Professional Documents

Culture Documents

PFC8

PFC8

Uploaded by

Rajen KeotCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFC8

PFC8

Uploaded by

Rajen KeotCopyright:

Available Formats

1

NSTRUCTON MANUAL FOR PFC14 / PFC8 POWER FACTOR CONTROLLER 2 CONTENTS SECTION I Introduction .................... 2 SECTION II Installation .................... 3 2.1 Preliminary Check 2.2 ConIiguration Settings 2.3 Mounting & Wiring SECTION III Operation ............... 16 3.1 Operation 3.2 Maintenance SECTION IV Specifications ...... 21 4.1 Panel cutout drawing SECTION V Wiring diagram ..... 24 ANNEXURE 1 C/K TABLE ..... 25 3 SECTION I INTRODUCTION Power Factor Controller Relay Model PFC 14 & PFC 8} is designed Ior automatic control oI capacitor banks to maintain system power Iactor under varying load conditions. It employs state-oI- the-art microprocessor techniques Ior measurement oI reactive current, system power Iactor and ensures hunt Iree operation. It can control up to 14 (8)* capacitor banks. The parameters such as number oI capacitor banks, switching program, switching delay are user selectable. It also displays system power Iactor continuously and indicates whether it is lagging or leading with respect to set power factor. PFCR Power Factor Controller Relay} protects the capacitor banks whenever power interruption occurs by switching OFF` all capacitor banks and providing a saIety lockout period oI minimum 60 sec. It also oIIers 4 over voltage protection by disconnecting all capacitor banks in case oI over voltage conditions. * Text written in parentheses corresponds to PFC 8 throughout this manual.

# For PFC 14 no. oI selectable capacitor banks are 4 to 14. # For PFC 8 no. oI selectable capacitor banks are 4 to 8. SECTION II INSTALLATION 2.1 Preliminary Check The relay packing consists oI: 1. PFC Relay 2. Mounting clamps 3. Instruction Manual 4. Test certiIicate Check the PFCR Ior any obvious damage, iI Iound 5 inIorm nearest L&T oIIice or dealer. Follow the instructions below Ior basic Iunctional check: a) Remove protective cover Irom the terminal block by removing Iour screws and connect 415V AC supply between terminals 22 & 23. b) Switch ON` the supply voltage. All LEDs on the Iront panel will Ilash twice and two digit seven segment display will keep toggling between number 1` and 3`. Whenever number 1` is displayed, a green LED marked OK` or Lead` or Lag` will glow and a red LED marked ALARM-CODE` will glow when number 3` is displayed. A yellow LED marked AUTO` will glow continuously. This indicates that PFCR is in AUTO mode. All other LEDs will remain OFF`. Whenever SET COS or SET C/K push buttons are referred then the relav is to be in AUTO mode. Whenever CAP or CAP- push buttons are referred, 6 relav is to be in MANUAL mode. This convention is followed throughout this manual. c) Press the button SET COS and turn the potentiometer COS by keeping the button SET COS in pressed condition. Observe that the display indicates 80 when potentiometer is in extreme counter clockwise position. Slowly turn the potentiometer clockwise, the display will go on increasing upto 99 and then show 1. Further turning oI potentiometer in same direction will result in display indicating again 99 and it will go on decreasing to show 95 in extreme clockwise

condition. Release SET COS button, display should start toggling between number 1` and 3` as beIore. d) Now turn potentiometer C/K` by keeping the button SET C/K in pressed condition. Observe that display changes Irom 05 to 1 as the potentiometer is moved Irom extreme counter clockwise position to extreme clockwise position. Release SET C/K button, display should start toggling between number 1` and 3`. 7 e) Press the middle button, LED marked AUTO` will go OFF` and a red LED marked MANUAL` will switch ON` indicating that PFCR is now in MANUAL mode. In this mode keep the button marked CAP in pressed condition continuously. Observe that aIter about 70 sec. aIter saIety lockout time} Iirst relay operates. This is indicated by a green LED marked 1. Keep the switch CAP in pressed condition. AIter about 3 sec green LED marked 2 will glow indicating that second relay has operated. II CAP switch continues to be in operated condition, one by one all 14 (8) relays will switch ON` II no. oI bank selected is 14 (8). ReI. section 2.2.3 Ior setting } and all 14 (8) green LEDs will start glowing. Operating button marked CAP- will switch OFF` the relays one by one starting Irom Iirst relay. This completes the Iunctional check oI PFCR. Switch OFF` the relays by disconnecting the supply. 2.2 Configuration Settings 8 User can set Iive diIIerent parameters while installing the PFCR, they are: Setting the:- Desired Power Iactor COS}. - C / K value. - No. oI capacitor banks in PFC 14 4 to 14}, PFC 8 (4 to 8). - Capacitor bank conIiguration. - Capacitor Bank switching delay. 2.2.1 Setting The Power Factor cos ] The desired power Iactor can be set as Iollows : Select AUTO mode. Press the button marked SET COS. Display will show the set power Iactor. Rotate the potentiometer COS keeping the button SET COS pressed to get the display oI desired power Iactor.

