Professional Documents

Culture Documents

Gnl3z PJ Piping Inspection

Gnl3z PJ Piping Inspection

Uploaded by

mohd84elfatihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gnl3z PJ Piping Inspection

Gnl3z PJ Piping Inspection

Uploaded by

mohd84elfatihCopyright:

Available Formats

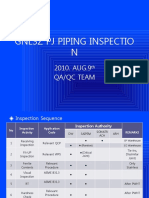

GNL3Z PJ PIPING

INSPECTION

2010. JUL.28

th

QA/QC TEAM

Inspection Sequence

No

Inspection

Activity

Application

Code

Inspection Authority

REMARKS

DW SAIPEM

SONATR

AH

ARH

1

Receiving

Inspection

Relevant QCP

2

Fit-UP

Inspection

Relevant WPS

3

Ferrite

Contents

Relevant

Procedure

Only

Stainless

4

Visual

Inspection

ASME B31.3

5 RT

ASME B31.3

After PWHT

6

Hardness

Check

Relevant

Procedure

After PWHT

7 PMI

Relevant

Procedure

Only

Stainless

8 Hydro Test

Relevant

Procedure

1. Receiving Inspection

1.1 Check Point

- Dimension Check

- Direction Check(Flange, Elbow, Blanch)

- Damage Check(Dent, Painting, Welding Bevel, Flange Face etc)

- Color Coding Check

- Preservation Check

1.2 Authorized Personnel

- Material Team

- Construction Team

- Saipem Authorized Personnel

- DW QC : Preparation of NCR( , )

1.3 Report

- Overage, Shortage & Damage Report

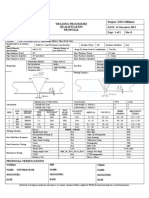

2. Fit-Up Inspection

1. Check Point

- Root Gap(WPS)

- Bevel Angle(WPS)

- Misalignment(1.59mm-API 1104)

- Tapered Angle(ASME B31.3)

- Foreign Material(Scale, Paint, Oil, Grease etc)

2. Authorized Personnel

- Construction Team : Preparation & Requisition of Inspection(RFI)

- DW QC : Implement of Inspection

- Saipem & Sonatrach Inspector

3. Report

Pre-Welding Visual Inspection Report(Form code: MDT.WL.CDQ.0150)

3. Ferrite Content Measurement

1. Check Point

- Fe Content Measure : Root Pass of Stainless Steel

- Carbon Wire

2. Authorized Personnel

- Construction Team : Preparation & Requisition of Inspection(RFI)

- DW QC : Implement of Inspection

- Saipem & Sonatrach Inspector

3. Device(Refer to Photograph)

4. Report : Non Destructive Examination Report(Form code:

MDT.WL.CDQ.0140)

4. Visual Inspection

1. Check Point(ASME B31.3 Para 344.1)

- Surface Imperfection of Weld

Crack : No Permitted

Lack of Fusion : No Permitted

Incomplete Penetration : No Permitted

External Porosity : No Permitted

Surface Roughness : 500 min Ra

Under bead : No Permitted

Undercut : 0.79mm

Height of Reinforcement

Base Metal Thickness(mm) Max Height of Reinforcement(mm)

T 6 1.5

6 < T 13 3.0

13 < T 25 4.0

T > 25 5.0

2. Authorized Personnel

- Construction Team : Preparation & Requisition of Inspection(RFI)

- DW QC : Implement of Inspection

- Saipem & Sonatrach Inspector

3. Device

4. Type of Imperfection

5. Report :

5. Radiographic Test

1. Application Code : ASME B31.3(High Pressure Piping)

2. Check Point

- Internal & External Welding Defect

3. Authorized Personnel

- Construction Team : Preparation & Requisition of RT

- QA/QC Team : RFI Issue, RT Result input in WICS & Notification of RT Result to

Construction Team

- NDE Subcontractor : Implement of NDE

- SAIPEM * SONATRACH Inspector : RT Film Review

4. Device : Ir-192 Radiation Equipment & Developing Facility.

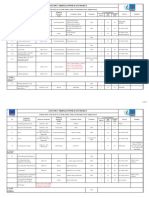

5. NDE Application (Piping Class Summary)

6. Report : Radiographic Examination Report(Form code: MDT.WL.CDQ.0141)

5.Piping Class Summary

Welding Class Piping Class NDE Application (%) Remarks

Class

A10K/1 A10N/1 A10U/1 A20K/1

1.Butt Weld: RT

(100%),Ferrite

Content(Diameter ,

SAIPEM Inspector

)

2.Fillet Weld(Seal

Welding) : PT or

MT(100%), Root Pass

10% PT

3. Hardness Test:

After PWHT

1.Stainless Pipe: PT

2. Carbon Pipe :

MT(After PWHT) A32A/1 A34A/1 A90K/0 B10K/1

B10N/1 B20K/1 B90K/0 D10K/1

D10N/1 D11A/1 D12A/1 D20K/1

D32A/B D41A/1 D42A/1 D90K/0

D91A/1 D92A/1 E10K/1 E10N/1

E11A/1 E32A/1 E41A/1

Class

A10V/B A11A/1 A12A/1 A15A/A

1.Butt Weld: RT

(10%),Ferrite

Content(Diameter ,

SAIPEM Inspector

)

2.Fillet Weld(Seal

Welding) : PT or

MT(10%), Root Pass

10% PT

3. Hardness Test:

After PWHT

1.Stainless Pipe: PT

2. Carbon Pipe :

MT(After PWHT)

3. RT 10% : Welder,

Line

4. 5 Point RT

A41A/1 A92A/1 B11A/1 B12A/1

B41A/1 B42A/B B91A/0

Class A80K/1 A80R/1 A82A/1 Branch Line : PT 10% Fabrication

6. Hardness Test

1. Application Code : ASME B31.3(High Pressure Piping)

2. Check Point

- Measurement of Hardness Value by BHN/RC Method after PWHT.

Carbon Steel : Max 238 BHN/RC

3. Authorized Personnel

- Construction Team : Preparation & Requisition of Hardness Test

- QA/QC Team : RFI Issue, Result input in WICS & Notification of Result to

Construction Team

- NDE Subcontractor : Implement of Hardness Test

- SAIPEM * SONATRACH Inspector : Witness

4. Device(Refer to Photograph)

5. Report : Hardness Examination Report(Form code: MDT.WL.CDQ.0431)

7. PMI

1. Application Code : ASTM & ASME section

2. Check Point : Stainless Steel Pipe Alloy Check.

3. Authorized Personnel

- Construction Team : Preparation & Requisition of PMI

- QA/QC Team : RFI Issue, Result input in WICS & Notification of Result to

Construction Team

- NDE Subcontractor : Implement of PMI

- SAIPEM * SONATRACH Inspector : Witness

4. Device(Refer to Photograph)

5. Report: PMI Report(Form code: MDT.WL.CDQ.0102)

Electrode Cr Ni Mo

A312 TP304/304L

18.0 ~ 22.0 9.0 ~ 11.0 -

A312 TP316/316L

17.0 ~ 20.0 11.0 ~ 14.0 2.0 ~ 3.0

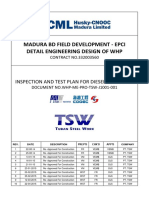

8. Hydrostatic Test

1. Application Code: ASME B31.3(High Pressure Piping)

2. Check Point

- Preparation of QC Document & AS Built DWG

- Confirmation of Piping Work

3. Authorized Personnel

- Construction Team : Preparation & Requisition of Hydro Test

- QA/QC Team : RFI Issue, Result input in WICS & Notification of Result to

Construction Team

- SAIPEM & SONATRACH Inspector : Witness

- ARH : Witness

4. Device : High Pressure Pump, Record, Temperature, Certificate of Water

5. Report : Inspection of Erected Line before Pressure Test(CDQ 0104)

Piping Pressure Test(CDQ 0195)

9. Follow Chart

Fit-Up Inspection

Receiving Inspection

Pre-Heating

<25mm : 10, -5

: 50

25mm: 100~150

Tag Weld: 2 : 3Point

2 ~14: 4Point

14 Over ; 6Point

In Process Inspection

(Random-Report)

Ferrite Content Check

(Stainless Steel-1st Pass

Post Heat Treatment

LTCS & C.S: 30mm Over(250,

30min Minimum)

Design Temp(Lower than -

20) : 32.mm

Welding

Visual Inspection

Post Weld Heat Treatment

NDT

Hardness & PMI Check

Repair : Up to 2

Hydro Test

Amin Line : 100%

LTCS & C.S : 20mm

Over

You might also like

- Ultimate Relationship ProgramDocument121 pagesUltimate Relationship ProgramSkyChng100% (9)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Boiler Installation Procedures With SamplesDocument67 pagesBoiler Installation Procedures With SamplesMalik RiazNo ratings yet

- Mil STD 3013Document127 pagesMil STD 3013Mirza Muneeb AhsanNo ratings yet

- Original SQL TEST 2018Document873 pagesOriginal SQL TEST 2018Selma Regita Mahardini0% (1)

- PHR PP QC GG 006 Welding ProcedureDocument17 pagesPHR PP QC GG 006 Welding Proceduremashari budiNo ratings yet

- Daily - Field Inspection Sheet (Date:-Xx - Xx.2018)Document7 pagesDaily - Field Inspection Sheet (Date:-Xx - Xx.2018)Balkishan DyavanapellyNo ratings yet

- Qualification of Procedure and Welder (19 February 2014)Document20 pagesQualification of Procedure and Welder (19 February 2014)Zanuardi YahyaNo ratings yet

- Activity Report Running WPS & PQRDocument3 pagesActivity Report Running WPS & PQRAndre Brama AlvariNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Lesson Plan - Boyle's LawDocument3 pagesLesson Plan - Boyle's LawQueencess Ara TorresNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Inspection and Test PlanDocument5 pagesInspection and Test Planmuhammad afrizalNo ratings yet

- Challenging Questions WorksheetDocument3 pagesChallenging Questions WorksheetmelissaNo ratings yet

- Body Flanges On ShellsDocument2 pagesBody Flanges On ShellsPadmanabhan VenkateshNo ratings yet

- TM - Carrier SelectionDocument5 pagesTM - Carrier SelectionunverNo ratings yet

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (6)

- Soil and Water Chemistry - An Integrative Approach - Essington, Michael E - CRC Press (2015)Document658 pagesSoil and Water Chemistry - An Integrative Approach - Essington, Michael E - CRC Press (2015)Abel Eloy Vargas MamaniNo ratings yet

- Review of GTAW Welding ParametersDocument14 pagesReview of GTAW Welding Parameterskervyn SáenzNo ratings yet

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- EIL Procedure For Technical Audit - 5-1940-8020 Rev. 5Document26 pagesEIL Procedure For Technical Audit - 5-1940-8020 Rev. 5EILA545 QAQCNo ratings yet

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocument50 pagesASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDocument9 pagesTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipeashokkahirwar100% (1)

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocument4 pagesWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanNo ratings yet

- SG Actuator Gas Over OilDocument4 pagesSG Actuator Gas Over Oiltoader56100% (1)

- Welding Repair ProcdureDocument16 pagesWelding Repair Procdureprem nautiyal100% (1)

- National Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedureDocument9 pagesNational Iranian Gas Company IGAT 5 Gas Compressor Stations: 602-106-TSH-VD-015 Rev. 0 PWHT ProcedurewiNo ratings yet

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDocument14 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocument8 pagesStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERNo ratings yet

- E-Mail Transmission: TO: Transmittal Ref. No.Document7 pagesE-Mail Transmission: TO: Transmittal Ref. No.Rahul MoottolikandyNo ratings yet

- Welding Coupon Witness ReportDocument18 pagesWelding Coupon Witness ReportRam KadamNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Safety and Operating Manual: Pipe Threading MachineDocument19 pagesSafety and Operating Manual: Pipe Threading MachineNalina S. Bala KumarNo ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFDocument8 pagesBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- ABout Preheat Before WeldingDocument2 pagesABout Preheat Before WeldingHary Olya AdriansyahNo ratings yet

- Basic WeldingDocument119 pagesBasic Weldingবিপ্লব পাল100% (2)

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19Document12 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19Dadaso Baburao JamdarNo ratings yet

- Section 9 - Welding ControlDocument6 pagesSection 9 - Welding ControlYasser Hammad MohamedNo ratings yet

- Testing Valve and NDTDocument5 pagesTesting Valve and NDTTran Trungtt100% (1)

- WPQTDocument18 pagesWPQTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- Standard Welding Procedures: by Walter J. SperkoDocument4 pagesStandard Welding Procedures: by Walter J. SperkoK ArunsiddharthNo ratings yet

- WPQ Flux CoreDocument1 pageWPQ Flux Corealberto jayaNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Welding Procedure DocumentDocument7 pagesWelding Procedure DocumentikponmwonsaNo ratings yet

- Compare S235JR, E250BRDocument6 pagesCompare S235JR, E250BRGANESHNo ratings yet

- ASTM and Grain Size MeasurementsDocument5 pagesASTM and Grain Size MeasurementsCarlos Ortega Jones100% (1)

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Requirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc NoDocument1 pageRequirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc Nonaveen_86No ratings yet

- Weldability of Materials - Nickel and Nickel AlloysDocument5 pagesWeldability of Materials - Nickel and Nickel AlloysmanimaranNo ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- LTHE-BFCCU-TUV-00103-LHP-IRN 01 DT - 02.06.2018Document1 pageLTHE-BFCCU-TUV-00103-LHP-IRN 01 DT - 02.06.2018bappadittaNo ratings yet

- PQR - WPQ Witness ReportDocument1 pagePQR - WPQ Witness Reportsdkeskar40No ratings yet

- GNL3Z PJ PIPING INSPECTION Rev1Document41 pagesGNL3Z PJ PIPING INSPECTION Rev1Aris BulaongNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Document4 pagesGlobe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1Ammanda ErnawanNo ratings yet

- ECEG 4123 Electrical Machines: Types of Synchronous MachinesDocument17 pagesECEG 4123 Electrical Machines: Types of Synchronous MachinesmebrahtenNo ratings yet

- Biogeochemical Cycles Webquest1 PDFDocument7 pagesBiogeochemical Cycles Webquest1 PDFsNo ratings yet

- Ground Atc TranscriptionDocument4 pagesGround Atc TranscriptionDesmond NgNo ratings yet

- Enthalpy For Pyrolysis For Several Types of BiomassDocument7 pagesEnthalpy For Pyrolysis For Several Types of BiomassSwiftTGSolutionsNo ratings yet

- Bh205e Ac 20170905061602Document4 pagesBh205e Ac 20170905061602amir sadighiNo ratings yet

- Lomas de Omedo SismicaDocument12 pagesLomas de Omedo SismicaClaudia Prezzi PrezziNo ratings yet

- ArticleText 57221 1 10 20210626Document8 pagesArticleText 57221 1 10 20210626Alley WaysNo ratings yet

- DBU2 - GDEX - Jolyn Lee Jia YingDocument30 pagesDBU2 - GDEX - Jolyn Lee Jia YingTay Khai SernNo ratings yet

- London Congestion Charge Case StudyDocument6 pagesLondon Congestion Charge Case Studyapi-241480872No ratings yet

- ANNEX B - Enclosures 1 22 To The Memo On Constitution and by Laws of The Learner Government ProgramDocument34 pagesANNEX B - Enclosures 1 22 To The Memo On Constitution and by Laws of The Learner Government ProgramElona Jane CapangpanganNo ratings yet

- 1.4.6 Energy Flow WorksheetDocument7 pages1.4.6 Energy Flow WorksheetChris MatierNo ratings yet

- Exercices Transistors Cor PDFDocument5 pagesExercices Transistors Cor PDFDaha AhmedNo ratings yet

- Discrete Fourier Series and TransformDocument88 pagesDiscrete Fourier Series and TransformKarthik IvaturiNo ratings yet

- CPO Transfemoral Prosthesis Above Knee PDFDocument2 pagesCPO Transfemoral Prosthesis Above Knee PDFkeerthiNo ratings yet

- 1st Quarter Classroom ObservationDocument4 pages1st Quarter Classroom ObservationJoriza NovioNo ratings yet

- Yamaha Outboard 4HP OEM Parts Diagram For CARBURETORDocument1 pageYamaha Outboard 4HP OEM Parts Diagram For CARBURETORCharterparty CadizNo ratings yet

- Using Commas To Clarify Meaning or Avoid Ambiguity in WritingDocument5 pagesUsing Commas To Clarify Meaning or Avoid Ambiguity in WritingewfewefwefNo ratings yet

- SwotDocument1 pageSwotTejas DeepNo ratings yet

- Eprs Stu (2019) 634414 enDocument60 pagesEprs Stu (2019) 634414 enGuilherme Ribeiro BarbosaNo ratings yet

- UNIDAD 1.-Introducción A La Simulación de Eventos Discretos 1.1 Introducción What Is Simulation?Document49 pagesUNIDAD 1.-Introducción A La Simulación de Eventos Discretos 1.1 Introducción What Is Simulation?Cristobal CmNo ratings yet

- 03 2023 2 01483344 Fee VoucherDocument3 pages03 2023 2 01483344 Fee VoucherMuhammad Asif 360-FSS/MSEDU/S20No ratings yet