Professional Documents

Culture Documents

Sample Galvanizing Procedure +ITP

Sample Galvanizing Procedure +ITP

Uploaded by

subash sivalingamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Galvanizing Procedure +ITP

Sample Galvanizing Procedure +ITP

Uploaded by

subash sivalingamCopyright:

Available Formats

G. K.

WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

PROCEDURE FOR SURFACE PREPARATION

AND HOT DIP GALVANIZING ON FABRICATED

STEEL ITEMS

PROJECT: EPC CPF Phase-1 al BADRA OIL FIELD

CLIENT: Unger Steel Middle East FZE / PETROFAC

P.O NO.: 2013030011

LOCATION: UAE

SUPPLIER: G.K.Wire Industries LLC

DOCUMENT NUMBER: LME- FCP-199-004

REV. ISSUE DATE PURPOSE OF ISSUE PREPARED APPROVED

01 05-09-2012 Customer Specific N.B.Joshi Dhananjay Joshi

02 05-09-2012 Customer Specific N.B.Joshi Dhananjay Joshi

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

REVISION HISTORY:

REV DATE DESCRIPTION PREPARED BY APPROVED BY

00 05.09.2012 Customer Specific N.B.Joshi Dhananjay Joshi

.

DEFINITIONS :

Project: EPC CPF Phase-1 al BADRA OIL FIELD

Contractor: PETROFAC / Unger Steel Middle East FZE

Galvanizer: G.K.Wire Industries LLC

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

TABLE OF CONTENTS

2. REFERENCE DOCUMENTS

articles

ple Salt)

( Hot dip Galvanizing ) of steel items

nching process

& Grinding of galvanized Items

k. Inspection

l. Adhesion

m. Repair

1. SCOPE

3. RESPONSIBILITIES

4. PROCEDURE

a. Blasting & Cleaning the surface of steel

b. Degreasing

c. Water Rinse

d. Pickling ( HCL Acid cleaning process )

e. Water Rinsing Process

f. Flux coating process :( Zinc Ammonium Chloride Tri

g. Drying of Articles

h. Zinc coating

i. Water Que

j. Cleaning

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

1. SCOPE

This Process procedure intends to have the clear guidelines for Hot Dip Galvanizing of fabricated Steel

products as per Order specification & Standard code specification requirements applicable to G.K.Wire

2.

on & test method.

related Rust

grades and products preparation grades of uncoated substrates and of steel substrates after

s coatings.

ification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel

Products

2013-200-CS-SP-002 Engineering Specification to structural steel work

4.

Industries LLC.

REFERENCE DOCUMENTS

1. BS EN ISO 1461:2009 Hot Dip galvanized coatings on fabricated iron & steel articles-

Specificati

2. ISO8501-1 - Preparation of steel substrates before application of paints and

overall removal of previou

3. ASTM A 123-Standard Spec

4. GB088-

3. RESPONSIBILITI ES

Production Engineer / QC Inspector

PROCEDURE

Preparation for Galvanizing Materials:

a. The Production Engineer decides on the article suspension method either tying or placing them in

suitable fixture taking into consideration the following points,

Articles shape, size, weight & Identification of member number.

Position of venting & drainage holes ( if required )

IG-6.7) if required, shall be drilled as per Job

material requirements. Dia 8 mm to 15 mm as required, if required depending upon shape and size.

rated balance & weight of items recorded in

logbook.

Availability of tying points

b. Vent holes & drainage holes (As per ASTM A385, F

c. Pre-weighing - Articles are weighed on the calib

d. All articles to be galvanized shall be handled in such a manner as to avoid any mechanical damage

and to minimize distortion due to mechanical force.

1) Blasting & Cleaning the surface of steel articles :

a. Articles are blasted with Automatic shot blasting method by using steel shots S-170 grade or other

grades. Used steel shots / scales are collected in drums & refilled with new shots & used shots are

disposed off to authorized dump yard.

ds required according to surface condition of articles.

r White Blast Metal.( SA 2-1/2 grade blasting surface finish (as per

r the contaminant

each article is tilted & shot particles shall be removed from inside portion of each

shaking each other.

b. Articles are blasted to ensure that the surface is entirely free of rust and other visible contaminants.

