Professional Documents

Culture Documents

TR Diss 1672 PDF

TR Diss 1672 PDF

Uploaded by

sujiv_sujiv1278Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TR Diss 1672 PDF

TR Diss 1672 PDF

Uploaded by

sujiv_sujiv1278Copyright:

Available Formats

A new approach to

the design of

gas-liquid separators

for the oil industry

*

/VTR diss

1672

R.A. Swanborn

NEW

OESIfiNS

MODI r epr oduces t he gas f l ow f i el d i nsi de a basi c separ at i on uni t ;

M0D2 descr i bes t he behavi our of t he l i qui d phase ( par t i cl e ' t r aj ect or i es,

r eent r ai nment and cr eep phenomena) ;

M0D3 descr i bes t he behavi our of a basi c separ at i on uni t ;

MOD*! quant i f i es t he measur e of mal di st r i but i on acr oss a f ul l si ze

separ at or ; no need t o model t hi s wi t h t he ear l i er ment i oned f l ui d

dynami c codes;

M0D5 combi nes t he pr edi ct i ve power s of M0D3 and M0D4 and shoul d t her ef or e

be abl e t o descr i be t he behavi our of an act ual scal ed separ at or over a

br oad r ange of oper at i ng condi t i ons;

EXP1 a. pr ovi des t he f l ui d dynami c code wi t h necessar y physi cal i nf or mat i on

t o st ar t wi t h ( st ar t i ng condi t i ons) and

b. pr ovi des t he exper i ment al dat a t o val i dat e MODI wi t h ( gas f l ow

f i el d measur ement s)

EXP2 i dent i f i es and quant i f i es phenomena r el at ed t o t he l i qui d phase

( r eent r ai nment , cr eep, par t i cl e t r aj ect or i es) ;

EXP3 pr ovi des t he exper i ment al dat a t o val i dat e M0D3 wi t h ( oper at i ng

char act er i st i cs of a basi c separ at i on uni t over a br oad r ange of

oper at i ng condi t i ons) ;

EXP4 a. pr ovi des physi cal i nf or mat i on ( st ar t i ng condi t i ons) f or M0D4;

b. pr ovi des t he exper i ment al dat a t o val i dat e MOD' * wi t h;

EXP5 pr ovi des t he exper i ment al dat a t o val i dat e M0D5 wi t h ( oper at i ng

char act er i st i cs of an act ual scal ed separ at or over a br oad r ange of

oper at i ng condi t i ons) ;

LI T r epr esent s t he i nf or mat i on acqui r ed t hr ough l i t er at ur e i nvest i gat i on

used f or val i dat i ng and suppl ement i ng model s.

VAL val i dat i on

.('

V

:t.

I V \

KVNI

~ 1 * > ?

< ^ a

^

. *

A NEWAPPROACH TO THE DESI GN OF GAS- LI QUI D

SEPARATORS FOR THE OI L I NDUSTRY

Front cover: An unrealistic simulation of the gas flow field inside a reverse

flow cyclone (see section 7.5).

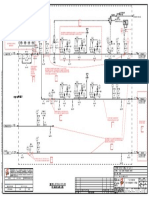

Innerside of front cover: Project structure and nomenclature (see chapter 4).

A NEW APPROACH TO THE DESIGN OF GAS-LIQUID

SEPARATORS FOR THE OIL INDUSTRY

PROEFSCHRI FT Ar

<

0

V\MI SC7^

o,

4/

fUj

p prometheOsple'm 1

262c ZC

DELFT

t er ver kr i j gi ng van de gr aad van doct or aan de

Techni sche Uni ver si t ei t Del f t , op gezag van de

Rect or Magni f i cus, Pr of . dr s. P. A. Schenck,

i n het openbaar t e ver dedi gen t en over st aan van een

commi ssi e door het Col l ege van Dekanen daar t oe aangewezen,

op di nsdag 25 okt ober 1988 t e 14. 00 uur

door

ROMBOUT ADRI AAN SWANBORN

gebor en t e Poi nt For t i n, Tr i ni dad

mi j ni ngeni eur

TR diss

1672

Di t pr oef schr i f t i s goedgekeur d door de pr omot or en

Pr of . xr . E. J . de J ong en Pr of . dr . i r . J . de Gr aauw

ADDENDUM TO: "A NEW APPROACH TO THE DESI GN OF GAS- LI QUI D

SEPARATORS FOR THE OI L I NDUSTRY",

by R. A. Swanbor n

I t has not been st at ed cl ear l y i n chapt er 6, sect i on 6. 3. 2. ,

bl ock RFC- EXP3 and RFC- EXP4 t hat t he det er mi ned char act er i st i cs

of ( si ngl e) cycl one t ype E and of ( mul t i ) cycl ones t ype B and C,

al l of whi ch have been desi gned by Pal adon Engi neer i ng Lt d. ,

shoul d not be consi der ed as r epr esent at i ve f or t he

char act er i st i cs of t he equi pment t hat i s pr esent l y desi gned by

t hi s company f or commer ci al pur poses.

The cycl one separ at or - desi gns t hat have been t est ed i n t hi s st udy

have been put at our di sposal by Pal adon, but concer n pr el i mi nar y

devel opment ver si ons t hat ar e di f f er ent f rom t he commer ci al

equi pment of t hi s f i r m bot h wi t h r espect t o geomet r y and

pr i nci pl e of oper at i on. The cycl ones t est ed wer e a desi gn

speci f i cal l y bei ng consi der ed t o over come er osi on pr obl ems i n

hi gh sand l oadi ng appl i cat i ons onl y.

Some of t he most i mpor t ant negat i ve char act er i st i cs wi t h r espect

t o ot her desi gns as t est ed i n t hi s st udy, can be expl ai ned

di r ect l y by t he pr esence of ext r a f eat ur es, not accommodat ed i n

t he convent i onal commer ci al desi gns, but obvi ousl y not yet of t he

opt i mal geomet r i cal f or mi n t he t est ed ver si ons.

"To some, science is an exalted goddess,

to others a cow which provides them

with butter"

B. Russell, 1928

Aan mijn ouders en Ella

CONTENTS

SUMMARY AND CONCLUSI ONS

SAMENVATTI NG EN CONCLUSI ES

1. I NTRODUCTI ON 1

2. CLASSI FI CATI ON OF PRESENT GAS/ LI QUI D SEPARATI ON APPLI CATI ONS 5

2. 1 I nt r oduct i on 5

2. 2 Basi c descr i pt i on of a gas pr oduct i on syst em 5

2. 3 I nvent or y of separ at or l ocat i ons 8

2. 3- 1 I nt r oduct or y r emar ks 8

2. 3- 2 Wel l head separ at i on 8

2. 3. 3 Scr ubbi ng 9

2. 3. 4 Of f shor e gas wi nni ng 14

2. 3- 5 Onshor e gas wi nni ng 14

2. 4 Eval uat i on of separ at or i nl et condi t i ons and r equi r ement s 15

3. PRESENT TECHNOLOGY 17

3. 1 I nt r oduct i on 17

3- 2 Basi c gas/ l i qui d separ at i on mechani sms 20

3. 3 Sedi ment at i on 23

3. 3- 1 Gener al aspect s 23

3. 3- 2 Knock- out vessel s 23

3. 4 I ner t i al separ at i on 26

3. 4. 1 I nt r oduct or y r emar ks 26

3. 4. 2 I ner t i al separ at i on by mesh t ype separ at or s 26

3. 4. 3 I ner t i al separ at i on wi t h vane- t ype separ at or s 28

3. 4. 4 Cycl one t ype separ at or s 32

3. 4. 4. 1 Pr el i mi nar y r emar ks 32

3. 4. 4. 2 ( Rever se f l ow) Dust cycl ones 34

3. 4. 4. 3 Mi st cycl ones 35

3. 4. 4. 4 Mul t i cycl ones 39

3. 4. 4. 5 St r ai ght t hrough cycl ones 40

3. 4. 4. 6 Char act er i st i cs of cycl one t ype separ at or s 44

3- 5 Di f f usi onal separ at i on 46

3. 6 Exi st i ng separ at or t ypes 48

3- 6. 1 Hor i zont al or ver t i cal posi t i on 49

3. 6. 2 Number of separ at i on st ages 50

3. 7 Eval uat i on of pr esent t echnol ogy 52

DESCRI PTI ON OF THE CURRENT RESEARCH PROJ ECT 55

4. 1 St r uct ur e of chapt er 55

4. 2 For mul at i on of r esear ch obj ect i ves 55

4. 3 Pr oj ect st r at egy and t ool s 57

4. 3- 1 I nt r oduct or y r emar ks 57

4. 3. 2 Pr oj ect st r at egy and t ool s 58

4. 4 Scope of pr esent r epor t 6l

RESULTS: LI TERATURE SEARCH 63

5. 1 I nt r oduct i on 63

5. 2 Det er mi nat i on of t he i nl et condi t i ons 63

5- 3 Fr i ct i on f act or s at gas/ l i qui d i nt er f ace 67

5. 3. 1 For mof gas/ l i qui d i nt er f ace 67

5. 3. 2 Fr i ct i on f act or s of l i qui d f i l m/ gas syst ems 69

5. 3. 2. 1 I nt r oduct or y r emar ks 69

5. 3. 2. 2 Wal l f r i ct i on f act or s of l i qui d f i l ms 69

5. 3. 2. 3 I nt er f aci al f r i ct i on f act or of l i qui d f i l ms 70

5. 3- 3 Fr i ct i on f act or s of r ot at i ng l i qui d f i l m/ gas syst ems 72

5. 4 Reent r ai nment and rel at ed ef f ect s 73

5. 4. 1 Fi l mbr eak- up mechani sms 73

5- 4. 2 I ni t i at i on cr i t er i a of r eent r ai nment 74

5. 4. 3 The r at e of r eent r ai nment 79

5- 4. 4 Dr opl et si ze di st r i but i on of r eent r ai nment 80

5- 4. 5 Di r ect i on of and i ni t i al vel oci t y of r eent r ai ned dr opl et s 81

