Professional Documents

Culture Documents

Appendix F Apqp Form4

Uploaded by

FranciscoBizarroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix F Apqp Form4

Uploaded by

FranciscoBizarroCopyright:

Available Formats

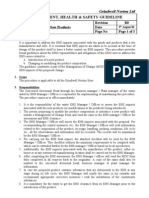

ADVANCED PRODUCT QUALITY PLANNING

STATUS REPORT

DATE:

Supplier Name:

Mfg. Location:

Supplier Code:

New: Site Technology Process

KPC #

Date of study:

APQP Elements AIAG Status Program Supplier Closed Resp. Remarks or

APQP (G, Y, R, Need Timing Date Engineer Assistance Required

Element or N/A) Date Date Initials

1 Design FMEA 2.1

2 Team Feasibility Commitment 2.13

3 Preliminary Process Flow and PFMEA *

4 Design Review(s) 2.4

5 Facilities & Tools 2.10

6 Gauging and Test Equipment 2.12

7 Prototype Build Control Plan 2.5

8 Design, Drawings and Specifications 2.6

9 Logistics/EDI Capability *

10 Packaging Specifications 3.1

11 Manufacturing Process Flow Chart 3.3

12 Process FMEA & Control Plan Review 3.6

13 Measurement Systems Evaluation 4.2

14 Pre-Launch Control Plan GP12 3.7

15 Operator Process Instructions 3.8

16 Production Trial Run (Capacity Verified) 4.1

17 Production Control Plan 4.7

18 Production Source Approval 4.5

19 Production Part Approval (PPAP) 4.4

20 Production Readiness *

( * ) = Specific Requirement. See Attached Reference.

Additional Comments:

filename: r:/Policy & Procedure/Forms/APQPFOR4.xls Page 1 of 1 Revised: 30-Nov-04

Contact Information (tele, fax, mobile, pager, etc.)

Part Number:

Part Name:

Rev., Date, ECN:

Report the Ppk of each KPC on an on-going basis, as the process changes and new lots are manufactured.

R I S K A S S E S M E N T

CAPABILITY STUDIES

Given by DRA at the time of Full PPAPApproval

REQUIRED to submit for review prior to PPAP

When did you recieve released drawings?

List available EDI transactions below

Team Members Title / Position Company

You might also like

- Zinc Oxide Pigments: Standard Specification ForDocument2 pagesZinc Oxide Pigments: Standard Specification ForMadhavanNo ratings yet

- PPAP Risk: MediumDocument8 pagesPPAP Risk: Mediumrajesh sharmaNo ratings yet

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocument4 pagesResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- 8D ReportDocument1 page8D ReportshazziiiNo ratings yet

- BMW 8D VerificationDocument10 pagesBMW 8D VerificationVijay patilNo ratings yet

- Apqp Rev 5Document2 pagesApqp Rev 5giovani3ou9No ratings yet

- Exedy India Ltd. APQP Process DocumentsDocument3 pagesExedy India Ltd. APQP Process Documentssam1hi5No ratings yet

- Apqp PhaseDocument6 pagesApqp PhaseDisha ShahNo ratings yet

- GNO-New Product Procedure For EHSDocument3 pagesGNO-New Product Procedure For EHSvijay2101No ratings yet

- Apqp Ppap TrainingDocument2 pagesApqp Ppap TrainingAnkur DhirNo ratings yet

- Quality Gate Review Checklists and Best PracticesDocument15 pagesQuality Gate Review Checklists and Best PracticesMOHAN SNo ratings yet

- C QM 0102 Product RealizationDocument2 pagesC QM 0102 Product RealizationGhulam MustafaNo ratings yet

- APQP Checklist Design PDFDocument3 pagesAPQP Checklist Design PDFShiva SNo ratings yet

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Document9 pagesMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaNo ratings yet

- Feasibility Report for New Part EnquiryDocument2 pagesFeasibility Report for New Part EnquiryaslamNo ratings yet

- APQP - Customer Input Requirement - Ver2Document3 pagesAPQP - Customer Input Requirement - Ver236hallsteveNo ratings yet

