Professional Documents

Culture Documents

Comparison of GB & ASME Standards

Comparison of GB & ASME Standards

Uploaded by

danianishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of GB & ASME Standards

Comparison of GB & ASME Standards

Uploaded by

danianishCopyright:

Available Formats

Comparison of GB and ASME

Standards

Special Thanks to:

ASME Pressure Systems Interest Group

Ministry of Manpower Singapore

SETSCO etc

Don Frikken

Shanghai MorimatsuPressure Vessel Co.

ABS Consulting Shanghai

DNV Shanghai

China Sichuan HuaCheng Oil & Gas Engineering Construction Supervision

Co.

Presenter: Tan HengLee : hltan2004@yahoo.comor

Heng-Lee.Tan@shell.com

Comparison of GB and ASME

Standards

GB= GuojiaBiaozhun( National Standard

in Chinese)

SY = Shi You (Petroleum)

J B = J ianBiao(Construction Standard)

GB/T = T : Tuijian(recommended GB)

HG = HuaGong (PetroChemical)

Comparison of GB and ASME

Standards

GB 150-89 : For Design Pressure <= 35 M

Pa ( latest issued on March 20, 1998).

ASME VIII- Div 1: DP up to 20 MPa

ASME VIII- Div 2: DP up to 70 MPa

ASME VIII- Div 3: DP above 70 MPa

Comparison of GB and ASME

Standards

Factor of Safety

GB 150-89 : 3.0 for carbon steel, low-alloy steel,

high alloy steel vessel

ASME VIII Div 1: 3.5 for carbon steel, low alloy

steel

ASME VIII Div 1 : 3.0 for High alloy steel

Note: ASME VIII Div 2: Factor of safety is 3.0

Comparison of GB and ASME

Standards

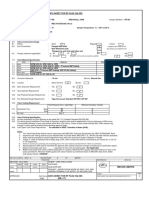

Weld J oint Efficiency

Comparison of GB and ASME

Standards

Design Formula and Table

Comparison of GB and ASME

Standards

Vessel Openings and Table

Comparison of GB and ASME

Standards

Chinese material : Not so systematic

ASME : Systematic in ASME II

Note: _-Vetolerance for Chinese Material

is commonly 0.6 to 0.8 mm for SS;

whereas in ASME, it is 0.25 mm

Comparison of GB and ASME

Standards

Design Temperature, if it is below 20C,

considered as LT vessel ( GB 150

Appendix C shall be applicable)

ASME : Per UCS 66 etc to calculate

MDMT of the material, and compare with

vessel MDMT, for determination of

CharpyImpact test requirement.

Comparison of GB and ASME

Standards

Welder Qualification

GB 150: Control by Government ( Safety

Surveillance Authority)

ASME VIII : ASME authorized

manufacturer per ASME IX

Comparison of GB and ASME

Standards

Welder Examination

GB 150: Basic theory +Welding skill

ASME VIII : Welder Skill

Certificates validity

GB 150: 3 years ( re-test may be exempted if continuous engaged in

welding work and below 50 years old).

ASME VIII: Not that specific

Re-qualification required : if not doing welding work for more than6

months.

Comparison of GB and ASME

Standards

Production Test Plates (Test Specimen)

GB 150 specify:

Mobile type

DP > 10 MPa

Spherical storage tank welded in-situ

Tensile strength > 540 MPa

Client requirement

Low temp vessel

What abut ASME vessel ?

Comparison of GB and ASME

Standards

Comparison of GB and ASME

Standards

Welding Repair

Not more than 2 times (GB 150 ) on the

same location

By qualified welder as per approved WPS

ASME: Repair shall be approved by AI

before the repair.

Comparison of GB and ASME

Standards

PWHT: GB 150 is essentially same as

ASME VIII

Note: If Vessel is designed as per GB 150

Appendix C LT Vessel, then PWHT is

required if vessel wall thickness is above

16 mm.

Comparison of GB and ASME

Standards

Pressure Test

Duration: 30 minsat test pressure. Then reduce to 80 %

for sufficient time for inspection work.

Comparison of GB and ASME

Standards

Documentation /Material Certification

Levels

Type: 3.1 B certificate ( or Type 3.1) as per

EN 10204: 2004. This EN is in GB 9711.2

Appendix.

Retention: 7 years (GB 150 )

Comparison of GB and ASME

Standards

GB 50235 and ASME B31.3

Material: Chinese standard / ASME II

Low Temp : -20 C / -20 F

Welding: Similar

PWHT: 19 mm for CS ( same)

NDT: 100 % on toxic and > 10 MPa(GB)

Hydrotest : Same, GB specify duration. Test

pressure is 1.5 DP for 10 mins, then at DP for 30

mins.( For water medium)

Test temp : > 5 C to avoid brittle rupture

Comparison of GB and ASME

Standards

SY- 0466-97: for gas pipeline

Ho-Lo : 1.5 mm

NDT

16 to 70 M Pa: 100 % UT + 100% RT

10 to 16 M Pa: 100% UT + 15 % RT

4 to 10 M Pa: 100 % UT + 10 % RT

1.6 to 4 M Pa: 100 % UT + 5 % RT

SY 0402: Oil and Gas station / Plant

Wind speed not suitable for welding is mentioned

in the code.

NDT

P> 16 M Pa: 100 % RT

4 to 16 M Pa: 100 % UT + 10 % RT

1.6 to 4 M Pa: 100 % UT + 5 % RT

< 1.6 M Pa: 50 % UT only

Comparison of GB and ASME

Standards

Comparison of GB and ASME

Standards

Chinese & ASME common material for PV

16 MnR A516-70

C 0.20 Max 0.27-0.31

Mn1.2 1.6 0.85-1.2

P 0.030 max 0.035 max0

S 0.020 max 0.035 max

16 MnR can have micro-element such as Cr, Ni, Cu each less

than 0.30 %, total less than 0.60 %.

Ref: handout given during seminar

Comparison of GB and ASME

Standards

Mechanical Properties Comparison

16 MnR A 516-70

Tensile 510-640 M Pa 485-520 M Pa

(for 6 to 16 mm)

Yield 345 M Pa Min 260 M Pa

( for 6 to 16 mm)

Elongation 20-21% 17-21%

Impact test 27J at 20C S5

Comparison of GB and ASME

Standards

GB and ASME B31.8 Pipeline Code

Comparison

1. Basic Reference International Code

GB 50251-1994

2. ASME B31.8

Comparison of GB and ASME

Standards

GB 50251 ASME 31.8 Remarks

Zone 1 < or =15 (

houses)

< or = 10 F = 0.72

Zone 2 < or = 100 < 46 F = 0.60

Zone 3 > 100 > or = 46 F = 0.50

Zone 4 plant plant F = 0.40

Comparison of GB and ASME

Standards

GB 50251 ASME

B31.8

Remarks

3.Casing

requirement

For Class I and

II highway and

railway

4. Material Follow API 5L

with:

C < 0.25 %

CE < 0.45 %

S < 0.035 %

P < 0.04 %

Follow API 5 L in

old revision.

Note: Shell follows

ISO 3183 in new

revision

C and CE etc are

modified for sour

service

Suggest to limit

carbon content

P, S and CE as per

Some Oil company

std.

Need to meet sour

gas requirement?

Comparison of GB and ASME

Standards

GB 50251 ASME B31.8 Remarks

5. Low

Temperature

classification

Less than

minus 20C

For

Temperature

below -20 F

To clarify and

specify impact

test.

6. Welding Undercut is

not totally

prohibited

Same.

Note:undercut is

not allowed for

low temp service

for some oil

companies

Suggest that undercut

is not allowed, to

specify in spec.

Comparison of GB and ASME

Standards

GB 50251 ASME B31.8 Remarks

7. Pipeline

valves

GB standard for

equivalent API 6D

valve??

API 6D is

required.

API 6D is

required, site

test required.

