Professional Documents

Culture Documents

2 Technology Evolution

2 Technology Evolution

Uploaded by

Arash AthCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Technology Evolution

2 Technology Evolution

Uploaded by

Arash AthCopyright:

Available Formats

Options

Next

Technology Evolution of the Proven Gas Turbine Models V94.2 and V84.2 for New UNITS and Service Retrofits Gerhard Bohrenkmper, Dietmar Reiermann, Gerald Hhne Dr. Ulrich Lingner Siemens AG, Power Generation, Germany

Page 1 of 20

Options

Previous

Next

Contents:

Abstract...................................................................................................................................3 Introduction ............................................................................................................................4 1 The proven models V94.2 and V84.2, important performers in the Siemens Heavy Duty Gas Turbine Product Line ............................................................................................5 2 Development Roadmap for V94.2 and V84.2 ................................................................6 Thermodynamic Performance and Design Evolution of V94.2 ..........................................7 Extension of Maintenance Intervals for V94.2 and V84.2 ...................................................7 3 Operating and Maintenance Results for V94.2 and V84.2 Fleet..................................8 4 Overview of V Gas Turbine Modernization Products ................................................10 5 Turbine Inlet Temperature Upgrade (TT1+) or Extended Maintenance Interval (41MAC).................................................................................................................................10 6 Compressor Mass Flow Increase Upgrade (CMF+) ...................................................13 7 Performance Upgrade Matrix for V94.2 fleet .............................................................13 8 Dry Low-NOx (DLN) Upgrade Using HR3 Burner........................................................14 9 Performance Boost with Wet Compression (WetC)...................................................16 10 Summary, Conclusion and Future Prospects.........................................................18 Appendix: 31 Figures...........................................................................................................18 References ............................................................................................................................19

Page 2 of 20

Options

Previous

Next

Abstract In the 1970s an increased demand arose for heavy-duty gas turbines. The Siemens answer to this trend was the development of the 50-Hz V94.2 gas turbine, followed by its 60-Hz sister model V84.2. Since market introduction of the first V94.2 gas turbine at Walheim (Germany) in1981 and the first V84.2 at Hay Road (USA) in 1989, the V94.2/V84.2 gas turbine fleet has accumulated over 10 million operating hours with more than 240 units installed. A continuous development process driven by both the new units market and the service modernization market has resulted in two gas turbine models that have demonstrated their outstanding capabilities in worldwide applications over the past 23 years. These applications include single- and multi-shaft combined cycle, simple cycle, cogeneration and integrated coal gasification combined cycle. In the case of the V94.2 gas turbine, incremental design improvements have increased output and efficiency from initially 112 MW/31% to 163 MW/34.5%. The performance evolution of the V84.2 is similar. During the last five years service modernization products have also contributed to design advancements for the new units market. Power augmentation measures such as classical water/steam injection or modern wet compression provide additional gas turbine power output during peak periods for both simple-cycle and combined-cycle operation. Unlike classical water/steam injection into the combustion chamber, which results in a drop in efficiency, the recently developed wet compression method has demonstrated significant efficiency improvements for the V84.2/V94.2 in simple cycle. Due to their specifically designed short startup times and fast responses to grid demands, frequency stabilization can be realized. Both gas turbine models are characterized by the same robust and mature design and a capability to burn a variety of fuels from low- to high-caloric gaseous and/or liquid fuels to treated heavy oil with extremely low emissions. For this purpose the VX4.2 is equipped with the Siemens Hybrid Burner System for single- or dual-fuel operation. Highest possible availability and reliability and lowest possible specific operating cost are major preconditions for economical plant operation. The moderate turbine inlet temperatures of the V94.2/V84.2 models result in extended maintenance intervals of up to 41,000 equivalent operating hours (EOH), increased availability and hence reduced life cycle cost. Numerous upgrades are available and this paper describes how and which of todays technologies can be applied to older VX4.2 installations in simple- or combined-cycle applications to respond to a market that is growing more and more competitive. New upgrade development are underway to further optimize customer and environmental benefits.

Page 3 of 20

Options

Previous

Next

Introduction Driven by market requirements Siemens develops V94.2 / V84.2 product upgrades for both service and new units business. For this purpose, state-of-the-art methods of analysis have been used in service engineering that have been calibrated and optimized based on operating results, prototype testing, plant tests and findings from minor and major inspections. Products reflect market needs for improved reliability and availability, lower life cycle cost, higher thermodynamic output and lower environmental impacts (nitrogen oxide (NOx) and carbon monoxide (CO) emissions). The efforts associated with modernizing and upgrading gas turbine power plants are made by owners and operators for a single reason: the profitability of their power plants. Profitability is improved in a number of ways. These can include more favorable power purchase agreements, improved timing and accuracy of bidding for power supply contracts on the open power supply market, decreasing operating costs, selling NOx credits, increasing plant efficiency and output, improving reliability and availability, employing best practices in plant operation and maintenance, increasing operational flexibility and decreasing maintenance outage time. Modernization products are designed to be implemented during the regular outage time for routine maintenance inspections. Various occasions for retrofits occur in practice: Minor inspections Hot-gas-path or major inspections Conversions to gaseous fuel Conversions to combined cycle Life time extension measures after 100,000 EOH when the hot-gas components have reached the end of their service lives. We have experienced, that the effects of upgrade technology can be maximized when used also to recover the effects of long-term degradation during major maintenance outages. Early discussions on upgrade opportunities with OEM input in respect to technologies available and electricity producer input in respect to specific market requirements lead to optimised mutual benefits.

Page 4 of 20

Options

Previous

Next

The proven models V94.2 and V84.2, important performers in the Siemens Heavy Duty Gas Turbine Product Line

Siemens' heavy-duty gas turbine product line covers the range from 67 MW to 278 MW for both the 50-Hz and 60-Hz markets (Figure 1); the industrial gas turbine product line with ratings between 5 MW and 43 MW is not shown here. The mature 163-MW 50-Hz gas turbine model V94.2 and the scaled 110-MW 60-Hz gas turbine V84.2 are highlighted in this paper. The gap between those frames and the largest Siemens model, the V94.3A rated at 278 MW is closed by the advanced 188MW V94.2A. Due to their long market history and their proven maturity the V94.2 and V84.2 gas turbines have been described in detail on several occasions in previous documents [1;2]. Their salient features demonstrating their simple and robust design can be summarized as follows (Figure 2): 17/16-stage compressor, adjustable inlet guide vanes (IGVs), optionally fastacting for grid frequency stabilization Two large external silo-type combustors carrying 2x8/2x6 burners for 50/60 Hz Hot casings weld-fabricated from Ni-based material, designed with single shell for elbow-shaped mixing casings or double shell for inner casing 4-stage turbine with conventionally cast blading made of Ni-based material, Stages 1 and 2 with conventional cooling providing fuel flexibility (including ash-forming fuels, that cannot be burnt in connection with applying film-cooled blading) and moderate maintenance costs Built-up disc rotor with radial Hirth serrations and one central tie rod for ease of recoating the compressor blading and for ease of modernization Two bearings only, no intermediate bearing in the hot section Generator at cold end facilitating unfired combined-cycle (GUD) plant design Axial exhaust design for ease of simple cycle and especially GUD plant design Fast starting capability, a major advantage for peaking and black start applications. Focussing on the silo-type combustor (Figure 3) the design for robustness and simplicity is evident: When looking at the silo-type combustor design (Figure 3) its robustness and simplicity become evident: Flame tubes are lined with easily replaceable ceramic tiles; for ash-forming fuels a specific flame tube option is available as well as for low-Btu gas Walk-in combustion chamber design enables minor walkthrough inspection without cover lift, only one manhole is opened Hybrid burners in premix mode for dry low NOx and low CO emissions (natural gas & fuel oil) Diffusion burners for special fuels, e.g. ash-forming fuel oil or low-Btu gas such as synthetic gas or coal gas used in V94.2 and V94.2K; these burners have options for integrated water or steam injection The combustion chamber dome can easily be modified when required for low-Btu gas diffusion burners Turbine blading benefits from highly uniform hot-gas temperature distribution due to the considerable mixing distance and from non-exposure to flame radiation.

Page 5 of 20

Options

Previous

Next

These features make the V94.2/V84.2 highly attractive for both continuous-duty combined cycles as well as peaking applications. Five years ago requirements from service modernization marketing as well as from new units marketing resulted in a development roadmap for the V94.2 and V84.2 and in subsequently developed upgrade products. These efforts have been rewarded by orders from both the service modernization and new units markets. Consequently V94.2 as well as V84.2 represent essential members and important performers in Siemens' heavy-duty gas turbine portfolio not only in 2004 but also in the future. 2 Development Roadmap for V94.2 and V84.2

A development roadmap also needs to be established in an iterative process. To meet the requirements from both service modernization and new units marketing, first design and market studies were performed regarding improvements in power output, efficiency, emissions, and availability & reliability. In these studies we evaluated the latest gas turbine and power plant technologies in terms of their feasibility for download to these mature frames (Figure 4) evaluated technological advances especially applicable for the V94.2 and V84.2 such as welding and coating procedures for welded hot casings, refined impingement cooling, upgraded maintenance procedures, etc. assessed related technical risks and managed those to be fairly low e.g. by strict validation and testing planning ensured value generation for our customers' overall plants to improve their profitability and competitiveness established viable commercial business cases for the OEM in view of the considerable R&D funding that is necessary. Secondly, the roadmap was set up based on the product development process, beginning with the product requirement specification and ending with product shipment. Furthermore this roadmap integrates modular upgrades into frame strategies for both frames, a simplified format of which is shown in Figure 5. The development roadmap was based on the V94.2(3) (read: V94.2 Version 3) in the year 1999. This version was supplied by the OEM from 1989 to 2001 with 1060C TT1-ISO as the most recent status. Modular upgrades that have meanwhile been released are: Turbine Inlet Temperature Upgrade (TT1+) from 1060C ISO to 1075C ISO achieved through hot-gas-path modernization measures; these measures can alternatively be used for an extended MAintenance Interval (41MAC) when operating at the base turbine inlet temperature of 1060C; this product has been available since 2001; Compressor Mass Flow Increase (CMF+) mainly produced by upgrading the front four rows of the compressor; this product has been available since 2003; Wet compression which was developed and made available in 2003. Because of market demands the 41MAC option is also available for the entire V94.2 roadmap, i.e. also for the CMF+ design. The upgrades introduced here are discussed in greater detail below.

Page 6 of 20

Options

Previous

Next

Thermodynamic Performance and Design Evolution of V94.2 The evolution in thermodynamic performance is shown in Figures 6 and 7 to illustrate the base-load performance gain indicated in the roadmap sketch. Although related to relatively limited and moderate component upgrades, a specific nomenclature for the different evolution steps of the VX4.2 family is used to facilitate understanding of the individual design modifications, performance steps and progress in maintenance interval extension: V94.0: forerunner of the V94.2, first frame designed at that time with a compressor mass flow of approximately 485 kg/s; V94.2(1): manufactured from 1980 to 1985; TT1-ISO = 930C to 1000C; salient hardware features: IGVs non-adjustable for the first units; welded hot casings made of austenitic steel; vane #1 and blade #1 as well as vane #2 cooled; blade #3 and #4 made of forged material; blade #4 with damping bolts; vane #4 segments with weld-in airfoils comparable to steam turbine design; analog I&C; V94.2(2): manufactured from 1986 to 1989; TT1-ISO = 1000C to 1050C; adjustable-pitch IGVs; welded hot casings made of Ni-based material; in addition blade #2 is cooled now; free-standing blade #4 with short shank design; single cast vane #4; digital I&C; V94.2(3): manufactured from 1990 to 2001; TT1-ISO = 1050C to 1060C; this design represents the majority of the fleet; vane carrier designed to allow rollout disassembly and clearance adjustment from outside; since then entire turbine blading has been conventionally (equiaxed) cast from Ni-based material; cooling and sealing air system improved by adding an internal extraction in the compressor to supply turbine Stages 2 to 4; diffusion-type chromium coatings later replaced by MCrAlY-type overlay coatings for turbine Stages 1 and 2; V94.2(4): V94.2(3) plus hot-gas-path upgrade TT1+, no longer in production by OEM since it has been replaced by the V94.2(6); V94.2(5): V94.2(3) plus compressor upgrade CMF+ ; V94.2(6): V94.2(3) plus TT1+ plus CMF+. The design evolution of the V84.2 was very similar to that of the V94.2. The performance evolution for the historical frames and versions from the V94.0 through the V94.2(1) and V94.2(2) to the V94.2(3) shows an output increase from 90 MW to 163 MW and an improvement in gas-turbine simple-cycle efficiency from 30.3% to 34.6% From the V94.2(3) to the V94.2(6) a remarkable power increase for both simple-cycle and combined-cycle operation and an improvement of 0.3 percentage points in combined-cycle efficiency have been gained. Extension of Maintenance Intervals for V94.2 and V84.2 The roadmap discussed so far also includes an extension of the maintenance interval for the V94.2/V84.2. The majority of the fleet operates on continuous or intermediate duty in unfired combined-cycle power plants. Planned outages for maintenance of the relatively small module gas turbine not only switch off the gas turbine power but also necessitate shutdown of the heat-recovery steam generator (HRSG) and the

Page 7 of 20

Options

Previous

Next

related steam production for the steam turbine. As the maintenance intervals of the gas turbine are much shorter than those of the steam turbine, generator and other major components of the overall plant, the mismatch in overall plant maintenance is evident. Therefore, for our service customers, a potential availability gain is extremely valuable since more megawatt-hours can then be sold to the market and turnover increases. Figure 8 shows the extension of the maintenance intervals in two steps. While the turbine inlet temperature TT1-ISO remained constant at 1060C, each evolutionary step is combined with the associated hardware upgrade: Starting point is the 25 kEOH MAintenance Concept (MAC) before 1996. This concept comprises hot-gas-path inspections every 25 kEOH and major inspections every 50 kEOH. As a main activity, hot-gas components such as inner casing, mixing casings and turbine Stages 1 and 2 need to be repaired or recoated every 25 kEOH. Assuming a base-load unit operating about 8000 EOH per year, a hot-gas-path inspection is scheduled for every 3 calendar years. Introduced in 1996, 33MAC is based on improved hot components such as the upgraded turbine blade row #1, MCrAlY-type overlay coatings instead of diffusion-type chromium coatings for Stages 1 and 2 and welded inner casing and mixing casings made of Ni-based material. With this concept hot-gas-path inspections are carried out every 33 kEOH and major inspections every 66 kEOH. Considering again a base-load unit operating about 8000 EOH per year, the hot-gas-path inspection is now planned for every 4 calendar years. The availability factor improves by 0.9% and within an operating interval of 100 kEOH one complete hot-gas-path inspection (2 instead of 3) and the associated maintenance and blade refurbishment costs can be eliminated. Based on the approach applied for the 33MAC upgrade and the experience and inspection findings gained from the fleet leaders after 33 kEOH we developed the 41MAC and released this in 2001. The 41MAC upgrade measures are explained below in greater detail. Considering again a baseload unit operating about 8000 EOH per year, the major inspection is now scheduled for one year later i.e. every 5 calendar years. The availability factor improves by 0.9% allowing more megawatt-hours to be sold and increasing turnover. With 2 major inspections after 41 kEOH and 82 kEOH the operating interval can be stretched from 100 kEOH to 123 kEOH. Due to the longer component service life and reduced repair effort, the average life cycle cost also decreases. Both effects availability and subsequent turnover increase on the one hand and life cycle cost reduction on the other help generate more benefit for our customers. 3 Operating and Maintenance Results for V94.2 and V84.2 Fleet

The V94.2 fleet of gas turbines with more than 160 units installed has to date accumulated 4.8 million operating hours (OH) and more than 7 million EOH. For the installed 80 units of the V84.2 model, 1.4 million OH and 2.5 million EOH have been logged. These fleets, together with V94.2 units from license projects, have experienced more than 134,000 starts and clocked up more than 10 million EOH so far (Figure 9).

Page 8 of 20

Options

Previous

Next

Taking a brief look at the fleet leaders (Figure 10) the results are as follows: With a world record in its class of 6900 starts at Freimann/Munich with the original rotor, the robust rotor design of the V94 has clearly been demonstrated. The slightly modified rotor of the V94.2(3) is now approaching 3000 starts (Serdang/Malaysia). Many V94.2 units have already reached the 100 kEOH milestone and are now undergoing life extension measures for another 100 kEOH or 123 kEOH according to the 41MAC upgrade; in fact, 8 units have already passed 150 kEOH and 2 units have logged even more than 200 kEOH. An important criterion in industry is always which reliability and availability figures are related to these operating data. The V94.2 and V84.2 models although operating with a high service factor because they are mostly used for continuous-duty applications enjoy excellent figures. An analysis was performed of 29 Model V94.2 units over a five-year period from 01/1999 to 12/2003: The reliability factor V3 reached 99.7% (average value) for the 29 units, with 8 of these units even reaching 100.0%. The availability factor V7 reached 94.7% (average value) including hot gas path and major inspections that are to be considered within the 5 years evaluation period. Among these, 2 units at Pasir Gudang/Malaysia even demonstrate an availability of 96.8% which for a continuous-duty GUD power plant is a benchmark. Diving deeper into the availability analysis we find that Pasir Gudang attained these excellent figures because they are using the 33MAC maintenance concept that provides for a hot-gas-path inspection every 4 years. In addition to this, a well-trained Siemens field maintenance group located in South-East Asia has enabled outage durations to be cut down to just 17 days ([3]. With more and more units using the 41MAC concept from now on, a further improvement of the availability in the order of 0.9% seems realistic. Although the majority of fleet operating hours originate from natural gas firing the smaller number of units firing fuel oil also provide an important contribution to the positive operation experience. Most applications use fuel oil no.2 quality and 3 units are also firing Naphtha. Applications vary : using fuel oil as a backup using fuel oil as single fuel dual fuel applications using proportionate both fuel oil and fuel gas. Being highly suitable for burning contaminated ash-forming fuels thanks to the VX4.2 combustor design and the conventional non-film-cooled hot gas path, the eight VX4.2 units considered here have accumulated around 300,000 fired hours with ashforming fuels (Figure 11). Vanadium contamination varies over a wide range from 14 to 300 ppm. By supporting operation and maintenance for this fuel variety, Siemens has gained enormous know-how in this specialized field. Another special fuel is syngas (low-Btu gas). Its caloric value can be one order of magnitude lower compared to natural gas or pure methane. To date, three units have accumulated more than 138,000 fired hours and have demonstrated a mature technology (Figure 12). One of these units, Buggenum in the Netherlands, is a

Page 9 of 20

Options

Previous

Next

customized V94.2 gas turbine operating in an integrated coal gasification combinedcycle (IGCC) power plant. Integrated means that a considerable amount of compressed discharge air is extracted from the compressor in order to compensate for the larger coal gas mass flow. This measure avoids an increase in pressure ratio for the gas turbine. The extracted air mass flow is used in an air separation unit for oxygen production for the coal gasification process. The N2-fraction is recompressed and after mixing with the coal gas supplied to the syngas burners [4]. A dedicated design has been developed for the gas turbine casing, the burners and the combustor as well as for fuel supply and I&C. The two other units are located in Italy. They operate in a non-integrated process at a higher pressure ratio due to the larger syngas mass flow entering combustor and turbine. This feature is covered by the V94.2K design. It is derived from the V94.2 but has 17 compressor stages instead of 16 in order to improve compressor surge stability, and features modified burners and combustors as well as an adapted fuel supply and I&C. Because of our earlier design efforts and good operation experience with the relatively hazardous Naphtha fuel for V94.2 , we have already a basis available for firing and handling comparable non-standard liquid fuels. Hence another special fuel, methanol, is currently being investigated within an R&D project, the aim being able to fire methanol as a liquid fuel in a liquid fuel burner as an equivalent or alternative to LNG. 4 Overview of V Gas Turbine Modernization Products

A wide range of products which are either already available or currently under development by modernization engineering is shown in Figure 13. The upgrade packages can be grouped systematically in the following main categories: Efficiency -through increasing turbine inlet temperature, enhancing turbine aerodynamics, advanced compressor cleaning system and wet compression / Power through larger compressor mass flow, water injection and wet compression Combustion- reducing emissions and reducing fuel consumption, diversification of fuels (by dry low NOx combustion, fuel conversion and water injection) Increasing operational flexibility - through fuel diversification, grid frequency stabilization, improved starting behavior Reliability and Availability - through I&C improvement, extended maintenance intervals, reduced maintenance time. In the following we focus on some of the significant modernization products for the VX4.2 fleet highlighted in Figure 13. 5 Turbine Inlet Temperature Upgrade (TT1+) or Extended Maintenance Interval (41MAC)

As already introduced above, this upgrade product features attractive alternatives which increase either availability or turbine inlet temperature. These consist of extending the inspection interval from 33 kEOH (most V94.2 units) or, where

Page 10 of 20

Options

Previous

Next

applicable, 25 kEOH (many V84.2 units) to 41 kEOH, or increasing the turbine inlet temperatures from 1060C to 1075C for base-load operation (Figure 14). In the following we explain our design approach and the upgrade package. Regarding the hot gas path starting in the combustion chamber the flame tubes (see Section 8), mixing casings and inner casing were improved. In the mixing casings additional horizontal guides were installed (Figure 14), which require a modification of the mixing casing as well as of the combustion chamber pressure shell. The additional horizontal guides minimize wear at the mixing casing/inner casing transitions and thus contribute to longer inspection intervals for the GT. The inner casing of the VX4.2 GT has been specially redesigned in response to inspection findings encountered in recent years. The hub, the part of this casing most exposed to thermal fatigue, has been redesigned for higher thermo-elasticity and better cooling (Figure 14); this feature and modifications made at other locations have already been discussed in greater detail in [5]. An upgrade of the premix gas spider piping (see Section 8) is also necessary for the 41MAC maintenance approach; other recommended features are recaulking of the inner compressor vane shrouds at two locations and an upgrade of the manhole insert in the mixing casings. A most important upgrade feature are enhanced protective coatings for the turbine blading. The coating choice has been based on finite element structural analysis and metallographic investigations of service-exposed blades. Representative McrAlYcoated blades and vanes coming especially from fleet leader units after 33 kEOH have been examined by visual inspection for cracks and oxidation by metallographic analysis for examining internal surfaces and distinctive structural features (e.g. brittle phases) by metallographic investigation to estimate blade material temperatures by means of the gamma-prime-coarsening criterion: the gamma-prime-coarsened metal structure of the service blade is compared to a material structure catalog containing reference structures for various temperatures. The results have been a very useful tool for calibrating the heat transfer and structural stress analysis. It should be emphasized that investigations for the upgrade discussed here also require recalculation of the baseline blades and vanes using state-of-the-art stress analysis tools. The original analyses performed many years ago are no longer sufficient, the tools from that time have meanwhile been replaced by state-of-the-art analysis tools. Over the past years Siemens has channeled considerable R&D effort into validation and improvement of turbine blading. The associated calculations for rotor blades include both static and dynamic component loading (creep strength and low cycle fatigue (LCF)). It should also be mentioned at this point that the LCF strength analysis is based on the latest insights gained (local stress-strain approach, reported in [6]). Validation of the LCF strength analysis in particular is based on a comparison of calculated component strength with crack indications revealed during standard inspections and refurbishing of GT blades; in this case a crack propagation analysis has to be included. The improved protective coating systems chosen are listed in Figure 15.

Page 11 of 20

Options

Previous

Next

Raising the turbine inlet temperature (TIT) in the operating regime from 1060C to 1075C or using 41MAC requires specific protective thermal barrier coatings to appropriately reduce the temperature gradients (hot gas side/cooling air side), thus sufficiently reducing the static and dynamic loads on the blade to achieve correspondingly long service lives. The protective coating systems must also ensure optimum bonding between the less ductile thermal barrier coating (TBC) and the base material [7; 8]. Specially developed bond coats are required for bonding the TBC to the base material (Ni-based casting) because of the extreme differences in the physical properties of these materials. These protective coatings (bond coats) must also provide protection against high-temperature oxidation and corrosion. Premature wall thinning due to internal oxidation in the cooling air channels is prevented by aluminizing the cooling air side using a process developed by Siemens that is known as Sicoat1411. We design our components in such a way that this internal coating does not require renewal over the entire service life of the blades used in our Vx4.2 fleet. This applies for turbine airfoils in the first three rows. Internal aluminizing is not necessary for blade row #2 due to lower thermal loading. Stage-3 turbine vanes are protected against oxidation by an McrAlY-type coating applied using HVOF (High Velocity Oxygen Fuel Thermal Spray Process); refurbishment of this coating is not necessary during the entire lifetime (Figure 16). Refurbishment of the blading is planned for the other externally coated vanes #1 and #2, and blades #1 to #3. These requirements together with those for the welded hot casings are tabled in Figure 16. The upgraded blading discussed here can be implemented according to the customers needs to make the transfer to the operating and maintenance upgrade as smoothly as possible: As a complete upgrade package of new parts to replace the original ones By using single upgraded rows of blades or vanes with the additional benefit of longer component life and the option for transferring to the upgrade concept (41MAC or TT1+) at a later point in time when the package has been completed Upgrading the coating of original service-exposed blades and vanes through refurbishment to meet the 41MAC or TT1+ requirements. In the latter case the service life of the blades which has already been utilized must be known in order to precisely determine the subsequent operating cycle following advanced refurbishment. This is done based on the rule of linear damage accumulation [9] and uses the results of the baseline calculation of the original blading as well as the evaluation of the upgrade version. It has been pointed out that the extended maintenance intervals were released to increase availability and reduce life cycle cost (LCC). The LCC reduction is clearly demonstrated in Figure 16: During a given operating interval measured in kEOH a smaller number of major maintenance outages are required From that the cost for the outage itself as well as refurbishment cost following the outage are reduced

Page 12 of 20

Options

Previous

Next

A most important LCC reduction originates from the extended component life from 100 kEOH to 123 kEOH or 41 kEOH to 82 kEOH for the relatively expensive hot components.

Compressor Mass Flow Increase Upgrade (CMF+)

An output upgrade with a certain increase in efficiency can be achieved by increasing compressor mass flow. As this was not feasible by simply higher loading of the original compressor blading, this was accomplished by redesigning the airfoils of the first four compressor blade rows (including inlet guide vanes!) with new controlleddiffusion-type airfoils (CDAs). The CDAs produce a controlled deceleration in the axial direction. Figure 17 shows the velocity profile on blade#2 and inlet guide vane before and after optimization. The new profile exhibits higher axial velocities with a uniform velocity distribution and thus reduced flow separation compared to the original design. The calculated simple-cycle output gain is approximately 3.5% with an efficiency increase potential of up to 1%. An output increase of up to 2.8% can be anticipated in combined-cycle operation. 7 Performance Upgrade Matrix for V94.2 fleet

Based on the design and performance evolution described in Section 2 we can establish the matrix for performance upgrade for all versions of the V94.2 in the service fleet (Figure 18). Many upgrade packages in this matrix are defined and can easily be customized project-by-project with minor design efforts only and without designing new parts. In one case, because of the various modifications in the core engine covered by the design transition from V94.2(2) to V94.2(3), retrofitability was not fully given. Therefore in a recent R&D program the required upgrade and modification scope was worked out and adapter parts designed to allow for the implementation of turbine Stages 3 and 4 of the V94.2(3) in the V94.2(2) combustion turbine. These R&D efforts have recently been rewarded by an order for two performance upgrade packages especially for rotors and hot casings from Ambarli/Turkey. This project was reported on at the POWER-GEN Europe conference in Dsseldorf last year [10]. This projects combines a power increase by compressor upgrade with extended maintenance intervals according to 41MAC and synchronizes these efforts with life time extension measures after 100kEOH. In this way modular upgrades are combined to a tailored solution. Further performance upgrade orders have been received from various V94.2 sites, integrated into very different projects: combined with lifetime extension after 100 kEOH within fuel and combined-cycle conversions together with hot-component harmonization at sites where different versions of the V94.2 are installed aimed at outage time reduction by using spare rotors ready for implementation etc.

Page 13 of 20

Options

Previous

Next

The performance upgrade products for the V94.2 and similarly for the V84.2 are available, with a limited customer order engineering (COE) scope remaining. We are well prepared for further orders. As not every cell in the matrix is sensible, an upgrading path is shown in Figure 18 for the most interesting upgrade options. The maximum customers benefit can be generated, when the site-specific needs are evaluated in a joint project and exactly those upgrades are chosen and customized, that fit the best. 8 Dry Low-NOx (DLN) Upgrade Using HR3 Burner

Since 1986 Siemens has supplied a hybrid burner for natural-gas dry low-NOx premix firing producing NOx values below 25 ppm and CO values below 9 ppm in the load range from 50% base load to 100% base load (Figure 19). Dry low-NOx fuel oil firing became available in 1993 [11] and since 1995 the HR3 burner design is available and used as the standard equipment in new plants since. The benefits, upgrade scope and references for the HR3 burner retrofits are explained in Figure 20 in more detail. Figure 21 shows the technical improvement of the HR3 burner which, compared to the original H burner, achieves optimum mixing of gas and air and hence more homogeneous combustion by injecting fuel through bores in the diagonal swirler vanes. Lowered or even eliminated temperature peaks in the combustion zone result in lower NOx emissions. The new diagonal swirlers generate a higher outlet velocity with their optimized flow channel and thus provide maximum flashback resistance. On the market we find the following business cases for modernizations using the HR3 fuel gas burner: Installed diffusion burner can no longer meet the stricter regulations for emissions of combustion products: this was the market driver for a recent retrofit order for HR3 burners won for a power plant with four V94.2 units in Singapore; Hand in hand with a gas conversion, the latest technology represented by the HR3 design: this was the case for a gas conversion carried out at two V94.2 units in Yang Pu/China; Retrofitting of existing H burners with HR3 burners to protect against flashbacks resulting from higher hydrocarbons in the fuel gas: a current order for a power plant with six V94.2 units in Egypt was driven by this; Compared to the H burner design, further NOx reduction provides benefits in connection with a turbine inlet temperature increase especially for sites in the USA with 9-ppm-NOx requirements. The latter aspect will now be analyzed more closely. An increase in turbine inlet temperature always involves an increase in NOx emissions. This is also the reason why the majority of the V84.2 fleet in America is operated at derated turbine inlet temperatures (TT1-ISO) at 1040C to meet the emissions limits under all operating conditions. For this fleet we have created a dedicated V84.2 HR3 burner upgrade package. One part of all HR3 burner retrofits is a flame tube upgrade. This is because the increased flow velocity from the new diagonal swirlers resulted in an increased angle

Page 14 of 20

Options

Previous

Next

in the flame cone which in turn - compared to the H burner design - shifted the hotter recirculation zone within the silo combustion chamber from the center more towards the upper region of the combustion chamber. This shift was also evident from increased oxidation findings on the metal tile holders in rows A1/A2 detected during inspections after operation with HR3 burners. For H burners comparable findings were already known but less distinctive. A subsequent computational fluid dynamics (CFD) analysis of the new temperature distribution in the silo combustion chambers also verified that the higher temperatures now occur in the upper region of the combustion chamber. When installing the HR3 burners, the A1/A2 tile rows need to be shifted from the upper position to the center position with lower temperatures (Figure 22). A gas premix spider-shaped pipe connects the diagonal swirler of each burner to the central pear-shaped gas distributor. Originally welded from a ferritic steel though located in the combustion chamber this part is subject to wet corrosion from the outer surface because of condensing water on the cold fuel gas pipes. To date the ferritic gas spider piping Is subject to maintenance activities during hot-gas-path inspection and, depending on the remaining wall thickness, replacement of individual pipes can be necessary. In one case this maintenance work was neglected during the hot-gaspath inspection and caused internal fire damage in the area above the flame tube bottom plates. A redesign has been released to make the gas premix spider maintenance-free over an interval of 123 kEOH using a wet-corrosion-resistant material instead of the original material. This spider upgrade is also a requirement for the 41MAC upgrade (see Section 5). NOx production and emissions depend on the combustion temperature which increases due to a higher turbine inlet hot-gas temperature and increases when the ambient temperature drops. To generate a customer benefit with our turbine inlet temperature increase even in connection with strict environmental requirements, we have developed a special GT NOx control concept. This concept enables adjustment of the turbine inlet hot-gas temperature as a function of ambient temperature for a specified constant NOx limit curve (e.g. 9 ppm in Figure 23). Looking at the low ambient temperature of -8C we find an allowable TT1-ISO = 1040C. With increasing ambient temperatures the turbine inlet temperature can be raised, thus achieving higher power output and better efficiency. Doing so the diagram shows an output gain of 3.6% at 15C and increases of up to 6.4% at 30C based on a turbine inlet temperature of 1075C. All these values are valid for constant NOx emissions of 9 ppm (@15% oxygen in the exhaust). Another relevant parameter is humidity. The operating curves shown here hold for optimized cooling air losses, optimized pilot gas flow and precisely adjusted radial blade clearances. These conditions prevail after a major inspection performed by the OEM Siemens AG. This open-loop control function thus enables adjustment of the entire turbine inlet temperature operating range and hence output and efficiency of the plant based on the specified NOx values. Always an option for a new unit configuration is the HR3 burner with the DLN fuel oil premix firing feature. It was introduced in 1993 and since then has been implemented in nine V94.2 unit. To date, these units have accumulated more than 30,000 operating hours in the field and have demonstrated reliable operation (Figure 24). This unique feature of fuel oil premix operation, which is very interesting especially

Page 15 of 20

Options

Previous

Next

where water for NOx reduction is an extremely valuable resource, is also available for retrofit purposes. 9 Performance Boost with Wet Compression (WetC)

The different locations in a GT application where water can be used for performance improvements are shown in Figure 25: evaporative cooling with water in the air filter house, fogging makeup water in the air intake wet compression with makeup water in the air intake makeup water injection (PAG operation) into the combustor Also included in this picture is the absorption chiller that uses exhaust heat from gas turbines operating in a simple cycle. The following focuses on the particularly effective wet compression upgrade; the other methods are described fairly well in the literature [12]. After Siemens and Westinghouse became one company, we were able to develop wet compression in an R&D program for the Vx4.2 frames for both the 50-Hz and 60Hz fleet based on applications and operating experience with Westinghouse W501 engines [13;14]. In wet compression, atomized water is injected through a nozzle rack into the compressor air intake (Figure 26). Part of the injected water evaporates in the air intake; the remaining water enters the compressor in liquid form (droplets of approx. 20m diameter at 90% probability). This achieves an intercooling effect. The injected water evaporates in the compressor stages. The energy required for evaporation is taken from the compressed air mass flow, which is thus continuously cooled. This cooling, coupled with the mass flow increase of the working fluid drawn in, results in a significant performance gain in both output and efficiency. In the baseline wet compression the performance gain is independent from ambient conditions. During the development of this upgrade, the design criteria assembled in Figure 27 were analyzed and met, and validation tasks for first-time application were defined. For example, we needed to ensure that water injection is homogeneous to prevent casing deformation due to non-uniform temperature fields. The spray pattern in the intake duct was therefore specified in advance on the basis of 3-CFD analyses and temperature field of the casings measured during the validation run. The amount of water is controlled by a mass flow control loop comprising the injection pump, a variable-frequency drive (VFD) and a controller. In order to maintain a desired mass flow the controller activates the VFD to set the appropriate speed at the pump motor. The pump directly feeds the desired amount of water into the feeding line. Thus an additional return line is no longer necessary. The entire equipment is arranged on the high-pressure wet-compression skid. As for thermodynamic performance a typical increase in the efficiency of the overall gas turbine in an open GT cycle is up to 5%, with an output increase of up to 20%. In Figures 28 and 29 the measured results after first-time implementation of a wet compression system in a V84.2 in America are also shown.

Page 16 of 20

Options

Previous

Next

Before wet compression implementation, the GT was operated with power augmentation (PAG), i.e. water injection in the combustion chamber, achieving an output increase at a NOx limit of 9 ppm and a turbine inlet temperature of 1040C. When using just the wet compression system without simultaneous power augmentation, the result was an efficiency increase of 6%, compared to an efficiency loss of 5% in the case of water injection into the combustion chamber. The measured output increase for a relative ambient humidity of approximately 90% was around 13% at 17.5C ambient temperature. Further calculated outputs as a function of relative humidity are given in the diagram in Figure 29. In contrast to wet compression, inlet cooling systems such as evaporative cooling or fogging coolers yield only a negligible increase or no increase whatsoever in output or efficiency under ambient conditions with high humidity or cold temperatures. As for combustion performance at a turbine inlet temperature of 1040C, NOx emissions were reduced from 9 ppm to 6 ppm, making it legitimate to conclude that a level of 9 ppm will not be exceeded at a turbine inlet temperature of 1060C. All required validation tasks (e.g. casing temperature measurements and vibration measurements of blade row #1) were performed during initial wet compression operation at the V84.2 unit in the USA. Any potential corrosion occurring on the compressor blades and vanes can be limited by coating the compressor parts. The first compressor stages must be monitored for erosion and corrosion during inspections performed at the standard intervals. Vibration measurements of blade row #1 of the first unit will be repeated after a sufficient number of wet compression operating hours and compared to the initial testing in order to evaluate erosion effects on the vibration behavior of the compressor rotor blading. This will be done at the fleet leader in wet compression operation. In addition an R&D program was started this year to provide new corrosion-resistant compressor blade materials and protective measures against erosion in the near future. Experience gathered at a specific Siemens Westinghouse GT W501D5A after some 25,000 operating hours with wet compression demonstrated that GT maintenance follows the standard inspection intervals. As is also the case for the implementation of power augmentation, the water factor must be included in the calculation of equivalent operating hours. Figures 30 and 31 give information about the upgrade scope and how the wet compression basic design, auxiliaries and I&C provide for proper plant integration.

Page 17 of 20

Options

Previous

Next

10 Summary, Conclusion and Future Prospects Our upgrade development follows the roadmap established for both the new sales units market as well as the service retrofit market. Therefore we have presented modular products that can be combined with each other for tailored solutions for specific plant needs. Particularly important features are that: The validation process for each upgrade is established according to the product development process in our company Upgrade packages have been designed to provide maximum benefit with minimum scope and to be easily retrofitable during routine inspections Joint overall plant analysis and upgrade projects by power producers and the OEM have proven to be highly beneficial and are therefore strongly recommended Total OEM plant competence ensures turnkey upgrades. During the past 5 years the modernization product portfolio has grown significantly. As customers have rewarded us with orders for these products, the modernization business has grown rapidly. In the new units market, fourteen V94.2(6) units ordered in 2003 will be installed from now on (6 units for Muara Tawar/Indonesia and 8 units for Az Zour/Kuwait). Version 6 is the one that includes the CMF+ upgrade plus the TT1+/41MAC upgrade. Recently another two V94.2(6) units were ordered for a peaking application in Australia and three V84.2(6) units for two sites in Saudi Arabia. As only one part of the service business, three orders for 3 CMF+ upgrades for the V94.2 have been booked. The success in both markets justifies our R&D activities. In closing, we predict that the end of the roadmap in Figure 5 has not yet been reached; also the product portfolio (Figure 13) has not been completely filled and therefore R&D efforts continue. We have shown the availability increase that can be obtained through the 41MAC interval extension. Several component upgrades designed in various programs have increased component life and now during minor inspections we expect reduced component wear. This indicates that there is further R&D potential for extending the minor inspection interval from 8 kEOH to 12 kEOH in the future to obtain a further gain in availability. As a second example, a hydraulic clearance optimization (HCO) system is currently being developed for the V94.2 to improve turbine efficiency. The HCO has already been successfully installed in a V94.3A in Germany [15]. The HCO involves an axial thrust compressor bearing with hydraulic pistons that shift the rotor axially towards the compressor, thus decreasing the radial clearances at the tips of the turbine rotor blading and improving turbine efficiency.

Appendix: 31 Figures

Page 18 of 20

Options

Previous

Next

References [1] [2] Maghon, H.; Maghon, H.; Kreutzer, A.; Termhlen, H.; Burchardt, H. E.; Die Gasturbine im Grundlasteinsatz VGB Kraftwerkstechnik 62, Heft 4, April 1982 The V84 Gas Turbine Designed for Base Load and Peaking Duty American Power Conference Chicago, Illinois, April 18 20, 1988. Paka and Pasir Gudang Almost Continuously Feeding the Grid Eight Years Success Story Using the Siemens Gas Turbine V94.2 Power-Gen Conference Asia, Singapore 2002 Gas Turbines above 150 MW for Integrated Coal Gasification Combined Cycles (IGCC) ASME Paper 91-GT-256, 1991. Modernization of 60-Hz SIEMENS Gas Turbines with Primary Focus on the V84.2 Frame and Upgrade Applications Power-Gen Conference America, Las Vegas 2003 Internal Report Ermdungsfestigkeit gekerbter / inhomogen beanspruchter Strukturen Siemens AG PG, Juli 2003. Oxide Layer Phase Structure of MCrAlY Coatings Surface Engineering 1997 Vol. 13 No. 5. Fortschrittliche Schutzschichten fr Gasturbinen VGB Kraftwerkstechnik 77 (1997). Internal Report Calculation of Damage Accumulation Siemens AG PG, July 2003. Making Ambarli Combined Cycle Power Plant fit for Europe Power-Gen Conference Europe, Dsseldorf 2003 A fuel oil premix burner for gas turbines Development and initial operating experience ASME Paper 94-GT-463, 1994. A comprehensive review of power augmentation options for simple and combined cycle applications in hot climates. Power-Gen Asia Conf., Singapore Sept. 9.-11. 1997.

Page 19 of 20

[3]

[4]

Becker, B.; Schetter, B.; Reiermann, D.; Hhne, G.; Bohrenkmper, G.; Dankert, M.;

[5]

[6]

[7] [8] [9]

Stamm, W. et al; Stamm, W. et al: Gross, H. J.;

[10]

Basaran, M.; Prei,U.; Schetter, B.; Schabbehard, H. W.; et al ; Flower,T.; Maes, D.; Zachary, J.:

[11]

[12]

Options

Previous

[13]

Nuding, J.-R.,and Johnke, T. Rising, B.; Nuding, J. R.;

Increasing GT Power and Efficiency Through Wet Compression Power-Gen Conference Europe 2002, Milano, Italy Wet compression Upgrade Technology - Operating Experience. Power-Gen Europe Conf. 2001, Brussels, Belgium Upgrade of the Siemens Gas Turbine V94.3A Power-Gen Europe 2004, Barcelona, Spain

[14]

[15]

Becker, B. ;

Page 20 of 20

You might also like

- Expanded RangersDocument26 pagesExpanded RangersKristopher Garrett100% (3)

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (3)

- DLN 2.0+ Fuel NozzleDocument1 pageDLN 2.0+ Fuel NozzleWedneslao Lopez100% (1)

- Ger 3928c Uprate Options Ms9001 Heavy Duty Gas TurbineDocument58 pagesGer 3928c Uprate Options Ms9001 Heavy Duty Gas Turbineamir moniriNo ratings yet

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien Alhosien100% (1)

- Ge 6faDocument1 pageGe 6faAnish DonaldNo ratings yet

- Service Experiences With The World Record Gas Turbine SGT-8000HDocument16 pagesService Experiences With The World Record Gas Turbine SGT-8000HabelsgNo ratings yet

- GE Frame 9Document4 pagesGE Frame 9Umar Saeed100% (1)

- Steam Turbine Gas Turbine 002Document6 pagesSteam Turbine Gas Turbine 002dheerajdb99100% (2)

- Gas Turbine Combustion SystemDocument14 pagesGas Turbine Combustion Systemrohit u100% (3)

- GTs World Comparison Picture - 1-130 MW - 2015 01Document2 pagesGTs World Comparison Picture - 1-130 MW - 2015 01dvcher78No ratings yet

- (ARTICLE) Gas Turbine DegradationDocument36 pages(ARTICLE) Gas Turbine DegradationFrancisco Baptista100% (1)

- SGT6-5000F PAC - LowRes PDFDocument18 pagesSGT6-5000F PAC - LowRes PDFmyegnrNo ratings yet

- MS6001FADocument14 pagesMS6001FAsureshkumar908No ratings yet

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- Ge Power Ststem Manuals PDFDocument157 pagesGe Power Ststem Manuals PDFveejai_kumar100% (2)

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- Service - Gas Turbine Modernization PDFDocument6 pagesService - Gas Turbine Modernization PDFDiego CarpioNo ratings yet

- Main Parts List PDFDocument34 pagesMain Parts List PDFOmar Rodriguez BarriosNo ratings yet

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash Srivastava100% (1)

- GT Frame 9 ManualDocument102 pagesGT Frame 9 ManualSSC & GSC of Lebanon100% (1)

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 pagesVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- 5 Gas Turbine - Turbine and Exhaust SystemDocument142 pages5 Gas Turbine - Turbine and Exhaust SystemMohamed Balbaa100% (3)

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyDocument2 pagesSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- Factsheet Industrial Trent 60 Us LowresDocument2 pagesFactsheet Industrial Trent 60 Us LowresAsri GaniNo ratings yet

- Material Inspection of Hot Gas PathDocument2 pagesMaterial Inspection of Hot Gas Patheankibo100% (2)

- Comp Amp Turbine COURS 9001EDocument27 pagesComp Amp Turbine COURS 9001Enabil160874100% (2)

- Ansaldo Energia AE94.2 Upgrading ProjectDocument20 pagesAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- GE's Next 7FA Gas Turbine "Test and Validation"Document20 pagesGE's Next 7FA Gas Turbine "Test and Validation"JJ100% (1)

- CCPP Cycling PDFDocument20 pagesCCPP Cycling PDFStefanos GabalacNo ratings yet

- Scope of Supply Titan130Document32 pagesScope of Supply Titan130danferreiro8318No ratings yet

- GE Gas Turbines Were Basically Divided Into 3 DifferentDocument3 pagesGE Gas Turbines Were Basically Divided Into 3 Differentsaikrish36100% (1)

- Trent 60 - REolls Royse - 60 MWDocument1 pageTrent 60 - REolls Royse - 60 MWcirius_coolNo ratings yet

- Proven Upgrade SGT5-4000FDocument9 pagesProven Upgrade SGT5-4000FThanapaet Rittirut100% (2)

- 6FA HDGT Product Brochure-GEA17987Document8 pages6FA HDGT Product Brochure-GEA17987mike100% (1)

- Compresor TITAN 130 (Solar)Document86 pagesCompresor TITAN 130 (Solar)Martínez Rodriguez DiegoNo ratings yet

- LM2500 50Hz Fact Sheet 2016Document2 pagesLM2500 50Hz Fact Sheet 2016joseomarlmNo ratings yet

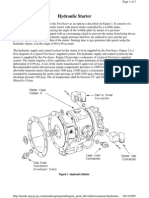

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- Single Shaft Design of Power PlantDocument12 pagesSingle Shaft Design of Power PlantSrinivasa Rao PallelaNo ratings yet

- Generator Cooling MethodsDocument16 pagesGenerator Cooling MethodsKVV100% (1)

- Siemens Sgt400 Powerplant BrochureDocument4 pagesSiemens Sgt400 Powerplant Brochuremasoud0% (1)

- Abb 13e2 GT24 1997Document11 pagesAbb 13e2 GT24 1997atfrost4638No ratings yet

- Sr. Inspection Engineer Sample ResumeDocument4 pagesSr. Inspection Engineer Sample ResumemaheshNo ratings yet

- Combustion Heavy DutyDocument28 pagesCombustion Heavy DutyIvan Poma Montes100% (2)

- HRSG Design Tutorial - Heat BalanceDocument3 pagesHRSG Design Tutorial - Heat BalanceRavi Kasaudhan100% (1)

- GT8BC and 8C - C2 Comp Upgrade - April2008 - FVDocument4 pagesGT8BC and 8C - C2 Comp Upgrade - April2008 - FVt.o.i.n.g100% (1)

- Gas Turbines TocDocument8 pagesGas Turbines Tocnasr305100% (1)

- 04 - LM2500 OverviewDocument27 pages04 - LM2500 OverviewLudovic LeroyNo ratings yet

- Bentofix IQ - Design ManualDocument12 pagesBentofix IQ - Design ManualCristian GiurgeaNo ratings yet

- MS5001PA Gas Turbine Fact SheetDocument3 pagesMS5001PA Gas Turbine Fact SheetGustavo Palacios100% (3)

- 9e Turbine Gea16035b 9e GT HRDocument1 page9e Turbine Gea16035b 9e GT HRFedor Bancoff.No ratings yet

- Fast, Efficient and Flexible Smart Maintenance Approach: The Compact ValueDocument2 pagesFast, Efficient and Flexible Smart Maintenance Approach: The Compact ValueIvana SpanovicNo ratings yet

- 10.1115 1.3240303Document6 pages10.1115 1.3240303ali a100% (1)

- Taurus 60 Packing ListDocument3 pagesTaurus 60 Packing Listhermit44535No ratings yet

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Mars 100 PlantDocument9 pagesMars 100 PlantabelsgNo ratings yet

- Siemens 1 GTX 100 TurbineDocument16 pagesSiemens 1 GTX 100 Turbinejparmar100% (1)

- Siemens GTDocument8 pagesSiemens GThbalu007No ratings yet

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- Presentation EuroturbineDocument56 pagesPresentation Euroturbinetmz100% (1)

- Ansalado TurbinesDocument8 pagesAnsalado Turbinesalexandr_popov_2No ratings yet

- GasDocument8 pagesGasscribdkhatnNo ratings yet

- Scheda Gas Turbine Ae64 3a LoDocument4 pagesScheda Gas Turbine Ae64 3a LoFadzil NorNo ratings yet

- Ved Module 6Document10 pagesVed Module 6Chen MaglunsodNo ratings yet

- CLSU-Agricultural Engineering Board Exam Review Materials: Farm PowerDocument11 pagesCLSU-Agricultural Engineering Board Exam Review Materials: Farm PowerKaren Joy BabidaNo ratings yet

- Netbiter Concept Brochure - WebDocument7 pagesNetbiter Concept Brochure - WebVidian Prakasa AriantoNo ratings yet

- Final - Manuscript (GROUP 1&3)Document82 pagesFinal - Manuscript (GROUP 1&3)SHIELOU LOMODNo ratings yet

- Epilepsy in ChildrenDocument34 pagesEpilepsy in ChildrenAdam MochtarNo ratings yet

- Tom Conley - Cartographic CinemaDocument274 pagesTom Conley - Cartographic CinemasaraNo ratings yet

- Broadband Gaas Mesfet and Gan Hemt Resistive Feedback Power AmplifiersDocument8 pagesBroadband Gaas Mesfet and Gan Hemt Resistive Feedback Power AmplifiersKhurram SamiNo ratings yet

- Agc-5200 5220 5240 5260 5280Document66 pagesAgc-5200 5220 5240 5260 5280Pedro Martinez GarayNo ratings yet

- LNP: April 10, 2016: News PresentationDocument80 pagesLNP: April 10, 2016: News PresentationLNP MEDIA GROUP, Inc.No ratings yet

- 1 s2.0 S1877705816312590 MainDocument9 pages1 s2.0 S1877705816312590 MainJafar A BarakatNo ratings yet

- Chapter 1 Oil Seal IntroductionDocument6 pagesChapter 1 Oil Seal IntroductionNCvetarskyNo ratings yet

- Handout3 Schrock CarbeneDocument3 pagesHandout3 Schrock CarbeneEustance JuanNo ratings yet

- Grammar Test 1Document5 pagesGrammar Test 1Vy NguyễnNo ratings yet

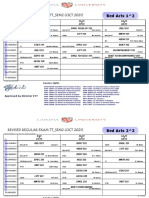

- Revised Regular Exam TT - Sem2 (Oct 2021) : Bed Arts 1 2Document78 pagesRevised Regular Exam TT - Sem2 (Oct 2021) : Bed Arts 1 2kelvinNo ratings yet

- BiotechnologyDocument27 pagesBiotechnologySunil PillaiNo ratings yet

- BurnerDocument2 pagesBurnerVishnu PatidarNo ratings yet

- Cambridge IGCSE ™: Physics 0625/43 October/November 2022Document16 pagesCambridge IGCSE ™: Physics 0625/43 October/November 2022azimagiccookieNo ratings yet

- Planck Paper PDFDocument4 pagesPlanck Paper PDFG. AlfredNo ratings yet

- Mind Body RelationshipDocument14 pagesMind Body RelationshipRitchie Michael GomezNo ratings yet

- Midterm QM MATERIALSDocument28 pagesMidterm QM MATERIALSTrần Thanh TrúcNo ratings yet

- Paper 4 - Structured QuestionsDocument20 pagesPaper 4 - Structured Questionsvita iftitahiyahNo ratings yet

- 33.michael A. LittleDocument273 pages33.michael A. LittleMatteo RiveraNo ratings yet

- Ideal Gas LawDocument16 pagesIdeal Gas LawJomari ValenzuelaNo ratings yet

- Characteristics and Classification of PCMDocument10 pagesCharacteristics and Classification of PCMJinto A JNo ratings yet

- Reduction of Early-Age Crack Risks in Concrete Walls by Using A New Casting TechniqueDocument9 pagesReduction of Early-Age Crack Risks in Concrete Walls by Using A New Casting TechniqueTeo Peng KeatNo ratings yet

- SpectraLayers One 8 Operation ManualDocument74 pagesSpectraLayers One 8 Operation Manual릴황No ratings yet