Professional Documents

Culture Documents

044 Types of Damages On Flexible Pavement For Malaysian Federal Road - 2

044 Types of Damages On Flexible Pavement For Malaysian Federal Road - 2

Uploaded by

Jalaluddin Johan0 ratings0% found this document useful (0 votes)

55 views12 pagesgood

Original Title

044 Types of Damages on Flexible Pavement for Malaysian Federal Road_2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

55 views12 pages044 Types of Damages On Flexible Pavement For Malaysian Federal Road - 2

044 Types of Damages On Flexible Pavement For Malaysian Federal Road - 2

Uploaded by

Jalaluddin Johangood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

421

TYPES OF DAMAGES ON FLEXIBLE PAVEMENT FOR MALAYSIAN FEDERAL ROAD

Nurul Elma Kordi

1

*, Intan Rohani Endut

1,2

, Bahardin Baharom

1,2

ABSTRACT:

Flexible pavements in Malaysia are designed until ten to fifteen years design life to support load.

However, sometimes these roads not able to carry the load with the specified design life especially in

industry areas because heavy lorries always using these road to move their goods. A lot of distress on the

flexible pavement and it become uncomfortable feelings to the driver. A lot of factors contribute the

problem of failure to flexible pavement either internal or external factors. Among the heavy trucks'

operators, they want to raise the axle loads limit for all trucks to avoid delivery delays and meet higher

storage chargers; in fact Road Transport Development (RTD) had given special permission to some 1000

lorries since August 2007 to carry the new maximum load. In order to quantify flexible pavement

damages, the impacts of increase axle load on Federal road must identify and evaluate. This paper

discusses a type of damages on the flexible pavement, causes of failure to flexible pavement and

appropriate structural requirements for pavement performance that can carry the load on a routine basis.

With the best understanding of the causes of failure and process to rehabilitation, the responsibilities'

authorities will know well the key to proper maintenance of flexible pavement in order to design, manage

and maintain the highways.

Keywords: Axle Load, Distress, Flexible Pavement, Rehabilitation

1

Malaysia Institute of Transport (MITRANS), Universiti Teknologi MARA, 40450 Shah Alam, Selangor, MALAYSIA

2

Faculty of Civil Engineering, Universiti Teknologi MARA, 40450 Shah AlamSelangor, MALAYSIA

* Correspondence Author: Nurul Elma Kordi, Malaysia Institute of Transport, Universiti Teknologi MARA, Malaysia.

Tel: +6003 5521 1492, Fax: +603 5544 2344. E-mail: ema_nuelko@yahoo.com

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

422

INTRODUCTION

Road has played an important role in the trade and transportation system throughout the world,

and it become rapid increase in the pavement infrastructure development in Malaysia. Gazette under

Federal Roads Ordinance is usually roads linking the state capitals, airports, railway stations and ports.

Currently, Malaysia has more than 80,300km roads. The road is divided into three main categories

namely toll expressway (1,700km), federal roads (17,500km) and state roads (61,100km) and the life

spans are between 10 to 15 years (Zakaria and Hassan, 2005). Local authority road (city mall, municipal

or local council) or kampong (district office) road is depending upon jurisdiction and normally maintained

by the responsibility local authority (Haron, 2004).

In Malaysia, Federal road use the flexible pavement that constructed with asphaltic cement and

aggregates and consist of several of layers with the lowest called the subgred which natural soil itself. The

next layer is the subbase, which consist of crushed aggregate. The next layer is called road base, which

can be made of crushed aggregates with a cementing material. The top layer is called surfacing layer. It is

usually made of asphaltic concrete. The structural strength depends on individual material strength

characteristic and thickness layer. Some form of deflection within the elastic limit is allowed. Surface

readability is good but relatively less durable or susceptible to high temperature (Haron, 2004).

Federal road at Malaysia almost used the flexible pavement compare to rigid pavement because

flexible pavement more comfortable to the user. Furthermore, flexible pavement can be use by users once

ready. Table 1 shows the differences between flexible and rigid pavement. With best design and proper

construction method, adequate routine and periodic maintenance are necessary to achieve the determined

design life spans and even beyond. The main factors of pavement deterioration due to increasing the

number of vehicle and load traffic by the run which is five percent per annum.

Table 1: The differences between flexible and rigid pavement

No. Flexible Rigid

1 Last for 20 years Last for more than 40 years

2 High cost and schedule maintenance More economic maintenance, no schedule

3 Cheap and easy to get the material Material shortage problem always occurs

4 Low initial cost Higher initial cost

5 Easy to upgrade / stage construction Cannot upgrade / no stage construction

6 Rutting and potholes may occur Free from rutting, potholes and corrugation

7 Less economic for the long duration More economical for the long duration

8 Can be used once ready Traffic disturbance, wait for maximum

strength (28 days)

(Source: Haron, 2004)

As a part of the study by research, this paper discusses on failure on flexible pavement, sources

failure of flexible pavement and appropriate structural requirements for pavement performance that can

carry the loads on a routine basis. This is a preliminary study before conduct the actual study which

mapping all the damages along Federal road number one after this.

TYPES OF DAMAGES

According to Highway Research Board, 1970 cited by Pavement Interactive, 2010, pavement

distress is "any indication of poor or unfavourable pavement performance or signs of impending failure;

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

423

any unsatisfactory performance of a pavement short of failure". The causes of pavement failures are

divided into two categories, which are an internal and external failure. Internal failures of pavement are

usually because of the lack pavement mixture, weaknesses of component materials and poor construction.

Meanwhile, external failures are due to overloading, diesel spillage, flooding, sink holes and other

unforeseen cause such as earthquake, volcanoes and others. The failures of flexible pavement are divided

into four categories, which are surface deformation, surface defects, cracking and patching and potholes

(Rani, 2007). Tables 2, 3, 4 and 5 below shows the lists the pavement distress groups, possible causes,

and the probable treatments that summarized by Rani, 2007 and PFI, 2010.