To specify in

spec.

8. PWHT thickness > 32 mm Thickness > 32

mm

Comparison of GB and ASME

Standards

GB 50251 ASME B31.8 Remarks

9. NDT- RT Zone 1 : 10 %

Zone 2 : 15 %

Zone 3 : 40 %

Zone 4 : 75 %

100% ?? UT or RT

10. Cleaning

2 times of pigging (

min).

Water Flushing :

>1.5 m/s

Air cleaning: > 20

m/s

Comparison of GB and ASME

Standards

GB 50251 ASME B31.8 Remarks

11. Hydrotest

Zone 1 : x1.10

Zone 2 : x1.25

Zone 3 : x 1.40

Zone 4 : x 1.50

to 90 % of SMYS

To clarify

SY 0401 also mentioned

max test pressure to 0.9

SMYS

12. Hydrotest

duration

4 hours strength

test- stabilization

24 hours gas

tightness test

Air test allowed

for zone 1 and 2

4 hrs at hydrotest

pressure and also 24

hours at 80 %

hydrotest pressure

OR: 24 hours at full

hydrotest pressure

To clarify

Generally, similar

Comparison of GB and ASME

Standards

GB 50235-1997 and ASME B31.3 Comparison

Descri pti on GB 50235-1997 ASME Remarks

1. Basic Reference International Code ASME B31.3 ASME B31.3 Same

2. Categorization Type A Severe Cyclic

Type B Category M

Type C Category Normal

Type D Cat D- Non Toxic etc

3. Material Chinese Material Follow API / ASTM/ SB etc Chinese material follows ISO 3183

Mainly Chinese Standards

4. Piping Components Bend ( t >19 mm) Bend ( t >19 mm) Heat treatment required ( 900 C)

Valves required seat testing before Not specifically mentioned

installation, std forms provided

5. Low Temperature classification Less than -20C Less than -20 F ( -29 C) To check impact test requirement

Comparison of GB and ASME

Standards

6. Welding Specify min distance between welds Not in details Basically follows ASME IX

e,g OD >150 mm, it is 150 mm and good engineering practice

OD <150 mm, it is ' OD' on weld joint edge cleaning

Hi-Lo : lesser of 0.1 t or 2 mm for CS GB 50236-98 follows ASME IX

TIG for root pass ( section 5.0.11) generally.

7. Fit-up/ Assembly Typical fit-up details provided for CS, Not in ASME B31.3, bot refer in ASME IX ,

Al and Ti pipes Approved WPS etc

8. PWHT thickness >19 mm for CS Thickness >19 mm for CS Same

9. NDT VT: Ref GB 50235 section 7 for details

MPI / DP: e.g 100% RT for :

RT : 100 % on toxic and HP ( >10 Mpa) Toxic

UT: as substitute for RT, approval req'd P>10 M Pa or 4 Mpa when T>400C

Temp <-29 C

Technical Spec

10. Cleaning Required to submit procedure No specifically mentioned Ref GB 50235 section 8

for approval, record req'd after cleaning

Comparison of GB and ASME

Standards

brittle materials) the material yield point. 30 mins at DP.

Water: 1.5 DP, temp >5 C Min duration: 10 mins Follows B 31.3, pneumatic not

Cl 2 content <25 ppm for SS pipe. Cl 2 <50 ppm allowed generally.

Weld J oint: not painted, Weld J oint: may be painted

12 Golden joints 100 % RT on butt welds, 100 % MPI Same. In progress examination and 100 % GB follows ASME B 31.3

or DP on branch welds. RT or UT.

13 Others

Flange Rating both American and US systems were Careful when purchase flanges

used. Mostly follows European need to specify US or European

PN 1.6 is 1.6 M Pa system.