5. 5 Char act er i zat i on of swi r l el ement s and swi r l i ng f l ows 82

5. 5. 1 I nt r oduct or y r emar ks 82

5. 5. 2 Exampl es of r ot at i ng f l ow f i el ds 82

5. 5. 3 Char act er i zat i on of swi r l el ement s and swi r l i ng f l ows 82

TEST FACI LI TI ES AND EXPERI MENTAL RESULTS 91

6. 1 St r uct ur e of chapt er 91

6. 2 Test f aci l i t i es 91

6. 2. 1 I nt r oduct i on 91

6. 2. 2 Test - r i g 1 ( bl ock EXP1, EXP2) 92

6. 2. 3 Test - r i g 2 ( bl ock EXP2, EXP3, EXP5) 3k

6. 2. 4 Test - r i g 3 ( bl ock EXP2. EXP4, EXP5) 98

6. 3 Exper i ment al r esul t s 102

6. 3- I Axi al cycl ones 102

6. 3. 2 Rever se f l ow cycl ones 108

6. 3. 3 Vanes 118

MODELLI NG RESULTS 129

7. 1 I nt r oduct i on 129

7. 1. 1 St r uct ur e of chapt er 129

7. 1. 2 Model l i ng t echni ques 129

7. 2 Numer i cal model l i ng of gas f l ow f i el ds 130

7. 2. 1 Physi cal backgr ound 130

7. 2. 2 Mat hemat i cal backgr ound 135

7. 2. 3 Fl ui d dynami c codes used 136

7. 3 Physi cal model l i ng of gas/ l i qui d i nt er act i ons 136

7. 3! I nt r oduct or y r emar ks 136

7. 3. 2 Behavi our of dr opl et phase 137

7. 3. 3 Behavi our of t he l i qui d f i l m 139

7. 4 Axi al cycl one model s 147

7. 4. 1 Bl ock AC- MODI 148

7. 4. 2 Bl ock AC- M0D2 157

7. 4. 3 Bl ock AC- M0D3 160

7. 4. 3. 1 St r uct ur e of model 160

7. 4. 3. 2 Pr i mar y separ at i on ef f i ci ency l 60

7. 4. 3. 3 Maxi mal capaci t y 162

7. 4. 4 Bl ocks AC- M0D4/ M0D5 164

7. 5 Rever se f l ow cycl ones 165

7. 5. 1 Bl ock RFC- MODI 165

7. 5. 2 Bl ock RFC- M0D2 166

7. 5- 3 Bl ock RFC- M0D3 167

7. 5- 3. 1 Pr i mar y separ at i on ef f i ci ency of a r ever se

f l ow cycl one 167

7. 5- 3- 2 Maxi mal capaci t y of a r ever se f l ow cycl one 168

7- 5- 3- 3 Pr essur e dr op of a r ever se f l ow cycl one 169

7. 5. 4 Bl ock RFC- M0D4 I 69

7. 5. 5 Bl ock RFC- M0D5 171

7. 6 Vanes 172

7. 6. 1 Bl ock V- M0D1 172

7. 6. 2 Bl ock V- M0D2 I 73

7. 6. 3 Bl ock V- M0D3 I 75

7. 6. 4 Bl ock V- M0D4 177

7. 6. 5 Bl ock V- M0D5 I 79

8. CONCLUSI ONS: I MPROVED DESI GNS AND DESI GN PROCEDURES 181

8. 1 I nt r oduct i on l 8l

8. 2 I mpr oved desi gns 181

8. 2. 1 Axi al cycl ones 181

8. 2. 2 Rever se f l ow cycl ones 187

8. 2. 3 Vanes 188

8. 3 I mpr oved desi gn equat i ons 192

8. 3- 1 I nt r oduct or y r emar ks 192

8. 3. 2 Tr adi t i onal axi al cycl ones 192

8. 3- 3 Rever se f l ow cycl ones 196

8. 3- 4 Vanes 198

LI ST OF SYMBOLS 203

REFERENCES 205

APPENDI CES

A 3. 3. 2 Knock- out vessel s A. 1

3. 4. 2 Mesh t ype separ at or s A. 5

3. 4. 3 Vane t ype separ at or s A. 12

3. 4. 4. 2 Rever se f l ow cycl ones A. 19

3. 4. 4. 3 Mi st cycl ones A. 37

3. 4. 4. 4 Mul t i cycl ones A

3. 4. 4. 5 St r ai ght - t hr ough cycl ones A

3. 5 Di f f usi onal separ at i on A

B Repr esent at i ve exampl es of swi r l i ng f l ow char act er i zat i ons B

B. l Swi r l i ng f l ow i n a smoot h pi pe B

B. 2 Swi r l i ng f l ow i n axi al cycl ones B

B. 3 Swi r l i ng f l ow i n r ever se f l ow cycl ones B

C Exper i ment al r esul t s C

D Tur bul ence model s D

D. 1 Tur bul ence model s based on t he concept of Boussi nesq D

D. l . 1 Backgr ound of Boussi nesq model s D

D. 1. 2 Zer o PDE model s D

D. 1. 3 One PDE model s D

D. 1. 4 Two PDE model s D

D. 2 Di r ect model l i ng of t ur bul ent shear st r esses D

CURRI CULUM VI TAE

ACKNOWLEDGEMENTS

SUMMARY AND CONCLUSI ONS

The most i mpor t ant gas/ l i qui d separ at i ons t hat t ake pl ace i n oi l f i el d

oper at i on have been i nvest i gat ed.

An i nvent or y has been made of t he condi t i ons under whi ch t he separ at i ons

have t o t ake pl ace and whi ch r equi r ement s have t o be f ul f i l l ed.

The pr esent l y avai l abl e separ at or t ypes have been eval uat ed wi t h r espect t o

t he sui t abi l i t y t o f ul f i l t he r equi r ement s l i st ed above.

I t appear ed t hat many separ at or t ypes wer e not speci f i cal l y desi gned f or

hi gh pr essur e gas/ l i qui d separ at i on ( r at her f or ei t her at mospher i c

gas/ l i qui d or hi gh pr essur e gas/ dust separ at i on) .

I t al so appear ed t hat i n many cases t he behavi our of t he separ at or coul d not

be r el i abl y pr edi ct ed under t he condi t i ons of t he pr act i cal appl i cat i on.

For t hi s r eason ef f or t s wer e concent r at ed on devel opi ng i mpr oved desi gns and

gener al l y val i d desi gn r ul es f or i mpr oved and exi st i ng separ at or t ypes.

The separ at or t ypes under i nvest i gat i on wer e mai nl y axi al , r ever se f l ow and

vane t ype separ at or s.

Each of t hese separ at or t ypes makes use of t he i ner t i a of t he mi st par t i cl es

t o ef f ect t hei r separ at i on.

The pr i nci pl es of oper at i on are schemat i cal l y depi ct ed bel ow.

To devel op improved desi gns and improved desi gn equations, physical and

mathematical models were set up that descri be the phenomena i nsi de the

separator over a wide range of operating conditions.

These models are on one hand based on numerical sol uti on schemes that

descri be the behaviour of a fluid in motion, and on the other hand on rul es

that describe the gas/liquid i nteracti ons speci fi c to these separators.

An extensi ve experi mental program accompanied the development of these

models to ensure thei r val i di ty.

With these models two new separator designs were developed, that both show

consi derabl y improved operati ng characteri sti cs wi th respect to the

tradi ti onal high pressure gas/liquid separators.

A new axi al cyclone design was developed and tested of which the throughput

i s not l onger confined by the tradi ti onal mechanism of l i mi tati on. This

resul ted i n a drasti cal l y improved size/throughput rati o.

Also a new vane desi gn was developed and tested, which shows the same

improved size/throughput rati o.

An i mportant conclusion that was drawn from the design equations that were

derived from the models was the fact that tradi ti onal l y the i nfl uence of

operati ng pressure i s nearly always misjudged. I t i s underestimated in case

of one type of axi al cyclone separator and overesti mated i n case of most

other cyclone and vane type separators. This was al so demonstrated by

experimental resul ts.

I n nearl y al l cases thi s misconception has lead to separators of which the

si ze i s not optimal for application, an important requirement for offshore

operati ons. Therefore, practi cal rul es were given how to account for

operating pressure i n the design of the separator types under i nvesti gati on.

SAMENVATTI NG EN CONCLUSI ES

Di t pr oef schr i f t begi nt met een opsommi ng van de bel angr i j kst e pl aat sen i n

ol i e/ gas pr odukt i esyst emen waar gas/ vl oei st of schei di ng pl aat svi ndt .

De bedr i j f somst andi gheden waar onder de di ver se schei di ngsoper at i es

pl aat svi nden, wor den geanal yseer d en de ei sen aan de schei di ngsoper at i es

wor den gei nvent ar i seer d. Hi er na wor den de beschi kbar e separ at or en

geval ueer d zodat een over zi cht kan wor den gegeven van de t ekor t komi ngen di e

de hui di ge st and der t echni ek met zi ch meebr engt .

Het bl i j kt dat de meest e i n gebr ui k zi j nde separ at or t ypen ni et speci f i ek

voor hogedr uk gas/ vl oei st of schei di ng ont wor pen zi j n, doch eer der voor hoge

dr uk st of schei di ng of at mosf er i sche gas/ vl oei st of schei di ng. Tevens bl i j kt

dat i n veel geval l en het gedr ag van de separ at or onder bedr i j f somst andi g-

heden ni et nauwkeur i g voor spel d kan wor den.

Daar om r i cht het ver der e onder zoek zi ch voor namel i j k op de ont wi kkel i ng van

ni euwe separ at or ont wer pen en al gemeen gel dende ont wer pr egel s voor de ni euwe

en t r adi t i onel e separ at or t ypen.

De dr i e separ at or t ypen di e onder zocht wor den, zi j n de axi aal cycl oon, de

r ever se f l ow cycl oon en de vanepl aat af schei der . Het wer ki ngspr i nci pe van

el k van de dr i e ber ust op t r aaghei dsaf schei di ng en i s onder st aand

schemat i sch af gebeel d.

Om verbeterde separator ontwerpen en ontwerpregel s te ontwikkelen worden

fysische en mathematische modellen geformuleerd di e de verschijnselen i n een

separator beschrijven voor een ruim bereik van bedrijfsomstandigheden.

Enerzi j ds bestaan deze modellen ui t mathematische oplosmethoden di e

gasstromi ngsvel den voorspel l en, anderzi j ds ui t toegespi tste f ysi sche

modellen die de gas/vloeistof i nteracti es in een scheider beschrijven.

De modelontwikkeling gaat gepaard met een experi menteel programma om de

betrouwbaarhei d van de model voorspel l i ngen te al l en ti j de te kunnen

veri fi ren.

Vanuit deze modellen worden twee nieuwe separator typen ontwikkeld die

aanzi enl i j k verbeterde karakteri sti eken vertonen i n vergel i j ki ng met

tradi ti onel e hoge druk gas/vloeistofseparatoren.

Een nieuwe axiaal cycloon wordt ontwikkeld en getest waarvan de capaci tei t

ni et l anger door het tradi ti onel e mechanisme wordt begrensd. Dit resul teert

in een aanzienlijk verbeterde capaci tei t/grootte verhouding.

Er wordt ook een verbeterde vane ontwikkeld di e dezel fde verbeterde

capaci tei t/grootte verhouding vertoont.

Een bel angri j ke concl usi e di e getrokken wordt ui t de nieuw ontwikkelde

ontwerpregel s i s dat de i nvl oed van de werkingsdruk bi j na al ti j d fout

beoordeeld wordt. Deze invloed wordt onderschat i n geval van n type axiaal

cycloon en overschat in geval van de meeste andere soorten cyclonen en

vanes. Dit wordt ook aangetoond met experimentele resul taten. In bijna al l e

gevallen l ei dt di t misverstand tot separatoren die ni et de optimale grootte

voor de toepassing hebben, een belangrijke verei ste voor offshore operati es.

Daarom worden voor de drie onderzochte separator typen prakti sche regel s

gegeven hoe de opschal i ng naar hogere werkdrukken ui tgevoerd di ent te

worden.

- 1-

1. I NTRODUCTI ON

The of f shor e act i vi t i es i n t he oi l - and gas- i ndust r y have gr own st r ongl y i n

t he l ast f i f t een year s. As a consequence t he demand f or equi pment sui t ed f or

appl i cat i on on t he spat i al l y r est r i ct ed dr i l l i ng and pr oduct i on pl at f or ms

has i ncr eased.

Somewhat compar abl e wi t h t he i nf l uence t he space pr ogr ammes of t he si xt i es

had on t he el ect r oni c i ndust r y, t he of f shor e act i vi t i es have gi ven an

i mpul se t o t he devel opment of an assor t ment of pr oduct s and t echni ques whi ch

ar e char act er i zed by ef f i ci ency, r el i abi l i t y and l i t t l e mai nt enance.

As an exampl e of t he di ver si t y wi t hi n t hi s assor t ment , one can see on t he

one hand t he speci al l y devel oped concr et e const r uct i on t echni ques t hat wer e

appl i ed dur i ng t he er ect i on of t he pl at f or ms i n t he Gul l f aks f i el d and on

t he ot her hand t he ver y compact and r obust r ot at i ng pr ocess equi pment

( especi al l y t ur bi nes and compr essor s) . Many r esear ch and devel opment ef f or t s

have pr eceded t hese novel t i es.

Thi s st udy f or opt i mi zat i on of gas/ l i qui d separ at or s was al so bor n under t he

si gns descr i bed above.

Toget her wi t h oi l / wat er separ at i on, gas/ l i qui d separ at i on i s an i mpor t ant

pr ocess oper at i on t hat i s essent i al on an of f shor e pr oduct i on pl at f or m.

The wel l f l ui ds ar e pur i f i ed of l i qui d and cont ami nat i ons t hat have been

pr oduced f romt he r eser voi r .

To pr event er osi on, pl uggi ng and cor r osi on of val uabl e pr ocess equi pment i t

i s of gr eat i mpor t ance t hat sand and wat er ar e separ at ed i n t he ear l i est

possi bl e st age of t he pr oduct i on.

The pr ocess equi pment t hat i s used f or t hese oper at i ons i s of consi der abl e

si ze and wei ght and has f or a l ong t i me been subj ect t o opt i mi zat i on

at t empt s. One of t he pr obl ems encount er ed i n t hi s f i el d i s t he f act t hat t he

behavi our of t he mul t i phase f l ow under t he pr evai l i ng ci r cumst ances i s

compl ex and ver y di f f i cul t t o pr edi ct , even i n t he mechani cal separ at or s

under di scussi on i n t hi s r epor t whi ch ar e usual l y qui t e si mpl e i n t hei r

geomet r y.

- 2 -

Where quanti tati ve descri pti ons of the properties of thi s type of process

equipment are defi ci ent, empi ri cal desi gns f l ouri sh. The val ue of these

empirics i s high, as i t i s based on decennia of oi l field experience.

However, these rel ati ons are much l ess suited for design opti mi zati on when

they are stretched beyond thei r ori gi nal range of appl i cati on.

A complication that occurs when attempti ng to quanti fy the behaviour of

these mul ti phase flows i s that under high pressure the properti es of the

mi xture may di f f er consi derabl y from those of the same mi xture under

atmospheri c condi ti ons. This effect requi res expensive experimental

equipment to conduct experiments under actual ci rcumstances and equal l y

equal l y expensive computing equipment and software to carry out numerical

flow simulations.

As, up to now, only rel ati vel y small companies have been involved in the

design and fabrication of a large part of thi s parti cul ar separati on equi p-

ment, much of the necessary, expensi ve, research i n thi s field has been

neglected. Many examples are found of i ncorrectl y sized separators. This has

i nduced some better fi nanced oi l rel ated i ndustri es to. tackl e these

problems. Presently, some large research i nsti tutes (parti cul arl y i n Norway

and the United States) are conducting very thoroughly structured research

programmes to i nvesti gate the multiphase flow behaviour under the mentioned

conditions.

The research project described here has been set up more modestly.

Shel l .I nternati onal e Petroleum Maatschappij B.V., the Ministry of Economic

Affairs of The Netherlands, Sombroek Zaandam B.V. and Stork Ketels B.V. were

wi l l i ng to finance a research proj ect that aimed at gaining more insight

i nto the phenomena that restri ct the capacity and effi ci ency of gas/l i qui d

separation in natural gas production.

I t i s expected that recommendati ons can be formul ated for a more

si gni f i cant and uniform design procedure and, moreover, that completely new

separator desi gns, speci f i cal l y sui ted for appl i cati on offshore can be

suggested.

The sponsor s of t he pr oj ect have t he commer ci al r i ght s of new desi gns.

- 3-

I n f i gur e 1. 1 t he l ogi cal st r uct ur e of t hi s r epor t i s pr esent ed.

I t compr i ses t he r esul t s and concl usi ons r eached i n t he f i rst f our year s of

t hi s st udy. A cont i nuat i on of t he pr oj ect f or t hr ee year s has been st ar t ed.

I NVENTORY OF PRACTI CAL r

REQUI REMENTS I

LI TERATURE SEARCH

k

d nu

I NTRODUCTI ON

I 3 I i I NVENTORY OF PRACTI CAL

POSSI BI LI TI ES

FORMULATI ON OF RESEARCH

OBJ ECTI VE

EXPERI MENTAL RESULTS

MODELLI NG RESULTS

~J^ PRACTI CAL RESULTS

Figure 1.1 Structure of this report

I n chapt er 2 at t ent i on wi l l be pai d t o t he di f f er ent condi t i ons pr act i cal

separ at or s have t o oper at e under . Thi s wi l l hel p t o speci f y t he t asks of a

separ at or .

Chapt er 3 wi l l gi ve an over vi ew of pr esent t echnol ogy wi t h i t s possi bi l i t i es

and l i mi t at i ons. The di scr epancy bet ween t he r equi r ement s of chapt er 2 and

t he possi bi l i t i es of chapt er 3 wi l l f ormt he basi s of chapt er 4, i n whi ch

t he obj ect i ves and st r at egy of t he pr esent r esear ch pr oj ect wi l l be

f ormul at ed and el abor at ed.

Chapt er s 5. 6 and 7 wi l l mai nl y deal wi t h t he di f f er ent t ypes of

i nvest i gat i on t hat have been car r i ed out i n or der t o gat her t he i nf or mat i on

necessar y t o r each t he f or mul at ed obj ect i ves. Chapt er 5 wi l l gi ve t he

r esul t s of a l i t er at ur e sear ch, chapt er 6 t he r esul t s of exper i ment al

i nvest i gat i ons and chapt er 7 t he r esul t s of model l i ng ef f or t s.

I n chapt er 8 t hi s i nf or mat i on wi l l be t r ansl at ed t o pr act i cal t er ms. Desi gn

pr ocedur es t hat ar e bet t er sui t ed f or appl i cat i on under t he pr evai l i ng

condi t i ons wi l l be pr oposed. Thr ee novel separ at or i nt er nal s wi l l be

i nt r oduced, of whi ch t wo wi l l be t est ed. They wi l l combi ne t he advant ages of

sever al exi st i ng separ at or desi gns.

- 5-

2. CLASSIFICATION OF PRESENT GAS/LIQUID SEPARATION APPLICATIONS

2.1 Introduction

Thi s chapt er gi ves an over vi ew of f r equent l y encount er ed appl i cat i ons of

gas/ l i qui d separ at or s. The over vi ew compr i ses separ at or s i n of f shor e and

onshor e pr oduct i on syst ems. Onshor e separ at or l ocat i ons ar e i ncl uded because

of f - and onshor e pr oduct i on syst ems ar e i nt egr at ed. Thi s way i t wi l l be

possi bl e t o hi ghl i ght some speci f i c di f f er ences bet ween bot h t ypes of

separ at or s. A basi c gener al pr oduct i on f l owsheet i s descr i bed i n sect i on

2. 2, so t hat i n sect i on 2, 3 t he t ypi cal gas/ l i qui d separ at i on oper at i ons

t hat t ake pl ace i n t he di f f er ent var i at i ons of t hi s basi c f l owsheet can be

cat al ogued accor di ng t o oper at i ng condi t i ons and r equi r ed pr oper t i es.

2. 2 Basi c description of a ga s production system

As al r eady ment i oned, pr oduced gas cont ai ns l i qui d and sol i d const i t uent s.

The r emoval of t hese f or ms t he most i mpor t ant pr ocess st ep bef or e del i ver y

can t ake pl ace. The l i qui ds al most i nvar i abl y consi st of wat er and

hydr ocar bons t hat ar e gaseous under r eser voi r condi t i ons but condense dur i ng

pr oduct i on due t o t he decr ease i n gas pr essur e and t emper at ur e. However , oi l

may be copr oduced f romt he r eser voi r .

Sol i d par t i cl es have t o be r emoved because of er osi on pr obl ems. The r emoval

of wat er i s necessar y because:

a. i n pr esence of C0

2

and Hj S (two ot her possi bl e const i t uent s of nat ur al

gas) wat er f or ms a hi ghl y cor r osi ve mi xt ur e;

b. under cer t ai n condi t i ons wat er t oget her wi t h hydr ocar bon component s can

f orm"hydr at es", f l aky sol i ds, whi ch coul d cause pl uggi ng.

The ext ent t o whi ch t he nat ur al gas shoul d be f r ee of wat er i s usual l y

expr essed i n t er ms of t he wat er dew poi nt of t he gas. Thi s i s t he

t emper at ur e at whi ch wat er st ar t s t o condense f romt he gas.

For obvi ous r easons hydr ocar bon condensat es ar e not al l owed i n sal es gas.