9 2.2.2 Setting The C/K Value C/K value is the measure oI Threshold Reactive Current. It is a ratio oI minimum capacitor bank size and CT ratio as given below: Pc C/K 0.66 --------------------------V * (3) * CT RATIO Where , Pc Minimum capacitor bank size kVAR}, V Supply Voltage 415 V}, CT RATIO Ratio oI current transIormer used Ior Ieeding current to PFCR. Eg. II CT used is 1000:5A, then CT RATIO is 200. The C/K setting can be done in two wavs, manuallv or automatic. 10 2.2.2.a Manual Setting Of C/K Calculate the value oI C/K using the above Iormula or get C/K value using C/K TABLE ANNEXURE 1}. Select AUTO mode. Press the button marked SET C/K. Display will show the SET C/K value. Rotate the potentiometer C/K` keeping the button SET C/K pressed to get the display oI desired C/K value. 2.2.2.b Automatic C/K Setting In this mode PFCR actually measures the capacity oI the bank and adjusts the C/K value. Hence it is more accurate than manual setting. Follow these instructions below Ior automatic C/K setting. Disconnect the load. Connect only the least capacitor bank to relay 1 R1, Terminal No.1}, iI Capacitor bank conIiguration is 11 1:1:1:1. II not connect least capacitor bank to R14 i.e., terminal No. 15 Ior PFC 14 (or R8 i.e., terminal No. 8 Ior PFC 8). Switch ON` the input voltage to PFCR by keeping SET COS and SET C/K buttons pressed. Display will indicate number 8` and Code LED will glow indicating that Auto C/K mode has been selected. Enter the CT RATIO in Iour digits as Iollows: a) Select MANUAL mode by pressing Auto/Manual button. LED marked Lead` will glow indicating that user can enter most signiIicant two digits oI CT RATIO using C/K` potentiometer.

b) Rotate C/K` potentiometer till display shows two most signiIicant digits oI the CT RATIO. e.g.: For a CT oI 1000:5, ratio is 200 and CT RATIO code to be entered is 0200. Adjust C/K control till display shows 02}. c) Press CAP- button. PFCR will accept two most signiIicant digits oI CT RATIO and LED marked 12 Lag` will start glowing indicating that user can enter least signiIicant two digits oI CT RATIO. d) Rotate COS potentiometer till display indicates required value In above example it is 00}. e) Press CAP button. PFCR will accept least signiIicant two digits. This completes the entering oI CT RATIO code. I) Return to AUTO mode by pressing AUTO / MANUAL button. PFCR will switch ON` the least valued capacitor. Rotate C/K` potentiometer till LED marked OK` glows. This completes the setting procedure. Press SET COS and SET C/K buttons together, PFCR will return to normal mode oI operation. NOTE : DIP Switch 8 Way DIP switch is located at the right hand bottom corner oI the Iront panel as shown in FIG 1. By this 13 DIP switch it is possible to select no. oI capacitor banks, testing oI relays, capacitor bank conIiguration & capacitor bank switching delay. The DIP switch should be selected when unit is in OFF` condition. Change in Dip switch position when PFCR is ON` will not come into effect except switch no. 3 by which PFCR will come out of relay test mode. 14 15 16 2.2.3 Selection of Number Of Capacitor Banks Set the positions oI DIP switch number 6, 7 and 8 as indicated in the TABLE-1 & FIG 2.a & FIG 2.b to get the required number oI capacitor banks. NO. OF BANKS S/W 6 S/W

7 S/W 8 4 OFF OFF OFF 5 OFF OFF ON 6 OFF ON OFF 7 OFF ON ON 8 ON OFF OFF * 10 ON OFF ON * 12 ON ON OFF * 14 ON ON ON TABLE 1: Selection of no. of capacitor banks. * These options are not available in PFC 8. CAUTION. IF SWITCH NO. 3 IS KEPT IN ON POSITION, PFCR GOES IN RELAY TEST MODE. {REFER SECTION 3.1.2.a FOR DETAILS} ENSURE THAT SWITCH NO. 3 IS IN OFF POSITION FOR NORMAL OPERATION. 17 2.2.4 Selection of Capacitor Bank Configuration: Positions oI DIP switch number 1 and 2 should be set as indicated in TABLE-2 & FIG 2.a & FIG 2.b to match the capacitor bank conIiguration available. Cap. Bank ConIiguration S/W 1 S/W 2 1:1:1:1:1:...:1 OFF OFF 1:2:2:2:2:...:2 ON OFF 1:2:4:4:4:...:4 OFF ON 1:2:4:8:8:...:8 ON ON TABLE 2: Capacitor bank configuration. 2.2.5 Selection of switching Delay Set the position oI DIPswitch number 4 and 5 as indicated in TABLE-3 & FIG 2.a & FIG 2.b to get the required delay. Switching Delay S/W 4 S/W 5 10 Sec. OFF OFF 20 Sec. OFF ON 40 Sec. ON OFF

60 Sec. ON ON TABLE 3: Switching delay selection. 18 After setting the required configuration fix the cover strip back with the help of two screws. 2.3 Mounting And Wiring PFCR is designed Ior Ilush mounting on the panel. ReIer. Section IV FIG 3} Ior panel cutout dimensions and space required behind the panel. Fix the mounting clamps supplied along with, to both the sides oI the relay. Insert the relay through the panel cutout and hold it Iirmly against the panel, tighten the screws on the mounting bracket. Wire the relay terminals as shown in the wiring diagram ReIer FIG 4.a & FIG 4.b}. Relay terminals are suitable Ior 2.5 mm. sq. lugs. Fix the protective cover back on the terminal block with the help oI Iour screws aIter completing the wiring. NOTE: 1. ENSURE PROPER EARTH CONNECTION TO THE RELAY. 2. IT IS RECOMMENDED TO REMOVE THE RELAY FROM THE PANEL DURING TRANSPORTATION. 19 2.3.1 CT/ PT Connections PFCR has a built-in CT which can accept current input Irom 1Amp or 5Amp CT. This input is to be taken Irom R phase CT output. Connect the current input to terminals 19 and 20 iI it is Irom 1Amp CT and to terminals 19 and 21 Ior 5Amp CT. PFCR has a built-in PT, which accepts 415V AC RMS voltage input. This input should be taken between Y and B phases. Connect terminal 22 to Y phase and 23 to B phase. NOTE . MAINTAIN PHASE CONNECTION AS SHOWN IN WIRING DIAGRAM {FIG 4.a & FIG 4.b}. 2.3.3 Wiring Of Capacitor Banks PFC 14 (PFC 8) has 14 (8) relays each with one N/O contact available on terminals 1to 15(8). One pin oI all N/O contacts is shorted together internally and this common point is available on terminal 12. Using these contacts an external contactor can be switched ON` or OFF` to connect or disconnect a capacitor bank as indicated in the wiring diagram FIG 4.a & FIG 4.b}. 20 Depending on conIiguration oI capacitor banks, connect all banks to PFCR through contactor as

mentioned below : 1. If the capacitor banks are in the ratio of 1:1:1:1..., i.e., all banks are of same value, then connect the capacitor banks to relays R1 to Rn where :n' is the number of banks selected. 2. If the capacitor banks are in the ratio of 1:2:2:2..., then connect the smallest capacitor bank to relay R14 (R8) and remaining banks to relays R1 to Rn-1 where :n' is number of capacitor banks selected. 3. If the capacitor banks are in the ratio of 1:2:4:4..., then connect the smallest capacitor bank to relay R14 (R8), the next higher to R13 (R7) and remaining banks to relays R1 to Rn-2 where :n' is number of capacitor banks selected. 4. If the capacitor banks are in the ratio of 1:2:4:8:8..., then connect the smallest capacitor bank to relay R14 (R8), the next higher to R13 (R7), the next one to R12 (R) and remaining banks to relays R1 to Rn-3 where :n' is number 21 of capacitor banks selected. 2.3.4 Wiring Of Alarm Contacts PFCR incorporates one relay to give alarm indication. One sC/O contact is available on terminal 16, 17 and 18 which can be used to initiate remote alarm. Aote that this relay is wired in Fail-Safe mode i.e., it remains energized under healthy conditions. The wiring diagram shows the contact position in power OFF` condition alarm relay de-energized}, hence under healthy` condition terminal 16, 17 will be open and terminal 17, 18 will be shorted. Alarm relay drops out to initiate alarm under Iollowing conditions: Over Joltage Under Compensation Over compensation Under current 22 2.3.5 Commissioning Switch ON` voltage and current inputs to PFCR. Check input connections polarity Refer Section 3.1.2]. Verify the number of banks selected Refer Section 3.1.3]. Adjust C/K control Refer Section 2.2.2 and Annexure I]. Set the desired power factor Refer Section 2.2.1]. SECTION III OPERATION