Table 2: Surface deformation

No. Possible Causes Probable Treatments

Shoving

1 Instability mixture of asphalt (course or fine

aggregate too rounded or too smooth textured)

Remove surface and base as necessary and

replace with a more stable material

2 Low modulus bases course Reconstruction of base

3 Thin wearing course Bituminous overlay

4 Dragging of pavers during laying when

bituminous mix temperatures were low

Remove surface and base as necessary and

replace with a more stable material

5 High stress due to braking and acceleration

movements

Bituminous overlay with the stiffer mix or use

the high compaction mix.

Corrugations

1 Inadequate stability of bituminous

surface (excessive moisture)

Replace bituminous surface

2 Compaction of base in wave form Base reconstruction

3 Faulty paver behaviour with some

mixes (contamination caused by oil spillage)

Replace the faulty mixes and correct the

faulty behaviour

4 Heavy traffic on steep downgrade or upgrade Mill off the corrugated surface and replace

with the stiffer mix or use hot mix asphalt

5 Stopping at intersection stop lights or

roundabout

Mill off the corrugated surface and replace

with the stiffer mix or use hot mix asphalt

6 Inadequate stability of base course Base construction.

Rutting

1 Inadequate pavement thickness Strengthening overlay or reconstruction

2 Inadequate compaction of structural layers Reconstruction

3 Unstable bituminous mixes Replace or recycle bituminous surfacing or

use the stiffer mix

4 Unstable shoulder material which does not

provide adequate lateral support

Shoulder improvement and overlay rutted

area with bituminous surfacing

5 Overstressed subgrade which deforms

permanently

Reconstruction

6 Unstable granular bases or subbases Base or sub base strengthening

Depression

1 Differential settlement of

subgrade or base materials

Subgrade or base reconstruction

2 Settlement of services and / or

widening trenches

Reconstruction of services and/or widening

trenches

3 Volume change of subgrade

due to environmental influences

Improve sub-soil drainage and

reconstruct

4 Settlement due to instability of embankment Embankment stabilization

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

424

(Source: Rani, 2007 and PFI, 2010)

Table 3: Surface defect

No. Possible Causes Probable Treatments

Bleeding / Flushing

1 Excessive asphalt in the surface layer. On hot

days the binder expands into air voids; if the

volume of air voids is too low, continued

expansion results in lower stability of the mix

with the consequence that traffic will force out

excess binder to the surface.

Apply hot sand to blot up the excess binder to

the stone size.

2 Paving over flushed surfaces. The excess

bitumen on the old surface may be pumped up

through the new paving over period of time.

Apply hot sand or aggregate seal coat.

3 Paving over excessively primed surfaces Apply hot sand

4 Lack of proper rolling during placement Resurfacing the asphalt

5 Failure to protect a newly constructed surface

from traffic until the asphalt cured sufficiently.

Resurfacing the asphalt

Ravelling

1 Insufficient bitumen content Thin bituminous overlay

2 Poor adhesion of bitumen binder to aggregate

particles due to wet aggregate

Thin bituminous overlay

3 Inadequate compaction or construction during

wet weather

Thin bituminous overlay

4 Deterioration of binder and/or aggregate Thin bituminous overlay

Polishing

1 Inadequate resistance to polishing of surface

aggregates particularly in areas of heavy traffic

movements or where high stresses are

developed between surface and tyres

The bituminous overlay of use of stiffer mix

2 Use of naturally smooth uncrushed aggregates Thin bituminous overlay.

Delimitation / Surface Lifting /Seal Break

1 Inadequate cleaning or inadequate tack cot

before placement of upper layers

Mill off and re-lay upper layers.

2 Seepage of water through asphalt, especially in

cracks, to break the bond between surface and

lower layers.

Replace wearing course or thin bituminous

overlay

3 Weak, loose layer immediately underlying seal Reconstruction of weak layers

4 Adhesion of surface binder to vehicle tyres Thin bituminous overlay

(Source: Rani, 2007 and PFI, 2010)

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

425

Table 4: Cracking crack

No. Possible Causes Probable Treatments

Fatigue (alligator/crocodile) crack

1 Inadequate pavement thickness Strengthen the pavement or reconstruction

2 Low modulus base Strengthen the base or reconstruction

3 Brittle base Base recycling or reconstruction

4 Poor base drainage Improve the drainage and reconstruct

5 Brittle wearing course Replace or treat wearing course

Block cracking

1 J oints in underlying layer Crushed aggregate overlay

2 Shrinkage and fatigue of underlying

cemented materials

Replace underlying cemented

materials

3 Shrinkage cracks (due to bitumen

hardening) in bituminous surfacing

Seal cracks or replace bituminous surfacing

4 Fatigue cracks in embrittled

bituminous wearing course

Cut and patch or crushed aggregate overlay

Longitudinal cracking

1 Reflection of shrinkage cracks Cut and patch

2 Poorly Constructed paving lane in bituminous

surfacing

Replace bituminous surfacing

3 Displacement of joints at pavement widening Reconstruction of joints

4 Differential settlement between cut and fill Crushed aggregate overlay or reconstruction

of joints.

Transverse (Thermal) Crack

1 Reflection of shrinkage cracks Cut and patch

2 Construction joint in bituminous surfacing Crack sealant

3 Structural failure of Portland Cement Reconstruction of base

4 Shrinkage crack bituminous surfacing Seal cracks or replace bituminous surfacing

5 Reflection of joints in the underlying base Crushed aggregate overlay or reconstruction

of joints

Edge cracks

1 Excessive traffic loading at the pavement

edge

Widen the pavement or strengthen the

pavement edge

2 Poor drainage at pavement edge and shoulder Improve drainage and shoulder

3 Inadequate pavement width which forces

traffic too close to the pavement edge

Widen treatment

4 Insufficient bearing support Reconstruction

Edge breaks

1 Inadequate pavement width Widen the pavement

2 Alignment which encourages drivers to

travel on the pavement edge.

Pavement widening and realignment

3 Inadequate edge support Shoulder strengthening

4 Edge drop-off Strengthening and leveling of shoulder with

road surface

5 Loss of a adhesion to base Cut and patch or bituminous overlay.

Edge drop-offs

1 Inadequate pavement width Widen the pavement

2 Shoulder material with inadequate resistance Replace shoulder material and reconstruct

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

426

to erosion and abrasion.

3 Resurfacing of pavement without

resurfacing of shoulder

Leveling of shoulder with road surface

Crescent shaped cracks / parabolic / slippage / shear cracks

1 Lack of bond between wearing course and

the underlying layers

Cut and patch

2 Low modulus bases course Reconstruction of

base

Reconstruction of base

3 Thin wearing course Bituminous overlay

4 Dragging of pavers during laying when

bituminous mix temperatures were low

Cut and patch

5 High stress due to braking and acceleration

movements

Bituminous overlay with the stiffer mix or use

the high compaction mix.

(Source: Rani, 2007 and PFI, 2010)

Table 5: Patching and Potholes

No. Possible Causes Probable Treatments

Patch/Patch Deterioration

1 Inadequate cleaning or inadequate tack cot

before placement of upper layers

Mill off and re-lay upper layers.

2 Seepage of water through asphalt, especially in

cracks, to break the bond between surface and

lower layers.

Replace wearing course or thin bituminous

overlay

3 Weak, loose layer immediately underlying seal Reconstruction of weak layers

Pothole

1 Loss of surface course Patching

2 Moisture entry to base course through a

cracked pavement surface

Cut and patch

3 Load associated disintegration of base Base reconstruction

(Source: Rani, 2007 and PFI, 2010)

From the table, it shows most of the possible causes damages of pavement are due to of

imperfection during construction. This failure will give uncomfortable to the users during their driving.

Either responsibility contractor does their work perfectly or not during construction of the road need to

investigate.

CHARACTERISTICS EFFECTING FAILURE OF PAVEMENT

Truck factors

Most comment from the users of the road about the vehicle that carries the heavy load that makes

the pavement damage. On behalf of heavy truck operators, they want to increase the axle load limit to

avoid delivery delays and meet higher storage chargers. Table 6 below shows the comparison weight limit

of the truck among various countries.

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

427

Table 6: Comparison Weight Limit of Truck among Various Countries

Country Type (load+vehicle) Weight

limit (maximum)

Malaysia Two-axle-fixed truck

Three-axle-fixed truck

Four-axle-fixed truck

16 tons

21 tons

25 tons

Thailand Two-axle-fixed truck

Three-axle-fixed truck

Five-axle-fixed truck

12 tons

21 tons

39 tons

Singapore Two-axle-fixed truck

Three- axle-fixed truck

Four-axle-fixed truck

Articulated truck

16 tons

24 tons

-

24 tons

ASEAN Standard Two-axle-fixed truck

Three-axle-fixed truck

Four-axle-fixed truck

Articulated truck

16 tons

21 tons

-

38 tons

(Source: MRTV3, 2010)

Table 7 show the comparison of axle load among various countries. Axle load and total truck load

limits are also an important factor, which can determine the efficiency of the road system and

competitiveness of the countrys logistics system. Thailands maximum axle load limit is 8.2 tons while

the truck limit had increased to 25 tons from 21 tons in 2006. Thailands axle load limit is lower than

other countries. Truck load limit and axle load limit will have impact on Thailands long-run freight

transport cost and road maintenance cost, which need to be balanced. Different load limits among

Thailand and neighboring countries might also cause problems for transshipment of goods across national

borders and complicate international trade negotiations (Transport Sector, 2008).

Table 7: Comparison of Axle Load among Various Countries

Country Axle Load Limit (Ton)

Malaysia 12

Thailand 8.2

Singapore 10

J apan 11

Europe 10-13

The Peoples Republic of China 10

ASEAN member countries 10

(Source: Transport Sector, 2008)

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

428

Heavy vehicle also contributed to deterioration of the road, there were 19.3 million registered

vehicles on the Malaysias road, and the government spent RM5 billion between 2001 and 2010 to keep

sustaining all the Federal roads (New Strait Times, June 2010). Heavy vehicle has been banned during

morning peak hours started 2 August 2010 from certain stretches to avoid traffic congestion on the North-

South Expressway. Federation of Malaysian Manufacturer presidents, Tan Sri Mustafa Mansur (2010)

said the move would not cause much impact as lorries could still use other alternative roads to get their

destination. This rule is applied after investigations have been done. The result shows the total of heavy

vehicle breakdown three times more than light vehicles and this situation will give big impact on traffic

congestion (Berita Harian, 2010). However, Pan Malaysia Lorry Drivers Association president, Er Sui

See, unhappy with the ban because it unfair and absurd to expect them apply for temporary permits each

time they need to use the highway during the ban time (The Star, J uly 2010).

Pavement and environmental factors

The other factor of pavement damages is due to extra ordinary weather such as heavy rain and

flooding. It is bringing on water absorption to pavement and weakened the structural pavement base. The

pavement will weaken and fail due to increasing moisture content of the subgrade. Therefore, drainage is

very important in the roads' system to keep the low water table. In Malaysia, RM220 million was spent

every year on repairing road damages by rains and floods (New Strait Times, 2010). In general,

conventional asphalt easy to damage when exposed to water and high incidences of flooding. The used

less quality of material, non effective construction, construction procedure without control and

overweight commercial transports also as sources of failure pavement.

Tolled expressways are better maintained than Federal roads because government has to take care

of more roads, which are 16,500km of federal roads compared only 1,360km that managed by private

highway concessionaires (The Star, 2010).

Contact condition and configuration of tire

The consensus is clear which the details of the contact conditions such as the exact area, pressure

and pressure distribution, effect stresses and strains near to the surface of the pavement, whereas the

response in the lower layers depends mainly on the overall load. Haas and Papagiannakis, 1986 (as cited

in Cole & Cebon, 1997) showed that increasing the tyre inflation (contact) pressure from 415 kPa to 830

kPa at constant load will increase the theoretical vertical compressive strain near to the surface of a

200mm thick asphalt layer by up to a factor of eight, but hardly affected the strain at the bottom of the

layer. In 1963, Zube and Forsyth (as cited in Cole & Cebon, 1997) performed an experimental

comparison of the vertical deflections and transverse strains of a flexible pavement surface, to wide-base

single tyres and dual wheels. Their results indicated that pavement deflection was equivalent to 27 kN

carried on a single tyre or 40 kN carried on a dual pair.

Cole and Cebon, 1997, conclude that fatigue cracking failed due to wide single tyres cause up to

seven times more damage than dual tyres carrying the same total load for the relatively thin asphalt

pavements (minor roads). For thicker pavements, where permanent deformation is the main mode of

failure, wide single tyres are likely to cause one and half to two times more damage than dual tyres.

Dadoo and Thorpe (2005) identify the main factors responsible for pavement damage caused by heavy

vehicle such as dynamic axle load, number and type of axles (e.g. single, tandem), tyre properties (e.g.

wide-base, dual) and pavement properties (e.g. pavement type, thickness, temperature and roughness).

This research will discover which these factors have the greatest influence on pavement response.

Marshek et al. (1986) lists of the possible damage or defect on the pavement are shown in Table 8. It can

be concluded that, pavement damage will be increased due to less of contact area of tires to road. The

higher pressure of tires is one of the factor's pavement damages because small of contact area between

tires and pavement.

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

429

Table 8: Summary of characteristics influencing pavement damage

Characteristic Decrease in Pavement Damage Increase in Pavement Damage

No. of Tires per Axle

More Tires per Axle (Tandem Axle)

Less Load per Tire

Less Load per Unit Contact Area

Decrease in Pavement Damage

Fewer Tires per Axle

Greater Load per Tire

Greater Load per Unit Contact

Area

Increase in Pavement Damage

No. of Axles

More Axles

Less Load per Axle

Less Load per Unit Contact Area

Decrease in Pavement Damage

Fewer Axles

Greater in Load per Axle

Greater Load per Unit Contact

Area

Increase in Pavement Damage

Load Distribution

Load Distributed Evenly Among

Axle

Less Load for the Most Heavily

Loaded Axle Group

Decrease in Pavement Damage

Load Not Distributed Evenly

Among Axles

Greater Load for the Most

Heavily Loaded Axle Group

Increase in Pavement Damage

Speed / Congestion

Higher Speeds

Decrease in Load Duration

Decrease in Pavement Damage

Lower Speeds

Greater Load Distribution

Increased Pavement Damage

Tire Pressure

Lower Tire Pressure

Greater Surface Contact Area

between Tire and Pavement

Less Load per Unit Contact Area

Decrease in Pavement Damage

Higher Tire Pressure

Smaller Surface Contact Area

between Tire and Pavement

Greater Load per Unit Area

Increase in Pavement Damage

EFFECTS OF INCREASED LEGAL LOAD LIMITS

Studies of the effect of increasing the legal load limit from 18,000 to 20,000 pounds for single

axles and from 32,000 to 36,000 pounds tandem axles were made by the California Transportation

Department. According to a study by Smith (1973) cited by Matthews and Baumeister (1976), if half load

trucks which hauled legal limit loads were to increase axle loads to the proposed limits, the decrease in

fatigue life of existing pavements is predicted to be between 20 and 25%. The effect of this decrease in

pavement life will be to increase maintenance costs on existing pavements considerably over what they

have been in the past and require reconstruction and rehabilitation at an earlier date. Findings from the

study indicate that an 11% increase in legal load limits appears to reduce service life in years

approximately 20% (Matthews and Baumeister, 1976).

J arviss (2008) opinion the increasing of truck Gross Vehicle Weights (GVW) on the federal

highway system, while keeping individual axle weight limits at the current level, will improve

productivity, fuel conservation, air quality, infrastructure conservation, and public safety, while reducing

carbon emissions and traffic congestion. While Eason and Greene (2008) explained by providing fuel-cost

savings, increasing the allowable GVW also would streamline trucking across national borders. Current

maximum GVWs allowed by Mexico and Canada are 106,920 pounds and 95,900 pounds, respectively.

According to the Americans for Safe and Efficient Transportation (ASET), the payload increase would

make trade more parallel and obtain $14.5 billion of potential savings in shipping costs. For an individual

truck, ASET also states that tractor-trailers (with six axles rather than five) can reduce vehicle miles

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

430

travelled (VMT) by 11% and reduce fuel usage by 6%. Accidents would decrease as well, as fewer trucks

driven by a smaller pool of more highly qualified drivers would be on the road. With the increasing

prices of fuel, the haulier needs to improve their trucking system because fuel costs will reduce the profit

margins on every industry in the economy, and logging is certainly no exception.

APPROPRIATE STRUCTURAL REQUIREMENT

The rehabilitation of flexible pavements encompasses a broad range of activities, which could be

grouped into three categories namely; restoration, resurfacing (structural) and reconstruction (Caltrans,

2000). In order to prevent failure flexible pavement, the polymer-modified asphaltic (PMA) concrete has

started used in several project road upgrading by Work Ministry. The National Economic Action Council

had agreed that PMA be used on five per cent of new projects as a part of the 10

th

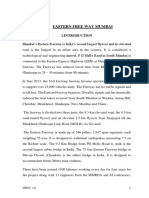

Figure 1 below illustrates the alternatives of pavement maintenance and rehabilitation. This

figure is helpful in understanding the aim for which a given treatment.

Malaysia plan. PMA is

a mixture of natural or synthetic polymer materials with conventional bitumen. Their rubberlike surfaces

are highly resistant against rutting and cracking and absorb little water, which is the cause of cracks in

roads. PMA has a lower life cycle cost and can admit the higher axle load, also, with using PMA it can

save until RM200,000 for every kilometer of the road in yearly maintenance work, although the cost

PMA is 1.7 times more than conventional (New Strait Times, 2010). A study was completed for the

Affiliate Committee of the Asphalt Institute on the use of PMA for reducing distress in flexible

pavements and hot mix asphalt (HMA) overlays. The results from that study found that the use of PMA

reduced pavement distress and increased the life of flexible pavements by two to ten years (Asphalt

Institute IS-215, 2005).

Figure 1: Alternatives of Pavement Maintenance and Rehabilitation

(Source: Monismith, 1979)

Pavement maintenance and

Rehabilitation

Maintenance Rehabilitation

Surface Subsurface

Overlays

Recycling Reconstruction

Combination of

recycling and overlays

- Preventive

- Corrective

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

431

There are differentiated between preventive and corrective approaches preventive strategies for

pavement surface include fog-seal asphalt, rejuvenators, joint sealing, seal coat (with aggregate) and thin

blanket. For surface corrective there are patching, crack filling, joint sealing, seal coat, friction course,

grooving, thin blanket, surface recycling, cold planning and drainage. For subsurface, there have drainage

for preventive maintenance and sub-sealing, in-situ stabilization and drainage for corrective maintenance.

CONCLUSSION

The failures of pavement have increased significantly over the year. The effect of axle load plays

an important role in the deterioration of flexible pavements. Although the Association of Malaysia

Hauliers (AMH) and truck operators want to raise the lorry load limit for all as similar size vehicles have

been transporting heavier loads at overseas, the responsibilities' authority still needs to investigate

carefully the effect to the road and users. Damaged roads need to repair immediately as they can cause

accidents and traffic congestion. The study that was conducted and discussed in this paper show that the

possible causes of flexible damages mostly did not cause by heavy truck. Therefore, the further research

needs to conduct to check whether the responsible contractor done their work properly or not and the

other factor of flexible pavement easy to damage need to consider and investigate. New road construction

will involve big investment. Therefore, to ensure life span of the road that constructed more durable,

comfortable and safe to the user, construction and maintained of the road need to be done effectively.

REFERENCES

Asphalt Institute, (2005). Quantifying the Effects of PMA for Reducing Pavement Distress,

Asphalt Institute Information Series 215.

Berita Harian. (2010, J uly 30). Tiada Kompromi Lori 6 Tayar Masuk Lebuhraya, pp. 2.

Caltrans, S. L. (2000). Maintenance Technical Advisory Guide (TAG). American Concrete Pavement

Association.

Dodoo, N. A. & Thorpe, N. (2005). New Approach for Allocating Pavement Damage between Heavy

Good Vehicles for Road-user Charging. School of Civil Engineering and Geosciences, University of

Newcastle Tyne, pp. 419-430.

Eason, K. & Greene, D. (2008), Potential Impact of 97,000-Gvw on Logging Costs. Retrieved from

Agricultural Transportation Efficiency Coalition website: http://ag-haul.org/resources/

multimedia/PDF/ AgTEC-GVWstatement.pdf.

Haas, R. C. G. & Papagiannakis, A. T. (1986). Understanding Pavement Rutting. Special Workshop on

Rutting in Asphalt Pavements, Toronto, Roads and Transport Association of Canada.

Haron, S. (2004). Highway and Traffic Engineering (1

st

ed.). Universiti Teknologi MARA, Perlis.

J arvis, S. (2008). Increase Truck Weight Limits For Agricultural Transportation from 80,000 to 97,000

Pounds. Retrieved from Agricultural Transportation Efficiency Coalition website: http://ag-

haul.org/resources/ multimedia/PDF/ AgTEC-GVWstatement.pdf.

Proceeding of Malaysian Universities Transportation Research Forum and Conferences 2010

(MUTRFC2010), 21 December 2010, Universiti Tenaga Nasional. ISBN 978-967-5770-08-1

432

J ohn, S. M. & William, Y. B. (2003). Distress Identification Manual for the Long-Term Pavement

Performance Program (4th revised ed.). U.S. Department of Transportation, Federal Highway

Administration, 6300 Georgetown Pike.

Marshek, K. M., Chen, H. H., Connell, R. B. & Saraf, C. L. (1986). Effect of Truck Tire Inflation

Pressure and Axle Load on Flexible and Rigid Pavement Performance. Transportation Research

Record N1070, Transportation Research Board, Washington DC.

Matthews, J . A. & Baumeister, K. L. (1976). Damage to Pavement due to Axle Load. Technical Report

Document Page, California Department of Transportation, Sacramento, California 95807.

Monismith, C. L. (1979). Pavement Evaluation and Overlay Design Summary of Methods. Transportation

Research Record No. 700, Transportation Research Board, National Research Council, Washington,

D.C.

New Strait Times. (2010, J une 22). Fewer Potholes with New Type of Asphalt, pp. 14.

Nicholas, J . G. & Lester, A. H. (2002). Traffic and Highway Engineering (3rd ed.). University of

Virginia, United States: Thomson Learning.

Pavement Failure Identification, PFI (2010). Retrieved from http://www.apai.net/cmdocs/apai/

designguide/Appendix_A-B.pdf

Pavement Interactive (2010). Pavement Distress. Retrieved from http://pavementinteractive

.org/index.php?title=Surface_Distress

Quintus, H. L. & Mallela, P. E. (2005). Reducing Flexible Pavement Distress in Colorado Through the

Use of PMA Mixtures. Final Report No. 16729.1/1 (prepared for the Asphalt Institute), Applied

Research Associates, Inc., Round Rock, Texas.

Rani, O. A. (2007). The Effectiveness of Pavement Rehabilitation at Kuala Lumpur Karak

Highway. Master thesis, Universiti Teknologi Malaysia.

Thailand Infrastructure Annual Report (2008) Retrieved on 12 April 2010 from

http://siteresources.worldbank.org/INTTHAILAND/Resources/333200-1177475763598/3714275-

1234408023295/5826366-1234408105311/chapter2-transport-sector.pdf

The Star. (2010, May 5). Tolled Roads are Better Maintained, pp 11.

The Star. (2010, J uly 27). Heavy Vehicle Banned, pp. 12.

Vehicles of today and motor ways in Myanmar (4). Retrieved on 16 August 2010 from

http://www.mrtv3.net.mm/open6/230909for1.html

Zakaria, S. & Hasan, M. Z. (2005). Data Collection Strategies in Malaysia, Public Work Department

Malaysia.

You might also like

- Spec Cold FormedDocument43 pagesSpec Cold Formedfarahazura88% (8)

- 20 S20 - Ground ImprovementDocument68 pages20 S20 - Ground ImprovementCarwen Wong100% (1)

- O&M ManualDocument127 pagesO&M ManualPrem100% (6)

- Specification For Structural Steelworks PDFDocument58 pagesSpecification For Structural Steelworks PDFfarahazura80% (5)

- Unit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Document19 pagesUnit 6 ( CONSTRUCTION OF THE FLEXIBLE PAVEMENT )Zara Nabilah87% (15)

- Uniform Building by Law PDFDocument196 pagesUniform Building by Law PDFfarahazuraNo ratings yet

- Kerja Cerun ContohDocument13 pagesKerja Cerun Contohkaz0% (1)

- Example MACKINTOSH PROBE TESTDocument10 pagesExample MACKINTOSH PROBE TESTAmy Nazmi100% (1)

- Probe Mackintosh TestDocument2 pagesProbe Mackintosh Testsalljuraij83% (18)

- Idp3-Road DesignDocument52 pagesIdp3-Road Designnuralazim kamarudin100% (7)

- Traffic Junction Capacity and SidraDocument15 pagesTraffic Junction Capacity and SidraMohamad NazranNo ratings yet

- Discussion: Geomatics Engineering (BFC 20703)Document4 pagesDiscussion: Geomatics Engineering (BFC 20703)Hani BarjokNo ratings yet

- Lab Skid ResistanceDocument1 pageLab Skid ResistanceMohamad Zahir Razak83% (6)

- Report EsteemDocument14 pagesReport EsteemNur Hazimah100% (1)

- CC503 - Traffic Engineering (Trafic Volume Study)Document19 pagesCC503 - Traffic Engineering (Trafic Volume Study)Kamarul Nizam100% (1)

- Ream TiaDocument40 pagesReam TiaTahmidSaanidNo ratings yet

- CBR Test UthmDocument8 pagesCBR Test UthmMohd Zairul Shafiq ZakariaNo ratings yet

- SPJ S4 2008 PDFDocument202 pagesSPJ S4 2008 PDFfarahazura100% (4)

- Specification Pre Fabricated Timber Roof Trusses 1 PDFDocument47 pagesSpecification Pre Fabricated Timber Roof Trusses 1 PDFAin Hanina100% (5)

- Microsoft PowerPoint - Instrumentations-JDDocument39 pagesMicrosoft PowerPoint - Instrumentations-JDfarahazuraNo ratings yet

- 2010 - Nevada DOT Standard Plans PDFDocument279 pages2010 - Nevada DOT Standard Plans PDFChunyu Zhang0% (1)

- Project Pavement Condition Survey at Parit Jelutong, Batu Pahat, JohorDocument73 pagesProject Pavement Condition Survey at Parit Jelutong, Batu Pahat, JohorMoganraj100% (3)

- Road Coring TestDocument2 pagesRoad Coring TestAmree Deaf50% (2)

- Calculation PCI METHODDocument5 pagesCalculation PCI METHODSiti Nurfatin67% (3)

- 1 (85) - ARAHAN TEKNIK Barrier & Guard RailDocument20 pages1 (85) - ARAHAN TEKNIK Barrier & Guard RailAllen Neoh100% (2)

- Full Report HighwayDocument19 pagesFull Report HighwayShahrel Bin Salleh100% (1)

- RC Mini ProjekDocument11 pagesRC Mini ProjekMohd HisbullahNo ratings yet

- Highway Report IntersectionDocument26 pagesHighway Report Intersectionidham11580% (5)

- Cc206 - Bab 4 Ibs Score NewDocument27 pagesCc206 - Bab 4 Ibs Score NewAdron LimNo ratings yet

- Water Treatment Plant in Politeknik Kota BharuDocument11 pagesWater Treatment Plant in Politeknik Kota BharuLidiah ImzaNo ratings yet

- 3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementDocument56 pages3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementFATIN NABILA100% (1)

- Spot Speed Study Lab ReportDocument8 pagesSpot Speed Study Lab ReportMuhammad ArbainNo ratings yet

- Introduction To Highway Pavement-1Document60 pagesIntroduction To Highway Pavement-1Sagni Oo ChambNo ratings yet

- Multilane Highway Capacity AnalysisDocument9 pagesMultilane Highway Capacity AnalysisIkhwan Z.100% (1)

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Document38 pagesStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi67% (3)

- Highway and Traffic Engineering ReportDocument24 pagesHighway and Traffic Engineering Reportnurhaslizana0% (2)

- CBR TestDocument8 pagesCBR TestAnonymous mF6tM5gPNo ratings yet

- Highway MaintenanceDocument13 pagesHighway MaintenancePia CajayonNo ratings yet

- Skid ResistanceDocument5 pagesSkid ResistanceMoyashi Desu100% (2)

- Spot Speed StudyDocument8 pagesSpot Speed StudyMuhammad AimiNo ratings yet

- Practical Task - Topic 4 Ibs Component InstallationDocument11 pagesPractical Task - Topic 4 Ibs Component InstallationtahirNo ratings yet

- PCI Method UthmDocument15 pagesPCI Method Uthmfaraeiin57No ratings yet

- Bukit LanjanDocument11 pagesBukit Lanjanahmad_shukriNo ratings yet

- Highway Report 2Document30 pagesHighway Report 2Kerol Kerol Kerol100% (1)

- Tension Coefficient MethodDocument9 pagesTension Coefficient Methodpeipei33% (6)

- JKR Flexible PavementDocument47 pagesJKR Flexible Pavementazu100% (2)

- Arahan Teknik (Jalan) 2A-85Document3 pagesArahan Teknik (Jalan) 2A-85mohdnizamNo ratings yet

- Ibs Company ProfileDocument52 pagesIbs Company ProfileFaeez ZainNo ratings yet

- REPORT Earthworks PDFDocument7 pagesREPORT Earthworks PDFWan MahiramNo ratings yet

- EW3D User ManualDocument55 pagesEW3D User ManualSim Khoon AunNo ratings yet

- Tutorial2 28answer 29Document3 pagesTutorial2 28answer 29PresidaNo ratings yet

- Slip Form and Fixed Form PaversDocument63 pagesSlip Form and Fixed Form PaversShubham Pawar100% (1)

- Sand ReplacementDocument4 pagesSand ReplacementHidayah MuzaimilNo ratings yet

- CEM6157F12017832278Document3 pagesCEM6157F12017832278Farisha AqilaNo ratings yet

- General Premix Road DesignDocument6 pagesGeneral Premix Road DesignAyie Khairi100% (3)

- 4.0 Structural Design of Flexible PavementDocument16 pages4.0 Structural Design of Flexible PavementAK47100% (2)

- MACKINTOSH PROBE Test ReportDocument8 pagesMACKINTOSH PROBE Test ReportKrisyen Murali Tharan100% (1)

- Aggregate Impact ValueDocument8 pagesAggregate Impact ValueAnis Nurfarahanim Abdul HalimNo ratings yet

- Recognize The Standard Safety Operational Procedure To Be Fulfilled Before Conducting This TestingDocument3 pagesRecognize The Standard Safety Operational Procedure To Be Fulfilled Before Conducting This TestingEzanie IzyanNo ratings yet

- Discussion Flakiness & Elongation IndexDocument2 pagesDiscussion Flakiness & Elongation IndexAidi RedzaNo ratings yet

- Sand PatchDocument1 pageSand Patchredz00100% (1)

- MS JKR Road Work SpecDocument6 pagesMS JKR Road Work SpecDarren WanNo ratings yet

- 2nd AssignmentDocument14 pages2nd AssignmentSyed Faizan KhalidNo ratings yet

- ThesisDocument13 pagesThesisRebuild ManagementNo ratings yet

- Chapter 1. Introduction: 1.1. OverviewDocument49 pagesChapter 1. Introduction: 1.1. OverviewFrank Diaz LuqueNo ratings yet

- A Comparative Study On Rigid and Flexible PavementDocument6 pagesA Comparative Study On Rigid and Flexible PavementKristophe WatsonNo ratings yet

- A Comparative Study On Rigid and Flexible Pavement: A ReviewDocument6 pagesA Comparative Study On Rigid and Flexible Pavement: A ReviewosichristoNo ratings yet

- Investigation On Causes of Pavement Failure and Its Remedial Measures Ijariie16932Document7 pagesInvestigation On Causes of Pavement Failure and Its Remedial Measures Ijariie16932Abraham OluwasolaNo ratings yet

- M&E & Arch CoordinationDocument29 pagesM&E & Arch CoordinationfarahazuraNo ratings yet

- Planning To PrecastDocument29 pagesPlanning To PrecastfarahazuraNo ratings yet

- Design of Wall StructureDocument21 pagesDesign of Wall StructurefarahazuraNo ratings yet

- Design of TiesDocument26 pagesDesign of TiesfarahazuraNo ratings yet

- Design of Precast Column PDFDocument54 pagesDesign of Precast Column PDFfarahazura100% (2)

- Design of Composite Precast BeamDocument47 pagesDesign of Composite Precast BeamfarahazuraNo ratings yet

- Current Compaction Practices For JKR Projects 2005 PPT Presentation PDFDocument33 pagesCurrent Compaction Practices For JKR Projects 2005 PPT Presentation PDFfarahazuraNo ratings yet

- 1.1 Introduction Background of VM - BLP - Ogos - 2015Document41 pages1.1 Introduction Background of VM - BLP - Ogos - 2015farahazuraNo ratings yet

- Analysis and Design of Precast FramesDocument37 pagesAnalysis and Design of Precast Framesfarahazura100% (1)

- Proof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan LabuanDocument82 pagesProof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan Labuanfarahazura100% (1)

- Adv Geotech Forensic Eng CompileWebDocument277 pagesAdv Geotech Forensic Eng CompileWebfarahazuraNo ratings yet

- 2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFDocument43 pages2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFfarahazuraNo ratings yet

- Proof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan LabuanDocument82 pagesProof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan Labuanfarahazura100% (1)

- 2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFDocument43 pages2.1 VMBOK - VM Study Process - BLP - Ogos - 2015 PDFfarahazuraNo ratings yet

- Gerbang Nilai Training Presentation PDFDocument62 pagesGerbang Nilai Training Presentation PDFfarahazuraNo ratings yet

- 3a. Design of Connection - 2 EC3Document82 pages3a. Design of Connection - 2 EC3farahazura75% (4)

- 1.precast Concrete Framed System 2Document87 pages1.precast Concrete Framed System 2farahazura100% (1)

- 1.precast Concrete Framed System 2Document87 pages1.precast Concrete Framed System 2farahazura100% (1)

- RSA IssuesDocument5 pagesRSA IssuesfarahazuraNo ratings yet

- Uniform-Building-by-Law 1984 (UBBL) PDFDocument196 pagesUniform-Building-by-Law 1984 (UBBL) PDFWilliam Ball96% (72)

- Asas Perancangan Rekabentuk Fasiliti Kesihatan (F)Document82 pagesAsas Perancangan Rekabentuk Fasiliti Kesihatan (F)farahazuraNo ratings yet

- Transport HandbookDocument937 pagesTransport HandbookUmesh Rai100% (9)

- An Overview On Natural Rubber Application For Asphalt ModificationDocument7 pagesAn Overview On Natural Rubber Application For Asphalt ModificationfarahazuraNo ratings yet

- Otta Seal Construction For Asphalt Pavement Resurfacing: July 2018Document12 pagesOtta Seal Construction For Asphalt Pavement Resurfacing: July 2018Alex del PinoNo ratings yet

- OCTOBER 2002: Japan International Cooperation Agency Nippon Koei Co., Ltd. Japan Engineering Consultants Co., LTDDocument94 pagesOCTOBER 2002: Japan International Cooperation Agency Nippon Koei Co., Ltd. Japan Engineering Consultants Co., LTDnakazibwe rachel27No ratings yet

- CE 326 Transportation Midterm ExamDocument5 pagesCE 326 Transportation Midterm ExamAlyza Caszy UmayatNo ratings yet

- Book 6 - Warning Signs (2001)Document168 pagesBook 6 - Warning Signs (2001)Sean DiamondNo ratings yet

- Lsmim: Lahore-Sialkot Motorway (B.O.T.)Document1 pageLsmim: Lahore-Sialkot Motorway (B.O.T.)husnain aliNo ratings yet

- Road Construction MethodsDocument163 pagesRoad Construction MethodsMichael Tan100% (1)

- Traffic Count and Speed SurveyDocument9 pagesTraffic Count and Speed SurveyAsitha RathnayakeNo ratings yet

- Iloilo City Regulation Ordinance 2015-045Document11 pagesIloilo City Regulation Ordinance 2015-045Iloilo City CouncilNo ratings yet

- Intersection of Road12Document61 pagesIntersection of Road12Raj Bharatiya100% (1)

- Detailed Design Stage ChecklistDocument17 pagesDetailed Design Stage ChecklistbalaNo ratings yet

- SCHEDULES - National Highways Authority of IndiaDocument101 pagesSCHEDULES - National Highways Authority of IndiaIrfanNo ratings yet

- Radburn LayoutDocument12 pagesRadburn Layoutkritish duaNo ratings yet

- Highway Engineering: Subject Code - CE 2255Document43 pagesHighway Engineering: Subject Code - CE 2255HanafiahHamzahNo ratings yet

- 0755 To ESTANCIA HS (Bus Mon) : RouteDocument9 pages0755 To ESTANCIA HS (Bus Mon) : RouteMartinRygielNo ratings yet

- Comparitive Statement For Minor BridgesDocument1 pageComparitive Statement For Minor Bridgesp. kiran kuamrNo ratings yet

- Driving in New Zealand English PDFDocument7 pagesDriving in New Zealand English PDFJing CaoNo ratings yet

- Driving Test Success - All TestsDocument3 pagesDriving Test Success - All TestsZirrus GlassNo ratings yet

- Highway Engineering Multiple Choice Questions and Answers - Preparation For EngineeringDocument19 pagesHighway Engineering Multiple Choice Questions and Answers - Preparation For EngineeringSyed Munawar Ali83% (6)

- Irc 86 1983Document38 pagesIrc 86 1983Rathinavel Subramanian0% (1)

- Site Plan Requirements PDFDocument13 pagesSite Plan Requirements PDFKavi1982No ratings yet

- Course Orientation: Highway and Railroad EngineeringDocument6 pagesCourse Orientation: Highway and Railroad EngineeringBart LuceñaNo ratings yet

- Pcci 4302 Te I 2Document315 pagesPcci 4302 Te I 2Saranya Godwin50% (2)

- Lto Exam Reviewer 2023Document11 pagesLto Exam Reviewer 2023Shyne HazyNo ratings yet

- Technical Seminar Lik FinalDocument19 pagesTechnical Seminar Lik FinalLikhith PadigeNo ratings yet

- Cop 201712Document130 pagesCop 201712Kelvin HoNo ratings yet

- Traffic System Components & Fundamental Theory of Traffic FlowDocument39 pagesTraffic System Components & Fundamental Theory of Traffic FlowAziemah SanNo ratings yet

- ROB Vs RUBDocument4 pagesROB Vs RUBrajesh kumarNo ratings yet

- Aggressive Driving Should Be AvoidedDocument3 pagesAggressive Driving Should Be AvoidedStephanieNo ratings yet