Piping -metallic Schedule not commonly used. Seamless, ERW, UOE, J COE

Follow GB 9711.2 etc which is similar SSAW, LSAW etc

to ISO 3183

Piping- Non metallic Trend toward the use of non-metallic Same

is also increasing, PVC, GRE etc

Max wind sped for welding work GMAW : 2.2 m/s

SMAW : 8 m/s

FCAW : 11 m/s

Comparison of GB and ASME

Standards

Thank You

Comparison of GB and ASME

Standards

You might also like

- Kum Co CatalogueDocument236 pagesKum Co CatalogueOzan67% (3)

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- Steel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardDocument8 pagesSteel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardElumalai Srinivasan75% (8)

- GB150 3-2011en PDFDocument271 pagesGB150 3-2011en PDFirfanlarikhotmailcom100% (2)

- Comparison of GB & ASME Standard: Double Sided or Full Penetration Single Sided Weld (As Per ASME With Backing Strip)Document1 pageComparison of GB & ASME Standard: Double Sided or Full Penetration Single Sided Weld (As Per ASME With Backing Strip)irfanlarikhotmailcom80% (5)

- GB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFDocument43 pagesGB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFhuangjlNo ratings yet

- Employee Laptop UsageDocument2 pagesEmployee Laptop UsageEssam AlsharabiNo ratings yet

- GB Steel For Boiler and Pressure VesselsDocument16 pagesGB Steel For Boiler and Pressure VesselsGovind RaoNo ratings yet

- GBT 13793-2008 - en - v1 - EnglishDocument21 pagesGBT 13793-2008 - en - v1 - EnglishAndres Felipe TabarquinoNo ratings yet

- JIS (Japanese) Standards For Steel MaterialsDocument2 pagesJIS (Japanese) Standards For Steel MaterialsLG Nguyen100% (1)

- NBT 47003.1-2009 钢制焊接常压容器Document177 pagesNBT 47003.1-2009 钢制焊接常压容器Nguyen Duc Anh100% (1)

- B31 3 (Mygaz) - 1Document1 pageB31 3 (Mygaz) - 1Nasrul AdliNo ratings yet

- Material EquivalentDocument1 pageMaterial Equivalentnareshfire86% (7)

- Asme Sa 240 PDFDocument16 pagesAsme Sa 240 PDFqaNo ratings yet

- GB 17395-2008ENgDocument35 pagesGB 17395-2008ENgGanesh Srinivasan100% (1)

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Document30 pagesLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Auto Trend ForecasterDocument15 pagesAuto Trend ForecasterherbakNo ratings yet

- GB 150 Part2 PDFDocument5 pagesGB 150 Part2 PDFDang Hieu NguyenNo ratings yet

- Chinese Standard For Pressure VesselDocument40 pagesChinese Standard For Pressure VesselirfanlarikhotmailcomNo ratings yet

- GB 5310Document25 pagesGB 5310Cong Son100% (1)

- Chinese Standards On Steel MaterialsDocument3 pagesChinese Standards On Steel MaterialsAnthony Ruth100% (1)

- People's Republic of China Industry Standard Welded Steel Pressure VesselDocument78 pagesPeople's Republic of China Industry Standard Welded Steel Pressure VesselmightsrightNo ratings yet

- Heat Treatment of SS Clad CS After Fiber ElongationDocument3 pagesHeat Treatment of SS Clad CS After Fiber ElongationarifhonNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- EN10034 Beams Rolling TolerancesDocument2 pagesEN10034 Beams Rolling Tolerancesrameshdatta100% (1)

- gb5310-2008-ク゚ムケケッモテボキ・ヨケワ-Seamless Steel Tubes and Pipes for High Pressure Boiler-en-ネォホトDocument31 pagesgb5310-2008-ク゚ムケケッモテボキ・ヨケワ-Seamless Steel Tubes and Pipes for High Pressure Boiler-en-ネォホトNguyễn Thanh TùngNo ratings yet

- Material Conversion TableDocument3 pagesMaterial Conversion TableNo PersonNo ratings yet

- PDF Engineering) Esab Welding Handbook - 5 EditionDocument143 pagesPDF Engineering) Esab Welding Handbook - 5 Editionmarshall, of course100% (3)

- Valves Shell Design StrengthDocument10 pagesValves Shell Design Strengthمحمد عبدالدايمNo ratings yet

- Minfm67141 Astm A182 Grade F6a 1 PDFDocument4 pagesMinfm67141 Astm A182 Grade F6a 1 PDFGỗ MộcNo ratings yet

- China Standard PDFDocument1 pageChina Standard PDFgaminNo ratings yet

- Material EquilentDocument16 pagesMaterial EquilentShoaib JadoonNo ratings yet

- Cross-Reference - DIN & ASTM MaterialsDocument3 pagesCross-Reference - DIN & ASTM MaterialsLightAcolyte100% (1)

- Expansion Joints For HRSG BoilersDocument12 pagesExpansion Joints For HRSG BoilersBruhaspathy KatikaneniNo ratings yet

- Cold Stretching of Cryogenic Pressure Vessels From Austenitic Stainless SteelsDocument6 pagesCold Stretching of Cryogenic Pressure Vessels From Austenitic Stainless SteelsAgustin Paradiso100% (1)

- PV EliteDocument6 pagesPV ElitevikrantgulhaneNo ratings yet

- Norma de Aço Chines GB 24511 - 2009Document25 pagesNorma de Aço Chines GB 24511 - 2009JULIO GOMES100% (1)

- Weldolet InfoDocument4 pagesWeldolet InfoChoon Wei WongNo ratings yet

- Ring Joint RTJDocument6 pagesRing Joint RTJzulikram100% (1)

- Botl and Nut SpecificationDocument17 pagesBotl and Nut SpecificationganeshNo ratings yet

- Sa 516Document4 pagesSa 516Vipul ShahNo ratings yet

- GB-T8163-1999 英文版Document11 pagesGB-T8163-1999 英文版saasim_1100% (1)

- Iso 10438 1 2003 FR en PDFDocument11 pagesIso 10438 1 2003 FR en PDFHefni Ossyan0% (1)

- Comparison of GB ASME StandardsDocument34 pagesComparison of GB ASME StandardsHJS7No ratings yet

- Step TraduçãoDocument2 pagesStep TraduçãoAugusto De DimaNo ratings yet

- SPE 77-163 (2004) Axial Disc Check Valves To ASME B16.34Document9 pagesSPE 77-163 (2004) Axial Disc Check Valves To ASME B16.34김창배No ratings yet

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsDocument2 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsGustavo SuarezNo ratings yet

- All B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeDocument39 pagesAll B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeEl FashelNo ratings yet

- What's in ASME B31.1?: Share The Piping KnowledgeDocument8 pagesWhat's in ASME B31.1?: Share The Piping Knowledgesteepa22No ratings yet

- A Review of Postweld Heat Treatment Code Exemption - Part 1 (March 2006) - TWIDocument26 pagesA Review of Postweld Heat Treatment Code Exemption - Part 1 (March 2006) - TWItuanNo ratings yet

- Asme Questions and Answers Part - IvDocument4 pagesAsme Questions and Answers Part - IvAshwani Dogra100% (1)

- All B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteeDocument24 pagesAll B31 Code Cases in Effect As of September 21, 2007 Will Remain Available For Use Unless Annulled by The B31 Standards CommitteealiNo ratings yet

- Koc MP 020Document16 pagesKoc MP 020Ravi MahetoNo ratings yet

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- Steel Castings, Carbon, Suitable For Fusion Welding, For High-Temperature ServiceDocument4 pagesSteel Castings, Carbon, Suitable For Fusion Welding, For High-Temperature ServicemasoudNo ratings yet

- CBT Questions For Piping-1Document40 pagesCBT Questions For Piping-1kumarNo ratings yet

- API 5l Spec OngcDocument27 pagesAPI 5l Spec OngcjamilvoraNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- Metalic Coating PDFDocument7 pagesMetalic Coating PDFshamsabbasNo ratings yet

- Heat Treatment RequirementsDocument7 pagesHeat Treatment RequirementsarunradNo ratings yet