3.1 Operation PFCR continuously monitors the reactive current drawn by the load and computes the power Iactor which will be displayed continuously. It compares the load power Iactor with set power Iactor and switches the relays inside ON` or OFF` which in turn can be used to connect or disconnect the capacitor banks. To achieve hunt Iree operation, iI reactive current measured is less than 66 oI the available bank size, it will not be switched ON`. 23 PFCR switches the capacitors in cyclic order so that all the capacitors are used equally and allows longer discharge time. This increases the liIe oI the capacitor bank. In cyclic switching, iI capacitor banks are in the ratio oI 1:1:1:1.. always bank no. 1 is switched ON` Iirst. The capacitor that was switched ON` or OFF` Iirst will be switched OFF` or ON` Iirst aIter utilizing all capacitors. II it is other than 1:1:1.., then all capacitor banks oI equal size will be used Ior rotational scheme. 3.1.1 Auto/Manual mode PFCR can be used in AUTO or MANUAL mode. Normally aIter power ON` it will be in AUTO mode, indicated by a LED marked AUTO`. In this mode PFCR automatically connects or disconnects the capacitor banks to maintain the load power Iactor as close as possible to the set power Iactor. The switching 24 delay between two consecutive banks can be set at 10, 20, 40 or 60 secs by the user ReI. Sec. 2.2.5 Ior details}. Pressing Auto/Manual switch will change the operating mode oI the unit Irom Auto to Manual or vice-versa. Operating mode is indicated by glowing oI appropriate LED. In MANUAL mode user can switch ON` or OFF` the capacitor banks by operating the buttons marked CAP or CAP- respectively. The switching delay between two consecutive banks is Iixed at 3 sec in MANUAL mode irrespective oI the switching delay selected by the user Ior AUTO mode operation. A row oI Iourteen (eight) LEDs marked 1 to 14 (8) indicates ON`/`OFF` status oI each relay in AUTO as well as MANUAL mode. 3.1.2 Testing Of Input Connections

Any time aIter power ON`, correctness oI input connections CT and PT connections Ior proper phase relation} can be checked as Iollows: 25 Select MANUAL mode by pressing Auto/Manual button. Press both CAP and CAP- buttons together. Display will show code 1` iI connections are correct and code 2` iI connections are reversed & ALARM Relay operates}. Error Code LED will also glow. II code 2` is displayed, then reverse either CT or PT connections but not both}. For correct indication oI CT and PT polarity, more than 10 oI the rated current should be Ilowing through the PFCR. 3.1.2.a Testing Output relays The output relavs can be tested bv switching ON DIP switch 3 which is located at right corner of the front panel. The DIP switch should be set ON before powering the PFCR. Test will switch ON and OFF the output relavs one after the other starting from one, the front capacitor bank LED will indicate. The PFCR 26 will be in this mode as long as this DIP switch is ON. So after one cvcle of testing switch it Off to come out of test mode. 3.1.3 Verifying Number Of Capacitor Banks Selected User can select capacitor banks between 4 and 14 Ior PFC 14 & between 4 and 8 Ior PFC 8 ReIer Sec 2.2.3 Ior details}. Number oI banks selected can be checked anytime by pressing both SET COS and SET C/K buttons in AUTO mode. The number will be displayed on the seven segment display. 3.1.4 Power Factor Display Load power Iactor is continuously displayed on two seven segment LED displays at all load conditions. Power Iactor display is available in both AUTO and MANUAL modes. The three LEDs marked Lead`, Lag` and OK`, mounted next to this display indicates status oI load power Iactor with respect to set power Iactor. 27 Eg. II Set Power Factor is 0.80 and actual power Iactor is less than 0.80, then Lag` LED will glow. Whereas iI actual power Iactor is greater than 0.80 Lead` LED

will glow even iI it is less than unity. NOTE . THE DISPLAY INDICATES TWO DIGITS AFTER THE DECIMAL POINT. THE DECIMAL POINT IS NOT INDICATED. 3.1.5 Alarms and Protections PFCR incorporates a separate relay which can be used to initiate remote alarm under certain conditions. Alarm conditions are also indicated on the Iront panel by displaying various ERROR-CODES`. 3.1.6 Over Voltage Protection II line voltage goes beyond 120 oI nominal voltage 415 V} Ior three seconds, all relays are switched OFF` at once. Alarm relay operates and CODE 4` is displayed. When voltage drops to less than 105 oI nominal value, PFCR will start switching ON` the capacitor banks again automatically. 28 3.1.7 Under Compensation Even aIter switching ON` all the capacitor banks iI measured reactive current inductive} is more than the set C/K level i.e., measured power Iactor is lagging with respect to set power Iactor} Under Compensation CODE 5` will be displayed on the Iront panel and Alarm relay will operate. 3.1.8 Over Compensation Even aIter switching OFF` all the capacitor banks iI measured reactive current capacitive} is more than desired C/K level i.e., measured power Iactor is leading with respect to set power Iactor} Over Compensation CODE 6` will be displayed and Alarm relay will operate. 3.1.9 Under Current Release II load current is less than 10 oI the CT rating 1A/5A} then all banks will be switched OFF` sequentially. Alarm CODE 3` is displayed. 29 3.2 Maintenance PFCR does not need any routine maintenance during its working liIe. It does not contain any user serviceable / replaceable parts. In case oI Iailure oI the PFCR inIorm nearest L & T oIIice or dealer. 30 31 SECTION IV SPECIFICATIONS Voltage Input

415VAC 20 , 50Hz . Current Input 5A / 1A Field selectable}. Accuracy oI PF Display 2 Irom 0.7 lag to 0.8 lead, under Iull load condition}. Desired Power Factor setting 0.80 lag to 0.95 lead. Threshold reactive current setting C/K} 0.05 to 1 Amps reactive. Capacitor bank selection 4-5-6-7-8-10-12-14PFC 14}; 4-5-6-7-8 (PFC 8); banks through DIP switch setting. Capacitor bank switching delay 10, 20, 40, 60 sec /- 10. SaIety lockout time 60 sec capacitor bank switching. Delay selected /- 10. 32 Capacitor bank conIiguration 1:1:1:1:1:...1, 1:2:2:2:2:...2, 1:2:4:4:4:...4, 1:2:4:8:8:...8. Auto / Manual operation AUTO/MANUAL`. Relay output rating N/O contact, 230VAC, 5A. Burden on a) PT b) CT Operational indicator Insulation Impulse test Noise interIerence test On line testing Less than 10VA at nominal voltage}. Less than 0.3VA at nominal current}. LED Ior all Relays, LED Ior ALARM`, LED Ior AUTO/MANUAL`, 7-Segment Display to show

PF` & Error Codes`. As per IS : 3231-1986. As per IS : 8686-1977. As per IS : 8686-1977. PFC relays can be tested using DIP switch. 33 Operating temperature Overall Dimension 0 to 55C. 144 144 mm; depth 100 mm. ConIorms to IS 3231-1986 Standards Ior all requirements. Fig. 3 : Panel Cutout Drawing 34 SECTION V 35 37 ANNEXURE 1. KVAR CT ratio 3 4 5 6 7.5 8.3 10 12.5 16.7 20 25 30 33.3 40 50 30/5 0.46 0.60 0.76 0.90 50/5 0.27 0.36 0.45 0.55 0.68 0.75 75/5 0.18 0.24 0.30 0.36 0.45 0.50 0.60 0.75 100/5 0.14 0.10 0.23 0.28 0.34 0.38 0.45 0.57 0.75 0.90 150/5 0.09 0.12 0.15 0.10 0.23 0.25 0.30 0.38 0.50 0.60 0.75 0.90 200/5 0.07 0.09 0.12 0.14 0.17 0.19 0.23 0.28 0.38 0.45 0.57 0.68 0.75 0.90 300/5 0.05 0.07 0.08 0.09 0.12 0.13 0.15 0.19 0.25 0.30 0.38 0.45 0.50 0.60 0.75 400/5 0.05 0.06 0.07 0.09 0.10 0.12 0.15 0.19 0.23 0.29 0.34 0.38 0.45 0.57 600/5 0.05 0.06 0.07 0.08 0.10 0.13 0.15 0.19 0.23 0.25 0.30 0.38 800/5 0.05 0.05 0.06 0.08 0.10 0.12 0.15 0.17 0.19 0.23 0.29 1000/5 0.05 0.06 0.08 0.09 0.12 0.14 0.15 0.18 0.23 1500/5 0.06 0.07 0.08 0.09 0.10 0.12 0.13 2000/5 0.05 0.06 0.07 0.08 0.09 0.12 2500/5 0.05 0.06 0.07 0.08 0.10 3000/5 0.05 0.06 0.07 0.08 4000/5 0.05 0.06 TABLE : C/K VALUES 39 WARRANTY LARSEN & TOUBRO LIMITED ( L&T) warrants that the protective Relay model PFC-14/PFC-8 will meet L&T s published speciIications and will be Iree Irom deIects in

workmanship and materials Ior a period oI 12 months Irom the date oI shipment. L&T`s obligation under this warranty shall be limited to servicing or replacing the deIective parts provided that notice oI such deIects and satisIactory prooI thereoI is given to L&T by it`s customer within the warranty period. This warranty does not cover any deIect caused by accident, misuse, neglect alteration, modiIication or substitution oI any oI the components or parts or any attempts at internal adjustment by unauthorized service personnel. Under no circumstances shall L&T will liable Ior any consequential damage, resulting injury, loss or expanse, directly or indirectly, arising Irom the use oI this product. This forgoing warranty is in lieu of all other warranties expressed or implied and is the sole and exclusive remedy for any claim arising from the defect in the product. 40 Manufactured by LARSEN & TOUBRO LIMITED, KIADB INDUSTRIAL AREA, HEBBAL, HOOTAGALLY, MYSORE - 570 018. Visit us @ www.Intmps.com www.Intebg.com www.Iarsentoubro.com Reach us @ mpsinfo@myw.Itindia.com Part No. 4D060079 Rev 2

You might also like

- Instrument Installation Hook Up DrawingsDocument0 pagesInstrument Installation Hook Up DrawingsHicoolguy Riq33% (3)

- MR590I - Manual - Neha RefuDocument182 pagesMR590I - Manual - Neha RefuNeha Auto100% (1)

- MC 31Document33 pagesMC 31nick321walkerNo ratings yet

- L T Acb Acc Pricelist-C-PowerDocument12 pagesL T Acb Acc Pricelist-C-PowerVimal SuryavanshiNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- Microsoft Word - AK-62 4 To 20maDocument2 pagesMicrosoft Word - AK-62 4 To 20maNisar Ahmed100% (4)

- C Power ACB ManualDocument9 pagesC Power ACB ManualanilerNo ratings yet

- L&T Control Range CatalogueDocument91 pagesL&T Control Range CatalogueAnonymous lFFnnXmjUuNo ratings yet

- 07-02-2018 12-59-46 - etaSMART APFC Relay - Catalogue PDFDocument5 pages07-02-2018 12-59-46 - etaSMART APFC Relay - Catalogue PDFIshwar ranawatNo ratings yet

- L&T Switchgear Panel Accessories Price ListDocument44 pagesL&T Switchgear Panel Accessories Price Listnitin hadkeNo ratings yet

- Medium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in IndiaDocument8 pagesMedium Voltage IGBT Drives HIVECTOL - HVI - E: Hitachi MV Drives Manufactured in Indiaharshad_soni7912No ratings yet

- MicrocontrollerDocument7 pagesMicrocontrollerThangarajan NagarajanNo ratings yet

- Star / Delta Selections For 415v 3 Phase MotorsDocument2 pagesStar / Delta Selections For 415v 3 Phase Motorsandri pristaNo ratings yet

- Siemens Timer CatalogDocument4 pagesSiemens Timer Catalogshamim93146No ratings yet

- Manual Book Soft Starter Renle JJR8000Document70 pagesManual Book Soft Starter Renle JJR8000Herie HeriadieNo ratings yet

- Power Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughDocument3 pagesPower Factor Controllers PFR-X R / PFR-M T: Because Excellent Capacitors Are Not EnoughMarvin RaxónNo ratings yet

- SLR140 - ArDocument51 pagesSLR140 - ArDeepak Ojha100% (1)

- DM6100/DM6300 Digital Meter: Quick Start Guide English Safety Precautions Digital Meter Physical DescriptionDocument4 pagesDM6100/DM6300 Digital Meter: Quick Start Guide English Safety Precautions Digital Meter Physical DescriptionSagar PatelNo ratings yet

- Instruction Manual: Energy MeterDocument2 pagesInstruction Manual: Energy MeterIshwar ranawatNo ratings yet

- MINILEC Full Cat PDFDocument68 pagesMINILEC Full Cat PDFDakshinaMoorthyNo ratings yet

- LC 1046Document4 pagesLC 1046Deep PrajapatiNo ratings yet

- SI 2018-177 Electricity (Public Safety) Regulations, 2018 - 0Document12 pagesSI 2018-177 Electricity (Public Safety) Regulations, 2018 - 0Flavious CoffeeNo ratings yet

- Trivector Meter Type Er300pDocument4 pagesTrivector Meter Type Er300pAnonymous q8EusUCNo ratings yet

- HH10 Series DriveDocument4 pagesHH10 Series DriveHarry FernandesNo ratings yet

- Rish Master 3428 MFMDocument5 pagesRish Master 3428 MFMAmit KumarNo ratings yet

- Installation Testing Troubleshooting Starters Overload RelaysDocument34 pagesInstallation Testing Troubleshooting Starters Overload RelaysGogula Gunasekhar100% (1)

- Softstarter Altistart 22Document85 pagesSoftstarter Altistart 22離子0% (1)

- GA700 Technical ManualDocument936 pagesGA700 Technical ManualTuanson Pham0% (1)

- New - Spectronic E-CatalogueDocument58 pagesNew - Spectronic E-CatalogueCARLOS LÓPEZNo ratings yet

- 12 KV Switchboard VCB & Panel Spare Management ProposalDocument10 pages12 KV Switchboard VCB & Panel Spare Management ProposalRaj EntrNo ratings yet

- VCB Maint ChecklistDocument3 pagesVCB Maint ChecklistAshish MahapatraNo ratings yet

- External CT Usage-EOCRDocument3 pagesExternal CT Usage-EOCRNaveen GuptaNo ratings yet

- 01 Process Indicator Controller Single Display UT-101 102 PDFDocument12 pages01 Process Indicator Controller Single Display UT-101 102 PDFvishadkapadiaNo ratings yet

- ATS Dwgs & PLC Manuals 1Document15 pagesATS Dwgs & PLC Manuals 1gigo_dreamNo ratings yet

- Final Documentation Drawings CS0928Document91 pagesFinal Documentation Drawings CS0928Gunji Venkata Srinivasa BabuNo ratings yet

- Electricneutron-Star Delta Motor ConnectionDocument7 pagesElectricneutron-Star Delta Motor ConnectionJoe ElectricneutronNo ratings yet

- 3 Phase 4 Wire LT Operated CT Dual Source Meter: User ManualDocument8 pages3 Phase 4 Wire LT Operated CT Dual Source Meter: User ManualIshwar ranawatNo ratings yet

- Control Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedDocument4 pagesControl Panel: ISO 9001 Certified ISO 14001 / OHSAS18001 CertifiedHaresh vaghelaNo ratings yet

- VLT SoftStarter Selection Guide - MCD600 SeriesDocument28 pagesVLT SoftStarter Selection Guide - MCD600 SeriesLim VincentNo ratings yet

- ACB SparesDocument8 pagesACB SparesVikas Yadav100% (1)

- ELF 3234 ManualDocument8 pagesELF 3234 ManualRajesh TKNo ratings yet

- ESP Price List 01 Feb 2021 (L&T)Document116 pagesESP Price List 01 Feb 2021 (L&T)Kavin Sengodan100% (2)

- TopSwitch Flyback Flyback Design Methodology AN16Document32 pagesTopSwitch Flyback Flyback Design Methodology AN16Burlacu AndreiNo ratings yet

- Controller User Manual - 12-24 Steps - RG1A-12Document91 pagesController User Manual - 12-24 Steps - RG1A-12ashNo ratings yet

- Siemens VFD Manual 193Document328 pagesSiemens VFD Manual 193nitinsomanathanNo ratings yet

- Smart Series Manual 02 SX 2000 90kWDocument348 pagesSmart Series Manual 02 SX 2000 90kWLalji Lunagariya0% (2)

- L&T Price ListDocument44 pagesL&T Price Listneetans67% (9)

- Maximum Demand ControllerDocument4 pagesMaximum Demand ControllerDIWAKAR NNo ratings yet

- ABB UNITROL 1005 1010 1020 EN RevF PDFDocument14 pagesABB UNITROL 1005 1010 1020 EN RevF PDFsrinivasNo ratings yet

- ADOR Equipment BrochureDocument36 pagesADOR Equipment BrochurePratap YallaNo ratings yet

- ImccDocument26 pagesImccIshaq khanNo ratings yet

- 8204 User ManualDocument41 pages8204 User ManualDhaniraj SinghNo ratings yet

- MBAS 9400 CatalogueDocument2 pagesMBAS 9400 CataloguebalajiNo ratings yet

- Kent USA Kls1840n - 2660N ElectricalDocument39 pagesKent USA Kls1840n - 2660N Electricalchidambaram kasiNo ratings yet

- MS2-User Manual FalconDocument19 pagesMS2-User Manual FalconFatmir Enila FerhatiNo ratings yet

- Static Capacitor Banks For Fast Power Factor Compensation Type EckDocument11 pagesStatic Capacitor Banks For Fast Power Factor Compensation Type EckAde WawanNo ratings yet

- Ic200cx QRG GBDocument58 pagesIc200cx QRG GBDouglasNo ratings yet

- SAILOR Battery Panel BP4680Document16 pagesSAILOR Battery Panel BP4680Md Sanaul Karim ShohelNo ratings yet

- Uploads Product Rishmaster EM3490 1PH Manual PDFDocument2 pagesUploads Product Rishmaster EM3490 1PH Manual PDFKo PaukNo ratings yet

- Jvs Manual JRC 122-124Document4 pagesJvs Manual JRC 122-124ashutosh2009No ratings yet

- Role of The GovernorDocument7 pagesRole of The Governorakela_lifeNo ratings yet

- Saans Song Lyrics DetailsDocument2 pagesSaans Song Lyrics Detailsakela_lifeNo ratings yet

- General Boiler InformationDocument15 pagesGeneral Boiler Informationm.sob7y7793No ratings yet

- EleDocument11 pagesEleakela_lifeNo ratings yet

- HMB CraneDocument2 pagesHMB Craneakela_lifeNo ratings yet

- Im30d R3Document34 pagesIm30d R3akela_lifeNo ratings yet

- EleDocument40 pagesEleakela_lifeNo ratings yet

- EleDocument25 pagesEleakela_lifeNo ratings yet

- IITJEE 2012 Solutions Paper-2 Physics EnglishDocument12 pagesIITJEE 2012 Solutions Paper-2 Physics EnglishResonance KotaNo ratings yet

- IITJEE 2012 Solutions Paper-1 Physics EnglishDocument14 pagesIITJEE 2012 Solutions Paper-1 Physics EnglishResonance KotaNo ratings yet

- Calibration Report: Equipment Name:-DIGITAL INDICATOR Model No. - DX 400Document1 pageCalibration Report: Equipment Name:-DIGITAL INDICATOR Model No. - DX 400akela_lifeNo ratings yet

- HMB Crane TBDocument14 pagesHMB Crane TBakela_lifeNo ratings yet

- Elect 09 Method Statement For MCC Modification and RecommissioningDocument7 pagesElect 09 Method Statement For MCC Modification and RecommissioningQwe7 Al-AlNo ratings yet

- Power System Protection and Switchgear: Current Based Relaying Scheme-VDocument16 pagesPower System Protection and Switchgear: Current Based Relaying Scheme-VSampath AnbuNo ratings yet

- Notes:: Colombo Port City Development ProjectDocument1 pageNotes:: Colombo Port City Development Projectnadim7862No ratings yet

- Iris Dic Pakistan 1Document48 pagesIris Dic Pakistan 1muzeek306No ratings yet

- ELCBDocument2 pagesELCBnarasimhamurthy414No ratings yet

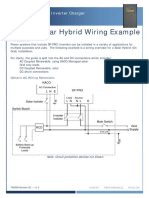

- TN0059 - 02 SP PRO Solar Hybrid Wiring ExampleDocument2 pagesTN0059 - 02 SP PRO Solar Hybrid Wiring ExamplePower Eng100% (1)

- S9-Battery ChargerDocument17 pagesS9-Battery ChargerVivek Kumar MNo ratings yet

- 83161.1 (10.1a) 83161.2 (15.1a) 83161.3 (10.1a) 83161.5 (4a) 83161.9 (0.1a) 83161.5SP4136 83161.9SP4136 83161.6 83161.8 (0.1a)Document3 pages83161.1 (10.1a) 83161.2 (15.1a) 83161.3 (10.1a) 83161.5 (4a) 83161.9 (0.1a) 83161.5SP4136 83161.9SP4136 83161.6 83161.8 (0.1a)Vilius BukysNo ratings yet

- Capacitors 2Document24 pagesCapacitors 2Zymone Eiron DinglasanNo ratings yet

- 2nd QTR '2009 Elec CBD For Dessie 2009nnnnnDocument166 pages2nd QTR '2009 Elec CBD For Dessie 2009nnnnnfirst name last nameNo ratings yet

- Termocupla y RTDDocument3 pagesTermocupla y RTDRUBEN DARIO BUCHELLYNo ratings yet

- User Manual For New HR11 6-10kVA Rack Mounted UPS (PF 1) - V1.4Document38 pagesUser Manual For New HR11 6-10kVA Rack Mounted UPS (PF 1) - V1.4Cristian ReyesNo ratings yet

- Lecture - 04Document15 pagesLecture - 04Em GomezNo ratings yet

- Precise CTDocument4 pagesPrecise CTThanasate PrasongsookNo ratings yet

- Experiment 7 FinalsDocument8 pagesExperiment 7 FinalsKlydeJoseNo ratings yet

- 100-101-10-Maxi Automation Pure Datasheet 20-06-2017Document5 pages100-101-10-Maxi Automation Pure Datasheet 20-06-2017Tházio LimaNo ratings yet

- Integrated Switchgear Solutions: Training Course Level 1Document59 pagesIntegrated Switchgear Solutions: Training Course Level 1prashantj_6100% (3)

- Wiring Diagram Electric Release 05Document94 pagesWiring Diagram Electric Release 05Bhira SomaNo ratings yet

- Module 5Document20 pagesModule 5yakomi suraNo ratings yet

- ALP CBT 2 Electronic Mechanic 21 Jan 2019 Shift 1 EnglishDocument16 pagesALP CBT 2 Electronic Mechanic 21 Jan 2019 Shift 1 EnglishDan Edison RamosNo ratings yet

- Neoctavia PDFDocument1 pageNeoctavia PDFAlvaro MesquitaNo ratings yet

- Names of Codes For Electrical WorksDocument8 pagesNames of Codes For Electrical WorksAsad KhanNo ratings yet

- Earthing of GIS Type ELK - GTIDocument20 pagesEarthing of GIS Type ELK - GTIJairo MoralesNo ratings yet

- Equivalent Circuit of Induction MachinesDocument16 pagesEquivalent Circuit of Induction MachinesutkanpazarNo ratings yet

- Choke Design Using Iron Powder Toroidal CoresDocument13 pagesChoke Design Using Iron Powder Toroidal CoresAbderrahim AbarayNo ratings yet

- Permanent Magnet DC MotorDocument4 pagesPermanent Magnet DC MotorPulkit ChaudhariNo ratings yet

- Insulation Coordination FundamentalsDocument62 pagesInsulation Coordination FundamentalsKashinath PscNo ratings yet

- High Resistance GroundingDocument3 pagesHigh Resistance GroundingRajendra Prasad ShuklaNo ratings yet

- Epower™: MC ControllerDocument2 pagesEpower™: MC Controllermonica_lelisNo ratings yet

- Installation&Operation Manual For MAX PDFDocument35 pagesInstallation&Operation Manual For MAX PDFJandiego SilvaNo ratings yet