- 6-

They f or m, however , l ess hazar ds dur i ng pr el i mi nar y pr oduct i on and

pr ocessi ng t han wat er , so t hat i n many pr oduct i on syst ems nat ur al gas and

i t s hydr ocar bon condensat es are al l owed t o coexi st much l onger .

For sal es gas t he speci f i cat i ons of l i qui d hydr ocar bon cont ent s ar e al so

of t en expr essed i n t er ms of dew poi nt s. The speci f i ed dew poi nt s usual l y

r el at e t o t he mi ni mumoccur i ng t emper at ur e of t he sal es gas ( approxi mat el y

bet ween - 3C and - 8C) .

Nor mal l y t he r emoval of t he l i qui ds f r ompr oduced gas i s carri ed out i n

t wo st eps.

The f i r st st ep, t he so- cal l ed wel l head separ at i on, t akes pl ace under hi gh

pr essur e. Wi t h t hi s oper at i on t he sol i ds shoul d be r emoved f r om t he gas t o

pr event er osi on of t he equi pment f ur t her downst r eam. Toget her wi t h t he

sol i ds t he bul k of t he al r eady condensed l i qui ds wi l l be r emoved f r om t he

gas. Behi nd t hi s separ at or of t en some f l ow or pr essur e cont r ol val ve wi l l

r egul at e t he gas f l ow t o i t s desi r ed val ue.

Thi s r esul t s i n a decr ease i n pr essur e and t emper at ur e, whi ch wi l l i n most

cases cause condensat i on of mor e l i qui ds, bot h wat er and hydr ocar bons ( t he

l at t er because of r et r ogr ade condensat i on) . Thi s expl ai ns why t he l i qui d

separ at i on ef f i ci eny of t he wel l head separ at or i s not consi der ed cr i t i cal .

I n t hi s st age t he gas i s of t en cool ed t o ef f ect t he condensat i on of even

mor e l i qui ds, af t er whi ch t he second separ at i on st ep wi l l t ake pl ace. Wi t h

t hi s st ep t he gas wi l l be br ought t o t he speci f i cat i ons r equi r ed f or

del i ver y t o t he sal es gas net wor k. Thi s appl i es t o bot h t he wat er ( of whi ch

t he r emoval i s cal l ed "dehydr at i on") and t he l i qui d hydr ocar bon cont ent

( whi ch wi l l be r ef er r ed t o as "condensat es scr ubbi ng") .

Thi s second separ at i on st ep usual l y consi st s of sever al i nt er dependi ng

i ndi vi dual separ at i on and t r eat i ng st eps. I t ' i s i n some cases di f f i cul t t o

compar e wi t h t he st r ai ght f orward wel l head separ at i on, f or i nst ance because

of t he addi t i on of chemi cal s, l i ke gl ycol , t o t he gas f l ow t o assi st i n t he

pr ocess.

Ther e are sever al basi c dehydr at i on/ scr ubbi ng pr ocesses. The most popul ar

are descr i bed i n sect i on 2. 3- 3-

When descr i bi ng t he "basi c" gas pr oduct i on syst em i n r el at i on t o possi bl e

appl i cat i ons of gas/ l i qui d separ at or s one i mpor t ant di st i nct i on must be

made: whet her gas i s pr oduced on- or of f shor e.

-7-

Obvi ousl y, of f shor e oper at i ons wi l l i mpose ext r a demands on t he desi gn

pr ocedur e as t o si ze and wei ght of a separ at or , whi ch r esul t s i n ext r a

const r ai nt s. An ot her i mpor t ant aspect i s t hat t he f or m of t he basi c

f l owsheet f or of f shor e pr oduct i on/ pr ocessi ng may di f f er f undament al l y f r om

t he si mpl e onshor e f l owsheet . Because t he wat er cont ent can be ver y

har mf ul t o t he gas pi pe l i ne i t shoul d be r emoved as soon as possi bl e.

Thi s means t hat t he dehydr at i on of t he gas on a pr oduct i on pl at f or mhas t o

be suf f i ci ent t o pr event wat er condensat i on dur i ng pi pel i ne t r anspor t at i on

t o onshor e f aci l i t i es.

As ext r a under sea pi pel i nes ar e ver y expensi ve, t he l i qui d hydr ocar bons

condensed sof ar wi l l be t r anspor t ed wi t h t he gas i n one pi pel i ne t o be

separ at ed agai n onshor e. Thi s i mpl i es t hat t he second separ at i on st ep, whi ch

separ at es si mul t aneousl y t he wat er and t he condensat es, must be spl i t up

i nt o an of f shor e and an onshor e par t .

A schemat i c expl anat i on of t he above i s gi ven i n f i gur es 2. 1A and 2. I B.

produced

natural gas

1 f

wellhead

separation

'

Jsand

/

^ S

" condensate \

dehydration

\ '

salesgas

^ i I

^ condensate

produced

natural gas

w el l h ea d

sepa ra tion

offshore

dehydration

&

scrubbing

condensate

scrubbing

E

| salesgas

sand

water

condensate]

water |

condensate I

Fig. 2.1A Simplified onshore produo- Fig. 2. IB Simplified offshore produc-

tion flowsheet tion flowsheet

- 8-

2. 3 I nvent or y of separ at or l ocat i ons

2. 3. 1 I nt r oduct or y r emar ks

As descr i bed i n t he pr evi ous sect i on, t wo di f f er ent cr i t er i a char act er i ze

t he l ocat i on of a separ at or :

- whet her t he separ at i on st ep t akes pl ace up- or downst r eam i n t he pr ocess

f l owsheet ( wel l head separ at i on or scr ubbi ng/ dehydr at i on) ;

- whet her t he gas i s pr oduced on- or of f shor e.

The char act er i zat i on of each l ocat i on t akes pl ace by def i ni ng t he i nl et

condi t i ons and t he r equi r ement s of t he separ at i on oper at i on.

The i nl et condi t i ons ar e det er mi ned accor di ng t o t he f ol l owi ng pr oper t i es:

1. Physi cal pr oper t i es of gas phase; especi al l y gas densi t y t hat i s mai nl y

det er mi ned by oper at i ng pr essur e and gas composi t i on.

2. Physi cal pr oper t i es of l i qui d phase; especi al l y sur f ace t ensi on,

vi scosi t y and densi t y.

3. Dr op si ze di st r i but i on of l i qui d phase;

k. Gas t o l i qui d r at i o;

5. Occur r ence of possi bl e f oul i ng agent s ( sand, wax) i n gas.

The r equi r ement s accor di ng t o:

1. Separ at i on ef f i ci ency ( wi t h r espect t o mi st s, sl ugs and sol i ds) ;

2. Tur n down r at i o;

3. Al l owabl e pr essur e dr op;

4. Possi bl e si ze const r ai nt s.

Af t er char act er i zat i on of al l t he i ndi vi dual l ocat i ons t abl es 2. 1 and 2. I I

i n sect i on 2A gi ve a summar y of al l i nvent or i es.

2. 3. 2 Wel l head separ at i on

The condi t i ons under whi ch wel l head separ at i on must t ake pl ace ar e of t en

ext r eme. Gas pr essur es may r ange up t o 600 bar and er osi ve sol i d par t i cl es

may shor t en t he l i f et i me of t he i nt er nal s consi der abl y. The l i qui d i n t he

gas consi st s of wat er and hydr ocar bons, of whi ch t he dr opl et si ze depends t o

- 9-

a gr eat ext ent on r est r i ct i ons upst r eami n t he pi pi ng ( choke, sharp bends

et c. ) . Under cer t ai n condi t i ons f or mat i on of sl ugs may occur , f or i nst ance

wher e t he pr oduct i on l i ne r uns acr oss t he sea bot t om. The amount of l i qui d

i n t he gas f l ow depends gr eat l y on t he composi t i on of t he gas and di f f er ence

i n condi t i ons i n r eser voi r and separ at or . The l i qui d separ at i on ef f i ci ency

i s not of cr i t i cal i mpor t ance when di r ect l y downst r eam of t he wel l head

separ at or equi pment i s si t uat ed t hat causes condensat i on of mor e l i qui ds,

ei t her del i ber at el y ( heat exchanger s) or not ( choke val ves) . An ext r a

separ at or sect i on i s usual l y i nst al l ed af t er t he wel l head separ at or t o

pr event l i qui d over l oadi ng of t he next pr ocess oper at i ons.

The most i mpor t ant oper at i ng condi t i ons ar e:

- The f ormof t he l i qui d l oadi ng may var y f rommi st t o sl ug;

- Bot h sol i d ( sand) and l i qui d ( wat er and hydr ocar bon) par t i cl es may have t o

be separ at ed;

- Pr essur es may r ange up t o 600 bar , dependi ng on t he gasf i el d; t emper at ur es

up t o 80- 100"C;

and t he most i mpor t ant separ at or r equi r ement s:

- Abi l i t y t o separ at e par t i cul at es f romhi gh densi t y gasses;

- Wel l abl e t o separ at e sl ugs;

- Good separ at i on of sol i d mat er i al .

2. 3. 3 Scr ubbi ng

For good or der i t i s r epeat ed t hat t he word "scr ubbi ng" wi l l be used as t he

gener al t er m f or t hor ough separ at i on of l i qui ds f r om t he gas f l ow.

"Dehydr at i on" r ef er s speci f i cal l y t o t he r emoval of wat er f romt he gas.

Fr om t he f ol l owi ng i t wi l l be cl ear t hat some dehydr at i on pr ocesses can not

r esor t under gas/ l i qui d separ at i on as t hey r at her achi eve a gas/ gas

separ at i on. They ar e descr i bed i n t hi s chapt er because t hese dehydr at i on

pr ocesses ar e near l y al ways accompani ed by one or mor e gas/ l i qui d separ at i on

st eps, necessar y f or successf ul oper at i on.

The t wo basi c f or ms of scr ubbi ng/ dehydr at i on ar e:

1. Cool i ng t he gas beneat h t he speci f i ed dew poi nt and separ at i ng t he

condensed l i qui ds f romt he gas ( gas/ l i qui d separ at i on) ;

2. Dr yi ng t he gas wi t h desi ccant s.

- 10-

ad 1. Scr ubbi ng/ dehydr at i on by gascool i ng

Thi s dehydr at i on met hod i s bet t er known as Low Temper at ur e Separ at i on ( LTS) .

The gas i s cool ed down t o such a t emper at ur e t hat af t er separ at i on of t he

condensed l i qui ds t he gas wi l l r emai n dr y even at l ower pr essur es above t he

speci f i ed dew poi nt . The advant age of t hi s met hod i s t hat i n one separ at i on

st ep bot h wat er and hydr ocar bon condensat es ar e r ecover ed.

Ther e ar e t wo common ways of l ower i ng t he gas t emper at ur e:

1) By usi ng t he cool i ng t hat occur s when t he gas i s expanded adi abat i cal l y;

2) By r ef r i ger at i ng t he gas mechani cal l y, a met hod whi ch i s used when t he

wel l pr essur e i s al r eady t oo l ow f or t he above cool i ng met hod. Thi s

met hod has become popul ar i n onshor e oper at i ons i n The Net her l ands.

I n bot h cases l ar ge heat exchanger s ar e necessar y t o make ef f i ci ent use of

t he r ef r i ger at i on. I n t he second case l ar ge quant i t i es of ener gy ar e

consumed by t he mechani cal r ef r i ger at i on. Dependi ng on t he t her modynami cs of

a gi ven gas, separ at i on t emper at ur es down t o appr oxi mat el y -25 C may be

necessar y t o f ul f i l t he r equi r ement s f or sal es gas. These l ow t emper at ur es

ar e necessar y, as t he separ at i on t akes pl ace at consi der abl y hi gher

pr essur es t han at whi ch t he gas wi l l be t r anspor t ed i n t he di st r i but i on

net wor k ( see f or i nst ance f i gur e 2. 2) .

When t oo l ow t emper at ur es ar e r eached bef or e t he separ at i on st ep hydr at e

f or mat i on can occur i n t he gas. Ther ef or e, an ( hydr at e- ) i nhi bi t or ( i n most

cases di et hyl enegl ycol , DEG) i s i nj ect ed at , or upst r eam of , t he heat

exchanger . A possi bl e conf i gur at i on i s shown i n f i gur e 2. 3-

p

4

r| heatexchanger \*I

DEO

r ef r i g er at o r

-_

cold separator I

cold separator

L-J

glycol/water

N

condensate

heatexchanger

T

Fig. 2.2 Example of a phase loop Fig. 2.3 Simplified set-up of LTS process

- 11-

I n most cases a second, t andem ( f i l t er ) separ at or i s si t uat ed di r ect l y

downst r eam of t he " col d" separ at or as a measur e agai nst possi bl e

mal f unct i oni ng of t he l at t er . The separ at i on ef f i ci ency of t hi s f i l t er

separ at or must be as hi gh as possi bl e, because t he gas i s suppl i ed t o t he

sal es gas net wor k di r ect l y af t er t hi s separ at i on st ep.

Summar y of t he oper at i ng condi t i ons and r equi r ed pr oper t i es:

Ma in sepa ra tor

Oper at i ng condi t i ons: 1. For mof l i qui d l oadi ng: r angi ng f rommi st t o sl ug,

dependi ng on upst r eamf l owsheet and pi pi ng;

2. Li qui d l oadi ng: consi st i ng of gl ycol / wat er and

hydr ocar bons;

3. Pr essur es: r angi ng f r om appr oxi mat el y 70- 90 bar ;

t emper at ur es: down t o appr oxi mat el y - 25C.

Requi r ed pr oper t i es: 1. Hi gh/ Ver y hi gh ef f i ci ency on mi st s;

2. Ver y hi gh ef f i ci ency on sl ugs;

3. Low pr essur e dr op.

Tandemsepar at or

Oper at i ng condi t i ons: 1. As t he l i qui d of f er ed t o t hi s separ at or i s car r i ed

over f r om t he col d separ at or , i t wi l l gener al l y be

l ow i n concent r at i on and ver y f i ne;

2. See above;

3. See above.

Requi r ed pr oper t i es: 1. Ver y hi gh ef f i ci ency on mi st s;

2. Low pr essur e dr op.

I n bot h cases a l ow pr essur e dr op i s r equi r ed because t he gas del i ver ed t o

t he sal es gas net wor k has t o meet a cer t ai n mi ni mum pr essur e. The i nl et

pr essur e of t he separ at or has t o be chosen as cl ose as possi bl e t o t hi s

mi ni numpr essur e, because t he condensat i on of hydr ocar bons i ncr eases wi t h

decr easi ng pr essur e ( r et r ogr ade condensat i on) .

ad 2. Dehydr at i on by maki ng use of desi ccant s

Two t ypes of desi ccant s may be appl i ed: l i qui d or sol i d. Sol i d desi ccant s

( cal ci umchl or i de, si l i cagel ) ar e used when ext r emel y l ow wat er dew poi nt s

have t o be r eached, and/ or when onl y smal l amount s of gas have t o be

pr ocessed. Gener al l y, sol i d desi ccant s have l ower dr yi ng capaci t i es t han

- 12-

l i qui d desi ccant s. Thi s i s t he r eason why i ni t i al and oper at i ng cost s of a

dehydr at i on syst embased on a l i qui d desi ccant ar e l ower . As t he r ol e of t he

gas/ l i qui d separ at i on st ep i s onl y modest i n a sol i d desi ccant dehydr at i on

pr ocess, t he f ol l owi ng sect i on i s f ocussed on l i qui d desi ccant pr ocesses.

The by f ar most popul ar dehydr at i on pr ocess ( especi al l y of f shor e) , gl ycol

absor pt i on, i s descr i bed next .

Dehydr at i on by gl ycol absor pt i on ( l i qui d desi ccant )

The popul ar i t y of t hi s pr ocess i s due t o i t s compact ness, r obust ness and

easy oper at i on. Gas i s br ought i n cont act wi t h gl ycol ( i n most cases

t r i et hyl enegl ycol , TEG) i n a cont act i ng t ower . The gl ycol absor bs onl y wat er

vapour f romt he gas and i s r egener at ed.

A si mpl i f i ed f l owsheet i s depi ct ed i n f i gur e 2. 4. For t he si ze and ener gy

consumpt i on of t he gl ycol r egener at i on sect i on i t i s ver y i mpor t ant t hat t he

gas i s f r ee of condensed l i qui ds when i t ent er s t he cont act i ng t ower . Fr ee

hydr ocar bons wi l l hi nder wat er vapour absor pt i on.

water

\

glycol

regeneration

section

lean glycol

rich glycol

three-phase mixture

from well head

gl ycol /wat er

separation

section

contactor

section

*: pr esepar at or . ^

wmmm.

dried gas

free water S

condensates

Figure 2.4 Flowsheet of glycol dehydration unit

- 13-

Wat er and condensat e wi l l st r ongl y i ncr ease t he ener gy consumpt i on of t hi s

r egener at i on sect i on. An i nl et separ at i on sect i on i s si t uat ed di r ect l y

upst r eam of t he cont act i ng t ower t o el i mi nat e t hese l i qui ds. The speci f i c

desi gn of t hi s i nl et separ at or depends on t he amount and f or m of t he f r ee

l i qui ds i n t he gas and t hus on t he upst r eamf l owsheet and gas pr oper t i es.

Downst r eamof t he cont act i ng sect i on (i n t he t op sect i on of t he cont act i ng

t ower i t sel f or i n a separ at e vessel ) a second separ at i on sect i on i s

si t uat ed t o cat ch ent r ai ned gl ycol / wat er sol ut i on. Gl ycol l oss i s one of t he

par amet er s t hat i nf l uences t he economi cs of t hi s pr ocess. The i nl et

separ at or wi l l be ref erred t o as absor pt i on separ at or I , t he ent r ai nment

separ at or as absor pt i on separ at or I I .

For bot h separ at or s a summar y of t he oper at i ng condi t i ons and t he r equi r ed

pr oper t i es i s l i st ed bel ow.

Absorption sepa ra tor I

For mof l i qui d l oadi ng: r angi ng f rommi st t o sl ug;

Li qui d l oadi ng: consi st i ng of wat er , hydr ocar bons

and gl ycol or met hanol as hydr at e i nhi bi t or s

( dependi ng on pr ocess, see next sect i on) may be

pr esent ;

Pr essur es: r angi ng f rom70- 100 bar ; t emper at ur es:

appr oxi mat el y f rom25- 40C.

Ver y hi gh ef f i ci ency on mi st s;

2. Ver y hi gh ef f i ci ency on sl ugs;

3. Low pr essur e dr op ( except f or of f shor e appl i ca-

t i ons, see next sect i on) .

Oper at i ng condi t i ons:

Requi r ed pr oper t i es: 1.

Absor pt i on sepa ra tor I I

Oper at i ng condi t i ons: 1.

Requi r ed pr oper t i es:

As t hi s l i qui d i s car r i ed- over f romt he cont act i ng

sect i on, i t wi l l gener al l y be a mi st ;

Li qui d l oadi ng consi st s of gl ycol / wat er ;

See above.

Hi gh ef f i ci ency on gl ycol mi st s;

2. As f or pr essur e dr op: see above.

I n t he pr evi ous sect i on t he oper at i ng condi t i ons i n up- or downst r eam

posi t i ons have been descr i bed. I n t he next sect i on t he i nf l uence of on- or

of f shor e oper at i on i s el abor at ed.

- 1 1 -

2.^.k Of f shor e gas wi nni ng

The usual Nor t h- Sea gas t r eat ment consi st s of wel l head separ at i on f ol l owed

by gl ycol dehydr at i on. The hydr ocar bon condensat es separ at ed sof ar ar e

br ought back i n t he gas f l ow and separ at ed agai n onshor e. Ther e, t he f i r st

separ at i on i s car r i ed out by massi ve sl ug cat cher s t o accommodat e t he

accumul at ed sl ugs, of t en f ol l owed by a second coar se separ at i on st ep bef or e

t he gas i s br ought t o speci f i cat i ons by, i n many cases, LTS. Two common

al t er nat i ves exi st : gl ycol dehydr at i on t akes pl ace on t he pl at f or mon whi ch

t he wel l head separ at or i s si t uat ed ( si t uat i on I , t abl e 2. I I ) , or dehydr at i on

t akes pl ace on a cent r al pr ocessi ng pl at f or mt o whi ch mor e pr oduct i on uni t s

ar e connect ed ( si t uat i on I I ) . I n t he l at t er case hydr at e f or mat i on i s

possi bl e, as sea wat er t emper at ur es r ange down t o 3C. Ther ef or e, t o pr event

hydr at e f or mat i on met hanol mi ght be i nj ect ed i n t he gas f l ow seasonal l y, or

DEG per manent l y. I n t hi s way f r ee l i qui ds i n t he pi pel i ne may bui l d up t o

sl ugs. I n case of a combi ned pr oduct i on/ pr ocessi ng pl at f or m ( si t uat i on I I ) ,

t he, i nl et condi t i ons of t he dehydr at i on sect i on wi l l be much mor e

f avour abl e, because no gl ycol wi l l be pr esent as hydr at e i nhi bi t or and

pr obabl y no sl ugs wi l l have bui l t up upst r eam.

For t he wel l head separ at or onl y const r ai nt s wi t h r espect t o si ze and wei ght

ar e added t o t he r equi r ement s f or an onshor e separ at or . Thi s coul d i nf l uence

r equi r ement s concer ni ng t ur ndown r at i o as wel l : when t he r eser voi r pr essur e

decl i nes, vol umet r i c gas f l ow i ncr eases and causes t he need f or a l ar ger

capaci t y. Thi s pr obl emi s usual l y sol ved much easi er onshor e by pl aci ng a

second separ at or i n par al l el .

The i nl et condi t i ons of t he t wo al t er nat i ve si t uat i ons descr i bed above ar e

summar i zed i n t abl e 2. 1.

2. ^. 5 Onshor e gas wi nni ng

Onshor e t he si t uat i on i s much l i ke f i gur e 2. 1A, i n whi ch i n one si ngl e

scr ubbi ng st ep bot h t he wat er - and t he hydr ocar bon dew poi nt ar e br ought t o

speci f i cat i on ( si t uat i on I I I ) . I t i s possi bl e t o i nj ect a hydr at e i nhi bi t or

bet ween wel l head- and dehydr at i on- sect i on when l ow t emper at ur es ar e

expect ed. When l onger st r et ches of pi pel i ne r un bet ween t hese sect i ons sl ug

f or mat i on may occur .

- 15-

2.4 E valuation of separator i nlet conditions and requirements

In thi s section the information presented in 2.2 and 2.3 i s summarized.

^Separator location

I nlet conditions

Operating pressure (bar)

Liquid sorts

Liquid to gas kg/10

6

Nm

3

DSD

Fouling agents present

Well head separator

100 - 600

hc,w

1000 - 6000

m.sl

poss.

Pre-separator TEG

onshore offshore

s i t. I s i t. I I

- 70 - 100

hc.w.g hc.w hc.w.g

500 - 1000

ra,sl(?) m m,sl(?)

poss. poss. poss.

Post-separator TEG

onshore offshore

- 70 ~100

w,g w,g

100-500 100-500

m m

LTS (onshore)

(or separator of

similar function)

- 70

hC.W.n

100-1000

m,sl(?)

g =glycol he =hydrocarbon m = mist si =slug w =water

Table 2.1 Inventory of the inlet conditions of the separator locations

^Separator location

I nlet conditions

High sep. eff. on:

mist

slug

sand/wax

High turndown ratio

Low allowable press.drop

Small size

Well head separator

onshore offshore

d

C

c

d c

nc nc

d c

Pre-separator TEG

onshore offshore

s i t. I si t. I I

c * c c

c c c

c c c

d e c

nc/d nc nc

d e c

Post-separator TEG

onshore offshore

c c'

NA NA

NA NA

d c

nc/d nc

d c

LTS (onshore)

(or separator of

similar function)

c*

c

c

d

c

d

nc =not cri ti cal NA =not applicable d =desirable c =cri ti cal * d.

f l

" lOu

"

d

50 "

lv

Table 2. II Inventory of the corresponding requirements

Wi t h t he i nf or mat i on pr esent ed i n t hi s chapt er i t wi l l be possi bl e t o

r oughl y char act er i ze t he i nl et condi t i ons of a cer t ai n t ype of separ at or and

t he r equi r ement s i t shoul d f ul f i l . Not al l possi bl e f l owsheet conf i gur at i ons

wi t h r espect t o gas/ l i qui d separ at or s have been descr i bed, but t he maj or i t y

of appl i cat i ons i s cover ed.

I t appear s t hat i n pr act i ce i t i s ver y di f f i cul t t o quant i f y t he f ormof t he

l i qui d phase i n t he pi pel i nes mor e pr eci sel y. Of t en t he si ze and ar r i val

f requency of sl ugs ar e di f f i cul t t o pr edi ct . Mor eover , t he exact dr opl et

si ze di st r i but i on of a mi st i s an unknown f act or . As most separ at or

per f or mances depend t o a l ar ge ext ent on t he f ormof t he l i qui d phase, t hi s

l ack of knowl edge can i nt r oduce a consi der abl e uncer t ai nt y i n t he desi gn

pr ocedur es of separ at or s.

- 17-

3. PRESENT TECHNOLOGY

3-1 I ntroducti on

Thi s chapter gi ves an overview of present i ndustri al separati on techni ques.

Attenti on i s pai d to pri nci pl es of operati on, operati ng characteri sti cs and

presentl y avai l abl e desi gn procedures. As ther e ar e many di f f er ent

separati on devi ces (whi ch can, al one or i n combi nati on, form a practi cal

separator) most of the l i ter atur e searches that form the basi s of thi s

chapter are descri bed i n separate appendices to keep thi s overview readabl e.

The general structure of chapter 3

i s

given in figure 3-1- This figure also

gives an overview of the different separation devices that will be

discussed.

3. 1 I NTRODUCTI ON

3. 2 BASI C SEPARATI ON MECHANI SMS

3. 3 SEDI MENTATI ON

3. 3- 2 Knock- out vessel

3. 4 I NERTI A

3. 4. 2 Mesh t ype

3. 4. 3 Vane t ype

3. 4. 4 Cycl one t ype

3. 5 DI FFUSI ON

3. 6 PRACTI CAL FORMS OF SI NGLE AND MULTI PLE STAGE SEPARATORS

3. 7 EVALUATI ON OF PRESENT TECHNOLOGY

Figure 3.1 General struetwce of chapter 3

The t hr ee basi c physi cal separ at i on met hods ar e descr i bed br i ef l y i n sect i on

3. 2. The pr act i cal appl i cat i ons of each separ at i on met hod ar e char act er i zed

ext ensi vel y i n sect i ons 3 3~3 - 5 Fi gur e 3- 2 gi ves t he f or mof t he char ac-

t er i zat i on of each separ at i on devi ce ment i oned i n f i gur e 31

-18-

PRI NCI PLE OF OPERATI ON

Li t er at ur e sear ch

THEORETI CAL BACKGROUND

( appendi x)

1. Separ at i on ef f i ci ency

2. Maxi mum capaci t y

3. Pr essur e dr op

Li t er at ur e sear ch

DESI GN PROCEDURES

( appendi x)

1. Separ at i on ef f i ci ency

2. Maxi mum capaci t y

3. Pr essur e dr op

CHARACTERI STI CS OF SEPARATI ON DEVI CE

OPERATI NG CHARACTERI STI CS

a. Separ at i on ef f i ci ency

b. Thr oughput per uni t vol ume ( si ze)

c. Pr essur e dr op

d. Abi l i t y t o separ at e non- l i qui d

const i t uent s

e. Tur ndown r at i o

f . Capi t al and oper at i onal cost s

g. Ot her

AVAI LABLE DESI GN PROCEDURES

AND EXPECTED RELI ABI LI TY

I nf l uence of

1. Oper at i ng pr essur e

2. Li qui d l oadi ng

3. Physi cal pr oper t i es of

l i qui d

on

a. Separ at i on ef f i ci ency

b. Maxi mum capaci t y

c. Tur n down r at i o

d. Pr essur e dr op

Figure 3.2 Form of the characterization of the separation devices described

in 3. 3, 3.4 and 3. S

Fi rst, the general operating principles and possible practi cal variations of

the design are described. Subsequently, the operati ng and design charac-

teri sti cs are summarized according to the enumeration given in figure 3-2.

The two l i terature searches on which the above characteri zati ons are based

are given in appendix A under corresponding section numbers. One l i terature

study i s made of the theoreti cal background of the pri nci pl e of operation of

each separati on devi ce, the other of the available corresponding practi cal

design procedures. The expected rel i abi l i ty of these desi gn procedures i s

i ndi cated i n the tabl es that summarize thi s information further in thi s

chapter. The val i di ty of most of the design procedures i s establ i shed in

section lA.

After characterization of al l l i sted separati on devi ces, secti on 3-6 wi l l

descri be the most i mportant practi cal separators which are composed or

consi st of the earl i er described elements. Finally, section 3-7 wi l l give a

summary of the characteri sti cs of the nowadays most popular separator

designs.

- 19-

Thi s sect i on wi l l be concl uded wi t h t he def i ni t i ons of some of t he oper at i ng

char act er i st i cs t hat wi l l be used t o j udge t he capabi l i t i es of separ at or

devi ces on:

Separ at i on ef f i ci ency

The def i ni t i on of ef f i ci ency of a gas/ l i qui d separ at or i s si mpl e and

unambi guous. I f a gas/ l i qui d mi xt ur e ( charact eri zed by * , * . , dr opl et si ze

di st r i but i on ( dsd) and physi cal pr oper t i es) i s separ at ed, t he separ at i on

ef f i ci ency i s def i ned as n =_/ *

1

, i n whi ch _ i s t he f l ow of separ at ed

l i qui d ( f i gur e 3- 3) n depends on *

vl '

dsd, physical properti es of

ori gi nal mixture and separator geometry. A good physi cal model of the

behavi our of the separator (or desi gn procedure) should quanti fy the

influence of each variable on n . Design equations, however, usual l y apply

only under certai n circumstances and are specific for a certai n geometry.

FEED

0

9

,0

v1

,dsd

SEPARATOR

CLEAN GAS

0j ,0,3,dsd

LIQUID

0

2

Figure 3.3 Nomenclature of separator operation

Thr ough- put per uni t vol ume ( si ze)

Some separ at or geomet r i es can handl e l ar ger gas f l ows at a cer t ai n si ze t han

ot her s. Especi al l y f or of f shor e appl i cat i ons t hi s pl ays an i mpor t ant r ol e.

Tur ndown r at i o

The turndown rati o, defined as the rati o between minimum and maximum gas

flow at a certai n minimum separati on effi ci ency, i s i mportant when

vari ati ons in gas flow are expected.

Pr essur e dr op

The pr essur e dr op depends on t he same var i abl es as separ at i on ef f i ci ency.

I n cases i n whi ch t he pr essur e dr op acr oss t he separ at or i s cr i t i cal , i t i s

necessar y t o be abl e t o pr edi ct i t . I n most cases empi r i cal cor r el at i ons

exi st t hat ar e speci f i c f or a cer t ai n geomet r y.

- 20-

Abi l i t y t o separ at e non- l i qui d const i t uent s

I n chapt er 2 i t appeared t hat somet i mes non- l i qui d par t i cl es ( sand, wax) ar e

of f er ed t o separ at or s. Some separ at or s possess a geomet r y t hat i s not sui t ed

f or t he col l ect i on or dr ai nage of t hese const i t uent s. Apar t f romdi r ect

consequences wi t h r espect t o t he separ at i on ef f i ci ency of t hese component s,

exposi ng t he separ at or t o t hese subst ances can l ead t o pl uggi ng of i nt ernal

par t s. Thi s l eads t o det er i or at i on of t he separ at i on char act er i st i cs wi t h

r espect t o l i qui ds as wel l .

Capi t al and oper at i onal cost s

Thi s char act er i st i c evi dent l y has a st r ong i nf l uence on t he det er mi nat i on

whi ch sol ut i on wi l l be chosen f or a cer t ai n appl i cat i on. However , t he

f i nanci al cont ext of t hi s t echnol ogy st r ongl y depends on f act or s whi ch l i e

out si de t he scope of t hi s r epor t . Ther ef or e, i n t he next sect i ons onl y

gener al r ecommendat i ons ar e gi ven i f a choi ce has t o be made bet ween

t echni cal l y equi val ent al t er nat i ves.

3.2 Ba sic ga s/liquid sepa ra tion mecha nisms

I n gener al , a dr opl et i s consi der ed t o be separ at ed f r om t he car r i er gas

when i t comes i n t ouch wi t h obst acl es i n t he gas f l ow or when i t r eaches one

of t he wal l s (or ot her l i mi t at i ons) of t he space i n whi ch t he mi xt ur e f l ows.

The capt ur ed dr opl et coal esces i n a l i qui d f i l mon ei t her obst acl e or wal l ,

and i s t hen dr ai ned. The di f f er ent separ at i on mechani sms t hat wi l l be

descr i bed her eaf t er ai mat cr eat i ng a r el at i ve vel oci t y of t he dr opl et s i n

r espect t o t he gas. Thi s way dr opl et s ar e concent r at ed at speci f i c l ocat i ons

of t he separ at or , wher e t hey ar e capt ur ed and dr ai ned as descr i bed bef or e.

The di f f er ent separ at i on mechani sms ar e based on:

a. sedi ment at i on ( gravi t y set t l i ng) ;

b. i ner t i al f or ces;

c. di f f usi on;

d. el ectrostati c forces;

e. ul trasoni c agglomeration.

- 21-

Al t hough al l f i ve ment i oned pr i nci pl es have been appl i ed successf ul l y and

al t hough ul t r asoni c aggl omer at i on coul d of f er some ver y di st i nct advant ages

i n desi gni ng ver y compact separ at or s, onl y t he f i r st t hr ee are of i mpor t ance

i n t he pr esent gas/ l i qui d separ at i on t echnol ogy of t he oi l and gas i ndust r y.

For t hi s r eason onl y t hese mechani sms wi l l be pai d at t ent i on t o i n t he r est

of t hi s r epor t . Bef or e t he di f f er ent pr act i cal appl i cat i ons of t hese t hr ee

separ at i on mechani sms wi l l be descr i bed, some gener al t heor et i cal backgr ound

of each i s gi ven bel ow.

ad a. Sedi ment at i on ( gravi t y set t l i ng)

When l ower i ng t he vel oci t y of a gas/ l i qui d mi xt ur e suf f i ci ent l y, dr opl et s

can exper i ence consi der abl e i nf l uence of gr avi t y and wi l l set t l e down.

I f i t i s assumed t hat t he gr avi t y f or ce i s onl y opposed by t he drag f or ce

and t hat f or Re < 1 St okes' Law wi l l appl y, t he r el at i ve set t l i ng vel oci t y

can be quant i f i ed accor di ng t o equat i on 3- 1.

( P!

g a

P g

l 8 u

( 3- D

ad b. I ner t i al f or ces

The vel oci t y vect or of a dr opl et i n a non- r ect i l i near l y movi ng gas fl ow" wi l l

gener al l y not be i dent i cal t o t he vel oci t y vect or of t he gas f l ow at t hat

l ocat i on (at l east when p / p. . ) . The st r onger t he var i at i ons i n vel oci t y

and di r ect i on of t he gas and t he l ar ger t he mass of t he dr opl et , t he l ar ger

t he r el at i ve movement of t he dr opl et i n r espect t o t he gas f l ow ( see f i g.

3. 4) . When onl y dr ag f or ces are t aken i nt o account t he f ol l owi ng der i vat i ons

wi l l i l l ust r at e t he qual i t at i ve st at ement s above.

The dr ag f orce on t he par t i cl e:

F

D

( t) - J- n

2

D

C

D

. | p

g

( v

g

( t) - v

p

( t) )

2

(3.2)

The accel er at i on of t he par t i cl e under i nf l uence of

t hi s dr ag f or ce:

Figure 3.4

Inertia of particle

dv

d^

=

r d^p^pJ ^D- ^g

K

c

n

. ( v( t ) - v

p

( t ) r (3- 3)

- 22-

When v ( t ) i s known t he t raj ect ory of a par t i el e can be det er mi ned. I t can

t hen be pr edi ct ed under whi ch ci r cumst ances a dr opl et wi l l be capt ur ed.

ad c. Di f f usi on

Under i nf l uence of t he i mpact s of t he sur r oundi ng gas mol ecul es, ver y smal l

par t i cl es (d < 1 um) wi l l show r andommovement var i at i ons ( bet t er known as

Br owni an movement ) . The r el at i ve t r aj ect or y t hat t he dr opl et s t r avel under

i nf l uence of t hi s ef f ect i s usual l y ver y smal l . I t i s quant i f i ed as f ol l ows:

't RT K t

X = = Ei nst ei n and Smol uchowski (3-' t)

m

3 n u N D

P

i n which K =Stokes Cunningham Correcti on path; vari es between 1 (parti cl es

of 10 um) to 3"5. dependi ng on temperature ( par ti cl es of

0.1 pm)

N =Avogadro's number

R =gas constant

X =l ength of path

t = time

These t hr ee separ at i on mechani sms ser ve di st i nct l y di f f er ent pur poses.

Sedi ment at i on i s mai nl y appl i ed i n si t uat i ons i n whi ch i t i s necessar y t o

( pr e- ) separ at e l ar ge vol umes of coar se l i qui d el ement s. Thi s met hod i s

har dl y usef ul f or mi st separ at i on. I ner t i al separ at i on on t he ot her hand i s

mai nl y appl i ed i n si t uat i ons i n whi ch f ai r l y l ow vol umes of mi st have t o be

separ at ed and i s not sui t ed t o handl e hi gh l i qui d l oadi ngs. Di f f usi onal

separ at i on i s appl i ed when i t i s necessar y t o col l ect even t he f i nest

dr opl et s t o achi eve a ver y hi gh separ at i on ef f i ci ency. Onl y ver y l ow l i qui d

l oadi ngs can be of f er ed t o a separ at or based on t hi s pr i nci pl e.

The f ol l owi ng sect i ons descr i be pr act i cal appl i cat i ons of t hese t hr ee

separ at i on pr i nci pl es. Each descr i pt i on i s st r uct ur ed accor di ng t o f i gur e

3. 2. One shoul d bear i n mi nd t hat f or many separ at i ons i n pr act i ce

r equi r ement s have t o be f ul f i l l ed t hat can not be of f er ed by onl y one of

t hese t hr ee mechani sms. Ther ef or e, t he desi gns descr i bed i n t he f ol l owi ng

sect i ons shoul d r at her be r egar ded as modul es whi ch can f or m a compl et e

separ at or , somet i mes al one but most of t en wi t h ot her modul es.

- 23-

3- 3 Sedi ment at i on

3. 3- 1 Gener al aspect s

Sedi ment at i on ( gr avi t y set t l i ng) i s t he si mpl est and ol dest f or m of

gas/ l i qui d separ at i on. I t i s mai nl y used as a means t o separ at e coar se

l i qui d el ement s ( sl ugs and l ar ge dr opl et s) f romt he gas f l ow.

I n sect i on 3- 3. 2 at t ent i on wi l l be pai d t o t he f ol l owi ng t wo appl i cat i ons:

1. When mi st par t i cl es i n t he gas ar e not consi der ed det r i ment al t o f ur t her

gas handl i ng pr ocesses ( f or i nst ance i n f eed l i nes t o f l ar e- st acks) a

separ at or mi ght be based onl y on gr avi t y separ at i on.

2. Gr avi t y set t l i ng i s al so of t en used f or pr esepar at i ng t he bul k of t he

l i qui d i n a gas, so t hat her eaf t er t he gas f l ow i s sui t ed f or mi st

separ at i on. Thi s concept l eads t o compound separ at or s i n whi ch t he f i r st

st age r el i es on gr avi t y separ at i on.

3. 3. 2 Knock- out vessel s

1. Principle of opera tion

Two basi c separ at or t ypes exi st t hat make use of gr avi t y set t l i ng:

- Si mpl e separ at or s f or coar se separ at i on pur poses;

- Compound separ at or s, i n whi ch t he gas must be pr epar ed f or t he mi st

ext r act i on st age.

As t he most i mpor t ant geomet r i cal var i abl es have t o be det er mi ned i n an

anal ogous way f or bot h t ypes, no f ur t her di f f er ent i at i on wi l l be made i n

t hi s sect i on. I n l at er sect i ons at t ent i on wi l l be pai d t o separ at or s t hat

accommodat e mor e st ages.

Usual l y a separ at or maki ng use of t hi s pr i nci pl e, cal l ed "knock- out vessel ",

i s a l ar ge empt y hor i zont al or ver t i cal vessel ( f i gur es 3- 5 and 3- 6) i n

whi ch upon ent r ance a l ar ge r educt i on i n gas vel oci t y wi l l t ake pl ace.

I n a ver t i cal vessel t he dr opl et s, t hat have a t er mi nal set t l i ng vel oci t y

l ar ger t han t he upwar d gas vel oci t y, wi l l be separ at ed.

I n a hor i zont al vessel t he dr opl et s t hat r each t he gas/ l i qui d i nt er f ace

i nsi de t he vessel i n t he t i me t he gas passes t hr ough t he vessel wi l l be

separ at ed.

- 24-

tf^Z *\ Hit

t=d %

Figure 3.S Horizontal separator Figure 3.6 Vertical separator

I n bot h cases t he separ at ed l i qui d i s col l ect ed i n t he l ower par t of t he

vessel . The l i qui d dr ai nage vel oci t y i s chosen so t hat ent r ai ned gas bubbl es

ar e per mi t t ed t o escape t o t he sur f ace. I n t he desi gn of a knock- out vessel

i t i s ver y i mpor t ant t hat t he t wo- phase f l ow i s evenl y di st r i but ed acr oss

t he cr oss sect i on of t he separ at or . For t hi s pur pose a l ar ge var i et y of

most l y pr opr i et ar y i nl et devi ce desi gns exi st s ( f i g. 3- 7) .

A second pur pose of t he i nl et devi ces i s t o separ at e l i qui ds by i ner t i al

ef f ect s t hat ar e creat ed by t he t ur ni ngs i mposed on t he gas f l ow. One i ssue

not t o be over l ooked i n t hi s r espect i s t he f act t hat sharp t ur ni ngs of t he

gas f l ow, especi al l y t hose caused by baf f l e pl at es or i nversed cones and as

such meant t o i nvoke l ar ge i ner t i al f or ces, may adver sel y af f ect t he

f unct i oni ng of t he separ at or . Dr opl et s may be shat t er ed and r edi sper sed i n

t he gas f l ow at dr opl et si zes possi bl y smal l er t han t hose of f er ed t o t he

separ at or .

Figure 3.7A Inlet devices 1 and 2

- 25-

Figure 2. TB Inlet devices 3 and 4

2. Cha ra cteristics of knock-out vessels (see a ppendix A 3^ 3-2)

2. A Oper at i ng char act er i st i cs

- separ at i on ef f i ci ency

f l ow per uni t vol ume

t ur n down r at i o

pr essur e dr op

abi l i t y t o separ at e non-

l i qui d const i t uent s

i nst al l at i on and oper at i onal

cost s

: l ow f or mi st s; d

50

~ 150 umf or wat er / ai r

under at mospher i c condi t i ons

: l ow; f or ver t i cal separ at or s t he l oad

f act or A amount s t o 0. 07; f or hor i zont al

separ at or s t o 0. 15

(A =v ^H

gmax PJI - P

: no t heor et i cal l ower l i mi t t o gas vel oci t y

: l ow; det er mi ned mai nl y by si ze and shape

of i n- and out l et nozzl es

: r easonabl e

: as required surface area increases strong-

l y with i ncreasi ng pressure (v

- 1/ 2

gmax

) , cost s wi l l show same t endency ( f or

g

a gi ven const ant vol ume r at e)

2. B Avai l abi l i t y and r el i abi l i t y of desi gn pr ocedur es

I n t abl e 3. 1 t he avai l abi l i t y and expect ed r el i abi l i t y of di f f er ent desi gn

cor r el at i ons ar e summar i zed.

For t hese separ at or t ypes or - modul es t he det er mi nat i on of t he t ur n down

r at i o and pr essur e dr op i s ei t her t r i vi al or not of i nt er est .

- 26-

separ at i on ef f .

avai l abi l i t y

exp. r el i abi l i t y

ma x. ca pa city

avai l abi l i t y

exp. r el i abi l i t y

as a f unct i on

of geomet r y

+

+/ -

+

+

as a f unct i on

of oper . pr ess

+

+

+

as a f unct i on

of l i q. l oadi ng

-

as a f unct i on

of l i q. property

onl y densi t y

/ -

onl y densi t y

Table 3.1

3-4 Inertia l sepa ra tion

3. 4. 1 I nt r oduct or y r emar ks

To cl ean t he gas st r eam f r om smal l er par t i cl es t han can be achi eved

economi cal l y by gr avi t y separ at i on, t he mi st i s subj ect ed t o i ner t i al

f or ces. At pr esent t hree pr act i cal separ at or t ypes used f or mi st col l ect i on

ar e based on t hi s separ at i on mechani sm. They ar e descr i bed i n t he next t hree

sect i ons. The st r uct ur e depi ct ed i n f i gure 3- 2 and descr i bed i n sect i on 3- 1

wi l l be used.

3. 4. 2 I ner t i al separ at i on by mesh t ype separ at or s

1. Principle of opera tion

The most common way t o i nduce var i at i ons i n t he gas f l ow di r ect i on i s t o

pl ace wi r e mesh i n t he gas f l ow. The wi r e mesh consi st s of mul t i pl e l ayers

of bl anket s consi st i ng of asymmet r i cal i nt er l ocki ng l oops of wi r e.

As t he gas cont ai ni ng ent r ai ned dr opl et s passes t hr ough a wi r e mesh, t he gas

easi l y f i nds i t s way r ound t he wi r es, whi l e t he dr opl et s, whi ch ar e heavi er ,

can not t ake t he t ur ns and i mpi nge on t he wi r es ( f i g. 3- 8) .

Figure 3.8 Principle of wire mesh separation

- 27-

The separ at ed dr opl et s f ormf i l ms ar ound t he wi r es t hat r un down t hrough t he

mesh pad. At t he under si de of t he pad t he f i l ms br eak up i nt o l ar ge dr opl et s

t hat f al l back agai nst t he gas f l ow. The most common met al mesh t ype used i s

appr oxi mat el y 0. 3 > i n di amet er , t he average por osi t y i s appr oxi mat el y 97%

whi l e t he t ot al hei ght of t he pad usual l y has a val ue of 100 mm.

The t wo most popul ar possi bi l i t i es of appl i cat i on of a mesh pad ar e depi ct ed

i n f i gur es 3- 9 and 3- 10.

t?

^

Figure 3.9 Vertical mesh pad Figure 3.10 Horizontal mesh pad

The f ol l owi ng descr i pt i ons and concl usi ons wi l l al l r el at e t o t he ver t i cal l y

f l owed t hr ough meshpad ( f i gur e 3- 9) They ar e al so i ndi cat i ve f or t he

hor i zont al l y f l owed t hr ough ver si on.

2. Cha ra cteristics of meshtype sepa ra tors

2. A Oper at i ng char act er i st i cs

- separ at i on ef f i ci ency

- f l ow per uni t vol ume

- t ur n down r at i o

- pr essur e dr op

- abi l i t y t o separ at e non-

l i qui d const i t uent s

- i nst al l at i on and oper at i onal

cost s

hi gh; d

so

~ 5 Pi

l ow; i f v

gmax

r

P

l "

P

g

A J *t hen

P

g

A * 0, 11 f or most appl i cat i ons

1/ 3 (1 bar , dr opl et si zes > 10 um)

l ow, AP ~ 5 mbar ( wat er / ai r , 1 bar )

ver y poor

rel at i vel y hi gh because of l ar ge r equi r ed

pl an ar ea

- 28-

2. B Avai l abi l i t y and r el i abi l i t y of desi gn pr ocedur es

I n t abl e 3- I I t he avai l abi l i t y and expect ed r el i abi l i t y of di f f er ent desi gn

cor r el at i ons ar e summar i zed.

as a f unct i on

of geomet r y

as a f unct i on

of oper . pr ess

as a f unct i on

of l i q. l oadi ng

as a f unct i on

of l i q. property

separ at i on ef f .

avai l abi l i t y

exp. r el i abi l i t y

ma x. ca pa city

avai l abi l i t y

exp. r el i abi l i t y

turndown ra tio

avai l abi l i t y

exp. r el i abi l i t y

pressure drop

avai l abi l i t y

exp. r el i abi l i t y

+

+/ -

? *

? *

cruci al desi gn i nf or mat i on

Table 3. II

3.4.3 I nerti al separation with vane-type separators

1. Principle of operation

Vane-type separators general l y consi st of a seri es of narrowly spaced

uniformly tortuous plates positioned in paral l el to the direction of the gas

flow. The gas flow has to make more or l ess sharp turns through the free

spaci ngs between the plates (fi g. 3- H)- The entrained droplets will not be

able to follow these changes of di recti on and wi l l impinge on the pl ates.

The l i qui d film which i s formed thi s way i s drai ned from the separation

chamber.

Figure 3.11 Principle of vane type separation

- 29-

Desi gns f or ver t i cal l y f l owed t hr ough vane- t ype separ at or s

For vane- t ype separ at or s t hat f l ow t hr ough ver t i cal l y, desi gns exi st i n

whi ch t he l i qui d i s dr ai ned t hr ough shi el ded sl ot s ( f i g. 3- 12) . Al so si mpl er

vane- t ype desi gns exi st i n whi ch t he l i qui d i s dr ai ned count er cur r ent l y i n

di r ect cont act wi t h t he gas f l ow ( f i g. 3- 13)

Figure 3.12 Shielded liquid drainage Figure 3.13 Counter-current drainage

Desi gns f or hor i zont al l y f l owed t hr ough vane- t ype separ at or s

Hor i zont al l y f l owed t hr ough vane- t ype separ at or s ( f i gure 3. 1*0 near l y al l

f eat ur e shi el ded l i qui d dr ai nage. Ther e i s l i t t l e quant i t at i ve i nf or mat i on

on t he i nf l uences of vane- bl ade geomet r y. Al t hough not al ways acknowl edged,

t he desi gn of t he f l ow pat h and t he posi t i oni ng of t he dr ai nage scoops or -

sl i t s i s cr uci al f or hi gh t hr ough- put oper at i on. Gar dner [ 1977] ment i ons t he

occur r ence of r i bbons of dr ai ni ng l i qui d i n f r ont of t he act ual dr ai nage

sl i t s whi ch pr obabl y means t hat eddi es ar e gener at ed at det r i ment al l oca-

t i ons, t hus pr event i ng t he l i qui d f romdr ai ni ng i n t he sl i t s. I n appendi x A

3. ^. 3 some, t o a l ar ge ext ent usel ess, at t empt s t o quant i f y t he i nf l uences

of some desi gn par amet er s are r epor t ed. The possi bi l i t i es t o opt i mi ze vane

pr of i l es and geomet r i es f or speci f i c appl i cat i ons ar e f ul l y not expl oi t ed.

Figure 3.14 Horizontal vane design

- 30-

Fi gur es 3. 15A and B show t wo separ at or desi gns based on hor i zont al l y f l owed

t hr ough vane packs and f i gur e 3- 15C one based on a ver t i cal l y f l owed t hrough

vane pack ( wi t h i nt er nal dr ai nage) .

a

^ ^

P=

Figures 3.15A and B Horizontally flowed

through vane packs

Figure 3.ISC Vertically flowed

through vane packs

2. Characteristics of vane type separators

2.A Operating characteri sti cs

- separation efficiency

- flow per unit volume

turn down rati o

good; d

50

=7-20 pm, depending on design

i n case of shi el ded l i qui d drai nage

(reentrainment-limited): high (v ~ 8-9

m/s, corresponding A ~0.3 (the use of the

load factor i s quite inappropriate i n.thi s

case; see appendix A, page A.11), water/

ai r, 1 bar); in case of fl oodi ng l i mi ted

operati on: medium (v ~ 5

_

6 m/s,

v

gmax