The shift foreman determines the no. of roun

c. Blasted articles are inspected visually by the Quality control engineer & items shall be shot blasted

to a surface cleanliness of Nea

SSPC,SP10)

d. Any incomplete blasted areas are assessed by QC Inspector to determine whethe

can be removed during the pickling process.

e. After blasting

article by

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

f.

g. ion, venting

drainage.

2 Degreasing

2.2 to 2.5mm dia. Black annealed wire pieces are used for tying the articles to the frames. The

batch articles are spaced along the frame to ensure no contact with each other.

The frames are attached to cranes & the wired articles are checked for uniform distribut

&

)

remove organic contaminants including dirt,

ater based paint markings, grease and oil. Degreased objects are visual inspected for removal of

fted and tilted to drain all solution from articles.

Articles are dipped in batches in degreasing tank to

w

impurities on the surface. Articles are li

3) Water Rinse

After cleaning articles are rinsed in water by immersing in Water bath.

Again articles are lifted and tilted to drain the water.

4) Pickling ( HCL Acid cleaning process )

a. After degreasing, articles are immersed for approx. 2 to 5 minutes in the pickling solution

uring fresh start of acid bath.

the articles for cleanliness after

hieved. Quality

ined & submitted to local Authority for approval. After approval from

ized surface, Black surface, Black spots, pH value 2-3, Iron content (Fe)

150gms/lit. max., HCL concentration % > Complete replacement of old acid from bath.

Acid strength shall be checked every 15 days interval at in-house laboratory & samples are

analyzed for Acid concentration & Iron content. Acid pH shall be checked everyday with pH paper

at the beginning of the shift.

The finished materials are bundled & packed as per job requirements & dispatch note is issued. If

direct delivery is arranged for finished materials then loading requisition note is issued against the

depending upon the size, type, shape and surface condition of the articles. Pickling is performed to

remove mill scales and /or surface rust.

b. Pickling solution comprising of commercial grade HCL acid (33%) diluted with water to

approximately 15% strength d

c. In regular use the shift foreman / QC Inspector visually inspects

pickling process.

d. On rejection articles are repeatedly pickled until the above conditions are achieved.

e. In regular use depending upon the quality of pickled galvanized materials the fresh acid + water in

2: 1 ratio respectively is added directly into the acid bath until the required pH is ac

of Pickled galvanized materials > Heavy coating thickness, Zinc flaking or peeling / chipping of zinc

> Replenished the acid bath.

f. HCL Concentration > Min.17 - 18% & Required pH Value > Min. 7

g. If the acid is found weaker for process then it is collected in containers which are neutralized to

7pH by adding caustic soda & samples are sent to an independent laboratory for analysis. Test

analysis certificate to be obta

Local Authority, this neutralized acid is disposed off to approve dump yard location.

h. Following Criteria is used for changing the complete acid from bath : Weaker Acid strength >

Blisters on galvan

i.

j.

loaded materials.

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

5) Water Rinsing Process :

a. Pickled articles are dipped into the rinsing bath completely & suspended over the bath until water

no longer pours off.

(pH <3).

b. Samples from rinsing water bath checked with pH paper every 7 days for determining the pH value,

results are recorded. Fresh water shall be added when water becomes too acidic

6) Flux coating process :( Zinc Ammonium Chloride Triple Salt)

a. Rinsed articles immersed in the flux bath for a minimum of two minutes, withdrawn & suspended

above the bath until flux is no longer runs off. Flux coating is performed to remove / dissolve

oxides of iron, which had formed after pickling also flux coating acts as anti oxidation coating on

esh start of Flux bath.

. Density of flux is maintained 22 30 Baume & flux bath temperature is maintained 70 80 C.

e Flux bath solution density is measured with Hydrometer at every 4 Hrs. intervals

& decided how much flux concentration or water is needed to restore the flux to the required

ux bath until the required relative density of

ality of Galvanized materials, every six month flux bath solution is checked

visually for flux bath solution quality, strength & if the solution is found weaker then it is disposed

t.

the surface.

b. Flux solution comprising of Galva flux - STC-III + Flux additives - STC prepared at 2 : 1 ratio

respectively mixed with fresh water in flux bath during fr

c

d. In regular use, th

density in the bath. Accordingly fresh solution of flux (100 kg. Galva flux STC-III + 30 kg. Flux

additives STC) is added with water directly into the fl

min. 22 30 Baume is achieved.

e. Depending upon the qu

off through Local Authority Environmental departmen

7) Drying of Articles :

a. The fluxed article frames are suspended in the oven & preheated to assist flux drying. The oven

temperature is maintained min. 110C to max. 120C.

b. The suspended article frames are detached from the 1

st

crane & attached to the 2nd crane for next

galvanizing operation.

8) Zinc coating ( Hot dip Galvanizing ) of steel items :

a. During fresh start of Zinc bath, 99.995% pure Zinc is added in the tank. An average molten zinc

bath temperature of 445C 5C is maintained.

b. Suspended articles are slowly dipped at an inclined position until fully immersed in the molten zinc

bath.

c. Depending upon the size, type & thickness of the section, the articles remains immersed until

violent reaction have ceased & white smoke disappears. The articles are swung & agitated to assist

disappearing of white smoke the articles are slowly withdrawn from bath at inclined

position to allow the free drainage of excess zinc & avoid lumps. Un-solidified excess zinc is

removed by scrapers from the surface of suspended articles.

6 from top) is maintained by adding fresh 99.995% pure

zinc slabs (24-26kg. each), depending upon the size & quantity of galvanized articles every day.

wetting.

d. The zinc bath surface is skimmed & zinc ash removed by scrapers.

e. After complete

f. In regular use, the level of zinc (max.

These fresh zinc slabs are preheated by keeping near the molten zinc before adding into the molten

bath.

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

g. Zinc ash is removed from bath every day & collected into drums, Zinc dross is removed from bath

on weekly basis. Both the wastages are weighed prior to dispose off to scrap dealers & records are

maintained.

9) Water Quenching process :

a. The Hot dip Galvanized articles are quenched in cooled running water bath by immersing gradually

g onto the concrete floor. The quenching suitability

frames / fixtures & moved to cleaning

in a manner which will enable the steam to escape safely The articles which may suffer distortion

during quenching are cooled naturally by lowerin

is determined by the Supervisor by assessing the article shape & size.

b. Cooled & quenched articles are removed from the suspended

operation.

10) Cleaning & Grinding of galvanized Items :

a. The tie wires (if any) are cut & removed from galvanized articles & surfaces are visually inspected.

l zinc deposits are removed from both ends of holes location by hammering the punch rod

spots (if any observed) are cleaned & sprayed with

hall be removed by hammering or send to Fabrication

ss

Zinc coating thickness for the steel thickness 3mm to above 6mm

in on calibrated balance & galvanized materials weight is

11)

The good galvanized materials are further cleaned with smooth grinding & excess lumps / flow

marks / excess zinc deposits are removed from the surface.

b. Additiona

& all hole edges are to be removed by grinding.

c. Tie wire markings & small pointed galvanized

zinc rich paint- As per BS 2569 minimum two coating layer.

d. Distortion due to heat (warpages / bends) s

department for removing with hydraulic jacking system.

e. Each batch of galvanized materials is inspected as per sampling plan for Coating thickne

(Magnetic method), the mean

shall be minimum 70m to 100m.

f. Finished materials are weighed aga

calculated. Accordingly daily production report is prepared along with weighing records sheets.

Inspection:

a. The integrity of the coating shall be determined by visual inspection and coating

thickness measurement as per BS 1461:2009

ndards of galvanizing. The final weight of galvanized coating shall be as

per BS 1461:2009. Table-3,4

12.

b. Inspection shall be witnessed at the galvanizer works by the customer QC Inspector and client

designated third party Inspector if required.

c. Where coating thickness measurement is not feasible the coating weight shall be determined as

noted the referenced sta

Adhesion : The test is to be carried out by the customer. G.K.Wire will provide test sample of the

material for his testing, if required.

nner tending to

) shell be

he coated article.

c) The galvanized coating shall be sufficient by adherent to withstand normal handling during

transport and erection.

same

a) The adhesion of the zinc coating to the surface of the base metal shall be determined by cutting or

prying with the point of a stout knife, applied with considerable pressure in a ma

remove a portion of the coating , otherwise a cross-hatch test (according to ISO 16276

followed.

b) The galvanizing coating shall be continuous adherent as smooth and evenly distributed as possible

and free from any defect that is detrimental to the stated end use of t

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

13. Repair:

a. If any black surface or blistered surface and peel off surface observed then these items are re-

galvanized by complete process and remedial action are recorded in log book.

b. Renovation of damaged zinc coating shall be followed as per BS 1461:2009 Para 6.3

c. Renovation shall be by thermal zinc spraying as per ISO 2063, or by a suitable zinc- rich paint

as per BS 2569. Where the zinc dust pigment conforms to ISO 3549 within the practical limits

of such systems, or by suitable zinc flake or zinc paste products.

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Head Office, Dubai - Tel.(9714) 8872904 , Fax.(9714) 8816250

E-mail : gabions@emirates.net.ae

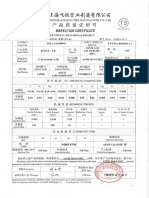

HOT DI P GALVANIZNG COATING CERTIFICATE

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

July 2012 Revision 1 Page 1 of 5

INSPECTION AND TEST PLAN

HOT DIP GALVANIZING

PROJECT: EPC CPF Phase -1 al BADRA OIL FIELD

CLIENT: Unger Steel Middle East FZE

P.O NO.:

LOCATION: UAE

SUPPLIER: LINK MIDDLE EAST LIMITED

Document No: GKWI-ITP-001

Rev. Issue date Purpose of issue Prepared Approved

0 Issued for Review Ronald Dsa

.

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

July 2012 Revision 1 Page 2 of 5

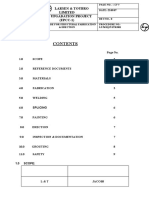

TABLE OF CONTENTS

1. SCOPE ............................................................................................................................................................. 3

2. DEFINITION...................................................................................................................................................... 3

3. REFERENCE CODE......................................................................................................................................... 3

4. INSPECTION AND TEST PLAN........................................................................................................................ 3

4.1 INSPECTION & TEST PLAN- RECEIVING INSPECTION OF RAW MATERIALS FOR FENCE AND GATES... 4

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

July 2012 Revision 1 Page 3 of 5

1. SCOPE

The scope of this Inspection and Test Plan is to establish the requirements of Fabricated Steel

Steel as per Specification and procedures.

2. DEFI NI TION

Contractor - : Unger Steel Middle East FZE/Petrofac

Supplier : G.K Wire Industries

3. REFERENCE CODE

ASTM A123 :

ISO BS EN 1461

4. I NSPECTI ON AND TEST PLAN

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Document No GKWI-ITP-001 : July 2012 Revision 0 Page 4 of 5

4. 1 I NSPECTI ON & TEST PLAN- RECEI VI NG I NSPECTI ON OF RAW MATERI ALS FOR FENCE AND GATES

LEGEND

C- Check Point Inspection by LME , H - Hold Point CLIENT must attend, W - Witness Point - CLIENT must be informed but if not in attendance work can proceed, R -

Review Point - Documents relevant to inspection shall be reviewed, QC Quality Control Inspector,USME Unger Steel Middle east, PIL- Petrofac

A

C

T

I

V

I

T

Y

WORK ACTIVITY

QUALITY CHARACTERISTIC

TO BE VERIFIED

PROCEDURE

REFERENCE/CODE/

STANDARD

ACCEPTANCE CRITERIA /

VALUE

PERFORMED

BY

G

K

W

I

U

S

M

E

P

I

L

QUALITY VERIFICATION

RECORD

1 Receiving of

fabricated

Structures, Pipes,

accessories

Completion of fabrication

Qty, Surface condition

damages and defects

Internal Procedure, GB088-

2013030011-CV-J04-001

Operation completion as

per drawing, specification

Qty as per Order

Free from damages and

Any defects

Quality

Control

Engineer

Production

Engineer

C R R Visual Inspection Report

2 Surface preparation

Blasting, Pickling,

Flux coating

Surface free from Rust, Mill

Scales and Loose Burrs, Oil,

paint, Corrosion Marks

2013030011-CV-J04-001 Blasting to a surface

cleanliness of near White

Blast Metal ( SA 2 -

grade blasting finish)

Clean Surface with flux

coat

Quality

Control

Engineer

C W R Visual Inspection Report

G. K. WIRE INDUSTRIES LLC

P.O.Box - 32820 , RAS AL KHAIMAH , United Arab Emirates

RAK - Tel.(9717) 2447970 , FAX.( 9717) 2447515

Document No GKWI-ITP-001 : July 2012 Revision 0 Page 5 of 5

LEGEND

C- Check Point Inspection by LME , H - Hold Point CLIENT must attend, W - Witness Point - CLIENT must be informed but if not in attendance work can proceed, R -

Review Point - Documents relevant to inspection shall be reviewed, QC Quality Control Inspector,USME Unger Steel Middle east, PIL- Petrofac

A

C

T

I

V

I

T

Y

WORK ACTIVITY

QUALITY CHARACTERISTIC

TO BE VERIFIED

PROCEDURE

REFERENCE/CODE/

STANDARD

ACCEPTANCE CRITERIA /

VALUE

PERFORMED

BY

G

K

W

I

U

S

M

E

P

I

L

QUALITY VERIFICATION

RECORD

3 Hot Dip Galvanizing Zinc coating thickness, Zinc

adhesion, visuals,

Instrument calibration

verification

2013030011-CV-J04-001

ASTM A 123

ISO BS EN 1461

Average Zinc Coating as

per specification

No Peel off.

No lumps

Quality

Control

Engineer

C H H Hot Dip Galvanizing

Certificate

4 Final Inspection,

Identification,

Packing

Zinc coating finish

Individual / Batch

Identifications marks

Packing as per

requirements

2013030011-CV-J04-001

Customer specifications

Zinc coating as per

specification, no defects

Identification as per Job

numbers

Rigid packing to avoid

damages

Quality

Control

Engineer

C H W Pre despatch Inspection

Report

You might also like

- Ga Irrsp Study GuideDocument7 pagesGa Irrsp Study Guidechesspupil100% (2)

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Galvanizing Procedure PDFDocument7 pagesGalvanizing Procedure PDFkhuzafa50% (4)

- Sample Control Plan - Hot Dip GalDocument5 pagesSample Control Plan - Hot Dip Galvinbrkrishna0% (1)

- INSPECTION Procedure For GalvanizingDocument14 pagesINSPECTION Procedure For Galvanizingjasminnee100% (1)

- 6-Hot Dip Galvanizing Procedure - Rev 0-PDocument9 pages6-Hot Dip Galvanizing Procedure - Rev 0-PNguyen Anh Tuan75% (4)

- Heat Straightening ProcedureDocument3 pagesHeat Straightening ProcedurerzsoltNo ratings yet

- TDC - CS PipeDocument1 pageTDC - CS PipetrushalpanchalNo ratings yet

- Pickling ProcedureDocument2 pagesPickling Proceduremahazari100% (6)

- Sample Galvanizing Procedure +ITPDocument14 pagesSample Galvanizing Procedure +ITPsubash sivalingam67% (3)

- Aws Welding 201308 PDFDocument122 pagesAws Welding 201308 PDFsubash sivalingamNo ratings yet

- Mos Galvanizing ProceduresDocument23 pagesMos Galvanizing ProceduresRajeswaran Rajachockalingam100% (1)

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument11 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsNguyen Duc Dung100% (1)

- Repair Welding ProcedureDocument3 pagesRepair Welding Procedurevalararumugams100% (2)

- Flame Straightening S355Document9 pagesFlame Straightening S355Anonymous oI04sS100% (1)

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Specification For Hot Dip GalvanizingDocument10 pagesSpecification For Hot Dip GalvanizingKyaw Kyaw Aung100% (1)

