Leaks: Aecc-Vacuum Testing MachineDocument2 pagesVacuum Test Individual Tubes For Pin Hole Leaks: Aecc-Vacuum Testing MachineTaha ZiaNo ratings yet

- Bright Hub EngineeringDocument5 pagesBright Hub EngineeringTaha ZiaNo ratings yet

- Coagulation Design HandoutDocument5 pagesCoagulation Design HandoutTaha ZiaNo ratings yet

- HIRIYUR 220KV BAY EXPANSION EARTHING LAYOUT WITH 7.5 MTR SPACINGDocument1 pageHIRIYUR 220KV BAY EXPANSION EARTHING LAYOUT WITH 7.5 MTR SPACINGsparkCENo ratings yet

- Pit Mounted Manual 06 - 19 - 12Document59 pagesPit Mounted Manual 06 - 19 - 12kirk sutherlandNo ratings yet

- Air Conditioner: Parts ListDocument4 pagesAir Conditioner: Parts ListDavid Lemos SanchezNo ratings yet

- Enfinity Water Source Heat Pumps: Small Capacity Horizontal Ceiling-Mounted ModelsDocument4 pagesEnfinity Water Source Heat Pumps: Small Capacity Horizontal Ceiling-Mounted ModelsHector LuisNo ratings yet

- Experiment 5 Line CodingDocument6 pagesExperiment 5 Line CodingMs. INDU Ms. INDUNo ratings yet

- Models - Rf.wilkinson Power DividerDocument24 pagesModels - Rf.wilkinson Power Dividernad_chadi8816No ratings yet

- Ethics Case Study - 3 - Ethics in Public and Personal Relationships - INSIGHTSDocument8 pagesEthics Case Study - 3 - Ethics in Public and Personal Relationships - INSIGHTSJishnu AsokNo ratings yet

- WorldwideCheckList PDFDocument790 pagesWorldwideCheckList PDFTHSNo ratings yet

- Ancon Windpost Design SheetDocument2 pagesAncon Windpost Design SheetIOANNOU ENGINEERSNo ratings yet

- Curvadora de Perfiles DURMA PBH 180 240 300 360Document3 pagesCurvadora de Perfiles DURMA PBH 180 240 300 360Fernando Rivas CortesNo ratings yet

- Logistic in Online ShoppingDocument108 pagesLogistic in Online ShoppingSuhail FaridNo ratings yet

- AMP Vol 171 - N°09 - September 2013Document89 pagesAMP Vol 171 - N°09 - September 2013bluecreteNo ratings yet

- LabSheet 4 - Audio Amplifier - Group - 8Document7 pagesLabSheet 4 - Audio Amplifier - Group - 8Nurein AfiefahNo ratings yet

- 09 WCDMA RNO Access Failure Problem AnalysisDocument50 pages09 WCDMA RNO Access Failure Problem AnalysisshahidusmaniNo ratings yet

- J. S. Institute of Banking and Finance Pvt. LTD.: in The Service of Bankers For Over Three DecadesDocument4 pagesJ. S. Institute of Banking and Finance Pvt. LTD.: in The Service of Bankers For Over Three DecadesAnmoldilip ShrivastavaNo ratings yet

- Lesson Plan Spanish AdjectivesDocument4 pagesLesson Plan Spanish Adjectivesapi-2314969060% (1)

- Edifice X12 810 V4010Document88 pagesEdifice X12 810 V4010jeffa123No ratings yet

- Catalog Paloma Sanitary - Callista Series (Everose Gold) 2021Document14 pagesCatalog Paloma Sanitary - Callista Series (Everose Gold) 2021Tiffany OktavianaNo ratings yet

- Case 1Document23 pagesCase 1Emad RashidNo ratings yet

- FC18-PC6-8F: Connection Solutions For Rooftop or TowertopDocument2 pagesFC18-PC6-8F: Connection Solutions For Rooftop or Towertopclaudia karina monteverde zazuetaNo ratings yet