- ASTM A106 A106M Standard Specification For Seamless Carbon Steel Pipe For High-Temperature ServiceDocument21 pagesASTM A106 A106M Standard Specification For Seamless Carbon Steel Pipe For High-Temperature ServiceRifqi AdityaNo ratings yet

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarNo ratings yet

- CBT Questions For PipingDocument41 pagesCBT Questions For PipingarulselvamNo ratings yet

- Solicitud Desclasificacion Informacion UFODocument2 pagesSolicitud Desclasificacion Informacion UFOkountluigiNo ratings yet

- Com 3013Document2 pagesCom 3013Jasleen KaurNo ratings yet

- 1 31 PDFDocument13 pages1 31 PDFRicardo Argentton FicanhaNo ratings yet

- 26 - I - Form Gratuity Appln by Emp. Who Appointed After 1.2 PDFDocument6 pages26 - I - Form Gratuity Appln by Emp. Who Appointed After 1.2 PDFDigraj MahantaNo ratings yet

- Trane 7.5 To 10 TonsDocument136 pagesTrane 7.5 To 10 TonsReinerio Praxedes Castillo CespedesNo ratings yet

- Crank Arm KinematicsDocument3 pagesCrank Arm KinematicsNoor Nabi MujahidNo ratings yet

- Macro CrawlerDocument6 pagesMacro Crawlerzakir_vjti20No ratings yet

- MCEGold White Paper2Document5 pagesMCEGold White Paper2Howk RiosNo ratings yet

- Frameworks For Analyzing Computer-Mediated-Communication in E-LearningDocument10 pagesFrameworks For Analyzing Computer-Mediated-Communication in E-LearningPilar 'Phie' S. CaparasNo ratings yet

- E14-X01 - 1 Substation Low Voltage Unitzed Dist Data SheetDocument2 pagesE14-X01 - 1 Substation Low Voltage Unitzed Dist Data SheetMuhammad IrfanNo ratings yet

- Chapter 5 Question - CostDocument4 pagesChapter 5 Question - Costnsadnan100% (1)

- Timing in Digital CircuitsDocument18 pagesTiming in Digital Circuitsshrish9999No ratings yet

- 2021 Paper TemplateDocument5 pages2021 Paper TemplateDarwin Torres RojasNo ratings yet

- CNC RamDocument29 pagesCNC RamAnand DubeyNo ratings yet

- Industrial Training Power PlantDocument24 pagesIndustrial Training Power PlantBen100% (1)

- AFM 34 en PDFDocument4 pagesAFM 34 en PDFDee RajaNo ratings yet

- MEE 1027 Transducers: Samar Singh Rathore 18BME1126Document19 pagesMEE 1027 Transducers: Samar Singh Rathore 18BME1126SAMAR SINGH RATHORE 18BME1126No ratings yet

- Steam Boilers, Engines, Nozzles and TurbinesDocument39 pagesSteam Boilers, Engines, Nozzles and TurbinesVinay AnkolekarNo ratings yet

- Niccomo enDocument43 pagesNiccomo enlucas_930% (1)

- 6.5.1.2 Lab - Building A Switch and Router NetworkDocument6 pages6.5.1.2 Lab - Building A Switch and Router NetworkMirela ȘorecăuNo ratings yet

- Testing Fresh Concrete: BS EN 12350-2:2019Document12 pagesTesting Fresh Concrete: BS EN 12350-2:2019resty manuel100% (2)

- Thermoplastics Pipes - ISO161Document10 pagesThermoplastics Pipes - ISO161anishsrNo ratings yet

- Protective Device Coordination - Ideal and Practical PDFDocument14 pagesProtective Device Coordination - Ideal and Practical PDFluhusapaNo ratings yet

- Api 682 Update PDFDocument5 pagesApi 682 Update PDFJ.SIVIRANo ratings yet

- Closing Report and MeasurementDocument1 pageClosing Report and MeasurementjoekaledaNo ratings yet

- DatasheetDocument12 pagesDatasheetebertecnicoNo ratings yet