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- 25 Tack Welder - ABSDocument7 pages25 Tack Welder - ABSvudinhnambrNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013No ratings yet

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Site Paint Repair Procedure IntumescentDocument4 pagesSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Flame StraighteningDocument3 pagesFlame StraighteningAvishek Gupta100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Weld Joint Repaire Procedure - 08.04.14Document6 pagesWeld Joint Repaire Procedure - 08.04.14Raj AryanNo ratings yet

- Wps (Argon Welding)Document1 pageWps (Argon Welding)M. R. Shahnawaz KhanNo ratings yet

- Weld Repair and Buttering ProcedureDocument9 pagesWeld Repair and Buttering ProcedureTaufik Santoso100% (2)

- Wps & PQR and Weld Map and Test PlanDocument67 pagesWps & PQR and Weld Map and Test PlanmarghoobNo ratings yet

- Revised IMIR ReportDocument2 pagesRevised IMIR ReportSimbu ArasanNo ratings yet

- Galvanizing Procedure (5400)Document5 pagesGalvanizing Procedure (5400)Syed Muzammil100% (2)

- Electrode Selection ChartDocument2 pagesElectrode Selection Chartg_sancheti100% (2)

- 3-Piping Repair Weld Procedure - PR003Document5 pages3-Piping Repair Weld Procedure - PR003mohd as shahiddin jafriNo ratings yet

- Fabrication ProcedureDocument17 pagesFabrication Procedureanang Wahjudi100% (2)

- MTC PDFDocument170 pagesMTC PDFShoukat Zaki0% (2)

- Baking Register Baking - 1 Baking - 2: Welder NoDocument3 pagesBaking Register Baking - 1 Baking - 2: Welder NoShivam TiwariNo ratings yet

- A 307Document1 pageA 307GHULAM NABINo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (2)

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument8 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsIan FletcherNo ratings yet

- Weld Plan D00651285Document14 pagesWeld Plan D00651285sandeepNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- PBI-CCP-QA-0001 QA Welding Consumable Control ProcedureDocument15 pagesPBI-CCP-QA-0001 QA Welding Consumable Control ProcedureTadaya KasaharaNo ratings yet

- Duties of The RWCDocument3 pagesDuties of The RWCbluegalago100% (1)

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- Bending ProcedureDocument1 pageBending ProcedureabbasNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionMel gibsonNo ratings yet

- Galvanising ManualDocument199 pagesGalvanising Manualdc12dc100% (1)

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- 1.welding Repair ProcdureDocument7 pages1.welding Repair Procduresethu1091No ratings yet

- Weldment Visual Inspection RequirementsDocument10 pagesWeldment Visual Inspection RequirementsKarthik P MuraliNo ratings yet

- 01 Procedure For Structural SteelDocument9 pages01 Procedure For Structural Steelpunitg_2No ratings yet

- RCJI-QA-SC118 (M) .xls-CHROME PLATINGDocument7 pagesRCJI-QA-SC118 (M) .xls-CHROME PLATINGChoice OrganoNo ratings yet

- Revised Draft Ammendment To IRS T29 MAR13Document11 pagesRevised Draft Ammendment To IRS T29 MAR13Shipra MishraNo ratings yet

- Inspection Check List 2Document34 pagesInspection Check List 2r.devendranNo ratings yet

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Passivation and Pickling of Stainless Steel Weld Joints Method StatementDocument7 pagesPassivation and Pickling of Stainless Steel Weld Joints Method StatementHabib RehmanNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- Hawle Response Letter For Gate Valve ITPDocument7 pagesHawle Response Letter For Gate Valve ITPMurali AnandNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- API 510 Pre-Course Practical Study GuideDocument156 pagesAPI 510 Pre-Course Practical Study GuidePrashant TiwariNo ratings yet

- GB088-2013-CV-TQ-0015-A-code 2Document3 pagesGB088-2013-CV-TQ-0015-A-code 2subash sivalingamNo ratings yet

- Aws WJDocument138 pagesAws WJsubash sivalingamNo ratings yet

- Asnt SN Tc1a (2006) PDFDocument37 pagesAsnt SN Tc1a (2006) PDFsubash sivalingamNo ratings yet

- MIL-W-8604A WeldingDocument20 pagesMIL-W-8604A Weldingbob_rocksNo ratings yet

- IndexDocument30 pagesIndexhortalemosNo ratings yet

- Welding Journal 1959 10Document136 pagesWelding Journal 1959 10AlexeyNo ratings yet

- Arc WeldingDocument26 pagesArc WeldingAkshay PadekarNo ratings yet

- Chem MCQ MetalsDocument8 pagesChem MCQ MetalsArundathyNo ratings yet

- (EW-492) - Flux Cored Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Document106 pages(EW-492) - Flux Cored Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Khaled Gamal100% (1)

- Submerged Arc WeldingDocument64 pagesSubmerged Arc WeldingLương Hồ Vũ100% (1)

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- The Development of 990 Gold-Titanium, and Its Production Use and PropertiesDocument9 pagesThe Development of 990 Gold-Titanium, and Its Production Use and PropertiesVigneswaranNo ratings yet

- Study of Electric Arc Welding Process and Various Types of JointDocument12 pagesStudy of Electric Arc Welding Process and Various Types of JointMohammed RakibNo ratings yet

- Welding ControlDocument6 pagesWelding ControlALNo ratings yet

- Usermanual: Quickoelectronic.,LtdDocument15 pagesUsermanual: Quickoelectronic.,LtdJoão RobertoNo ratings yet

- Reasoned Document IRS M-39-2020Document42 pagesReasoned Document IRS M-39-2020Metal deptNo ratings yet

- Aluminium Recycling Scrap Melting and Process Simulation - Article-22 PDFDocument15 pagesAluminium Recycling Scrap Melting and Process Simulation - Article-22 PDFWillian Bella RosaNo ratings yet

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- Section 12 - 12 Silver Brazing266 - 154577Document8 pagesSection 12 - 12 Silver Brazing266 - 154577gianNo ratings yet

- Soft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesDocument10 pagesSoft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesselocaNo ratings yet

- BRA - Jointing Cooper Brazing ProcedureDocument40 pagesBRA - Jointing Cooper Brazing ProcedureGistek MarcoNo ratings yet

- General Principles and Process of Isolation of Elements: SynopsisDocument32 pagesGeneral Principles and Process of Isolation of Elements: SynopsisGayatri GNo ratings yet

- Cored Solder Wires Cored Solder Wires For Aluminium: Alu-SolDocument4 pagesCored Solder Wires Cored Solder Wires For Aluminium: Alu-Solpaula09No ratings yet

- CBLM 6 Terminate Connect Electrical Wiring Electronic CircuitsDocument39 pagesCBLM 6 Terminate Connect Electrical Wiring Electronic CircuitsDivina LayaNo ratings yet

- Body RepairDocument19 pagesBody RepairPUTRA SANINo ratings yet

- As 1858.1-2003 Electrodes and Fluxes For Submerged-Arc Welding Carbon Steels and Carbon-Manganese SteelsDocument7 pagesAs 1858.1-2003 Electrodes and Fluxes For Submerged-Arc Welding Carbon Steels and Carbon-Manganese SteelsSAI Global - APACNo ratings yet

- Soldring MechineDocument16 pagesSoldring MechinePrabir Kumar Pati100% (1)

- Aluminum in Galvanizing Graham PoagDocument16 pagesAluminum in Galvanizing Graham PoagTeka KamNo ratings yet

- 021 C 99 S 2 C 16Document16 pages021 C 99 S 2 C 16Ricardo QuillahuamanNo ratings yet

- Chapter - 1 Introduction:-: Variable Power Supply With Digital Control 2011Document49 pagesChapter - 1 Introduction:-: Variable Power Supply With Digital Control 2011Subhash BajajNo ratings yet

- Leaded Surface Mount Technology - SMTDocument14 pagesLeaded Surface Mount Technology - SMTEdson CostaNo ratings yet

- De 82004 0005 BR enDocument108 pagesDe 82004 0005 BR enAndor Tony CiguNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet