Professional Documents

Culture Documents

Visual Inspection of Welds

Visual Inspection of Welds

Uploaded by

vsnaiduqcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visual Inspection of Welds

Visual Inspection of Welds

Uploaded by

vsnaiduqcCopyright:

Available Formats

Visual Inspection Of Welds (VT)

Visual Inspection Of Welds (VT)

Failure Due To Brittle Cracking

Visual Inspection Of Welds (VT)

Prerequisites

As with any other non destructive inspection

method, there are various prerequisites that should

be considered prior to performing visual

examination.

Some of the more common attributes to consider are

discussed as follows:

Visual Inspection Of Welds (VT)

Visual Acuity

One of the most obvious prerequisites is that the visual

examiner should have sufficient visual acuity to

perform an adequate inspection.

Consideration should be given to near and far vision

with natural or corrected vision.

Visual Inspection Of Welds (VT)

Visual Acuity

A documented periodic visual inspection of the

requirement of many codes & specifications and is

generally considered good practice.

An eye examination by a qualified examiner is a

prerequisite for the certification by AWS as a Certified

Welding Inspector (CWI) or A Certified Associate

Welding Inspector (CAWI). CSWIP Visual Inspector

or Welding Inspector.

Visual Inspection Of Welds (VT)

Experience & Training

Another obvious prerequisite is that the visual

inspector should have sufficient knowledge and skill

to perform the examination successfully and

meaningfully.

Knowledge and skill can be imparted or obtained

through the education and training processes. Both

method can be formal (classroom) or on the job.

Visual Inspection Of Welds (VT)

Sufficient time should be allowed for different

individuals to properly grasp key points pertaining to:

Joint Preparations

Welding preheat

Interpass temperature

Weldment distortion

Welding consumables and other materials.

Additionally, sufficient exposure to the many types of

workmanship variances should be allowed.

Visual Inspection Of Welds (VT)

Certification Programme

To provide assurance that visual inspectors are

qualified (that is, sufficient prerequisites are obtained

and maintained), it may be desirable to have visual

inspection personnel formally certified. Certification is

a testimony of qualification.

Visual Inspection Of Welds (VT)

Certification Programme

The American Welding Society offers Certified Welding

Inspector (CWI) and Certified Associate Welding

Inspector (CAWI) programme.

Other programme such as TWI / CSWIP also offers

such programme.

Visual Inspection Of Welds (VT)

Safety

Visual

inspectors

should

receive

sufficient

indoctrination on welding safety practices. There are

many potential safety hazards present (electricity,

gases, fumes, ultraviolet light, heat, etc.).

Visual Inspection Of Welds (VT)

Fundamentals Of Visual Inspection.

Many programme instituted by the manufacturer or

fabricator to control quality of the products utilise visual

examination as the primary, and in some instances the

only, evaluation method of inspection.

It can be an invaluable tool when properly applied. In

addition to locating surface flaws, visual examination

can be an excellent process control technique to help

identify subsequent fabrication problems.

Visual Inspection Of Welds (VT)

Visual examination is a method for identifying surface

flaws

and

imperfections.

Consequently,

any

conscientious quality control programme consisting

essentially of visual inspection should include a

continual sequence of examinations performed during

all phases of fabrication.

This will allow visual inspection of the exposed

surfaces as they occur in the fabrication sequence.

Visual Inspection Of Welds (VT)

Discovery and repair of any defects at that time results

in substantial cost reduction.

It has been shown that a conscientious programme of

visual inspection occurring before, during, and after

welding can result in discovery of the majority of all

defects which would have been detected later using

more expensive test methods.

Visual Inspection Of Welds (VT)

The effectiveness of visual inspection is improved

when a system is instituted which provides for

coverage at all phases of the welding process (before,

during, and after welding).

The sooner the examination process is introduced into

the system, the better the coverage.

Visual Inspection Of Welds (VT)

Inspection Prior To Welding.

Prior to welding, some typical action items requiring

attention by the visual inspector include:

Review drawings and specification

Check qualification of procedures and personnel to be

utilised

Establish check points

Set up a plan for the recording of results

Review materials to be utilised

Visual Inspection Of Welds (VT)

Inspection Prior To Welding.

Check for base metal discontinuities

Check fit-up and alignment of weld joints

Check preheat, if required

If the inspector pays particularly close attention to

these preliminary items, many problems which might

occur later can be prevented. It is very important that

the inspector knows exactly what requirements are to

be met. Governing construction codes and

specifications will provide these data.

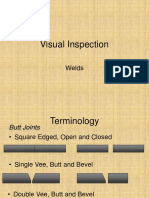

Joint Configuration

Visual Inspection Of Welds (VT)

Hold Points.

Consideration should be given to the establishment

of hold points or check points where an examination

is to occur prior to the accomplishment of any further

fabrication steps.

This is of utmost importance on large construction

projects or massive welded fabrications.

Visual Inspection Of Welds (VT)

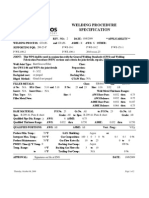

Welding Procedures

Another preliminary step which should occur is to

ensure that the applicable welding procedures comply

with the job requirements.

The proper documentation of the qualification or

certifications of the individual welders should be

reviewed. The drawings and specifications will dictate

what base metals are to be joined and what filler metal

will be utilised.

Visual Inspection Of Welds (VT)

Welding Procedures

For structural welding and other critical applications,

welding is normally carried out in accordance with

qualified procedures which record the essential

variables of the process and by welders qualified for

the process, material, and position to be welded.

Additional procedural steps might be needed to

accommodate certain materials. An example of a

procedural step is that when low-hydrogen electrodes

are specified, storage facilities as recommended by

the manufacturer are required.

Visual Inspection Of Welds (VT)

Base Materials.

Prior to welding, identification of the material type and

a thorough examination of the specific base metal

should be made. If a discontinuity, such as a plate

lamination, is present and remains undetected, it may

affect the overall structural integrity of the weldment.

Very often, a lamination will be visible along plate

edge, especially on a flame cut edge.

Visual Inspection Of Welds (VT)

Joint Fit-up.

For a weld, the most critical part of the base material is

that area which has been prepared to accept weld

metal in some form of joint shape. The importance of

the joint fit prior to welding cannot be stressed enough.

Therefore, the visual examination of joint fit-up is of

highest priority.

Visual Inspection Of Welds (VT)

Joint Fit-up.

Items that may be considered prior to welding include:

Groove angle

Root opening

Joint alignment

Backing

Consumable insert

Joint cleanliness

Tack welds

Preheat

Visual Inspection Of Welds (VT)

Joint Preparation / Fit-up

Visual Inspection Of Welds (VT)

Joint Preparation

Visual Inspection Of Welds (VT)

Preheating

Visual Inspection Of Welds (VT)

Preheating

Visual Inspection Of Welds (VT)

Joint Fit-up.

All of these factors could have a direct bearing on the

resultant weld quality. If the fit-up is poor, then the

weld will most likely be of substandard quality as well.

Extra care taken during the joint assembly can greatly

improve welding effectiveness.

Sometimes, examination of the joint prior to welding

will reveal irregularities within code limitations, but

these becomes areas of concern and can be watched

carefully during later stage.

Visual Inspection Of Welds (VT)

Joint Fit-up.

For example, if a T-joint for fillet weld exhibits an

excessive root opening, the size of the required fillet

weld should be increased by the amount of the root

opening present.

So, if the inspector knows that this situation exists, the

drawing or weld joint can be marked accordingly, and

final determination of weld size compliance can be

correctly interpreted.

Joint Fit-up - Excessive Gap

Visual Inspection Of Welds (VT)

During Welding.

During welding, there are a number of items which

require control so that the resulting weld will be

satisfactory. Visual examination is the primary method

for controlling this aspect of the fabrication.

Visual Inspection Of Welds (VT)

During Welding.

Some of these aspects of fabrication which can be

checked include:

Quality of weld root bead

Joint root preparation prior to welding the second side

Preheat and interpass temperature

Sequence of weld pass

Subsequent layers for apparent weld quality

Cleaning between passes

Conformance with the applicable procedure; i.e. voltage,

amperage, heat input, speed, etc.

Visual Inspection Of Welds (VT)

Weld Root Pass

Perhaps the most critical part of any weld is the weld

root pass. Problems which exist at this point in the

progression combine to make the successful

completion of the balance of the weld difficult to

accomplish.

Consequently, many defects which are later

discovered in a weld associated with the weld root

bead.

Visual Inspection Of Welds (VT)

Weld Root Pass

Another critical joint root condition exists whenever

second side treatment is applied to a double welded

joint. This usually includes removal of slag and other

irregularities by chipping, thermal gouging, or grinding.

Once this removal process has been accomplished,

examination of the excavated area prior to welding the

second side is required. This is to assure that all

discontinuities have been removed.

Visual Inspection Of Welds (VT)

Preheat & Interpass Temperature

Preheat & interpass temperature can be critical and,

if specified, be measured. The limits are often

described as a minimum, a maximum, or as both.

Also, to help in controlling the amount of heat in the

weld zone, the sequence and placement of the

individual passes can be important.

Visual Inspection Of Welds (VT)

Preheat & Interpass Temperature

The inspector should always be conscious of the

extent and location of any distortion or shrinkage

caused by the welding heat.

Often, corrective measures can be taken as the

welding heat progresses to alleviate the problem.

Visual Inspection Of Welds (VT)

Between Layer Examination

To evaluate the quality of the weld as work progress, it

is prudent to examine each layer visually to judge its

integrity.

This also provides a check to determine if adequate

cleaning is being accomplished between passes. This

may help to alleviate the occurrence of slag inclusions

in the final weld.

Visual Inspection Of Welds (VT)

Between Layer Examination

Many of these items may be addressed in the

applicable welding procedure. In that case, visual

inspection performed during the welding is basically a

check to determine id there is compliance with the

requirements of the welding procedure.

Visual Inspection Of Welds (VT)

After Welding.

Many people feel that visual inspection commences

once the welding has been completed.

However, if all the previously discussed steps have

been taken before and during welding, this final phase

of visual inspection will be accomplished easily. It will

simply provide a check to be sure that the steps taken

have resulted in a satisfactory weld.

Visual Inspection Of Welds (VT)

Some of the various items which require attention

after welding has been completed are:

Final weld appearance

Final weld size

Weld length

Dimensional accuracy

Amount of distortion

Post weld heat treatment.

Visual Inspection Of Welds (VT)

Final Weld Inspection

The basic purpose of final weld inspection is to assure

the welds quality. Therefore, visual examination of

several things are required.

Most codes and specifications describe the extent of

discontinuities that are acceptable, and many of these

can occur on the surface of the completed weld.

Visual Inspection Of Welds (VT)

Discontinuities

Typical discontinuities in found in welds are:

Porosity

Incomplete fusion

Incomplete joint penetration

Undercut

Overlap

Cracks

Slag Inclusion

Excessive reinforcement.

Weld Discontinuities

Visual Inspection Of Welds (VT)

Weld Discontinuities

Visual Inspection Of Welds (VT)

Discontinuities

While code requirements may permit limited amounts of

some of these discontinuities, cracks and incomplete

fusion defects are not allowed.

For structures exposed to cyclic or fatigue loading, the

criticality of these surface discontinuities is increased. In

conditions such as these, visual examination of the

surface may be the most important inspection which can

be performed.

Visual Inspection Of Welds (VT)

Discontinuities

The existence of undercut, overlap and improper contour

results in stress raisers; fatigue loading can cause

premature failures which propagate from these

discontinuities.

This is why, often the proper contour of a weld can be

much more important than the actual weld size, since a

slightly undersized weld, free from abrupt surface

irregularities, could perform more satisfactorily than a

weld of adequate size exhibiting a poor contour.

Visual Inspection Of Welds (VT)

Discontinuities

To determine if compliance has been attended, the

examiner should check to see if all welds meet drawing

requirements for size and location. Fillet size can be

determined by using one or several types of weld gauges to

provide a more efficient and accurate measurement of size.

Groove welds should be measured for proper

reinforcement on both sides of the joint. Some conditions

may require the fabrication of special weld gauges

Visual Inspection Of Welds (VT)

Post Weld Heat Treatment

Due to size, shape, or base metal type, post weld heat

treatment may be specified in the welding procedure.

This may involve only the application of heat at or near

the interpass temperature range to provide a post weld

condition that will aid in metallurgical control of the final

weldment properties. Heating at the interpass

temperature will not affect the microstructure.

Visual Inspection Of Welds (VT)

Post Weld Heat Treatment

Some conditions may require the accomplishment of a

thermal stress relief treatment. Here, the weldment is

gradually heated at a prescribed rate to the stress

relief range of 590 C to 650 C for most carbon steel.

After holding at this temperature for one hour for each

once of base metal thickness, then weldment is

allowed to cool to about 315 C at a control rate.

Visual Inspection Of Welds (VT)

Final Dimensional Examination

Another measurement that affects the performance of

a weldment is its dimensional accuracy. If a welded

part will not fit an assembly, it may be useless, even

though the weld is of adequate quality.

Visual Inspection Of Welds (VT)

Welding heat will distort the base metal, and can alter

overall component dimensions.

Therefore, dimensional examination after welding may

be required to determine the weldmentss fitness for its

intended use.

Visual Inspection Of Welds (VT)

Discontinuities & Defects

A discontinuity is defined as an interruption of the

typical structure of a weldment, such as lack of

homogeneity in the mechanical, metallurgical, or

physical characteristics of the material or weldment.

A discontinuity is not necessarily a defect.

Discontinuities are rejectable only if they exceed

specification requirements in terms of type, size,

distribution, or location.

Visual Inspection Of Welds (VT)

Discontinuities & Defects

A rejectable discontinuity is referred to as defects. By

definition, a defect is a discontinuity whose size,

shape, orientation, or location makes it detrimental to

the useful service of the part in which it occur.

Discontinuities may be found in the weld metal, heat

affected zone, or base metal of many weldments.

Visual Inspection Of Welds (VT)

Four basic weld joints are considered in this

presentation:

Butt

T

Corner

Lap

Visual Inspection Of Welds (VT)

Discontinuities & Defects

Weld and base metal discontinuities of specific types

are more common with certain welding processes and

joint details are used.

An example is the tungsten inclusion, which only

occurs in welds made using gas tungsten arc welding.

Visual Inspection Of Welds (VT)

Discontinuities & Defects

Other conditions, such as high restraint and limited

access to portions of a weld joint, may lead to a higher

than normal incidence of weld and base metal

discontinuities.

Visual Inspection Of Welds (VT)

Porosity

Porosity is characterised by cavity type discontinuities

formed by gas entrapment during solidification. The

discontinuity formed is generally spherical but may be

cylindrical.

Often, porosity is an indication that the welding

process is not being properly controlled, or the base

metal or filler metal is contaminated, or that the base

metal is of a composition incompatible with the filler

metal or process.

Visual Inspection Of Welds (VT)

Porosity

Visual Inspection Of Welds (VT)

Porosity

Visual Inspection Of Welds (VT)

Scattered Porosity

Scattered porosity is porosity widely distributed in a

single weld bead or in several beads of a multi pass

weld. Porosity will be present in a weld if the welding

technique, or material used or the conditions of the

weld preparation, lead to gas formation and

entrapment.

If weld cool slowly enough to allow gas to pass to the

surface before weld solidification, there will generally

be no porosity in the weld.

Visual Inspection Of Welds (VT)

Cluster & Linear Porosity

Cluster porosity is a localised group of pores. It often

results from improper starting and stopping of welding

pass. Conditions causing arc blow can also result in

cluster porosity.

Linear porosity is a number of pores which are aligned.

It often occur along the weld interface, the weld root, or

an inter-bead boundary, and developed by

contamination that causes gas to be liberated at those

locations.

Visual Inspection Of Welds

(VT)

Linear & Clustered

Porosities

Visual Inspection Of Welds (VT)

Incomplete Fusion

Incomplete fusion is termed as fusion which does not

occur over the entire base metal surfaces intended for

welding and between all adjoining weld beads.

Incomplete fusion can result from insufficient heat

input or the improper manipulation of the welding

electrode. While it is a discontinuity more commonly

associated with weld technique, it could also be

caused by the presence of contaminants on the

surface being welded.

Visual Inspection Of Welds (VT)

Incomplete Fusion

Visual Inspection Of Welds (VT)

Incomplete Fusion

Visual Inspection Of Welds (VT)

Incomplete Fusion

Visual Inspection Of Welds (VT)

Incomplete Joint Penetration

Incomplete joint penetration is defined as penetration by

weld metal that does not extend for the full thickness of the

base metal in a joint with a groove weld.

Incomplete penetration may result from insufficient welding

heat, improper lateral control of the welding arc, or improper

joint configuration. Some welding process have greater

penetrating ability than others and would therefore be less

susceptible to this problem. Pipe welds are especially

vulnerable to these discontinuities, since the joint is usually

inaccessible for welding from the root side.

Visual Inspection Of Welds (VT)

Incomplete Joint Penetration

Visual Inspection Of Welds (VT)

Undercut

Undercut creates a transition which should be

evaluated for a reduction in cross section, and for

stress concentrations or notch effect when fatigue is a

consideration.

Undercuts, controlled within the limits of the

specification, is not usually considered a weld defect.

Undercut is generally associated with improper

welding technique or weld parameters, excessive

welding current or voltages or both.

Visual Inspection Of Welds (VT)

Undercut

Visual Inspection Of Welds (VT)

Undercut

Visual Inspection Of Welds (VT)

Underfill

Underfill is a depression on the weld face or root

surface extending below the adjacent surface of the

base metal. Underfill is usually defined as a condition

where the total thickness through a weld is less than

the thickness of the adjacent base metal.

It results from the failure of a welder or welding

operator to completely fill the weld joint, and is rarely

acceptable.

Visual Inspection Of Welds

(VT)

Underfill

Visual Inspection Of Welds (VT)

Overlap

Overlap is the protrusion of weld metal beyond the

weld toe, or weld root. It can occur as a result of poor

control of the welding process, improper selection of

welding materials prior to welding.

If there are tightly adhering oxides on the base metal

that interfere with fusion, overlap will often result.

Overlap is a surface discontinuity that forms a

mechanical notch, is often considered rejectable.

Visual Inspection Of Welds (VT)

Overlap

Visual Inspection Of Welds (VT)

Overlap

Visual Inspection Of Welds (VT)

Lamination

Laminations are flat, generally elongated, base metal

discontinuity usually found at the centre of wrought

product.

Lamination can be completely internal, and are then

only detected non destructively by ultrasonic testing.

They may also extend to an edge or end where they

are visible at the surface and may be detected by

visual, penetrant, or magnetic particle testing. They

may also be revealed when exposed by cutting or

machining operations.

Visual Inspection Of Welds (VT)

Lamination

Laminations are formed when gas voids, shrinkage

cavities, or non metallic inclusions in the original ingot are

rolled flat. They generally run parallel to the surface of

rolled products and are most commonly found in bars

and plates.

Some laminations are partially forged welded along their

interface by high temperature and pressure of the rolling

operation. Tight laminations will sometimes conduct

sound across the interface and, therefore, may not be

fully evaluated / detected by ultrasonic testing.

Visual Inspection Of Welds (VT)

Lamination

Laminar Tearing

Visual Inspection Of Welds (VT)

Cracks

Cracks form in the weld and base metal when localised

stresses exceed the ultimate strength of the material.

Cracking may occur at evaluated temperatures during

weld solidification, or after solidification, when the

weldment has equalised in temperature.

Cracking is generally associated with stress amplification

near discontinuities in welds and base metal, or near

notches associated with the weld joint design. Welding

related cracks are generally brittle in nature, exhibiting

little plastic deformation at the crack boundaries.

Visual Inspection Of Welds (VT)

Cracks

Cracks can be classified as either hot cracks or cold

cracks. Hot cracks develop at elevated temperatures.

They form on solidification of the metal at temperature

near the melting point. Cold cracks develop after

solidification id complete.

Cracking associated with hydrogen embrittlement,

commonly referred to as delay cracking, is a form of

cold cracking. Hot cracks propagate along grain

boundaries and through grains.

Visual Inspection Of Welds (VT)

Various Types Of Cracks

Visual Inspection Of Welds (VT)

Crack Orientation.

Crack orientation may be termed longitudinal or

transverse, depending on the crack direction with respect

to the weld axis. When a crack is parallel to the axis of

the weld, it is called a longitudinal crack, regardless of

whether it is a centerline crack in the weld metal or a toe

crack in the heat affected zone of the base metal.

Transverse cracks lie perpendicular to the weld axis. This

may be limited in size and confined to the weld metal or

they propagate from the weld into the adjacent heat

affected zone and into the base metal.

Visual Inspection Of Welds (VT)

Crack Orientation.

In some weldments, transverse cracks will form in the

heat affected zone and not in the weld.

Longitudinal cracks in welds, made by machine

welding, are commonly associated with high welding

speed and are sometimes related to porosity that does

not showed at the weld face. Welds having high depth

to width ratios may also be susceptible to longitudinal

cracking due to the resulting solidification patterns.

Visual Inspection Of Welds (VT)

Longitudinal Verses

Transverse Crack.

Visual Inspection Of Welds (VT)

Throat Cracks

Throat cracks are longitudinal cracks in the weld face

in the direction of the weld axis. They are generally,

but not always hot cracks.

Visual Inspection Of Welds

(VT)

Solidification Cracking

Visual Inspection Of Welds (VT)

Solidification Cracking

Visual Inspection Of Welds (VT)

Root Cracks.

Root cracks are longitudinal cracks in the weld root.

They are generally hot cracks.

Visual Inspection Of Welds

(VT)

Root Cracks

Visual Inspection Of Welds (VT)

Crater Cracks

Crater cracks occur in the weld crater and are formed

by improper termination of welding arc. A non standard

term for crater cracks is star cracks though they may

have other shapes. Crater cracks are shallow hot

cracks usually forming a multi-pointed star-like cluster.

Visual Inspection Of Welds (VT)

Crater Cracks

Visual Inspection Of Welds (VT)

Toe Crack

Toe cracks are generally cold cracks. They initiate and

propagate from the weld toe where restraint stresses are

highest. Abrupt profile changes at the toe caused by

excessive convexity or weld reinforcement can amplify

stresses, making the weld toe a more likely area for

cracking to occur.

Toe cracks initiate approximately normal to the base

metal surface. These cracks are generally the result of

thermal shrinkage stresses acting on the weld heat

affected zone.

Visual Inspection Of Welds (VT)

Toe Cracks

Visual Inspection Of Welds (VT)

Underbead & HAZ Cracks

Underbead and heat affected zone cracks are

generally cold cracks that form in the heat affected

zone of the base metal.

Underbead and heat affected zone cracks can be

either longitudinal or transverse. They are found at

regular intervals under the weld and also outline

boundaries of the weld where residual stresses are

highest.

Visual Inspection Of Welds (VT)

Underbead & HAZ Cracks

Underbead cracks can become a serious problem

when the following three elements are present

simultaneously:

Hydrogen

Crack-susceptible microstructure

Stress

Visual Inspection Of Welds (VT)

Slag Inclusion

Slag inclusion are nonmetallic solid material entrapped

in weld metal or between weld metal and base metal.

Slag inclusion are regions within the weld cross

section or at the weld surface where once-molten flux

used to protect the molten metal is mechanically

trapped within the solidified metal. This solidified slag

represents a portion of the welds cross section where

the metal is not fused to itself.

Visual Inspection Of Welds (VT)

Slag Inclusion

This can result in a weakened condition which could

impair the serviceability of the component. Although

normally thought of being subsurface discontinuities,

inclusions may also appear at weld surface.

Like incomplete fusion, slag inclusions can occur

between the weld and base metal or between

individual weld passes. In fact, slag inclusion are often

associated with incomplete fusion.

Slag Inclusion

Visual Inspection Of Welds (VT)

Weld Reinforcement.

Weld reinforcement is weld metal in excess of the

quantity required to fill a groove weld. It is that amount

of weld metal in a groove weld that is above the base

metal surface.

All weld reinforcement produces a notch effect at the

weld toe. Weld reinforcement, when excessive, does

not add to the strength of the weld but may act as a

stress raiser to amplify the applied stress.

Visual Inspection Of Welds (VT)

Weld Reinforcement.

Greater reinforcements are associated with reduced

re-entrant angles, which result in greater notch effect.

Reinforcement which are excessive tend to produce

significant notch effects at the toe of the weld, which

acts as stress raiser and can produce cracking in

service.

Visual Inspection Of Welds

(VT)

Excessive Reinforcement

Weld Profile

Visual Inspection Of Welds (VT)

Convexity & Concavity

Convexity is the maximum distance from the face of a

convex fillet weld perpendicular to a line joining the

weld toes. Like weld reinforcement, when the amount

of this convexity is excessive, the notch created at the

weld toe could result in toe cracking.

Concavity is the maximum distance from the face of a

concave fillet weld perpendicular to a line joining the

weld toes. Concavity is only considered detrimental

when it results in an undersize weld.

Visual Inspection Of Welds (VT)

Concave Fillet Weld

Visual Inspection Of Welds (VT)

Convex Fillet Weld

Visual Inspection Of Welds (VT)

Arc Strikes

An arc strike is a discontinuity consisting of any

localised re-melted metal, heat affected metal, or

change in the surface profile of any part of a weld or

base metal resulting from an arc.

Arc strikes result when the arc is initiated on the base

metal surface away from the weld joint, either

intentionally or accidentally.

Visual Inspection Of Welds (VT)

Arc Strikes

When this occurs, there is a localised area of the base

metal surface which is melted and then rapidly cooled

due to massive heat sink created by the surrounding

base metal.

Arc strikes are not desirable and often not acceptable,

as they could lead to cracking during cooling process

or under fatigue conditions.

Visual Inspection Of Welds (VT)

Arc Strikes

Visual Inspection Of Welds (VT)

Spatter

Spatter consist of metal particles expelled during fusion

welding that do not form a part of the weld. Those particles

that are actually attached to the base metal adjacent to the

weld are the most disconcerting form of spatter. Particles

which are thrown away from the weld and base metal are,

by definition, spatter.

Normally, spatter is not considered to be a serious flaw

unless its presence interferes with subsequent operations,

especially non destructive testing, or the serviceability of the

part. It might be indicative of the welding process being out

of control.

Visual Inspection Of Welds (VT)

Spatter

Visual Inspection Of Welds (VT)

Inspection Equipment

There are numerous inspection devices used by the welding

inspector. The following are some of the tools & gauges /

instruments most frequently used in visual welding inspection:

Ampere meter

Temperature sensitive crayons (Tempilstiks)

Surface contact thermometer (Pyrometer)

Weld gauge

Fiberscope & borescope

Ferrite gauge

Visual Inspection Of Welds (VT)

Ampere meter

An ampere meter of the tong test type is a unique,

portable instrument that will measure current flowing in

a circuit without making an electrical connection to it.

This is an efficient way to verify the amperage that is

being used during welding. By placing the jaws of the

tong tester around the conductor carrying current , a

reading in amperes can be obtained.

Visual Inspection Of Welds (VT)

Ampere meter

Visual Inspection Of Welds (VT)

Temperature Sensitive Crayons

Temperature sensitive crayons are frequently used to

give an approximate temperature indication. A crayon

mark is made across the metal in the area to be

checked; for example 100 C crayon, the temperature

of the piece will be at least 100 C when the crayon

mark melts. This measurement usually should be

made within 25 mm of the weld on the base metal.

Crayon marks should never be made directly on the

weld because of possible contamination.

Visual Inspection Of Welds (VT)

Temperature

Sensitive Crayons

Visual Inspection Of Welds (VT)

Surface Contact Thermometer

The surface thermometer provides a direct indication of

the surface temperature of pipe or other joint members.

The pyrometer is an electrical instrument which offers

direct indication of temperature. The point of the probe is

placed on the work and the temperature is read from the

digital scale. These type of instruments give a more

accurate indication than the surface thermometer and

crayons.

Visual Inspection Of Welds

(VT)

Surface Contact

Thermometer

Visual Inspection Of Welds (VT)

Weld Gauge

The fillet weld gauge offers a quick means of measuring

most fillet welds of 3.2 mm through 25 mm in size. It

measures both convex and concave fillet welds.

Multipurpose Gauge

There are several multipurpose welding gauges available

on the market today. A multipurpose gauge is capable of

performing many measurements, such as measuring

convex and concave fillet welds, weld reinforcement, and

root opening.

Visual Inspection Of Welds (VT)

Multipurpose Gauge

Visual Inspection Of Welds (VT)

Taper Gauge

The taper gauge is inserted into the opening of a joint to

measure root opening (gap) The root opening is taken from the

gauge at the point where the gauge becomes snug in the joint.

Hi-Lo Gauge

The hi-Lo gauge, also called a mismatch gauge, is used to

measure the internal alignment of a pipe joint. After the gauge

has been inserted and adjusted, the thumb screw is tighten,

and the tool is removed for measurement of misalignment.

Visual Inspection Of Welds (VT)

Hi-Lo Gauge

Visual Inspection Of Welds

(VT)

Taper Gauge /Fillet

Weld Gauge

Visual Inspection Of Welds (VT)

Fiberscope & Videoscope

These are fiberoptic instruments ideal for weld

examination where there is restricted access.

A flexible fiberscope is basically an optical instrument.

This allows the inspector to look into small holes and

around corners. These units are also available with

magnifying lenses, images can be projected on a

screen, and the result stored.

Visual Inspection Of Welds (VT)

Fiberscope

Videoscope

Visual Inspection Of Welds (VT)

Ferrite Gauge

The present of a small fraction of the magnetic delta

ferrite phase in an otherwise austenitic (non magnetic)

weld metal has a pronounced in the influence in the

prevention of weld centerline cracking and fissuring.

The amount of ferrite in as-welded weld metal is largely,

but not completely, controlled by a balance in the weld

metal composition between the ferrite-promoting

elements and the austenite-promoting elements.

Visual Inspection Of Welds (VT)

Ferrite Gauge

When welding austenitic stainless steel, with insufficient

delta ferrite structure, the weld metal has a tendency to

develop small cracks or fissures. This small fissures tend to

be located transverse to the weld interface in the weld

beads and base metal that were reheated to near the

melting point.

Ferrite content of the weld metal is indicated in ferrite

number (FN), and may be bracketed between two values.

This provides sufficient control in most applications where

minimum ferrite content or a ferrite range is specified.

Visual Inspection Of Welds (VT)

Ferritescope

Visual Inspection Of Welds (VT)

Lighting

The inspector should have adequate illumination,

either natural or artificial, while performing visual

inspection. This may be determined using a fine line,

approximately 0.8 mm in width, drawn on a 18%

neutral grey card.

The card should be placed near the area under

examination; if this fine line is distinctly visible, the

inspector may consider this as a demonstration of

adequate illumination.

Visual Inspection Of Welds (VT)

Lighting

Generally, a flashlight / torchlight will provide sufficient

lighting.

Some code specify minimum foot candle / lux of

illumination that are required while performing visual

inspection; for example 15fc (16lx) for general

examination and a minimum of 50fc *54 lx) for the

detection of small discontinuities.

Visual Inspection Of Welds (VT)

Records.

As with any type of inspection, once completed, any

defective area should be identified in some manner to

assure that it will be located and repaired properly. Many

methods are available, so specific conditions may dictate

which marking system would be more effective.

One method commonly used is to record the type, size

and location of any defects so that they can be located,

identified and repaired. Perhaps more effective, however,

is the identification of the defective area by marking

directly on the part.

Visual Inspection Of Welds (VT)

Records

An inspector should be able to maintain adequate records.

Inspectors should be able to writ clear and concise reports

so that superiors will have no difficulty understanding

reasons for past decisions if they are reviewed later.

Inspection report should be concise, yet complete enough

to be clear to a reader unfamiliar with the product

inspected. In preparing the records, the most basic facts

should be included even though they are well known and

understood at the time of writing, since they may not be

remembered so clearly later.

Visual Inspection Of Welds (VT)

Records.

Thus, good records not only protect the inspectors who wrote

them, they also help in adhering to a policy of uniform

standards.

Any work performed under a specification or code that requires

inspection, examination or tests may also require records.

However, whether required or not, the inspector should kept

adequate records.

It is also the inspectors duty to examine all records for

completeness and accuracy in accordance with specified

requirements and to make certain that they are available when

needed.

Visual Inspection Of Welds (VT)

Records.

Any records that require the fabricators signature should

be prepared by the fabricator rather than the inspector.

Records should be in as much detail as necessary. The

inspector should comment on the general character of

the work, how well it stayed within prescribed tolerances,

difficulties that occurred, and any defects.

Any repair should be explained. Copies of these records

should goes to all persons entitled to receive them, and a

copy should be kept for the inspectors own file.

Visual Inspection Of Welds (VT)

Records.

It should be remembered that facts well known at the

time of the writing may not be recalled so clearly,

completely, or accurately later.

Check lists can be used to document inspection points

during fabrication. Lack of explanatory information and

documentation can result in costly delays.

You might also like

- Welding Visual InspectionDocument67 pagesWelding Visual InspectionSaravanan Saran100% (2)

- NDE Handbook: Non-Destructive Examination Methods for Condition MonitoringFrom EverandNDE Handbook: Non-Destructive Examination Methods for Condition MonitoringKnud G. BøvingRating: 4.5 out of 5 stars4.5/5 (4)

- Visual Inspection WeldsDocument35 pagesVisual Inspection Weldsaravindan100% (8)

- Dreamweaver Cs3 HelpDocument735 pagesDreamweaver Cs3 Helpsjois_hsNo ratings yet

- A Quick Guide to Welding and Weld InspectionFrom EverandA Quick Guide to Welding and Weld InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Ethics Ans PDFDocument1 pageEthics Ans PDFsjois_hs0% (1)

- 9 Cswip 3.1 Book 2010 Coloured BookDocument338 pages9 Cswip 3.1 Book 2010 Coloured BookBùi Công LộcNo ratings yet

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryFrom EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNo ratings yet

- 610 SIdata SheetsDocument26 pages610 SIdata Sheetssjois_hsNo ratings yet

- Technology WeldingDocument925 pagesTechnology Weldingdonnyars1979No ratings yet

- Weld DefectsDocument45 pagesWeld DefectsEhigiator Joseph100% (5)

- 09 WIS5 Welding SymbolsDocument56 pages09 WIS5 Welding SymbolsPria Gautama100% (3)

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- Weld RepairsDocument24 pagesWeld RepairsLương Hồ VũNo ratings yet

- Visual Examination ProcedureDocument10 pagesVisual Examination Proceduresantanurini50% (2)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Consumables Identification & ControlDocument61 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Consumables Identification & ControlKrishnamoorthi Venkatesan100% (2)

- Welding Technology InspectionDocument32 pagesWelding Technology InspectionChaitanya Sai T100% (1)

- TWI 3.2 TRAINING SPEC 12-15 Rev3.5 - StudentDocument49 pagesTWI 3.2 TRAINING SPEC 12-15 Rev3.5 - StudentMusa Çelik33% (3)

- TWI CSWIP Visual Inspection of WeldDocument102 pagesTWI CSWIP Visual Inspection of WeldOnur Altuntaş100% (24)

- Welding Visual Inspection and Tools PDFDocument21 pagesWelding Visual Inspection and Tools PDFtoby100% (3)

- 2 Welding TerminologyDocument26 pages2 Welding TerminologynaguNo ratings yet

- Heat Treatment ManualDocument25 pagesHeat Treatment Manualraj101086100% (1)

- Cwi Twi 2006Document333 pagesCwi Twi 2006Lajit SubramanianNo ratings yet

- CSWIP 3.1: Ref. Document No.: CSWIP-WI-6-92Document695 pagesCSWIP 3.1: Ref. Document No.: CSWIP-WI-6-92Hasmukh Jain100% (6)

- ISO 3834 by SelvaDocument83 pagesISO 3834 by Selvaaravindan100% (11)

- Weld Defects TWIDocument96 pagesWeld Defects TWISabir Shabbir100% (7)

- Welding Defect ChartDocument2 pagesWelding Defect ChartPavan_yoyo100% (4)

- Techniques of Visual InspectionDocument80 pagesTechniques of Visual InspectiontranngNo ratings yet

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AFrom EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANo ratings yet

- Wis10 NDTDocument99 pagesWis10 NDTsiva8000100% (2)

- Visual Inspection WeldDocument53 pagesVisual Inspection Weldshifa100% (1)

- Welding Defects - PresentationDocument40 pagesWelding Defects - Presentationforgameslive100% (18)

- Cswip 3.1 New BookDocument342 pagesCswip 3.1 New BookMohsin Rasul90% (52)

- NDT & Visual InspectionDocument95 pagesNDT & Visual InspectionAravindan RangaNo ratings yet

- CSWIP 3.1 Study Book 2013 Rev 2 EditionDocument601 pagesCSWIP 3.1 Study Book 2013 Rev 2 EditionAndrés Maigua100% (1)

- WIS10 M.TestDocument46 pagesWIS10 M.TestUmaibalan100% (1)

- Stress Concentration FactorsDocument30 pagesStress Concentration Factorssjois_hsNo ratings yet

- Iiw Welding GuidelinesDocument95 pagesIiw Welding Guidelinestomychalil100% (2)

- Welding Defect TWI CSWIPDocument54 pagesWelding Defect TWI CSWIPMahdi Daly100% (4)

- Turbines 1Document40 pagesTurbines 1sjois_hsNo ratings yet

- WeldersVisual Inspection HandbookDocument77 pagesWeldersVisual Inspection HandbookJesus PlacedesNo ratings yet

- Cswip 3.1 2011Document400 pagesCswip 3.1 2011Anonymous SA40GK6No ratings yet

- RTFI-weld-defect-repairs-twiDocument61 pagesRTFI-weld-defect-repairs-twismsunil12345No ratings yet

- Welding Inspection VT Course-New PDFDocument82 pagesWelding Inspection VT Course-New PDF7okaz100% (2)

- Module 1Document30 pagesModule 1mahmoud aliNo ratings yet

- Welding Defects Causes & SolutionsDocument30 pagesWelding Defects Causes & SolutionsAkshay Kumar100% (1)

- Weld RadiographsDocument18 pagesWeld Radiographsadeoye_okunoyeNo ratings yet

- Non-Destructive TestingFrom EverandNon-Destructive TestingJ. BoogaardRating: 4 out of 5 stars4/5 (7)

- SSAB Weld DefectsDocument16 pagesSSAB Weld Defectspozolab0% (1)

- AutoPIPE Modelling ApproachesDocument110 pagesAutoPIPE Modelling Approachessjois_hs100% (1)

- CSWIP 3.1-2010 The Welding Inspection of SteelDocument317 pagesCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- AutoPIPE BASIC PDFDocument228 pagesAutoPIPE BASIC PDFsjois_hsNo ratings yet

- 610 10th Ed Datasheets (SI)Document11 pages610 10th Ed Datasheets (SI)sjois_hsNo ratings yet

- Heat Treatment Manual Part IIDocument21 pagesHeat Treatment Manual Part IIAnonymous lmCR3SkPrK100% (3)

- An Introduction To Welding InspectionDocument3 pagesAn Introduction To Welding InspectionMUHAMMAD SHARIFNo ratings yet

- Steel BookDocument463 pagesSteel Booksjois_hsNo ratings yet

- Module 8 Welding Metallurgy For The WIDocument39 pagesModule 8 Welding Metallurgy For The WIOskar Giancarlo Sifuentes Eche100% (1)

- Wis5 DefectDocument46 pagesWis5 DefectQuang Duan Nguyen100% (1)

- 16 Welding ConsumablesDocument63 pages16 Welding ConsumablesJawed AkhterNo ratings yet

- CompressorDocument118 pagesCompressorsjois_hs100% (1)

- Engineering EconomicsDocument19 pagesEngineering Economicssjois_hsNo ratings yet

- 01-Visual Inspection & Welding InspectorsDocument7 pages01-Visual Inspection & Welding InspectorsSaif UllahNo ratings yet

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindNo ratings yet

- Visual Guide To Weld Defects & DiscontinuitiesDocument44 pagesVisual Guide To Weld Defects & DiscontinuitiesGTPATELNo ratings yet

- Radiographic Interpretation Graphs GuidelineDocument15 pagesRadiographic Interpretation Graphs GuidelineMhd Ebal100% (1)

- Visual InspectionDocument1 pageVisual InspectionVinod Kumar VermaNo ratings yet

- API-510 QuestionsDocument21 pagesAPI-510 Questionssjois_hs100% (1)

- 610 USdata SheetsDocument24 pages610 USdata Sheetssjois_hsNo ratings yet