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- TVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRDocument5 pagesTVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRSAKTHIVEL ANo ratings yet

- Apqp PQP Flow ChartDocument1 pageApqp PQP Flow ChartmjapmgNo ratings yet

- APQP FormDocument103 pagesAPQP FormJERFSON AUGUSTONo ratings yet

- Apqp Stages AIAG-1Document49 pagesApqp Stages AIAG-1Jose Antonio Santoyo RayaNo ratings yet

- PPAP Sign Off Checklist (3rd Ed) : Product Submission Warrant (PSW)Document1 pagePPAP Sign Off Checklist (3rd Ed) : Product Submission Warrant (PSW)SudhaNo ratings yet

- Development Procedure 16-08-2021Document6 pagesDevelopment Procedure 16-08-2021CompdevpNo ratings yet

- Procedure For ApqpDocument19 pagesProcedure For ApqpRaja RehaNo ratings yet

- Prepared By: Mr. Prashant S. Kshirsagar (SR - Manager-QA Dept.)Document38 pagesPrepared By: Mr. Prashant S. Kshirsagar (SR - Manager-QA Dept.)Brijesh ChaubeyNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- FMEA PDocument6 pagesFMEA Pparu1982No ratings yet

- Format No-Blank/Dir: Detail Inspection ReportDocument18 pagesFormat No-Blank/Dir: Detail Inspection ReportRock RockyNo ratings yet

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDocument6 pagesPpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNo ratings yet

- Taking The Next Leap Forward in Semiconductor SHORTDocument16 pagesTaking The Next Leap Forward in Semiconductor SHORTGerard StehelinNo ratings yet

- APQP TrackerDocument10 pagesAPQP TrackerBharathNo ratings yet

- APQPDocument33 pagesAPQPAtul SURVENo ratings yet

- Mammut Industries Trailer Design ProcessDocument9 pagesMammut Industries Trailer Design ProcessvinothNo ratings yet

- GA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Document26 pagesGA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Manoj Pai D100% (1)

- 5.2 Process Capability Analysis Rev2ADocument8 pages5.2 Process Capability Analysis Rev2APollyNo ratings yet

- PPAP Package for Inner Pipe PartDocument31 pagesPPAP Package for Inner Pipe PartPk NimiwalNo ratings yet

- INGFRT-11 Run at RateDocument3 pagesINGFRT-11 Run at RateMarisol RubioNo ratings yet

- Cipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Document8 pagesCipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Marvin CubeNo ratings yet

- Repair and Modification of Printed Boards and Electronic AssembliesDocument6 pagesRepair and Modification of Printed Boards and Electronic AssembliesArvind NangareNo ratings yet

- DaimlerChrysler Ford GM Part Submission WarrantDocument4 pagesDaimlerChrysler Ford GM Part Submission WarrantEly SaldivarNo ratings yet

- Apqp 2Document2 pagesApqp 2Isabel SierraNo ratings yet

- 6 Team Feasibility STUDDYDocument6 pages6 Team Feasibility STUDDYkamalNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- Delphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Document15 pagesDelphi Technologies Customer Specific Requirements for ISO 9001 and IATF16949Ram100% (1)

- 7.2.4 APQP Phase 1 Checklist Dec 2013Document24 pages7.2.4 APQP Phase 1 Checklist Dec 2013Mani Rathinam RajamaniNo ratings yet

- APQP and PPAP ExplainedDocument3 pagesAPQP and PPAP ExplainedignaunaqNo ratings yet

- PPAP Training OverviewDocument17 pagesPPAP Training OverviewRicky MarkNo ratings yet

- Autocar Ppap Requirements Rev 5Document17 pagesAutocar Ppap Requirements Rev 5man hoNo ratings yet

- APQPDocument18 pagesAPQPMy Dad My World100% (1)

- Appendix 11 Design FMEA ChecklistDocument16 pagesAppendix 11 Design FMEA ChecklistDearRed FrankNo ratings yet

- APQP Timing Plan SampleDocument3 pagesAPQP Timing Plan SampleDhananjay Patil75% (4)

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet