Professional Documents

Culture Documents

Flange Failure 1

Flange Failure 1

Uploaded by

gvvrsuneelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Failure 1

Flange Failure 1

Uploaded by

gvvrsuneelCopyright:

Available Formats

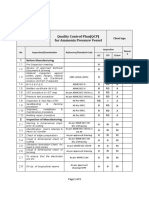

QUALITY BULLETIN 1/2008

FAILURE OF FABRICATED TEST BLIND FLANGE FOR HYDROSTATIC

TESTING

During the hydrostatic testing of a 40 HP Fuel Gas line, a 40diameter, 4 thickness

blind flange failed at approximately 1500 psig pressure before reaching test pressure of

1753 psig. Failure attributed to:

Failure by Contractor to meet specified quality requirements

Failure by Saudi Aramco Inspection personnel to verify requirements

The test blind flange was fabricated from plate material by the construction subcontractor (Inspector was informed this was the first time the test blind had been used.)

Following the incident, the prime contractor was instructed by SAPMT to perform an

investigation into the root cause of the failure. At the same time, Inspection instructed

corrective actions to be implemented to prevent a similar occurrence. These instructions

were again restated to the Prime and construction sub-contractor and SAPMT during the

weekly quality meeting. A preliminary report was required to be submitted to SAPMT

by close of business day.

This report was still being prepared by Contractor and the subcontractor.

An independent review by Inspection Department consisting of visual inspection of the

failed blind flange, review of the hydrostatic test package as well as several meetings

with Contractor Quality Assurance Manager and Construction QC Manager was able to

determine the following:

Blind Flange

The test flange fabricated by CCC contained no markings as to material, type and grade.

Pressure rating of 600 was written on the flange in ink marker. Further, neither

Contractor nor Construction subcontractor could provide any information regarding

welding procedures applied and welder(s) qualification. The blind flange was fitted with

two welded nipples intended for filling and venting.

Weld defects were observed on visual inspection as shown above. The flange was

fabricated during an extreme cold period the week before. The following factors may

have contributed to the failure:

The lack of pre-heat

maintaining interpass temperature control

PWHT

unsuitable welding procedures

welder qualifications

welding consumables

inadequate quality control i.e. visual and NDE inspections

Hardness tests of the weld, heat affected zone (HAZ) and base metal were requested from

Contractor. Results of hardness tests are still outstanding. It appears that failure

originated in the HAZ of the 1 nipple welded in the center of the blind flange and

propagated across the entire face of the plate to opposite bolt holes (laminar tearing type

defect.)

The failure crack depth is approximately 3 deep. Both ASME pressure vessel and piping

codes and SAES-A-004 allow for the use of fabricated flanges from plate material based

4

on appropriate calculations. SAIC-A-2009 requires fabricated flanges to be supported

with appropriate engineering calculations.

Since the construction sub-contractor fabricated the blind flange in their weld

shop, calculations should have been available along with the welding procedures

and detail of the connections approved by prime contractor engineering.

The calculations were requested from both Contractor and sub-contractor but could not

be produced.

Based on actual thickness of the flange (100mm), its estimated to be at least

35% under thickness.

Hydrostatic Test Package

A hydrostatic test package is prepared for each hydrostatic test. The make-up and review

of each test package is an ongoing process involving all parties, contractor, subcontractor

and Inspection.

the hydrostatic test package was initiated by Contractor Engineering

a Pressure Testing Punchlist (Pre-Test) was prepared by subcontractor and

reviewed by contractor and PID inspector

completion of A items (work to be completed prior to hydro test) was signed

off by Contractor, subcontractor and the Saudi Aramco inspectors

Isometric/Spool control sheet was reviewed by PID inspector for completeness

Pre-Test Check List was completed by subcontractor but does not indicate review

and approval by Contractor

Item number 30 of the Contractor/Sub-contractor Pre-Test Check List (Confirm

test spades/blinds installed (as per limits)) was signed off by Sub-contractor QC

There is no provision on the Pre-Test Check List for review and sign-off by the

Saudi Aramco inspector

Test Pack Release Record (for hydro test) was initiated by subcontractor and

reviewed by prime contractor covering:

Test Pack Review Contents

Punch List Clearance (A items completed)

Isometric Control Sheet sign off

Pretest Check List

Test Pack Release Record was not signed off by the Saudi Aramco inspector

The Pre-test Check List clearly shows the sign off by the subcontractor QC inspector to

confirm that the test blind was properly installed per the test limits (item 30 on the check

list.) The Contractor/Sub-contractor hydrostatic test procedure also confirms that the

requirements of SAES-A-004 will be met. Due to the absence of calculations, this

suggests that the sign-off of item 30 was done by sub-contractor QC without actually

verifying the existence of the required calculations to verify the appropriateness of the

test flange.

Saudi Aramco Inspection Monitoring

PID inspector was present at time of hydro

The PID inspector relied on the Sub-contractor QC to verify the test flange was

of the proper rating. Saudi Aramco Checklist SAIC-A-2009 (Verification of Test

Preparation and Test Equipment for Pressure Testing), items B1 and B2 clearly

state:

Test piping, fittings and hoses are designed or have pressure rating that match or

exceed the system test pressure (G.I. 2.102, Section 4)

Paddle blinds or spectacle blinds used to isolate the test sections are of the same

class rating of the system or may be fabricated based on appropriate calculations

(SAES-A-004, Para. 7.3)

PID inspector did not verify that the installed test blind was suitable for the test

PID inspector did not utilize SAICs during reviewing and monitoring pre-test

activities

Had SA Checklists been utilized to verify test preparation and readiness then this would

have clearly identified the need to verify blind flange was supported by engineering

approved calculations.

SAIC are only used as the basis of focused assessments. At the time of this test, no

focused assessment had been done for verification of preparation of hydrostatic testing.

Corrective Actions

Project Inspection instructed Contractor/Sub-contractor to implement the following:

verify all fabricated flanges have appropriate calculation approved by Prime

Contractor engineering

all hydrostatic test equipment must be suitably identified (preferably with color

coding) to indicate the safe pressure rating

include hydrostatic test equipment list with pressure ratings and include in

hydrostatic test package

QC to verify correct test equipment is installed prior to start of test

At the time of my visit, sub-contractor was in progress of segregating and color coding

test flanges per their pressure rating/thickness. It is estimated that as many as 1000

flanges must be identified and color coded. Many test flanges were observed in the

hydrostatic test yard without any form of identification. Color coding has started on test

flanges without weld connections. Once these are complete, sub-contractor will inspect

and identify pressure ratings of flanges that have welded connections.

Note this may require the removal and re-welding of connections/attachments.

PID inspection will review that appropriate calculations have been prepared and

approved by prime contractor engineering and that welding has been performed in

accordance with suitably approved WPS and welders are qualified and will perform a

random inspection of flanges (thickness check) and color coding applied.

Recommendations

This project is in the early stages of hydrostatic testing, with over 6500 hydrostatic tests

remaining to be completed. This construction contractor as well as most others

construction contractor working on Saudi Aramco projects frequently use fabricated test

flanges for hydrostatic testing which are fabricated in their own weld shops.

All projects need to ensure to review the capability of the hydrostatic test facility

prior to start of hydrostatic testing to include all testing equipment, including test

manifolds, blind flanges, bolts, gaskets to ensure that all test equipment is

properly identified and suitable for testing

7

All project inspection sections need to implement the Saudi Aramco ID SATIPs

and SAICs (Using SAIC makes the inspector more aware of SA requirements.)

ID management needs to mandate the use of the SAIC by inspectors

Revise SAES-A-004, paragraph 7.3 to include review and approval of

calculations and fabrication of test flanges by engineering/SAPMT?

You might also like

- Pressure Vessel, Asme CodeDocument10 pagesPressure Vessel, Asme Codeabhi_mohit2005100% (1)

- Quality Control Engineer General ResponsibilitiesDocument29 pagesQuality Control Engineer General ResponsibilitiesAkansha SharmaNo ratings yet

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Recommendations For FRP VesselsDocument2 pagesRecommendations For FRP VesselsA. Adriano UreñaNo ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Quality Control Engineer General ResponsibilitiesDocument29 pagesQuality Control Engineer General ResponsibilitiesAkansha SharmaNo ratings yet

- About Techshore Inspection ServicesDocument6 pagesAbout Techshore Inspection ServicesTechshore Inspection Services100% (1)

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Pressure Vessel - Columns - AnimateDocument16 pagesPressure Vessel - Columns - AnimateSamir ChaudharyNo ratings yet

- Foam SprinklerDocument2 pagesFoam SprinklerMokhles KichoNo ratings yet

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDocument3 pagesQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Fabrication of ManifoldDocument2 pagesFabrication of Manifoldsarangpune100% (1)

- Pad Type NozzleDocument2 pagesPad Type NozzleSajal Kulshrestha0% (1)

- Pressure Vessel Design ASME Sec. VIIIDocument37 pagesPressure Vessel Design ASME Sec. VIIIprayogo1010No ratings yet

- Pressure Vessel Design Safety: Suryakant RanderiDocument46 pagesPressure Vessel Design Safety: Suryakant Randericonny julandaNo ratings yet

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDocument319 pagesA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocument1 pageShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Welding Procedure PIPE HDPE - Rev.03Document29 pagesWelding Procedure PIPE HDPE - Rev.03DORBANI NedjmeddineNo ratings yet

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- Hydrotesting Not Required Under New API-653 Procedure - Oil & Gas JournalDocument9 pagesHydrotesting Not Required Under New API-653 Procedure - Oil & Gas JournalamokhtaNo ratings yet

- Blind Flange With Multiplpe Opening (U Stamp) )Document12 pagesBlind Flange With Multiplpe Opening (U Stamp) )Ashish Dhok0% (1)

- Inspection and Test Plan For Reciprocating CompressorDocument21 pagesInspection and Test Plan For Reciprocating CompressorNorman Morales100% (1)

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 pagesCollar Bolts: in Shell and Tube Heat ExchangersMahdi Hocine100% (1)

- Welding Inspection ProcedureDocument5 pagesWelding Inspection ProcedurePugalNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Hydrotest BlindDocument9 pagesHydrotest BlindAdrian RogersNo ratings yet

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNo ratings yet

- Con8522 - Casey-Fdmee Epm and Erp Integration Con8522Document41 pagesCon8522 - Casey-Fdmee Epm and Erp Integration Con8522parmitchoudhuryNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Pneumatic Test Procedure For SeagullDocument4 pagesPneumatic Test Procedure For SeagullDarkvaderNo ratings yet

- QC Questionery. PIPINGDocument6 pagesQC Questionery. PIPINGMd Sharique100% (3)

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocument18 pagesCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- Overhaul Manual: Continental Aircraft EngineDocument438 pagesOverhaul Manual: Continental Aircraft EngineHermes Garcia Vaquero100% (2)

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan Panchal100% (1)

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- Using s275jr For Asme Div1 Vessel-UnassignedDocument6 pagesUsing s275jr For Asme Div1 Vessel-UnassignedNasrul AdliNo ratings yet

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure CalculationChetan B Kapadia100% (13)

- Ped Hazard Check ListDocument2 pagesPed Hazard Check ListakisdassasNo ratings yet

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Design Calculation Anchor Flange ASME VIII Div 1Document4 pagesDesign Calculation Anchor Flange ASME VIII Div 1Dhia SlamaNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Material Handling Equipment: RAFIULLAH KHAN MSC PROJECT REPORT PDFDocument46 pagesMaterial Handling Equipment: RAFIULLAH KHAN MSC PROJECT REPORT PDFrafimarwat67% (12)

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGAR100% (1)

- Hot Bolting Procedure PDFDocument2 pagesHot Bolting Procedure PDFmasmarkun4444100% (3)

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Performance of Austenitic Stainless Steel in Wet Sour Gas Part 2Document5 pagesPerformance of Austenitic Stainless Steel in Wet Sour Gas Part 2wholenumberNo ratings yet

- BOLTRIGHT Tightening Procedure 20-900Document2 pagesBOLTRIGHT Tightening Procedure 20-900zeids100% (4)

- Conpipe - CementlingDocument43 pagesConpipe - Cementlingויליאם סן מרמיגיוס50% (2)

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDocument2 pagesAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- Vessel Pressure TestingDocument3 pagesVessel Pressure TestingYetkin ErdoğanNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Inspection and Test Plan For Pressure Vessel - Important PointsDocument21 pagesInspection and Test Plan For Pressure Vessel - Important PointsNorman MoralesNo ratings yet

- Fabrication, Inspection, Testing and Supply of Stainless Steel DrumsDocument17 pagesFabrication, Inspection, Testing and Supply of Stainless Steel DrumsAmitNo ratings yet

- Inspection and Test Plan (Itp) For Control ValvesDocument15 pagesInspection and Test Plan (Itp) For Control ValveszakariaNo ratings yet

- Procedure Plant and Equipment SafetyDocument9 pagesProcedure Plant and Equipment SafetyJean Claude EidNo ratings yet

- Spherical Bearings Loader Slot Bearings Rod End Bearings Sleeve BearingsDocument43 pagesSpherical Bearings Loader Slot Bearings Rod End Bearings Sleeve BearingsMar SolNo ratings yet

- Cloud Computing Is Internet-BasedDocument16 pagesCloud Computing Is Internet-BasedsnaveenrajaNo ratings yet

- Airport Safety Management SystemDocument33 pagesAirport Safety Management Systemrashid01032No ratings yet

- 601 0532 Rev1Document47 pages601 0532 Rev1Ing NavaNo ratings yet

- Bill of QuantityDocument7 pagesBill of QuantityAnonymous YHVmpLoNo ratings yet

- Gurunadh R: Professional ProfileDocument4 pagesGurunadh R: Professional ProfileMahendraKumarNo ratings yet

- Part 21 AMCGM Rev 4 Incl 69-2014 01-12-2014Document472 pagesPart 21 AMCGM Rev 4 Incl 69-2014 01-12-2014Marius IlieNo ratings yet

- An Organization Study On Rydon Industries at CBEDocument40 pagesAn Organization Study On Rydon Industries at CBElavanya mohanNo ratings yet

- Fastwind Monoshock 200 Picture Book 2011 EpaDocument32 pagesFastwind Monoshock 200 Picture Book 2011 EpaJe AnNo ratings yet

- Flight Performance of A Package Delivery Quad Rotor BiplaneDocument12 pagesFlight Performance of A Package Delivery Quad Rotor BiplaneBreno Brito MirandaNo ratings yet

- Commonwealth HS Roofing DPDocument4 pagesCommonwealth HS Roofing DPjay vasquezNo ratings yet

- 1327 - VE Ref. MNL by F. Sherwin, 62Document334 pages1327 - VE Ref. MNL by F. Sherwin, 62Anonymous FpRJ8oDdNo ratings yet

- CP 2 Vibration Monitoring and Analysis GuideDocument5 pagesCP 2 Vibration Monitoring and Analysis GuideCristian GarciaNo ratings yet

- Resume - Welding InspectorDocument4 pagesResume - Welding InspectorPradeep ManivannanNo ratings yet

- PJHA Minggu 1Document2 pagesPJHA Minggu 1jumaliNo ratings yet

- Standard Products: INR Price List No. DFL-08 Effective 1st Oct 2018Document11 pagesStandard Products: INR Price List No. DFL-08 Effective 1st Oct 2018RAHUL RICONo ratings yet

- An Analysis of The Madaras Rotor Power Planta - Alternate Method For Extracting Large Amounts of Power From The Wind - Vol 2Document427 pagesAn Analysis of The Madaras Rotor Power Planta - Alternate Method For Extracting Large Amounts of Power From The Wind - Vol 2binho58No ratings yet

- Sop QutDocument2 pagesSop QutTrans Globe JamnagarNo ratings yet

- AGRISTA: Vol. 4 No. 3 September 2016: Hal. 405 - 413 ISSN 2302-1713Document9 pagesAGRISTA: Vol. 4 No. 3 September 2016: Hal. 405 - 413 ISSN 2302-1713Vhisnu DharmaNo ratings yet

- Control of The Twin-Rotor System: Than T. ThinhDocument8 pagesControl of The Twin-Rotor System: Than T. ThinhDouglas SanchezNo ratings yet

- Plant LocationDocument8 pagesPlant LocationMuhtasim FuadNo ratings yet

- Facilitator: Dr. N. Vishal Kumar Gupta, Asst. Professor, Dept. of Pharmaceutics, Jss Colege of Pharmacy, MYSORE-15Document21 pagesFacilitator: Dr. N. Vishal Kumar Gupta, Asst. Professor, Dept. of Pharmaceutics, Jss Colege of Pharmacy, MYSORE-15kavya nainita0% (1)

- Mohammed Shaban, M.SC., PMP®: About MeDocument3 pagesMohammed Shaban, M.SC., PMP®: About MeMohammed ShabanNo ratings yet

- Maintenance Performance Measurement (MPM) : Issues and ChallengesDocument14 pagesMaintenance Performance Measurement (MPM) : Issues and ChallengesMitt JohnNo ratings yet